INSPECTION

| INSPECTION |

Check the following items before taking wheel alignment measurement.

Check items before taking wheel alignment measurement:

| • |

tire air pressure

|

|

| • |

unbalanced right and left tire wear,

size difference

|

|

| • |

tire run-out

|

|

| • |

ball joint excessive play, wear

|

|

| • |

tie rod end excessive play, wear

|

|

| • |

wheel bearing excessive play

|

|

| • |

right and left wheel base imbalance

|

|

| • |

steering link part deformed, excessive

play

|

|

| • |

suspension part deformed, excessive

play

|

|

Check, adjust and/or measure the wheel alignment in accordance with procedures indicated in the figure:

Wheel

arch height (Front and rear)

|

|

↓

|

Camber

(Front and rear)

|

|

↓

|

Caster

(Front)

|

|

↓

|

Steering

angle

|

|

↓

|

Front

wheel toe-in

|

|

↓

|

Rear

wheel toe-in

|

|

↓

|

Thrust

angle

|

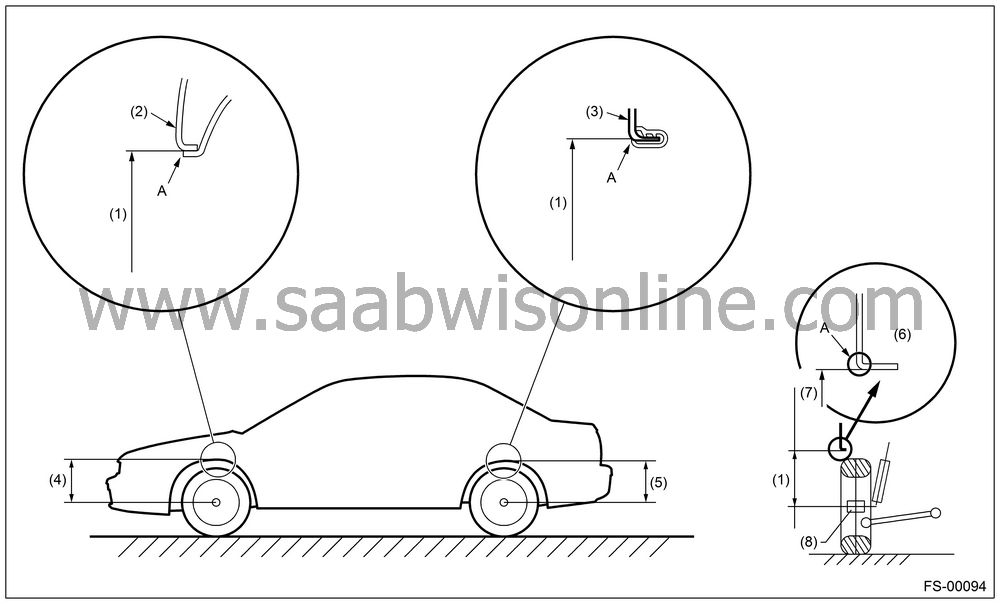

| WHEEL ARCH HEIGHT |

Set the vehicle on a level surface.

Set the vehicle to “curb weight” conditions. (Empty luggage compartment, install spare tire, jack, service tools, and top up fuel tank.)

Set the steering wheel in a straight line, then remove the vehicle straight ahead more than 5 m (16 ft) to settle the suspension.

Suspend the thread from wheel arch (point “A” in figure below) to determine a point directly above center of wheel.

Measure the distance between measuring point “A” and center of wheel.

|

(1)

|

Wheel arch

height

|

(4)

|

Front wheel

arch height

|

(7)

|

Measuring

point

|

|

(2)

|

Front fender

|

(5)

|

Rear wheel

arch height

|

(8)

|

End of

spindle

|

|

(3)

|

Rear quarter

|

(6)

|

Flange

bend line

|

| Model | Specified wheel arch height | ||

| Saab 9-2X 2.5i Linear | Saab 9-2X 2.0T Aero | ||

|

Front

|

397+12/−24

mm (15.63+0.47/−0.94 in)

|

387+12/−24

mm (15.24+0.47/−0.94 in)

|

|

|

Rear

|

381+12/−24

mm (15.0+0.47/−0.94 in)

|

376+12/−24

mm (14.80+0.47/−0.94 in)

