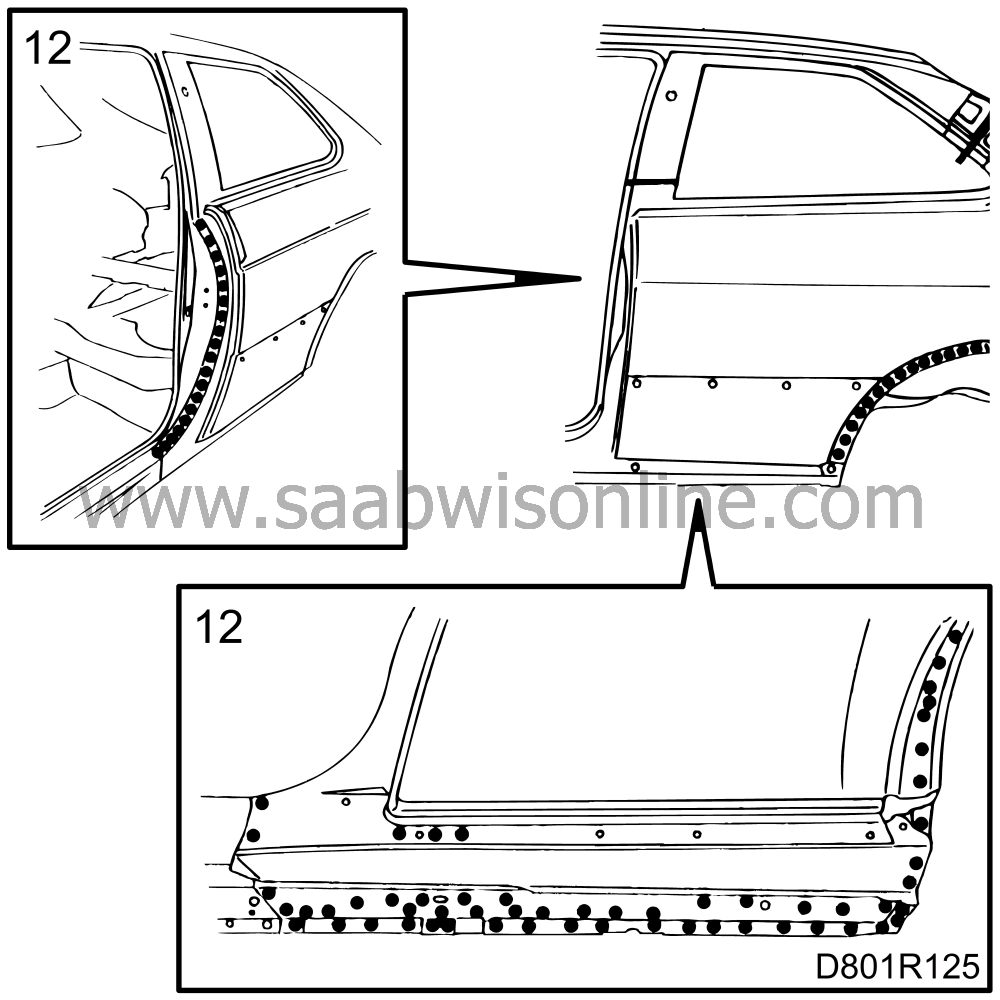

Part of side panel, three-door body

|

|

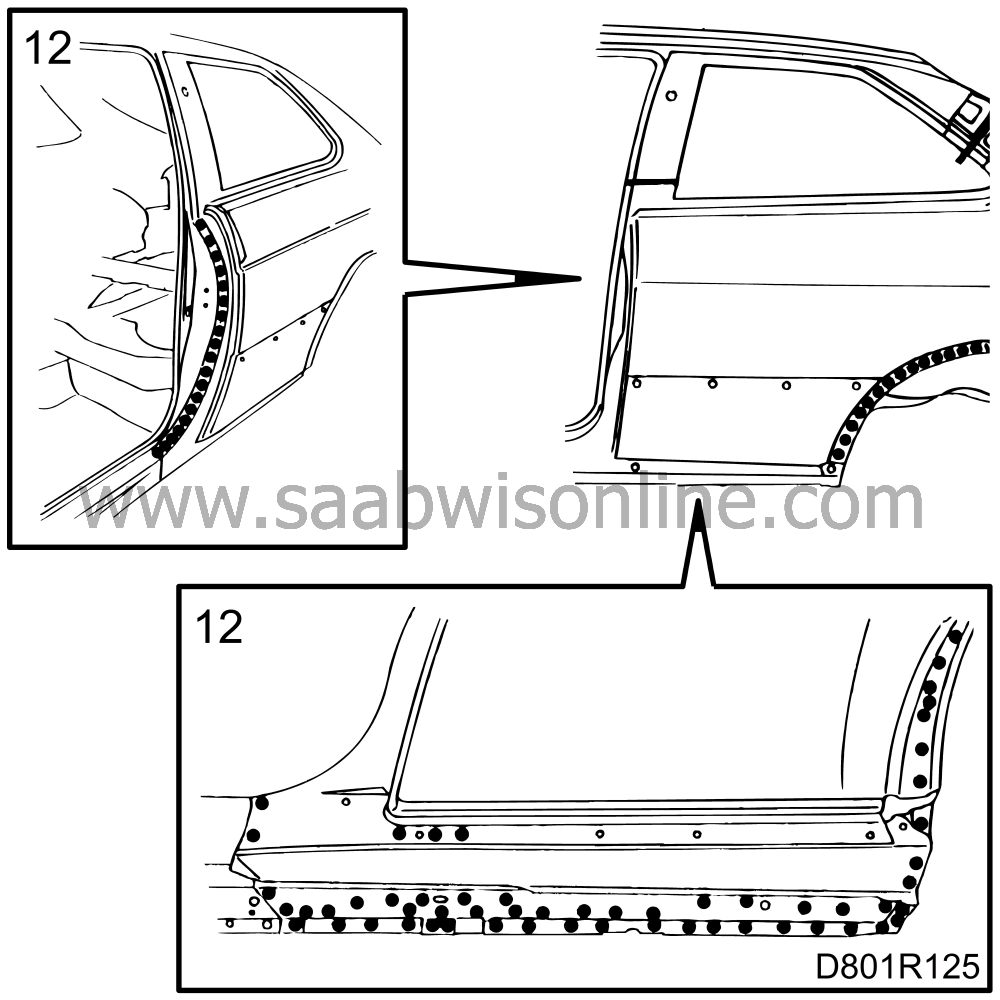

Part of side panel, three-door body

|

If the roof is undamaged, the side panel can be cut and joined further down the C pillar. Damage to the paintwork on the roof will then be avoided when the new side panel is welded in place.

|

Important

|

|

The C pillar may be cut only as described below. If it is not, the reinforcement inside it could very likely be damaged.

|

|

|

|

1.

|

Mount the car on an aligning bench and realign to the correct measurements if necessary.

|

|

2.

|

Cut the side panel as shown in the illustration. Do not damage the underlying metalwork. The C pillar is to be cut 40 mm above the ball joint that the tailgate gas spring is attached to.

|

|

3.

|

Drill out the spot welds.

Drill out the spot welds.

Drill out the spot welds.

|

|

4.

|

Knock loose the side panel and realign any deformed metalwork.

|

|

5.

|

Cut the spare part roughly to size so that it will overlap the joint by about three centimetres.

|

|

6.

|

Drill holes for plug welding in the spare part.

|

|

7.

|

Position the spare part and align it by fitting screws in the window frame. Fix the spare part with a few welding clamps.

|

|

8.

|

Cut through the spare part and the body simultaneously so that the joint can be welded edge-to-edge.

|

|

9.

|

Remove the spare part and use a grinder to clean the areas on the spare part and body that are to be welded.

|

|

10.

|

Apply welding primer to the surfaces which are to be spot welded. Use Teroson Zinkspray.

|

|

11.

|

Position the spare part and fix it with a few welding clamps.

|

|

12.

|

Spot weld the spare part in place.

Spot weld the spare part in place.

|

|

14.

|

Grind the welds clean.

|

|

15.

|

Wash off surplus welding primer. Welding primer makes for poorer adhesion of paint, filler and sealant.

|

|

16.

|

Apply primer to all surfaces that have been ground clean. Use Standox 1K Füllprimer.

|

|

17.

|

Seal joints and metal folds with putty. Use Terostat 1K-PUR.

|

|

18.

|

Apply anti-corrosion agent to the inside surfaces of the side panel after painting. Use Terotex HV 400 or Mercasol 1.

|