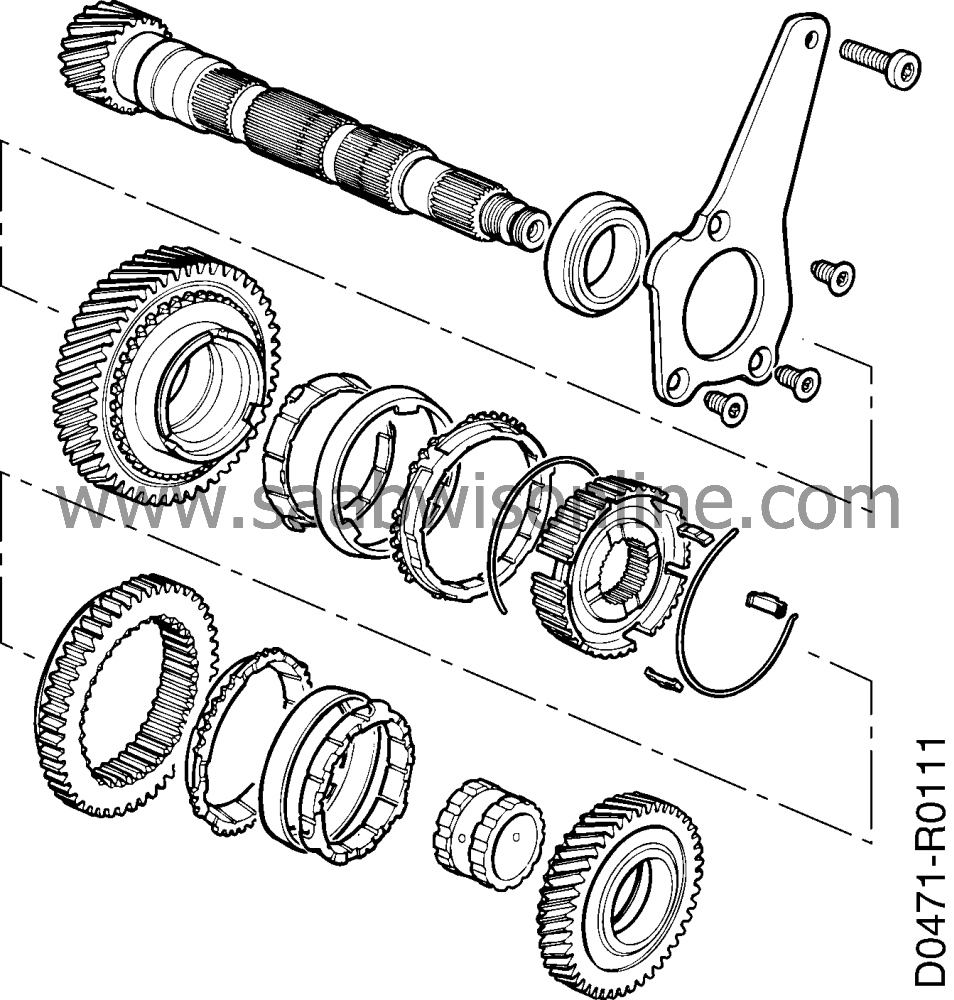

Output shaft

| Output shaft |

| To dismantle the 1st/2nd gear synchromesh assembly |

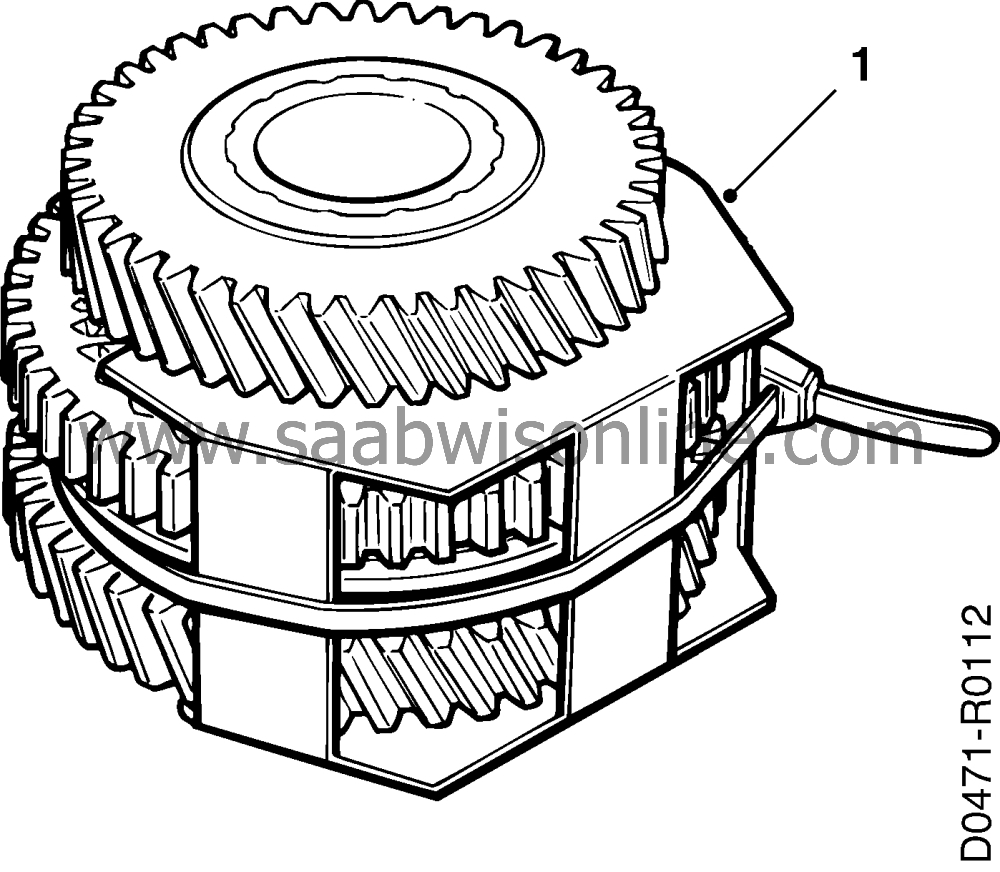

