Testing for continuity/shorting

|

|

Testing for continuity/shorting

|

|

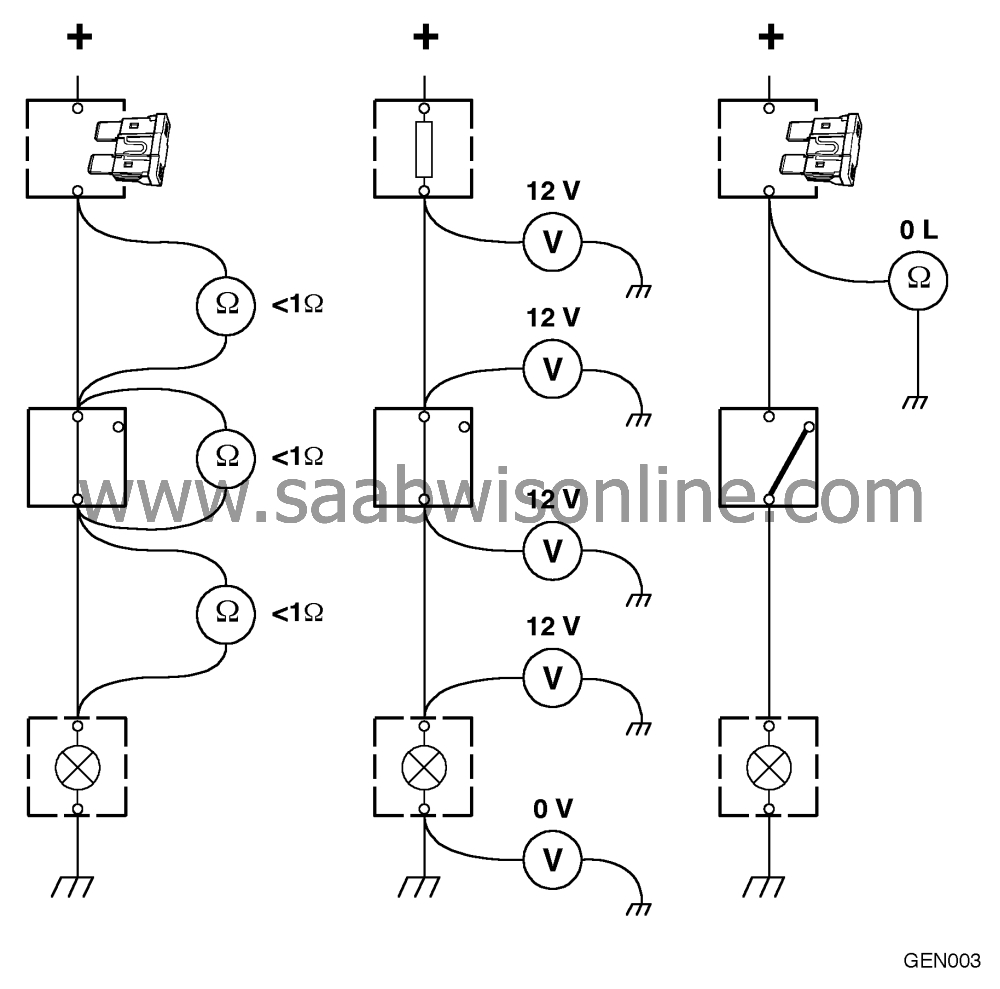

Testing for continuity (Resistance measurement)

|

|

1.

|

Make sure that the component

or cable to be checked is not live.

|

|

2.

|

With the instrument set to measure resistance, connect the test

leads to each end of the component or cable to be checked.

In the wiring, the resistance should normally be less

than 1 ohm. For components, the specified resistance should be obtained

as a reading.

|

|

Testing for continuity (Voltage measurement)

|

|

1.

|

Connect up the load, if any.

|

|

2.

|

With the instrument set to measure voltage, connect the black test

lead to a good ground and the red test lead to the wiring side

(positive).

|

|

3.

|

At the output of a control module or switch: take readings in the

direction away from the component and proceed successively out towards

the load. When the voltage reading drops to zero you have just passed

the break in continuity.

|

|

4.

|

At the input of a control module or load: take readings from the power

source and proceed successively in towards the control module or load.

When the voltage reading drops to zero you have just passed the break

in continuity.

|

|

Shorting to ground (Resistance measurement)

|

|

1.

|

Make sure that the cable to be

checked is not live and that the

load, if any, is disconnected.

|

|

2.

|

With the instrument set to measure resistance, connect one of the

test leads to the load side of the cable and the other test lead to a

good ground.

|

|

3.

|

Carefully move the wiring about while checking the instrument to see

whether it shows infinite resistance (OL) the whole time.

|