Control module

| Control module |

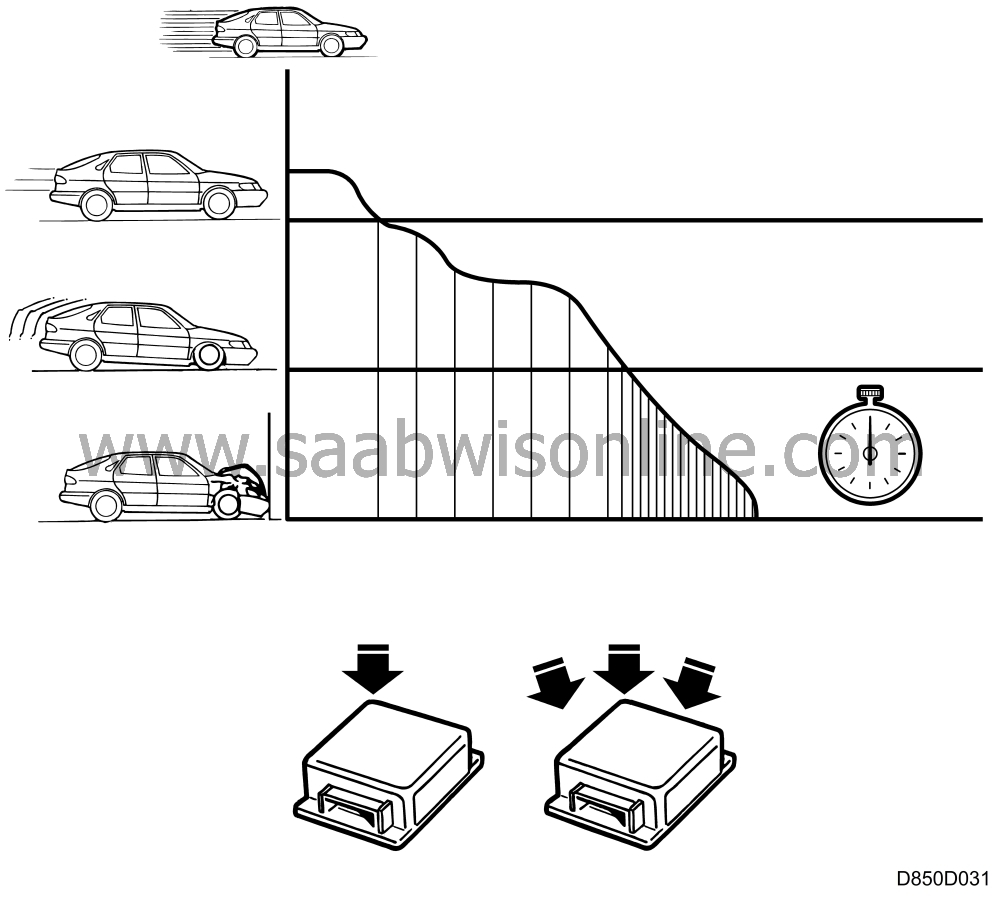

The mounting position of the control module is direction-dependent due to the acceleration sensor that detects the acceleration and retardation in the direction of travel of the car. When retardation exceeds a certain value, the processor will start to process the signals from the acceleration sensor more precisely. If retardation continues to increase and exceeds the values that define a collision, the processor will send a current pulse to the electric detonators whereby the airbags are inflated and the seat-belt tensioners are activated.

The Energy reserve is supplied with energy from the voltage converter that increases the voltage to just over twice the battery voltage. There is an energy reserve for the detonators as well as a further one that keeps the processor working for a short time in case of a drop in voltage.

The control module can be programmed with the diagnostic tool for correct configuration (airbag driver's side or airbag driver's side + passenger side).