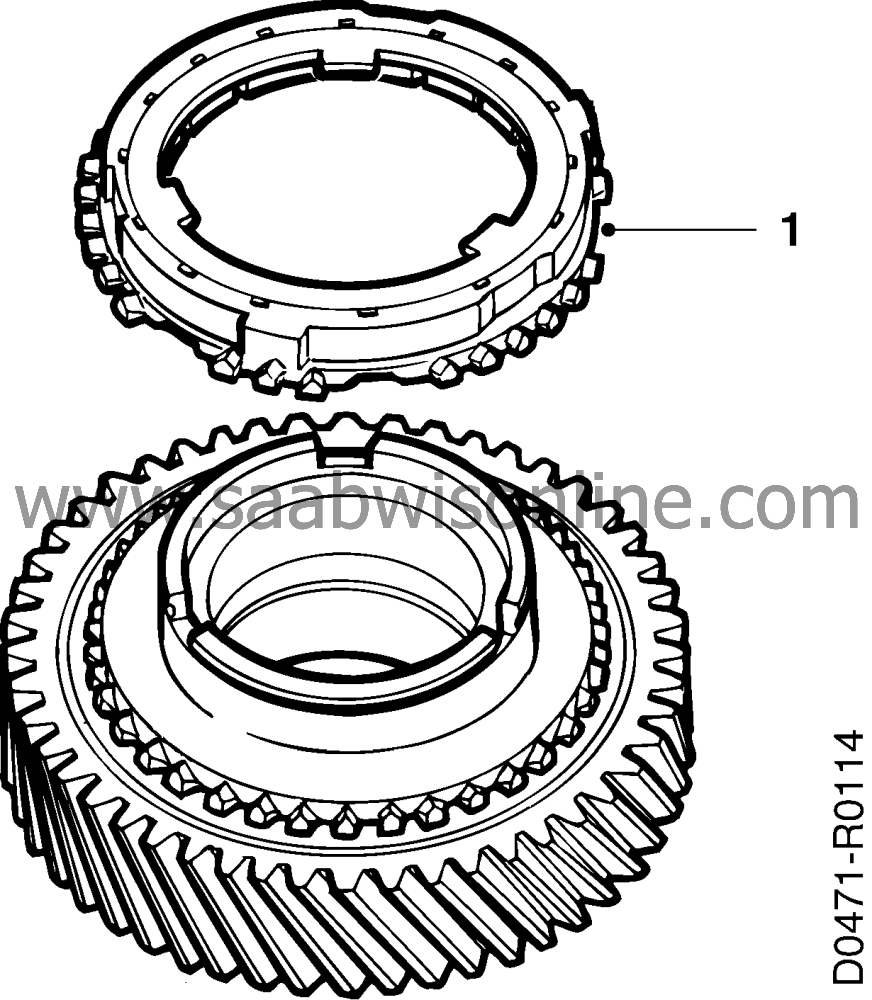

In connection with removal, place fixture 87 92 103

over the gear wheels to hold the synchromesh assembly together.