|

|

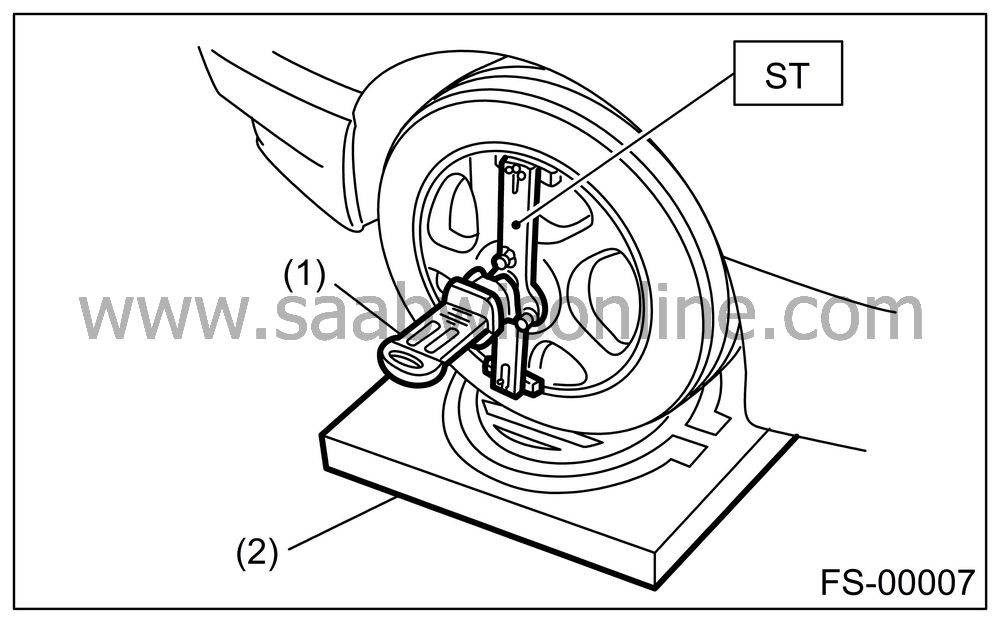

| CAMBER |

Inspection

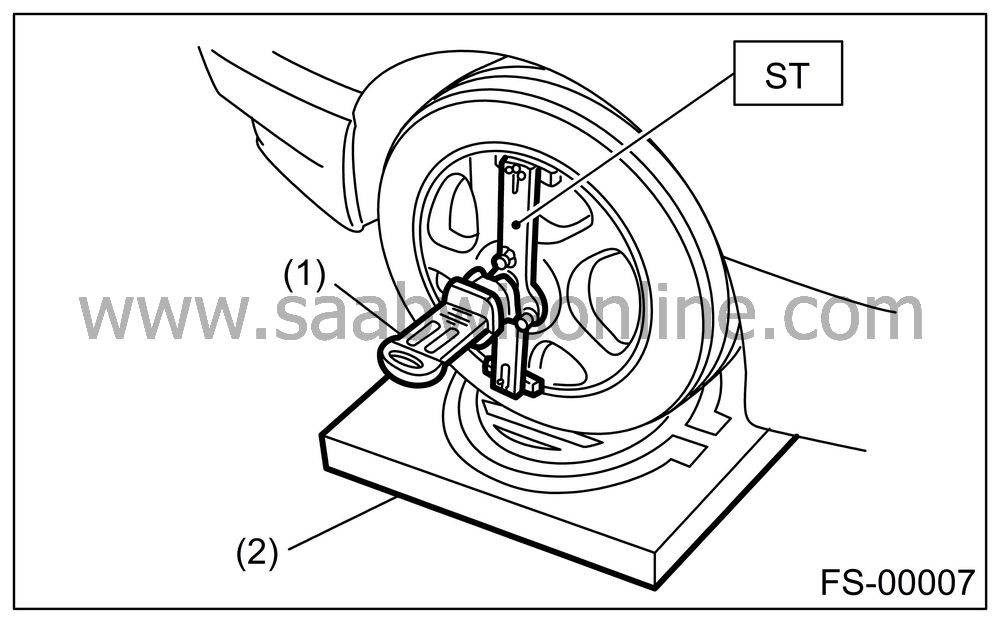

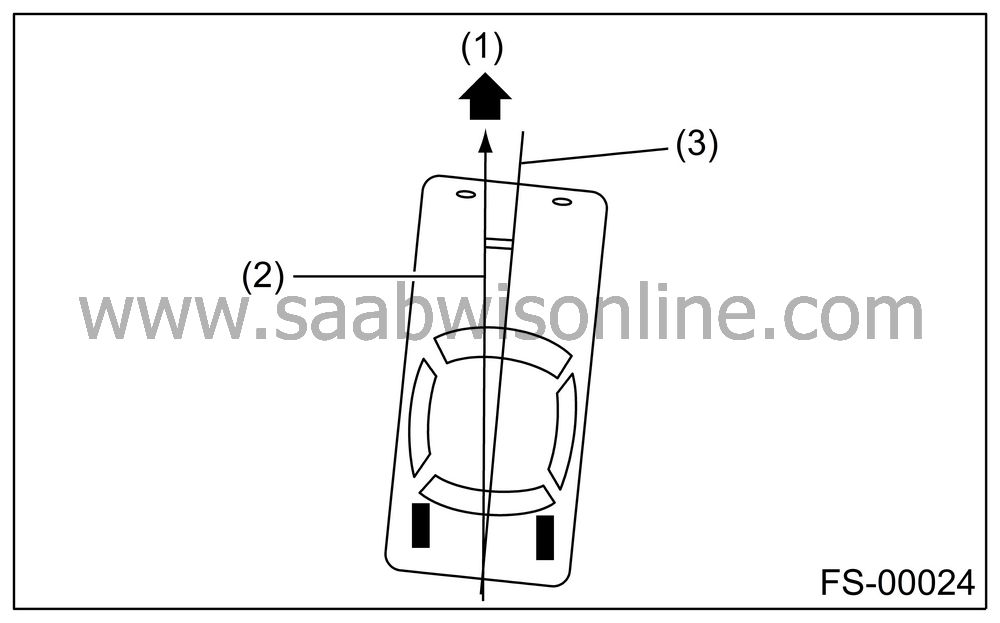

Place the front wheel on turning radius gauge. Make sure ground contacting surfaces of front and rear wheels are set at the same height.Set the ST into the center of wheel, and then install the wheel alignment gauge.

ST 32005204 ADAPTER

|

(1)

|

Alignment

gauge

|

|

(2)

|

Turning

radius gauge

|

Follow the wheel alignment gauge operation manual to measure camber angle.

