SUSPENSION, INSPECTION

| SUSPENSION, INSPECTION |

| SUSPENSION BALL JOINT |

Jack-up the vehicle until front wheels are off ground.

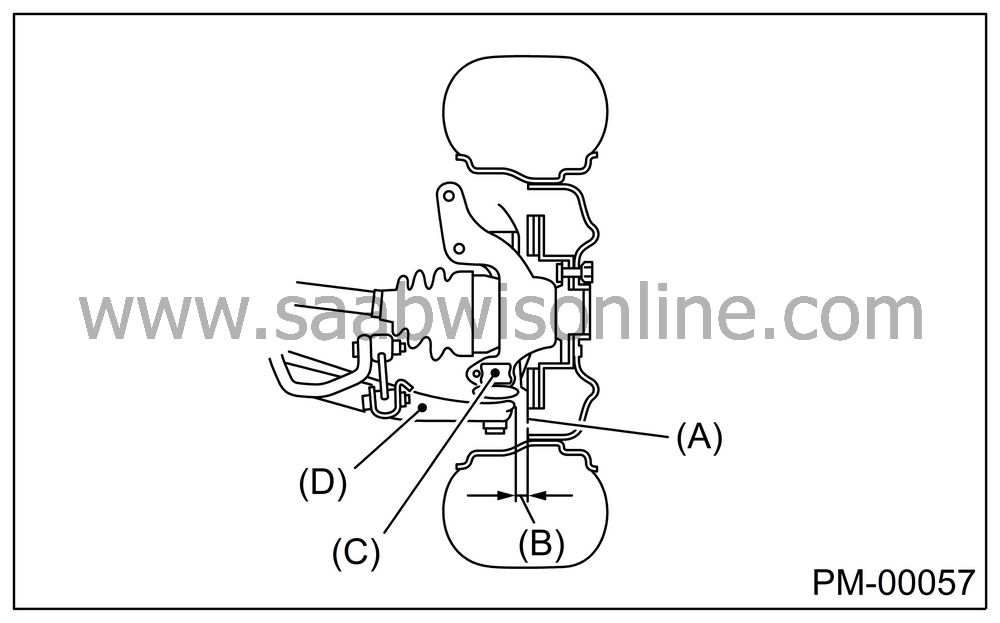

Next, grasp the bottom of tire and move it in and out. If relative movement (B) is observed between the brake disc cover (A) and end of transverse link (D), ball joint (C) may be excessively worn.

If relative movement is observed in the immediately preceding two steps, remove and inspect the ball joint. If free play exceeds standard, replace the ball joint.

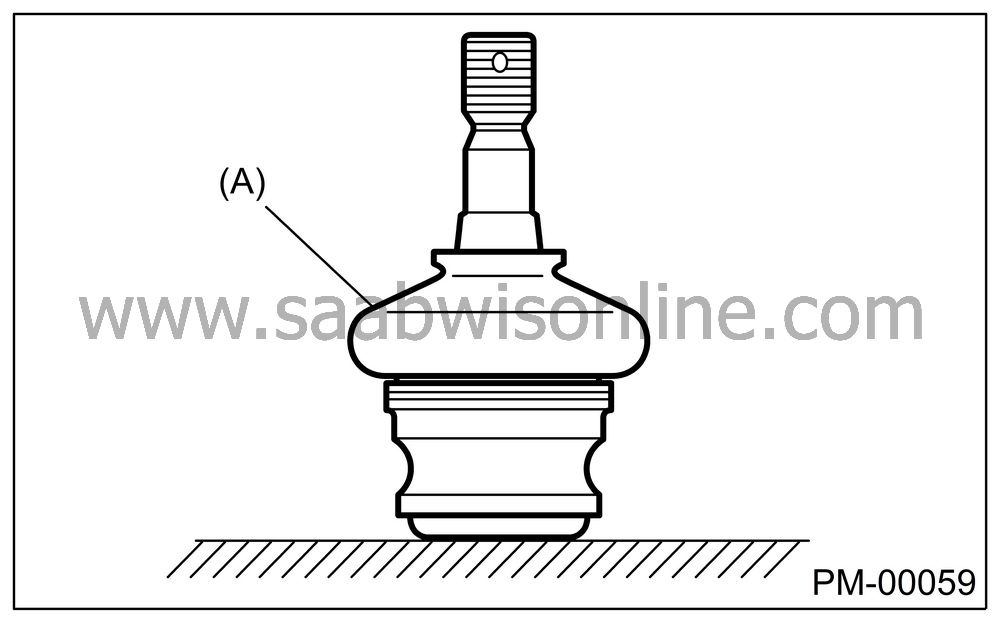

Damage of dust seal

Visually inspect the ball joint dust seal. If it is damaged, remove the transverse link.