over the gear wheels to hold the synchromesh assembly together.

| 1. |

Snip the cable tie and remove fixture 87 92 103 from the synchromesh assembly.

|

|

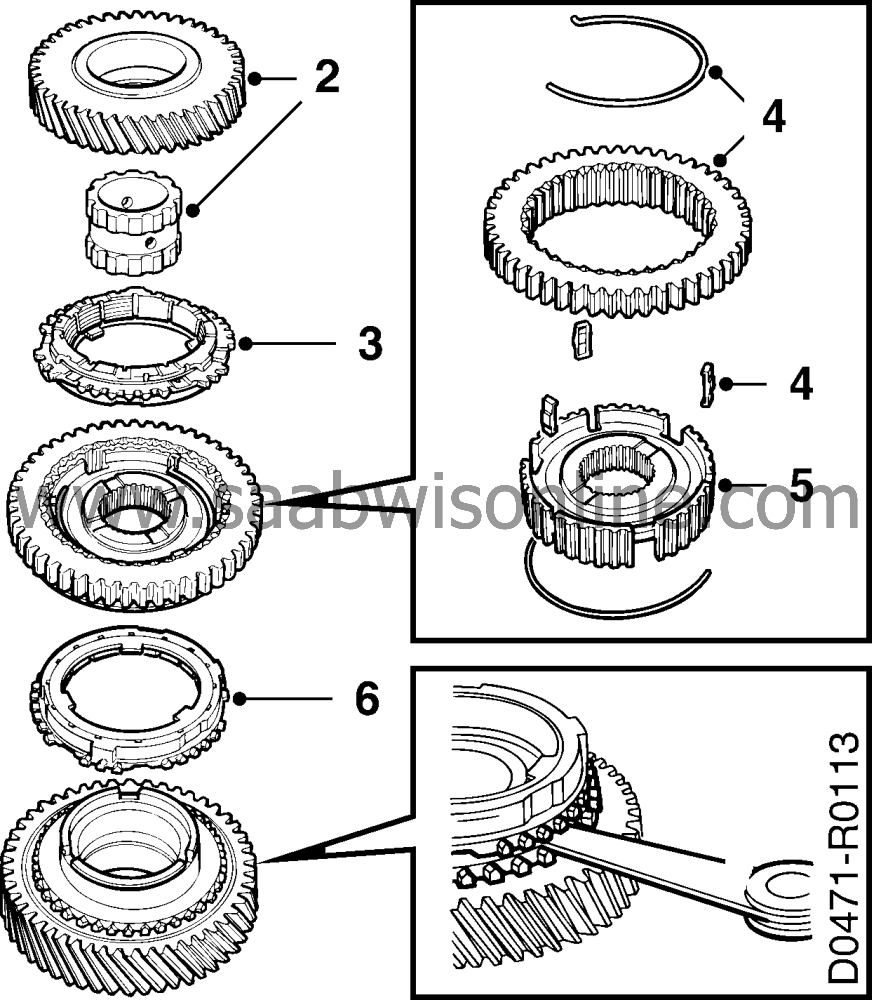

| 2. |

Lift out the 2nd gear wheel and its bearing sleeve.

|

|

| 3. |

Lift away the synchromesh.