| Note | ||

|

Refer to the “SPECIFICATIONS” for camber values. |

||

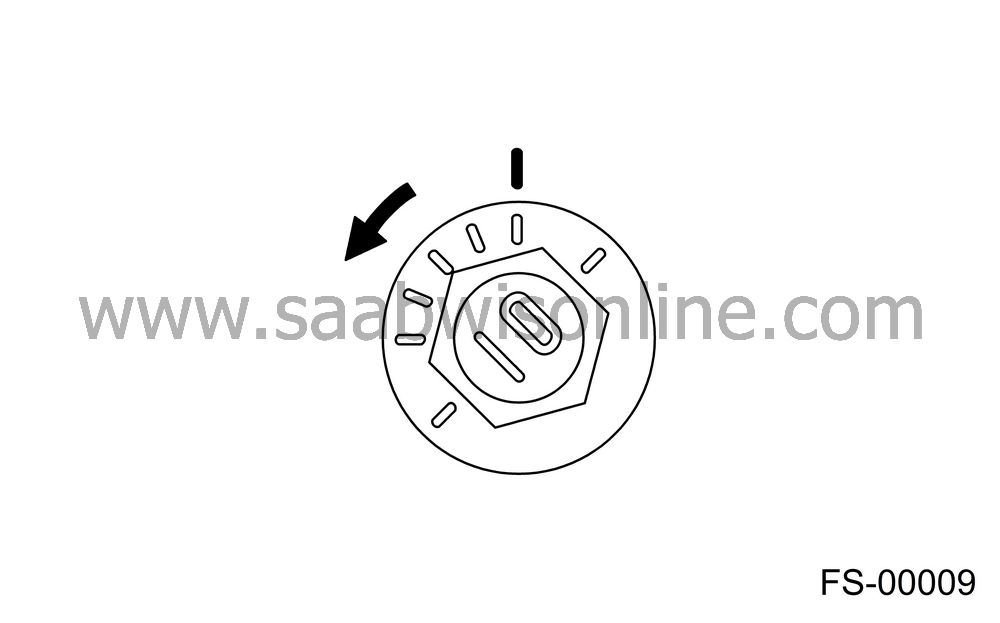

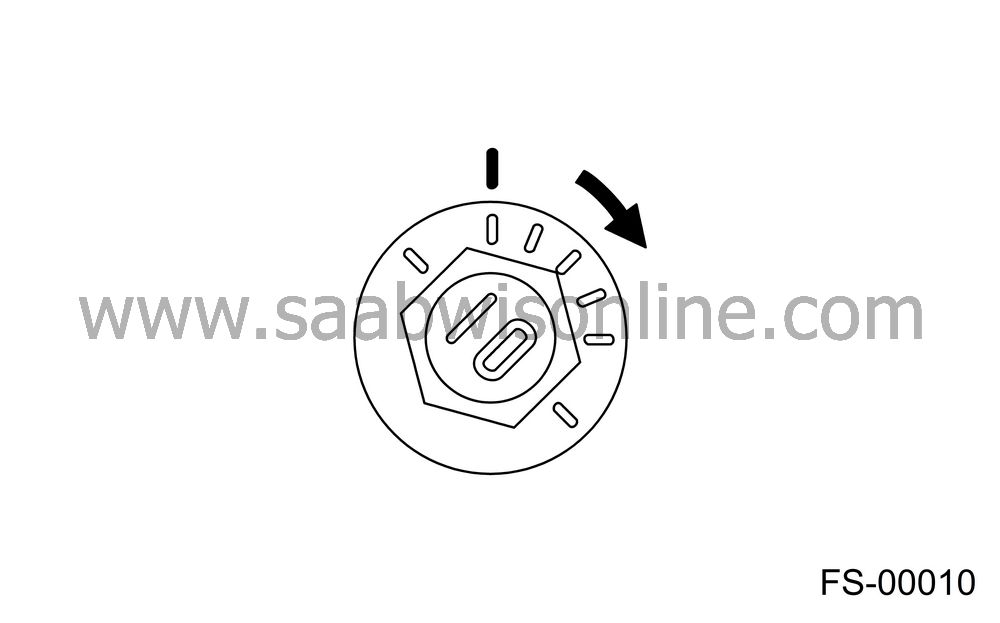

Front Camber Adjustment

Loosen the two self-locking nuts located at lower front portion of strut.| Note | ||

|

When adjusting bolt needs to be loosened or tightened, hold its head with a wrench and turn self-locking nut. |

Turn the camber adjusting bolt so that camber is set at the specification.

| Note | ||

|

Moving the adjusting bolt by one scale graduation changes camber by approx. 0°10′. |

|

(1)

|

Strut

|

|

(2)

|

Adjusting

bolt

|

|

(3)

|

Housing

|

|

(4)

|

Outer

|

|

(5)

|

Inner

|

|

(6)

|

Camber

is increased.

|

|

(7)

|

Camber

is decreased.

