Fuel injection

| Fuel injection |

| Injectors |

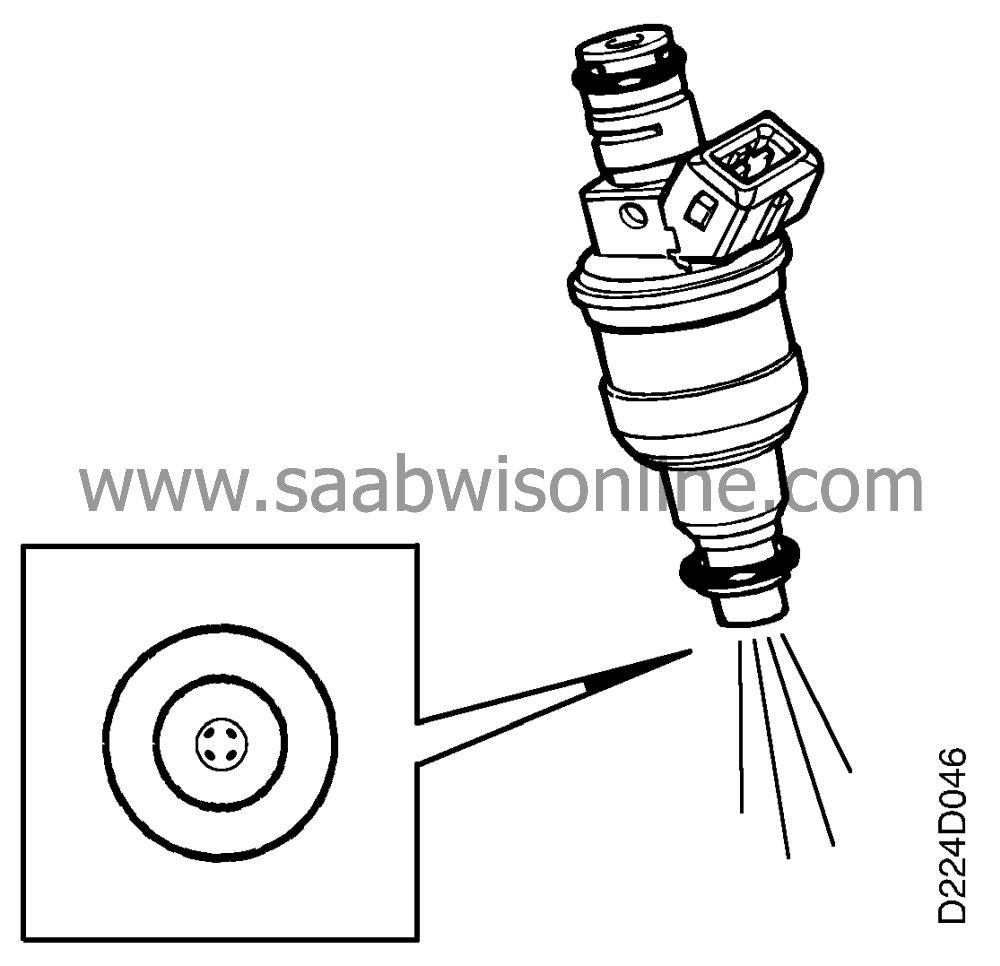

The injectors are of the solenoid type with needles and seats and open when current flows through the and close by means of a powerful spring when the current is broken.

To obtain the best possible combustion and therefore cleaner exhaust gases, the injectors are provided with four holes which ensure good fuel distribution.

The fuel jets are very precisely set (two jets on each intake valve). This makes the fixing of the injectors very important. To ensure that this is done properly, the injectors are fixed in pairs in special mounts between cylinders 1-2 and cylinders 3-4.

