Before changing a control module

|

|

Before changing a control module

|

When all tests and checks have been carried out in accordance with the

diagnostics procedure for the relevant diagnostic trouble code, or by manual fault diagnosis,

without any faults having been found, it is natural to assume that the control module is at fault.

Therefore, go through all the following points very carefully before definitely pinpointing

the Motronic control module as the cause of the fault.

|

1.

|

Check once again that every

single point in the diagnostic procedure for the diagnostic trouble code in question has been

carried out.

|

|

2.

|

Study the wiring diagram of the circuit in question and make sure you understand

how it works. Relevant parts of the technical description may be of assistance in this respect.

|

|

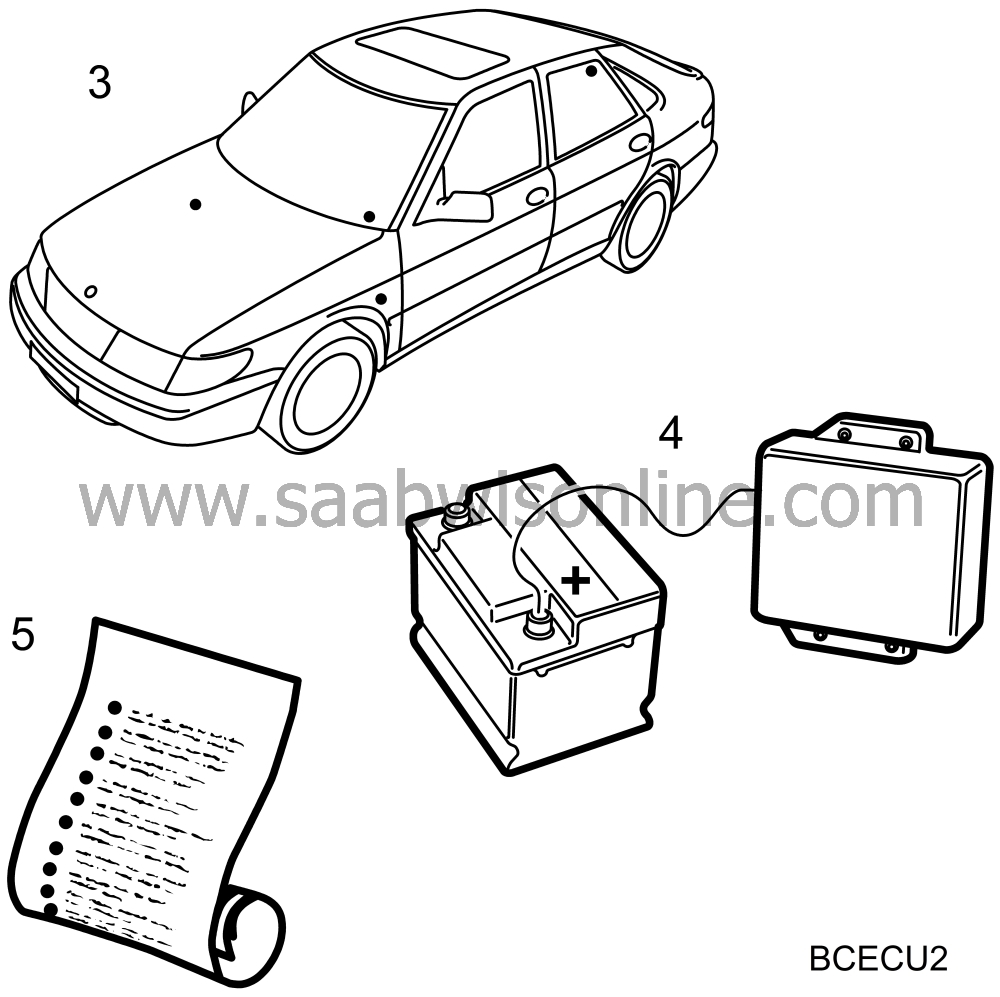

3.

|

In connection with removing and fitting the control module, bear in mind its

sensitivity to electrostatic discharges. See

for more detailed

information.