|

|

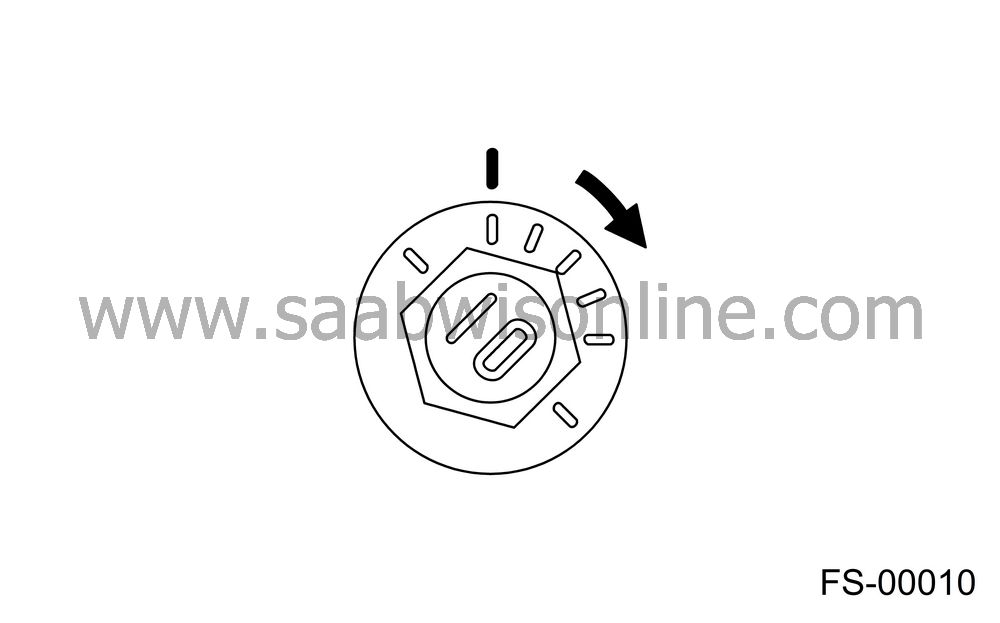

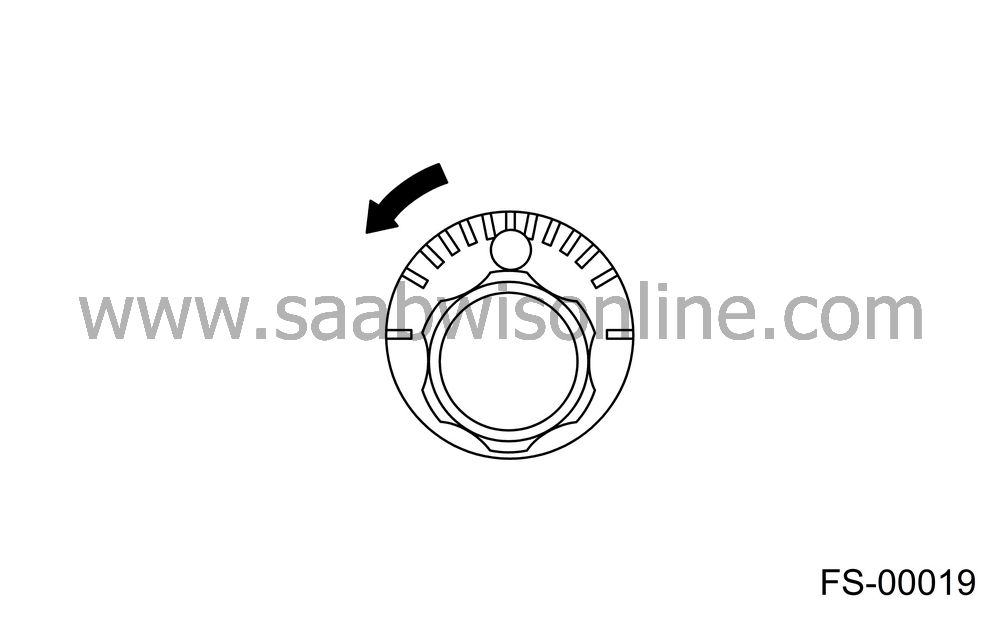

To increase Camber

|

|

|

Rotate

camber adjusting bolt LH counterclockwise.

|

Rotate

camber adjusting bolt RH clockwise.

|

|

|

|

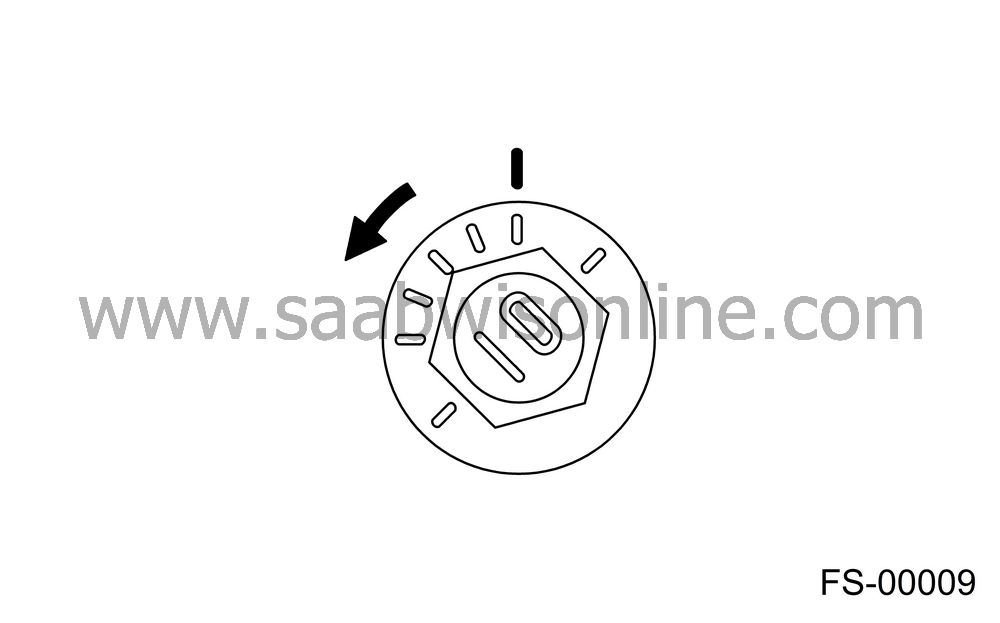

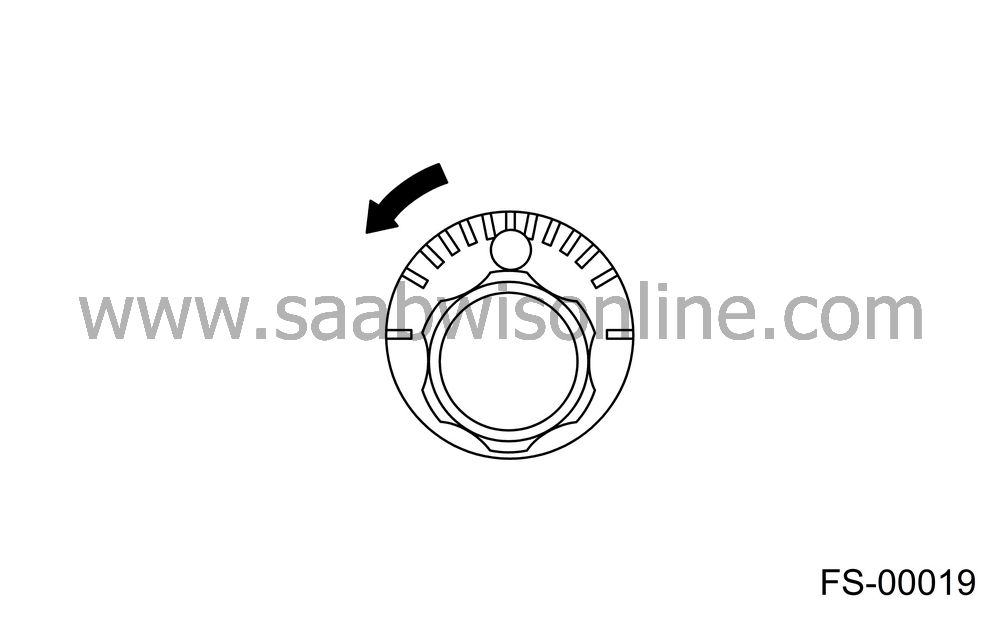

To decrease Camber

|

|

|

Rotate

camber adjusting bolt LH clockwise.

|

Rotate

camber adjusting bolt RH counterclockwise.

|

|

|

Tighten two new self-locking nuts.