| Self-diagnostics |

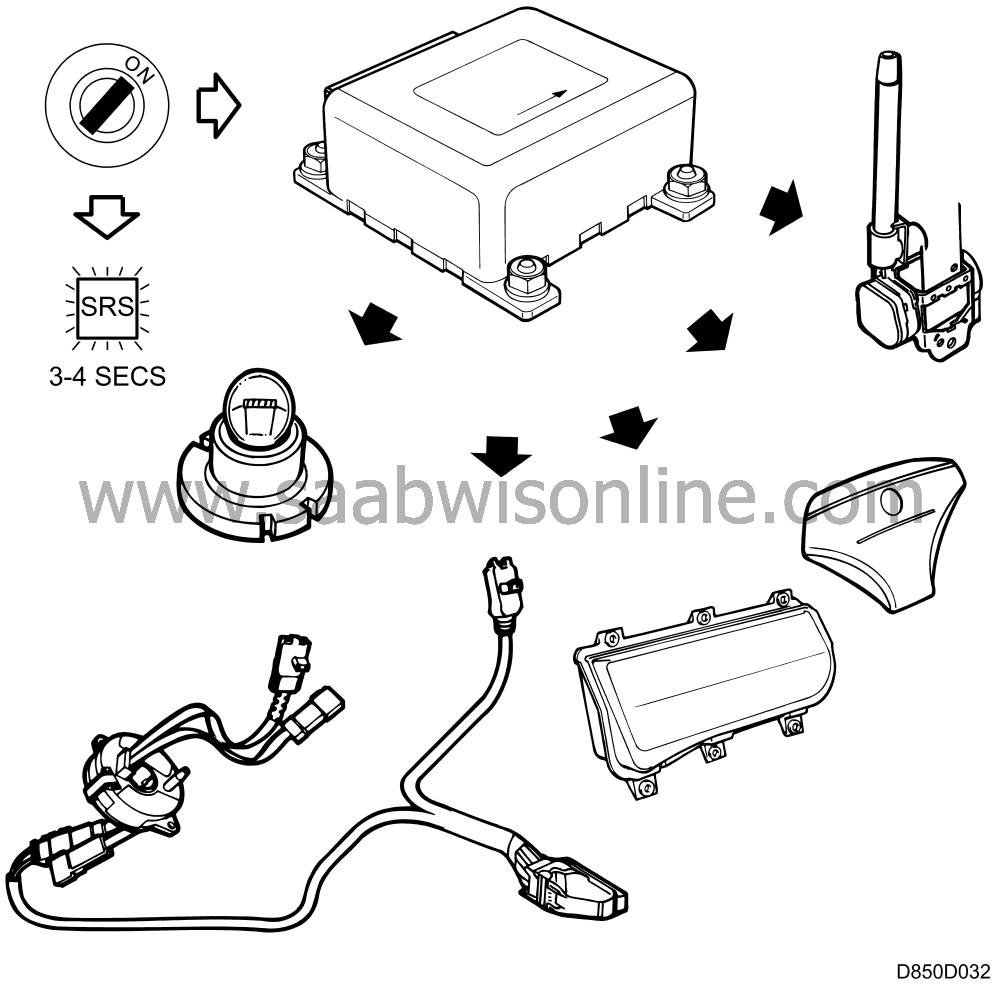

When the ignition switch is in the ON position and the system is supplied with current, the control module carries out initial self-diagnosis for a maximum of 10 seconds. As a safety measure, the airbags cannot be activated during this period.

During the self-test, the electric detonators are checked with the wiring harness, SRS lamp and processor.

The SRS lamp comes on during the first test for 3-4 seconds when the ignition is turned on to enable the lamp to be tested. The self-diagnosis then continues for as long as the power supply is turned on. The system is then working normally and can detect a collision.

In case of a fault, the SRS lamp will come on and shine continuously.

| Important | ||

|

With ignition on: The SRS system will not work for the first 6 seconds. |

||

When a fault is registered for the first time, a diagnostic trouble code is generated. A “P” in front of the diagnostic trouble code means that the fault is permanent and an “l” that the fault is intermittent. At the same time as the diagnostic trouble code is registered, a fault counter and a fault time counter will be started. The fault counter calculates how many times each respective fault has been registered, up to 255 times. The fault time counter shows how long a permanent fault has been registered (max 40 hours), alternatively how much time has passed since the intermittent fault was registered for the first time. The fault time counter counts in five minute intervals of fixed current time. The first interval, however, is two and a half minutes long so that even faults that are registered after being generated for a short time can be captured.

The control module stores up to five different diagnostic trouble codes plus diagnostic trouble code B1615 (detonator circuit activated). Further diagnostic trouble codes are not registered.

When the feed voltage is cut it takes a maximum of 5 seconds for the processor to disconnect the energy reserve from the detonator circuits.

The control module is for one time use, if it has once activated the airbags it can no longer be used. If this has happened the SRS lamp will come on.

The diagnostic trouble codes can be read after the airbags have been activated, but they cannot be cleared.