And

measure free play of ball joint.

And

measure free play of ball joint.

When looseness exceeds standard value, replace the ball joint.

If the dust seal is damaged, replace with the new ball joint.

| Note | ||

|

When the transverse link ball joint

has been removed or replaced, check the toe-in of front wheel. If

the front wheel toe-in is not at specified value, adjust the toe-in.

|

|

(A)

|

Dust seal

|

| TRANSVERSE LINK’S REAR BUSHING |

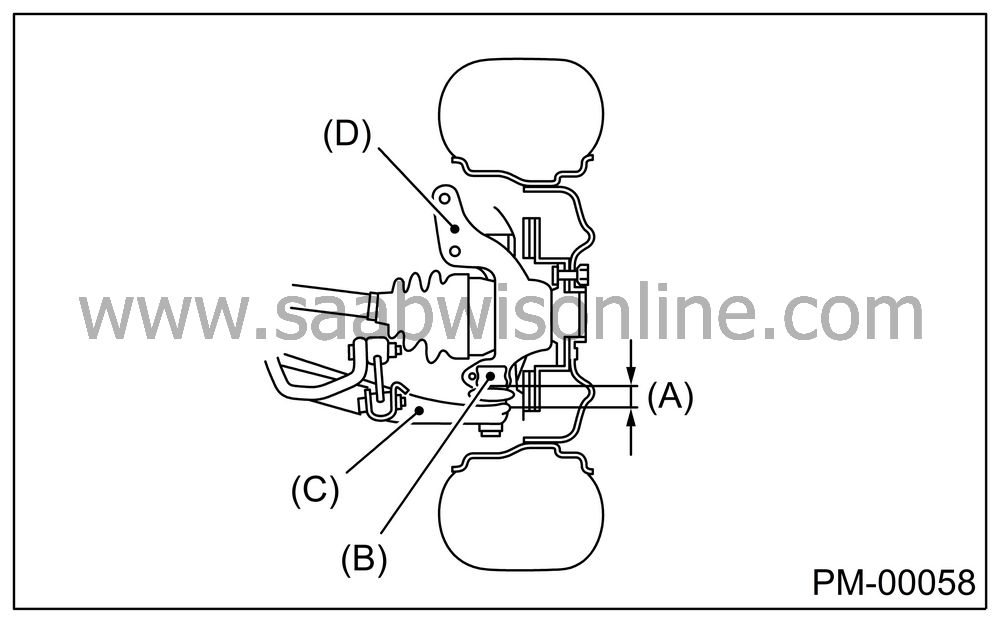

Check oil leaks at around liquid-filled bushing. If oil leaks, replace the bushing.

|

(A)

|

Rear bushing

|

|

(B)

|

Transverse

link

|

| WHEEL ARCH HEIGHT |

Unload cargoes and set the vehicle in curb weight (empty) condition.

Then, check the wheel arch height of front and rear suspensions to ensure that they are within specified values.

When the wheel arch height is out of tolerance visually inspect the following components and replace deformed parts.

| • |

Suspension

components [Front strut assembly and rear shock absorber

assembly]

|

|

| • |

Parts connecting between suspension and body.

|

|

When no components are deformed, adjust the wheel arch height by replacing coil spring in the suspension which wheel arch height is out of standard.

| WHEEL ALIGNMENT OF FRONT SUSPENSION |

Check the alignment of front suspension to ensure that following items conform to tolerance values.

| • |

Toe-in

|

|

| • |

Camber angle

|

|

| • |

Caster angle

|

|

| • |

Steering angle

|

|

When the caster angle does not conform to reference, visually inspect the following components and replace deformed parts.

| • |

Suspension

components [Strut assembly, crossmember, transverse link,

etc.]

|

|

| • |

Body parts to which suspensions are installed.

|

|

When the toe-in and camber are out of tolerance value, adjust them so that they conform to respective standard value.