Tightening torque:

175 Nm (17.8 kgf-m, 129 ft-lb)

| CASTER |

Inspection

Place the front wheel on turning radius gauge. Make sure ground contacting surfaces of front and rear wheels are set at the same height.Set the ST into center of wheel, and then install the wheel alignment gauge.

ST 32005204 ADAPTER

|

(1)

|

Alignment

gauge

|

|

(2)

|

Turning

radius gauge

|

Follow the wheel alignment gauge operation manual to measure caster angle.

| Note | ||

| STEERING ANGLE |

Inspection

Place the vehicle on a turning radius gauge.While depressing the brake pedal, turn the steering wheel fully to the right and left. With the steering wheel held at each fully turned position, measure both the inner and outer wheel steering angle.

Steering angle:

| Model | Saab 9-2X 2.0T Aero | Saab 9-2X 2.5i Linear |

|

Inner wheel

|

34.5°±1.5°

|

37.3°±1.5°

|

|

Outer wheel

|

30.3°±1.5°

|

32.4°±1.5°

|

Adjustment

Turn the tie-rod to adjust steering angle of both inner and outer wheels.Check the toe-in.

| Note | ||

|

Correct the boot if it is twisted. |

|

(1)

|

Lock nut

|

| FRONT WHEEL TOE-IN |

Inspection

Toe-in:1.8±3 mm (0.08±0.12 in) (tolerance)

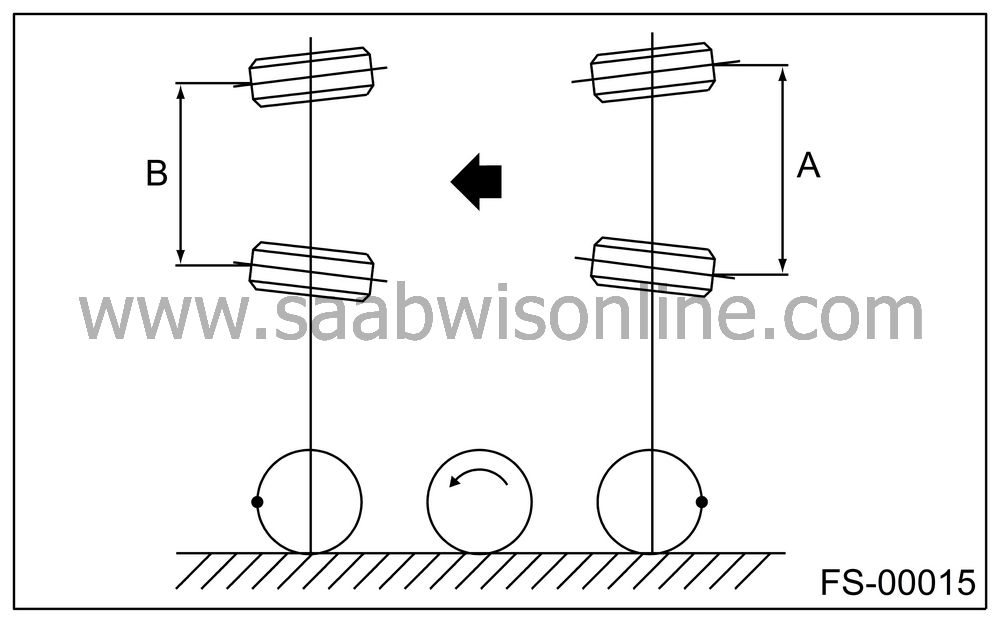

Set the toe-in gauge to rear sides of right and left front tires at height corresponding to center of spindle.

Mark each right and left tires at height corresponding to center of spindle and measure the distance “A” between marks.

Move the vehicle forward to rotate wheels 180°.

| Note | ||

|

Whenever rotating the wheels, drive the vehicle forward. |

Measure the distance “B” between right and left marks. Toe-in can then be obtained by the following equation:

A − B = Toe-in

Adjustment

Make sure that the right and left steering angles are within specified value.Loosen the right and left side steering tie-rods lock nuts.

Turn the right and left tie rods equal amounts until the toe-in is at the specification.

Toe-in:

1.8±2 mm (0.08±0.08 in) (adjustment standard)

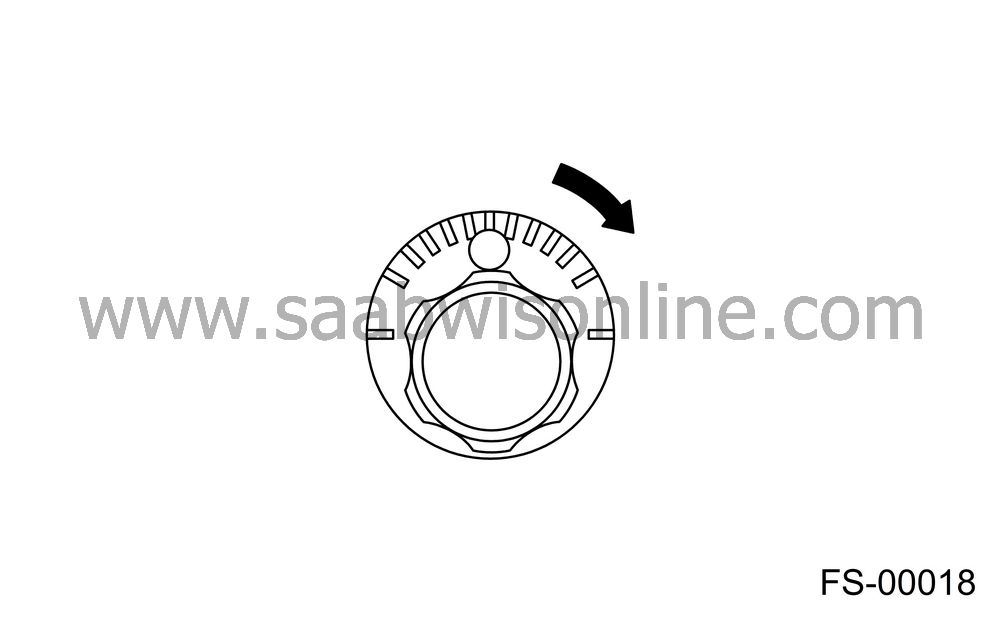

Both the right and left tie-rods are right-hand threaded. To increase toe-in, turn both tie-rods clockwise equal amounts (as viewed from inside of the vehicle).

|

(1)

|

Lock nut

|

Tighten the tie-rod lock nut.