|

|

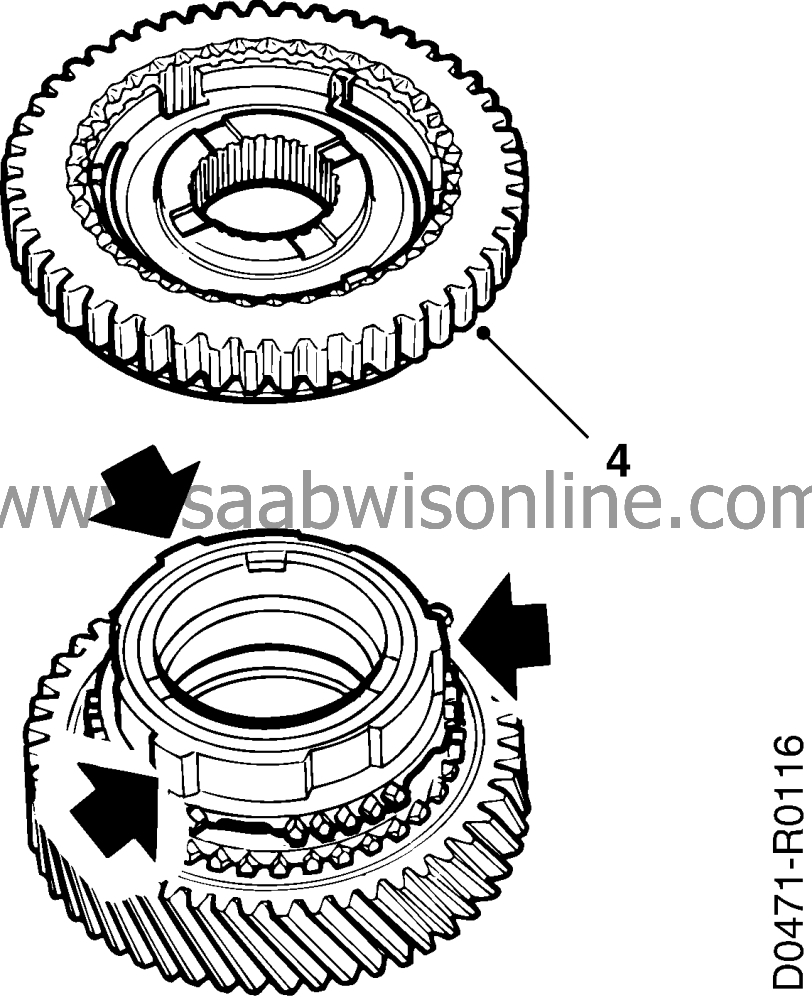

| 4. |

Detach the retaining spring from the "beans". Lift out the sleeve and place the beans in a safe place.

|

|

| 5. |

Lift out and turn the synchromesh hub. Remove the locking spring on the bottom side.

|

|

| 6. |

Remove the 1st synchromesh from the gear wheel.

|

|

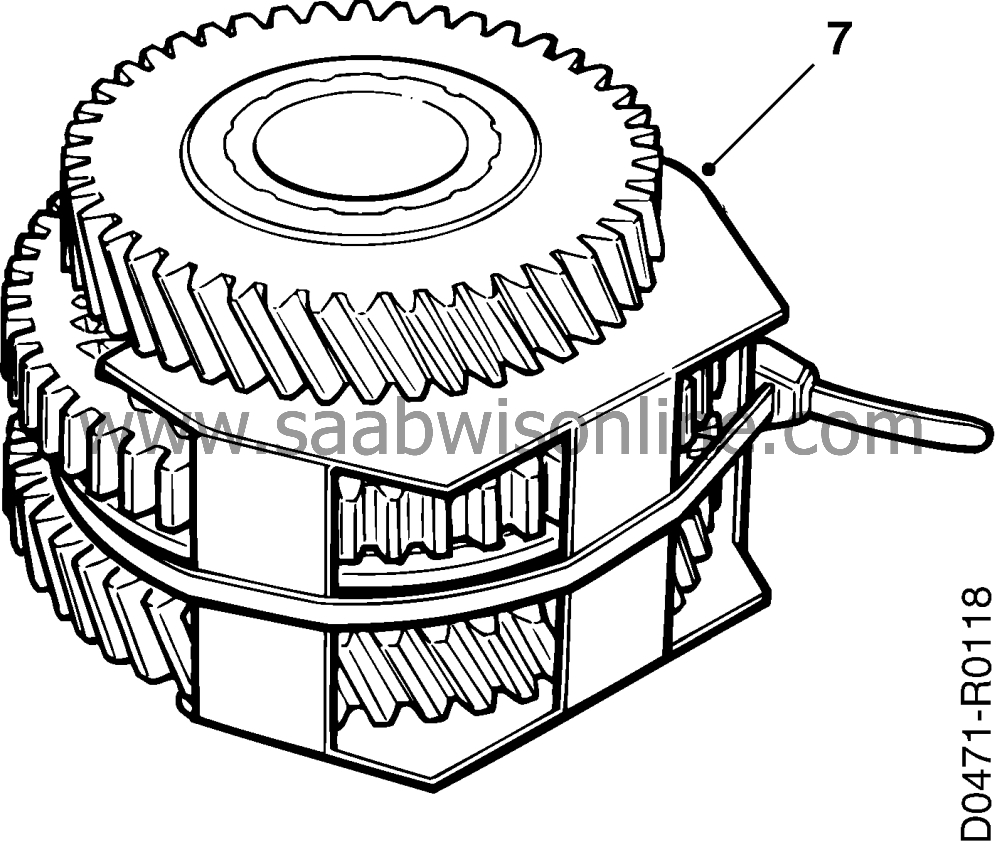

| 7. |

Check the condition of all parts as regards wear. Replace damaged or defective parts. Measure the wear on the trisected synchromeshes by fitting them into their respective places. Measure with a feeler gauge in three places between the large baulk ring and the carriage wheel and calculate a mean value. New synchromesh 1.4 1.5 mm.