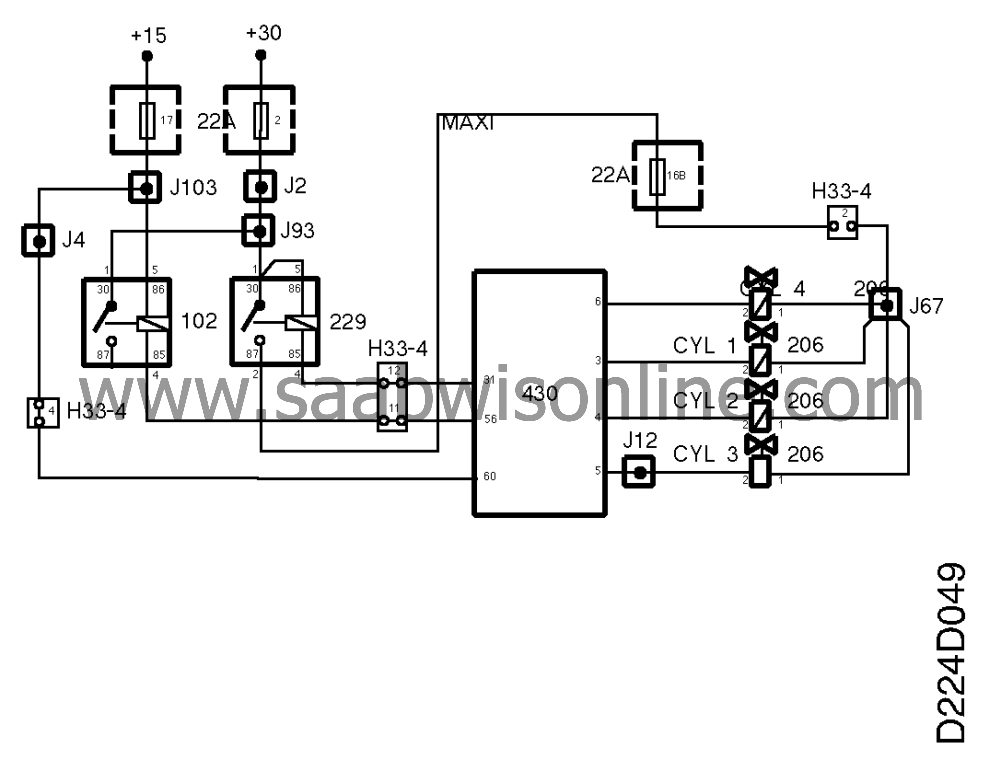

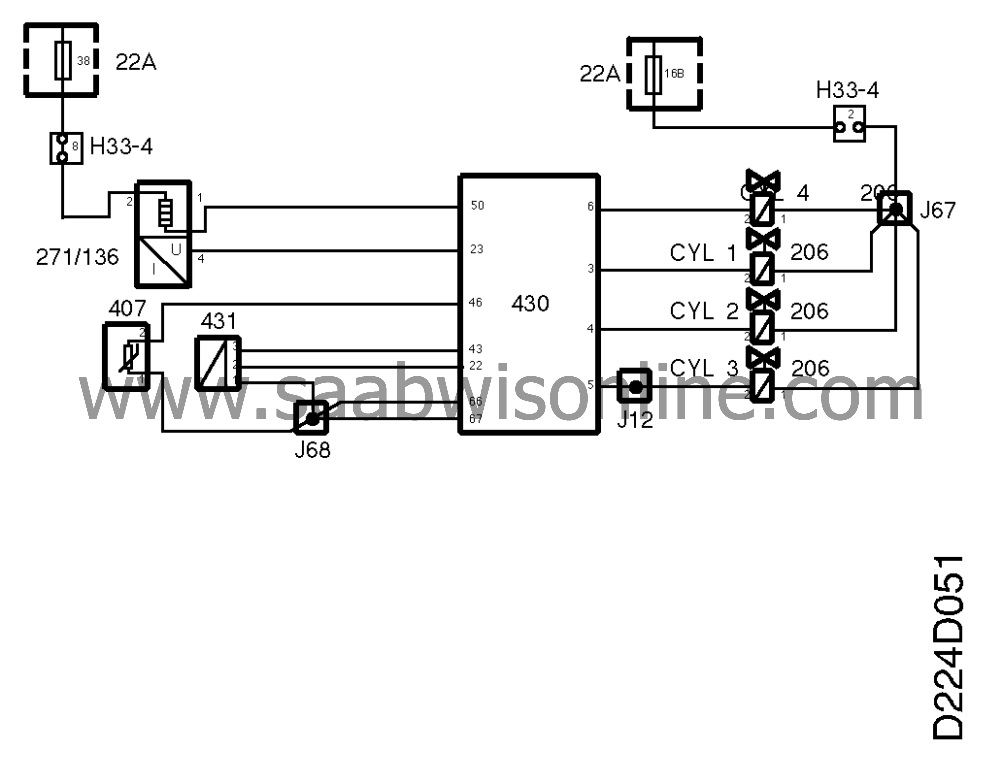

The injectors receive their voltage from the main relay, whilst the ECM grounds the injectors as follows:

| • |

valve 1 receives ground

from pin 3

|

|

| • |

valve 2 receives ground from pin 4

|

|

| • |

valve 3 receives ground from pin 5

|

|

| • |

valve 4 receives ground from pin 6

|

|

| Pre-injection |

When the ignition is switched on, both the main relay and the fuel pump relay operate for a few seconds. After fuel pressure has built up, fuel injection dependent on engine coolant temperature takes place with the four fuel injectors simultaneously. This means that short starting times are achieved.

If the engine is not started, this function is blocked for 15 minutes. If the engine is started and is switched off a short time afterwards, another pre-ignition is obtained after waiting for at least 45 seconds with the ignition turned off.

| Calculation of fuel injection time |

To determine how much fuel has to be injected into each intake manifold, the ECM calculates the air mass drawn into each cylinder.