Tightening torque:

83 Nm (8.5 kgf-m, 61.5 ft-lb)

| Note | ||

|

Correct the tie-rod boot, if it is twisted. |

| REAR WHEEL TOE-IN |

Inspection

Toe-in:0±3 mm (0±0.12 in) (tolerance)

For rear toe-in inspection procedure, refer to FRONT WHEEL TOE-IN procedure.

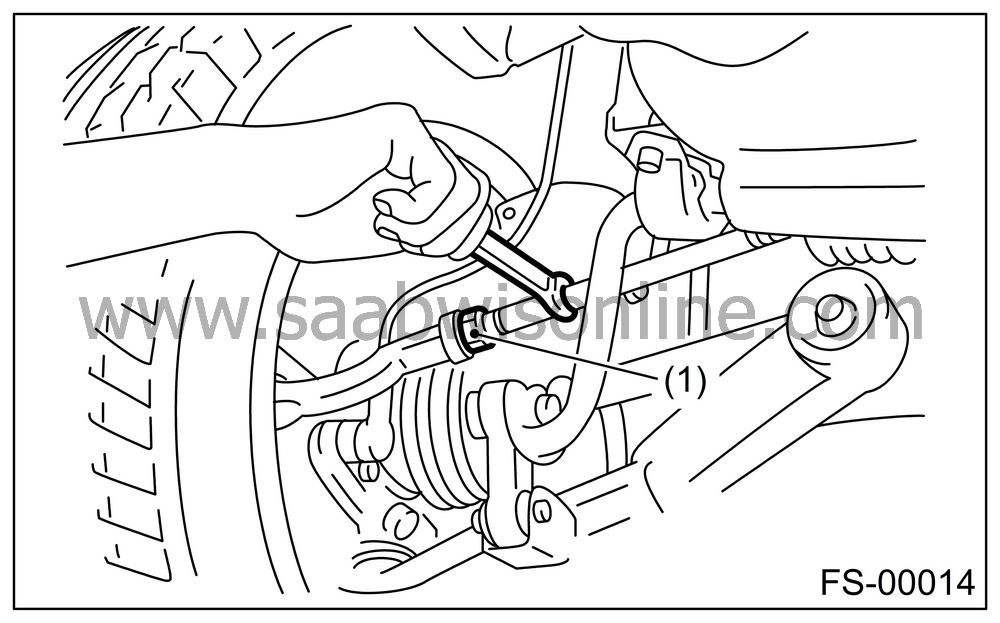

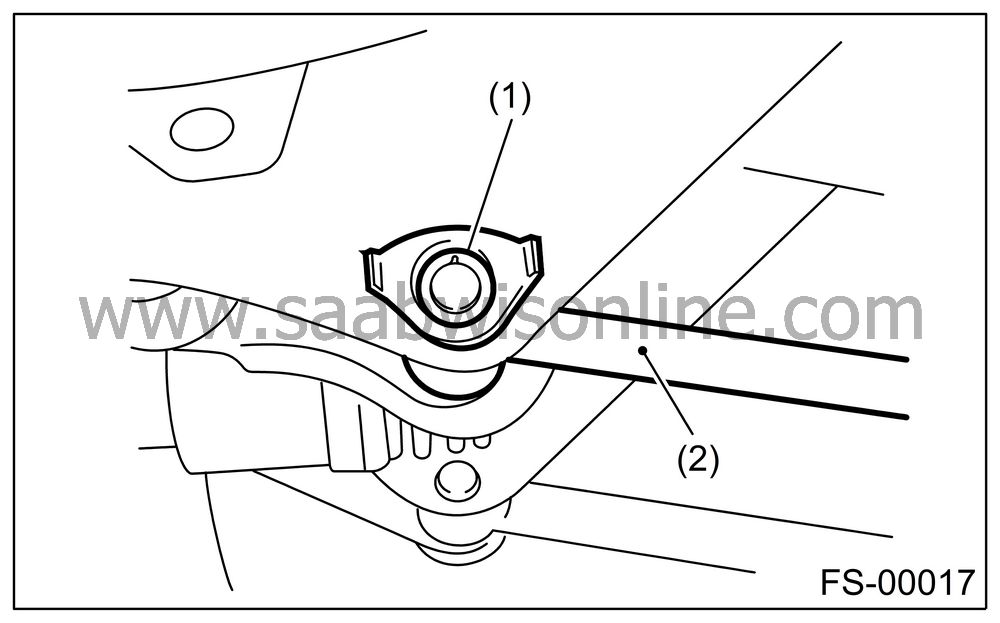

Adjustment

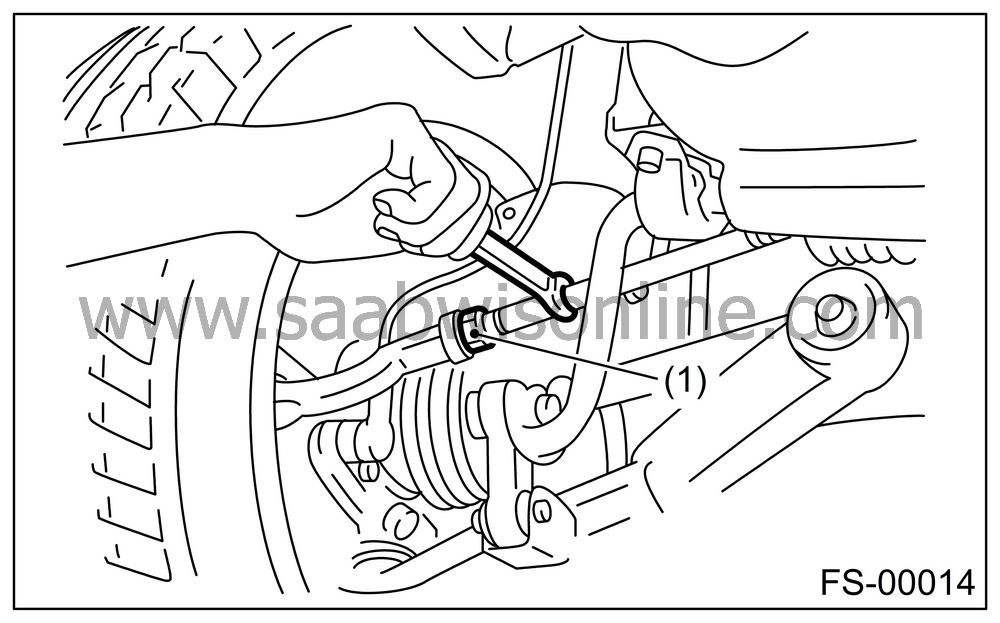

Loosen the self-locking nut on inner side of link rear.| Note | ||

|

When loosening or tightening the adjusting bolt, hold the bolt head and turn self-locking nut. |

|

(1)

|

Adjusting

bolt

|

|

(2)

|

Link rear

|