If the mean value is less than 0.8 mm, the synchromesh should be changed.

|

|

| Fitting |

Lubricate all parts with engine oil 10 W 30 before they are fitted.

| 1. |

Assemble and fit the 1st synchromesh to the 1st gear wheel.

|

|

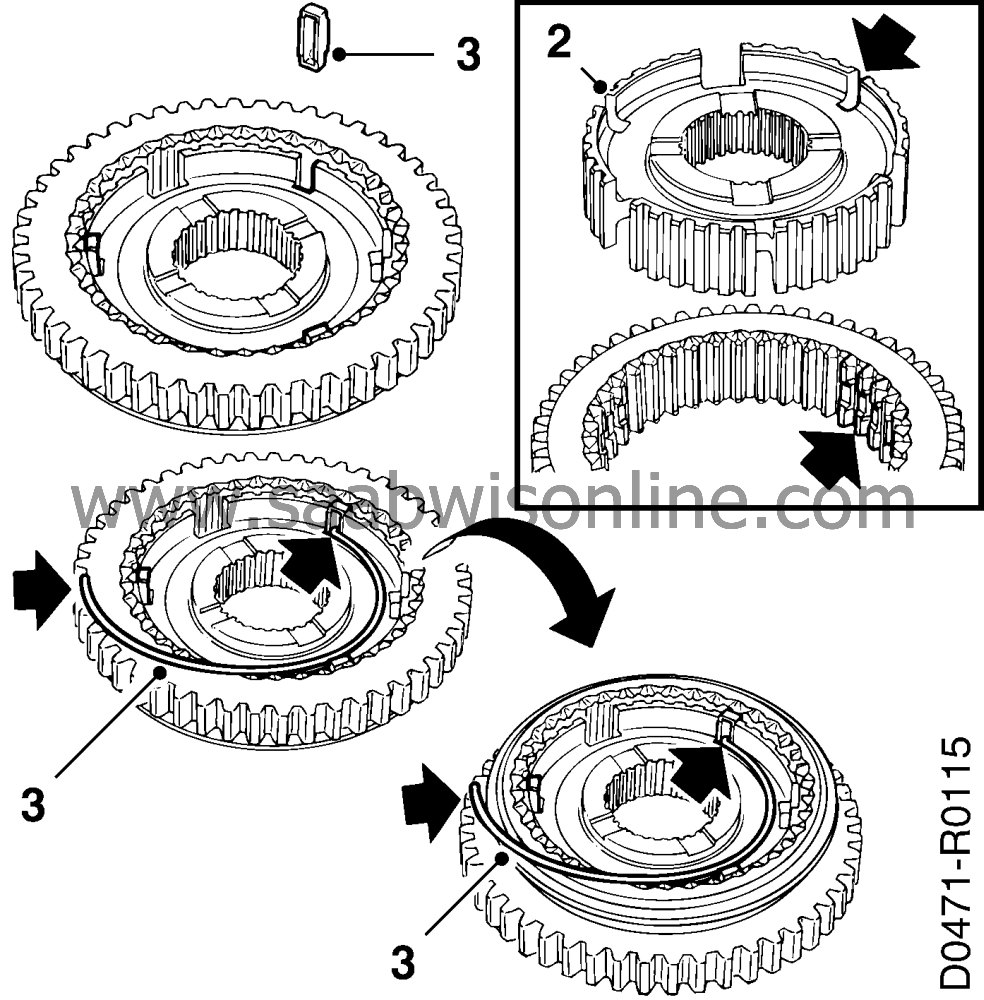

| 3. |

Position the three clips and fit them in place. Fit the locking spring clockwise. Carefully turn the synchromesh hub over and then also fit the other locking spring clockwise on the underside of it.

|

||||||||||

| 4. |

Place the synchromesh sleeve (the side with the fork groove facing down) and the synchromesh hub on the 1st synchromesh. The recesses in the synchromesh hub should fit over the lugs in the synchromesh.

|

|

| 5. |

Assemble and fit the 2nd synchromesh to the 2nd gear wheel. Fit the bearing sleeve in the 2nd gear wheel and fit the entire assembly in the synchromesh sleeve and synchromesh hub. The lugs on the baulk ring should fit the recesses in the synchromesh hub.

|

|

| 6. |

Hold down the gears wheels and try shifting gear.

|

|

| 7. |

Fit tool 87 92 103

over the synchromesh assembly so that it does not fall apart during assembly.

over the synchromesh assembly so that it does not fall apart during assembly.

|

|