The calculation is made as follows: (each cylinder in the B204L engine has a capacity of 0.5 l): 0.5 l air with a certain density has a particular weight. The density is calculated using the pressure and temperature in the intake manifold.

The ECM keeps the injection valve open until the correct amount of fuel has been injected in relation to the measured air mass.

The fuel injection time is corrected by means of the oxygen sensor so that lambda=1.0 is obtained. If the throttle is opened wide, the lambda control is disconnected and the fuel/air mixture is made richer at full load for maximum performance. When the throttle is opened, a richer mixture is produced during acceleration and a leaner mixture is produced during deceleration. When starting from cold and during engine warm-up before lambda control has been activated, a richer mixture is produced depending on engine coolant temperature.

If the engine has warmed up and battery voltage is normal, the fuel injection times vary between approx. 2.5 ms during idling and approx. 18 ms at wide open throttle.

| Fuel shut-off |

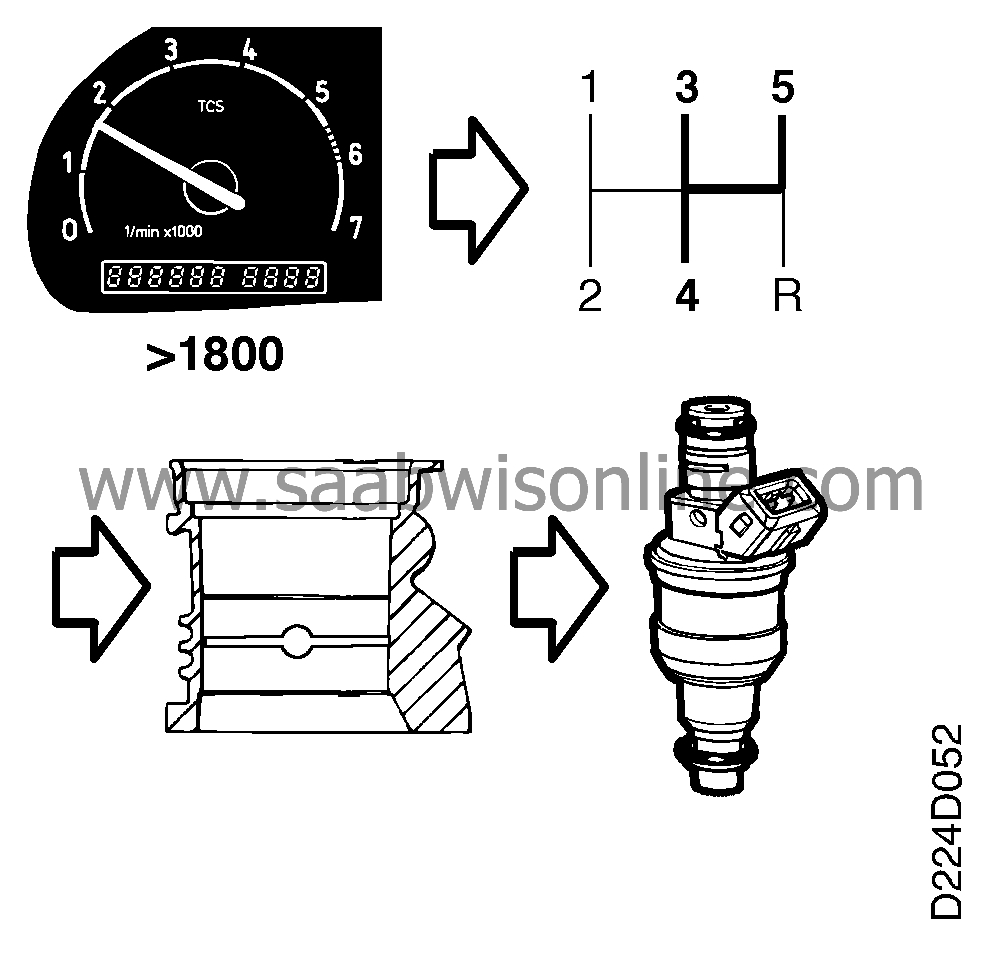

With the throttle completely closed and an engine speed above 1800 rpm, in 3rd, 4th and 5th gear, fuel shut-off takes place after a certain delay (about one second).

On cars with automatic transmission, fuel shut-off takes place in all gears.

The injectors are re-activated when the engine speed drops below 1400 rpm.

| Fuel consumption |

The lead from the ECM to injector 3 is also connected to the main instrument. The main instrument calculates fuel consumption from the length of the fuel injection pulses. Fuel consumption is used to obtain an accurate picutre of the level in the fuel tank and for the calculation of the average fuel consumption in the SID.