Turn the adjusting bolt head until toe-in is at the specification.

Toe-in:

0±2 mm (0±0.08 in) (adjustment standard)

| Note | ||

|

When the right and left wheels are adjusted for toe-in at the same time, the movement of one scale graduation changes toe-in by approx. 1.5 mm (0.6 in). |

|

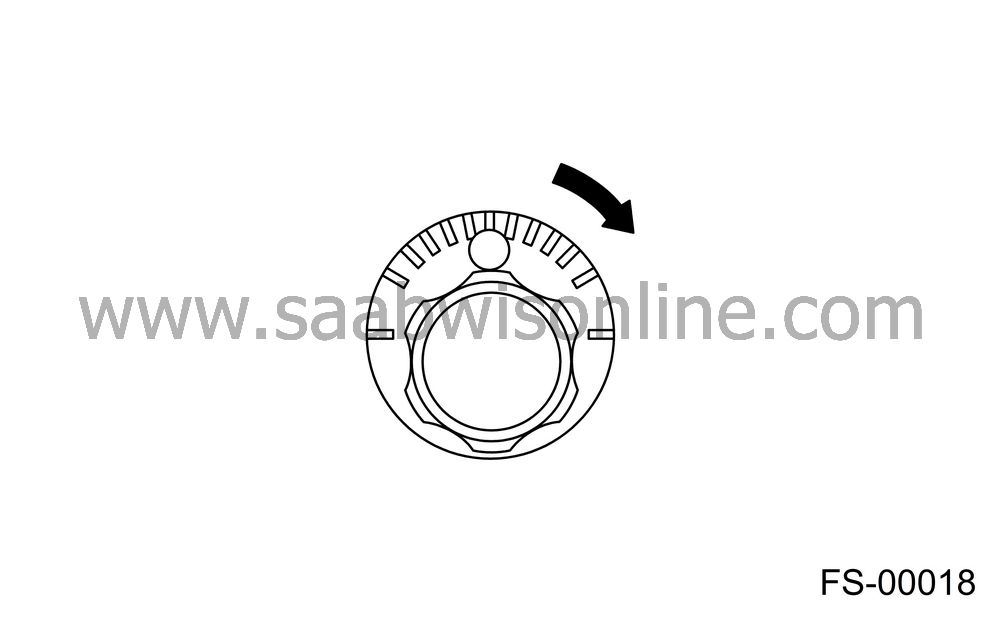

To increase Toe-in

|

|

|

Rotate

camber adjusting bolt LH clockwise.

|

Rotate

camber adjusting bolt RH counterclockwise.

|

|

|

|

To decrease Toe-in

|

|

|

Rotate

camber adjusting bolt LH counterclockwise.

|

Rotate

camber adjusting bolt RH clockwise.

|

|

|

Tighten a new self-locking nut.

Tightening torque:

100 Nm (10.2 kgf-m, 74 ft-lb)

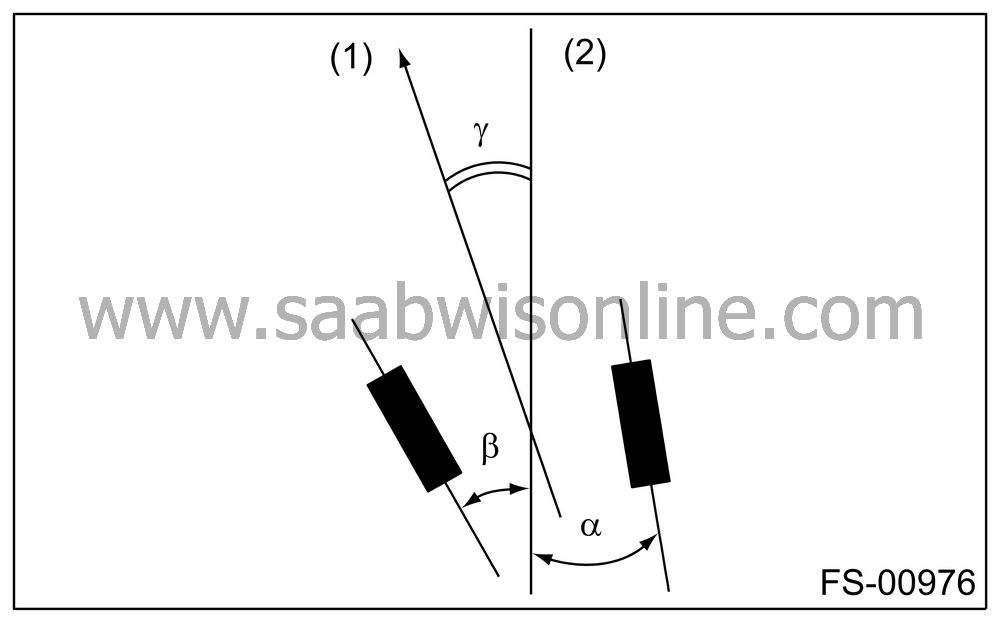

| THRUST ANGLE |

Inspection

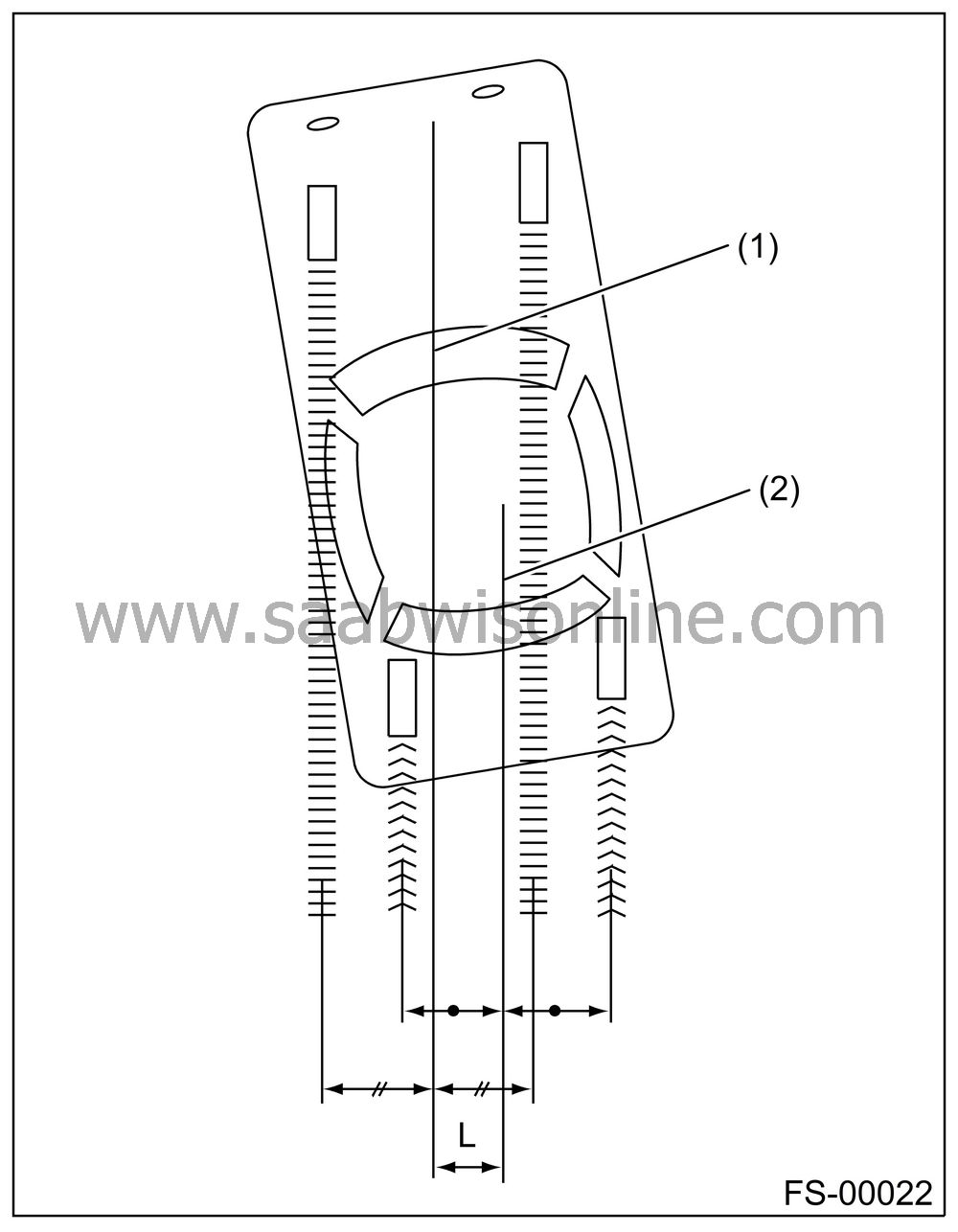

Position the vehicle on a level surface.Move the vehicle 3 to 4 m (10 to 13 ft) directly forward.

Determine the center lines of loci of both front and rear axles.

Measure the distance “L” between center lines of loci of the axles.

Thrust angle:

Less than 30′ when “L” is less than 22 mm (0.9 in).

|

(1)

|

Center

line of loci (front axle)

|

|

(2)

|

Center

line of loci (rear axle)

|

Adjustment

Make the thrust angle adjustments by turning toe-in adjusting bolts of rear suspension equally in the same direction.When one rear wheel is adjusted in a toe-in direction, adjust the other rear wheel equally in toe-out direction, in order to make thrust angle adjustment.

When the right and left adjusting bolts are turned incrementally by one graduation in the same direction, the thrust angle will change approx. 16′ [“L” is almost equal to 12 mm (0.472 in)].

Thrust angle:

0°±30′ (tolerance)

0°±20′ (adjustment standard)

|

(1)

|

Front

|

|

(2)

|

Thrust

angle

|

|

(3)

|

Body center

line

|

| Note | ||

|

Thrust angle refers to a mean value of right and left rear wheel toe angles in relation to the vehicle body center line. Vehicle is driven straight in the thrust angle direction while swinging in the oblique direction depending on the degree of the mean thrust angle. |

Thrust angle: r = (α − β)/2

α: Right rear wheel toe-in angle

β: Left rear wheel toe-in angle

Here, use only positive toe-in values from each wheel to substitute for α and β in the equation.

|

(1)

|

Front

|

|

(2)

|

Body center

line

|