for more detailed

information.

|

|

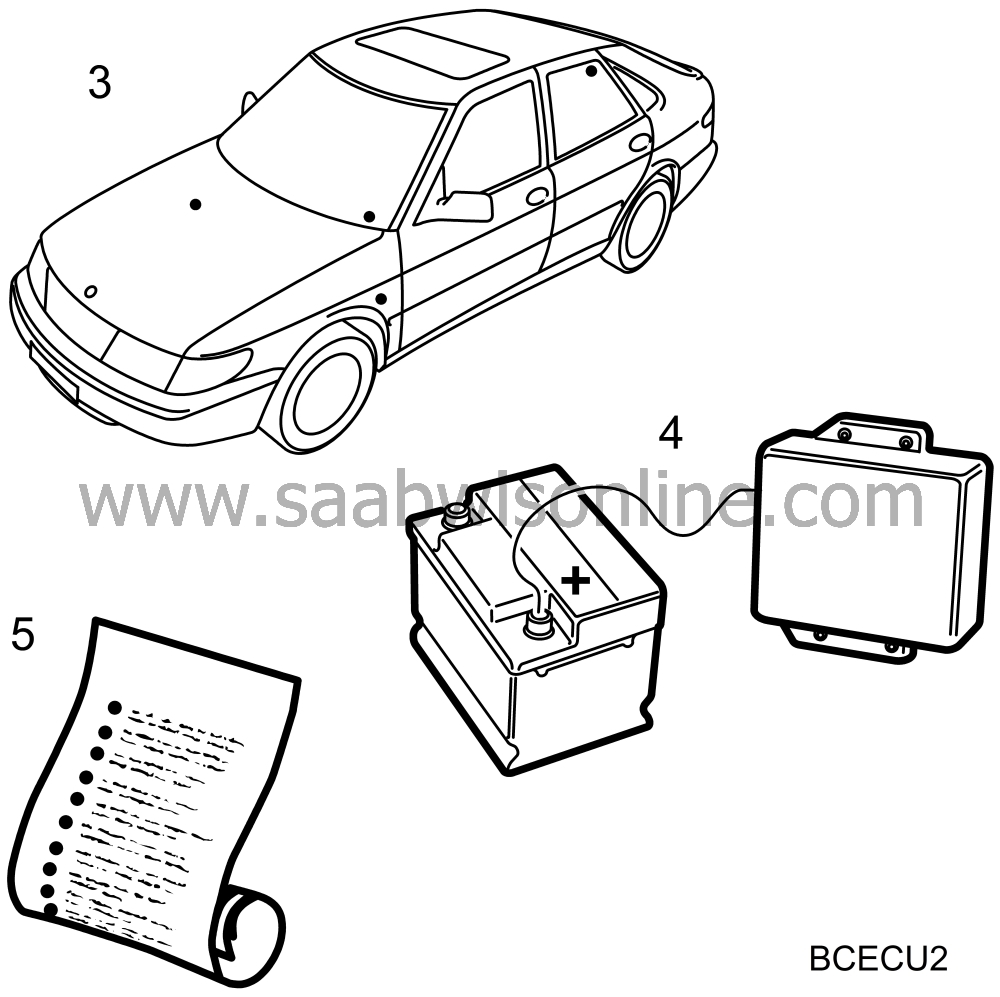

4.

|

Check all grounding points and the control module's power supply. If you

have already done so, do it once again. Check that power ground (G7P) and sensor ground

(G7S) are physically and electrically separated from each other. See diagnostic trouble code

P1500.

|

|

5.

|

If the suggested fault diagnosis procedures do not produce results, try to trace

the trouble by consulting and analysing "Test readings, control module connections".

|

|

6.

|

Think of all possible and reasonable causes of the fault before changing the

control module. When changing a control module for testing purposes, always refit the original

control module.

|

|

7.

|

If the original fault still persists in spite of this, then the Motronic control module

will have to be changed.

|

for more detailed

information.

for more detailed

information.