When the right-and-left turning angles of tire are out of standard, adjust to standard value.

| WHEEL ALIGNMENT OF REAR SUSPENSION |

Check the alignment of rear suspension to ensure that following items are within tolerance values.

| • |

Toe-in

|

|

| • |

Camber angle

|

|

| • |

Thrust angle

|

|

When the camber angle does not conform to reference, visually inspect parts listed below. If deformation is observed, replace the damaged parts.

| • |

Suspension

components [Shock absorber, link F, link R, link UPR, arm

R, sub frame, etc.]

|

|

| • |

Body parts to which suspensions are installed.

|

|

When the toe-in and thrust angle are out of tolerance value, adjust them so that they conform to respective standard value.

| OIL LEAKAGE OF STRUT |

Visually inspect the front strut and rear strut for oil leakage as instructed. Replace front strut and rear strut if oil leaks excessively.

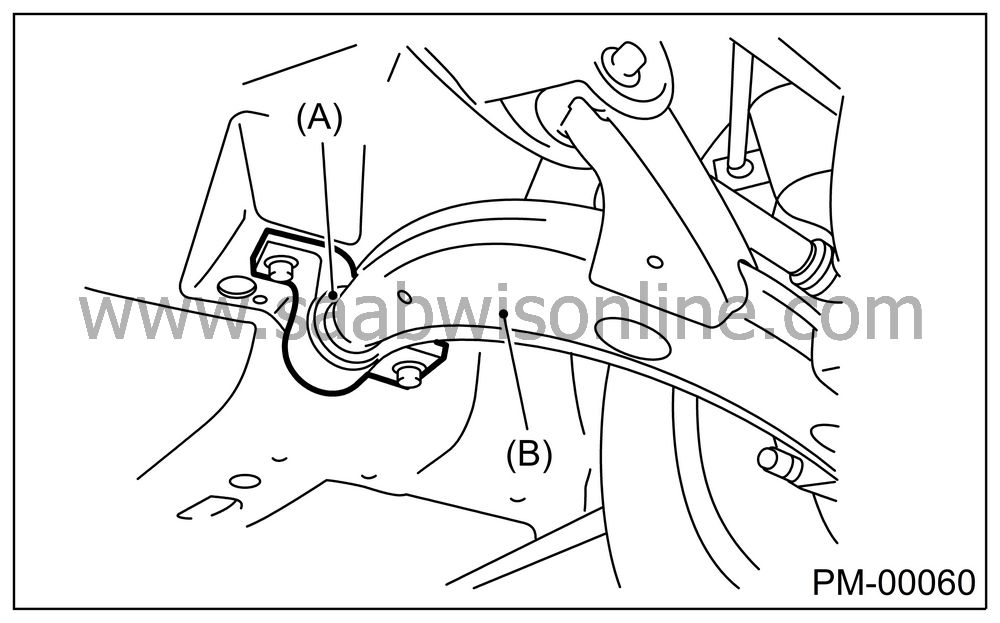

| TIGHTNESS OF BOLTS AND NUTS |

Check the bolts and nuts shown in the figure for looseness. Retighten the bolts and nuts to specified torque. If the self-lock nuts and bolts are removed, replace them with new ones.

Front suspension:

Rear suspension:

| DAMAGE TO SUSPENSION PARTS |

Check the following parts and the fastening portion of the vehicle body for deformation or excessive rusting which impairs the suspension. If necessary, replace the damaged parts with new ones. If minor rust formation, pitting, etc. are noted, remove the rust and apply remedial anti-corrosion measures.

| • |

Front

suspension

|

|

| • |

Transverse

link

|

| • |

Crossmember

|

| • |

Strut

|

| • |

Rear suspension

|

|

| • |

Crossmember

|

| • |

Lateral links

|

| • |

Trailing link

|

| • |

Strut

|

| • |

In the district where salt is sprayed to melt snow on

a road in winter, check suspension parts for damage caused by rust

every 12 months after lapse of 60 months. Take rust prevention measure as

required.

|

|