Fuel evaporation

| Fuel evaporation |

| Evaporative emission canister |

The evaporative emission canister consists of a container filled with activated charcoal, the task of which is to "temporarily store" fuel vapours from the tank and then release the vapours via the purge valve to the intake manifold for combustion.

The evaporative emission canister thus has a hose connection both to the fuel tank and to the intake manifold, but is also connected to the surrounding air. Air is drawn via this connection with the surrounding air through the evaporative emission canister and brings fuel vapours into the intake manifold with it.

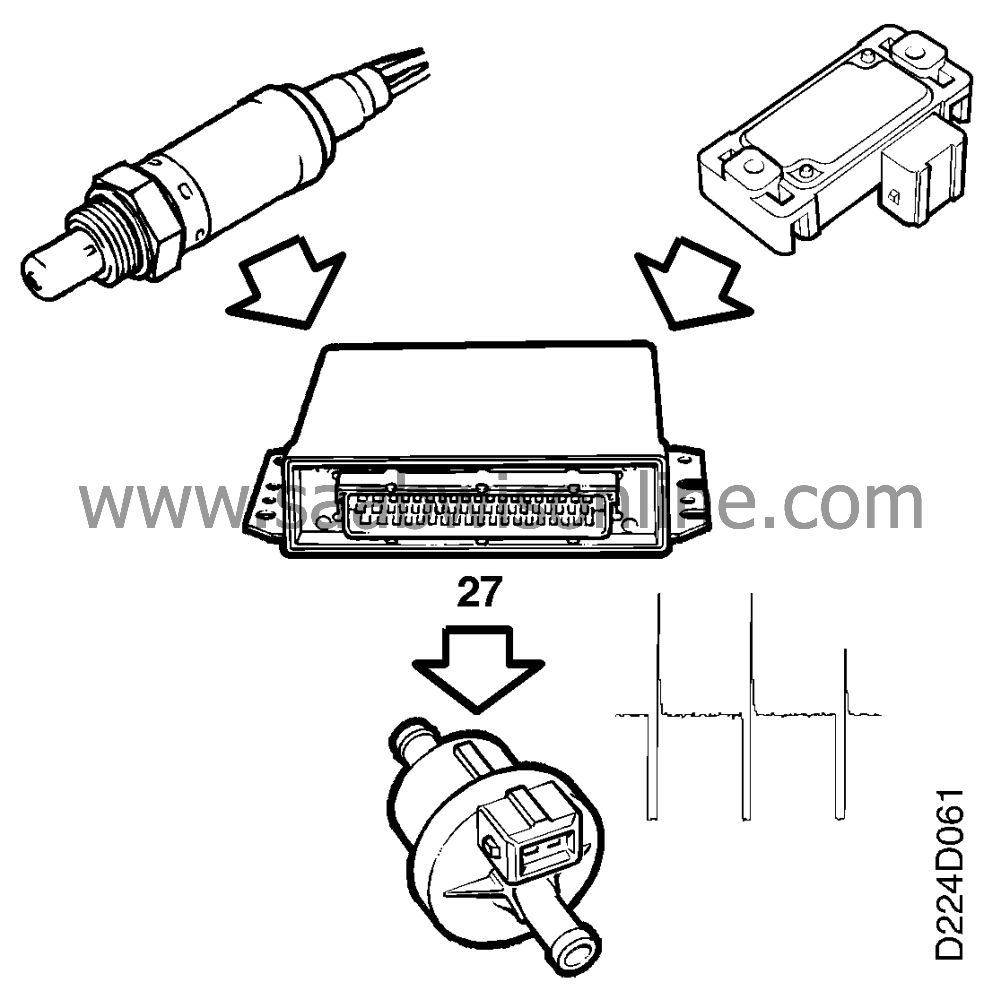

| Evaporative emission canister purge valve |

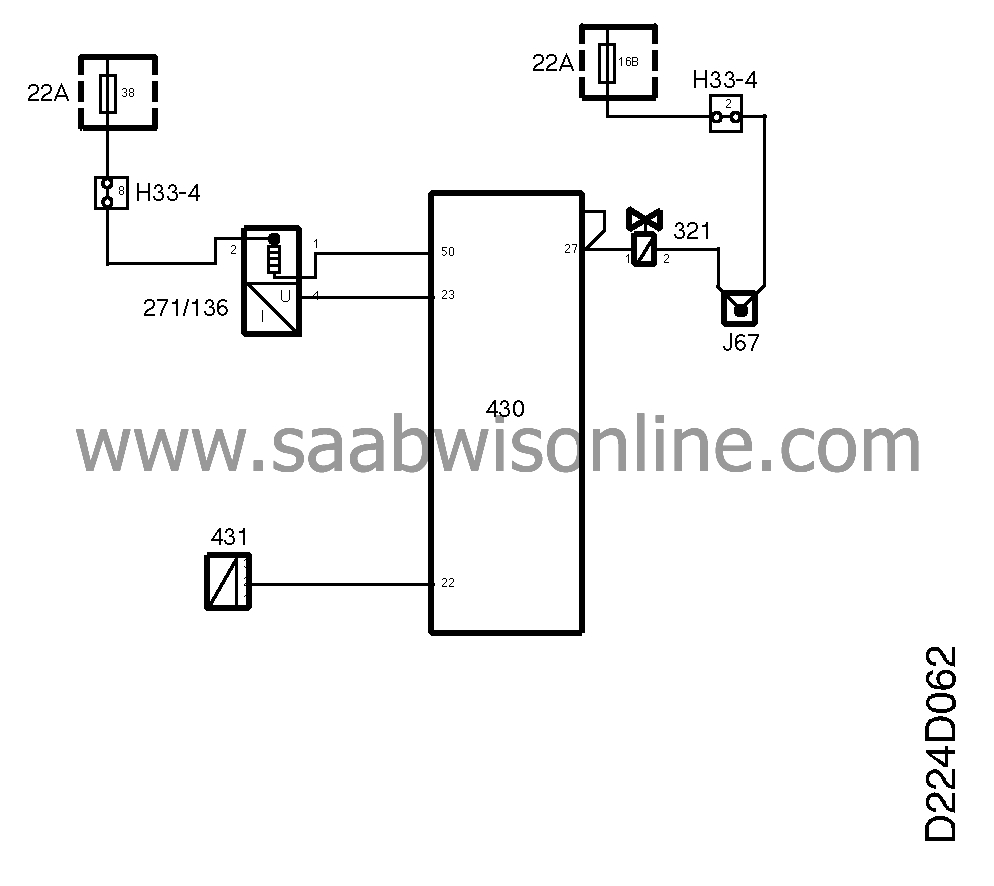

The purge valve takes the form of a solenoid valve located on the vacuum hose between the evaporative emission canister and the intake manifold after the throttle.

The valve is supplied from the main relay and is controlled from pin 27 on the ECM. The lead is connected to pin 21 on the ECM. The ECM determines whether operation is electrically correct by measuring the voltage on pin 21.

The valve is supplied with an 8 Hz PWM and starts to operate as soon as the lambda control is activated and the pressure in the intake manifold is less than 90 kPa.

The ECM starts the purging phase with very short ground pulses, the length of which increases gradually. The reason for this is that the lambda control has to have time to compensate for the surplus of fuel. The valve operates for 4 1/2 minutes, followed by a pause of 1/2 minute, and then operates for 4 1/2 minutes again, and so on.

If there is a discontinuity in the circuit to the valve, the malfunction indicator lamp (CHECK ENGINE) will light up on the main instrument.

If the valve becomes stuck in the open position, oxygen sensor operation becomes faulty, causing the malfunction indicator lamp on the main instrument to light up.