PROCEDURE

| PROCEDURE |

Carry out trouble diagnosis shown in the following DTC table.

When performing trouble diagnosis which is not shown in the DTC table, refer to the next item Drive cycle.

| DTC | Item |

|

P0031

|

HO2S

Heater Control Circuit Low (Bank 1 Sensor 1)

|

|

P0032

|

HO2S

Heater Control Circuit High (Bank 1 Sensor 1)

|

|

P0037

|

HO2S

Heater Control Circuit Low (Bank 1 Sensor 2)

|

|

P0038

|

HO2S

Heater Control Circuit High (Bank 1 Sensor 2)

|

|

P0102

|

Mass or

Volume Air Flow Circuit Low Input

|

|

P0103

|

Mass or

Volume Air Flow Circuit High Input

|

|

P0107

|

Manifold

Absolute Pressure/Barometric Pressure Circuit Low Input

|

|

P0108

|

Manifold

Absolute Pressure/Barometric Pressure Circuit High Input

|

|

P0112

|

Intake

Air Temperature Circuit Low Input

|

|

P0113

|

Intake

Air Temperature Circuit High Input

|

|

P0117

|

Engine

Coolant Temperature Circuit Low Input

|

|

P0118

|

Engine

Coolant Temperature Circuit High Input

|

|

P0122

|

Throttle/Pedal

Position Sensor/Switch “A” Circuit Low

Input

|

|

P0123

|

Throttle/Pedal

Position Sensor/Switch “A” Circuit High

Input

|

|

P0131

|

O

2

Sensor

Circuit Low Voltage (Bank 1 Sensor 1)

|

|

P0132

|

O

2

Sensor

Circuit High Voltage (Bank 1 Sensor 1)

|

|

P0137

|

O

2

Sensor

Circuit Low Voltage (Bank 1 Sensor 2)

|

|

P0138

|

O

2

Sensor

Circuit High Voltage (Bank 1 Sensor 2)

|

|

P0181

|

Fuel

Temperature Sensor “A” Circuit Range/Performance

|

|

P0182

|

Fuel

Temperature Sensor “A” Circuit Low Input

|

|

P0183

|

Fuel

Temperature Sensor “A” Circuit High Input

|

|

P0222

|

Throttle/Pedal

Position Sensor/Switch “B” Circuit Low

Input

|

|

P0223

|

Throttle/Pedal

Position Sensor/Switch “B” Circuit High

Input

|

|

P0301

|

Cylinder

1 Misfire Detected

|

|

P0302

|

Cylinder

2 Misfire Detected

|

|

P0303

|

Cylinder

3 Misfire Detected

|

|

P0304

|

Cylinder

4 Misfire Detected

|

|

P0327

|

Knock

Sensor 1 Circuit Low Input (Bank 1 or Single Sensor)

|

|

P0328

|

Knock

Sensor 1 Circuit High Input (Bank 1 or Single Sensor)

|

|

P0335

|

Crankshaft

Position Sensor “A” Circuit

|

|

P0336

|

Crankshaft

Position Sensor “A” Circuit Range/Performance

|

|

P0340

|

Camshaft

Position Sensor “A” Circuit (Bank 1 or Single

Sensor)

|

|

P0341

|

Camshaft

Position Sensor “A” Circuit Range/Performance

(Bank 1 or Single Sensor)

|

|

P0447

|

Evaporative

Emission Control System Vent Control Circuit Open

|

|

P0448

|

Evaporative

Emission Control System Vent Control Circuit Shorted

|

|

P0452

|

Evaporative

Emission Control System Pressure Sensor Low Input

|

|

P0453

|

Evaporative

Emission Control System Pressure Sensor High Input

|

|

P0458

|

Evaporative

Emission Control System Purge Control Valve Circuit Low

|

|

P0461

|

Fuel

Level Sensor Circuit Range/Performance

|

|

P0462

|

Fuel

Level Sensor Circuit Low Input

|

|

P0463

|

Fuel

Level Sensor Circuit High Input

|

|

P0502

|

Vehicle

Speed Sensor Circuit Low Input

|

|

P0503

|

Vehicle

Speed Sensor Intermittent/Erratic/High

|

|

P0512

|

Starter

Request Circuit

|

|

P0600

|

CAN

Communication Circuit

|

|

P0604

|

Internal

Control Module Random Access Memory (RAM) Error

|

|

P0605

|

Internal

Control Module Read Only Memory (ROM) Error

|

|

P0607

|

Control

Module Performance

|

|

P0638

|

Throttle

Actuator Control Range/Performance (Bank 1)

|

|

P0691

|

Cooling

Fan 1 Control Circuit Low

|

|

P0692

|

Cooling

Fan 1 Control Circuit High

|

|

P0700

|

Request

AT Mil ON

|

|

P0851

|

Neutral

Switch Input Circuit Low

|

|

P0852

|

Neutral

Switch Input Circuit High

|

|

P1152

|

O

2

Sensor

Circuit Range/Performance (Low) (Bank1 Sensor1)

|

|

P1153

|

O

2

Sensor

Circuit Range/Performance (High) (Bank1 Sensor1)

|

|

P1160

|

Return

Spring Failure

|

|

P1400

|

Fuel

Tank Pressure Control Solenoid Valve Circuit Low

|

|

P1420

|

Fuel

Tank Pressure Control Solenoid Valve Circuit High

|

|

P1446

|

Fuel

Tank Sensor Control Valve Circuit Low

|

|

P1447

|

Fuel

Tank Sensor Control Valve Circuit High

|

|

P1518

|

Starter

Switch Circuit Low Input

|

|

P1560

|

Back-up

Voltage Circuit Malfunction

|

|

P2101

|

Throttle

Actuator Control Motor Circuit Range/Performance

|

|

P2102

|

Throttle

Actuator Control Motor Circuit Low

|

|

P2103

|

Throttle

Actuator Control Motor Circuit High

|

|

P2109

|

Throttle/Pedal

Position Sensor A Minimum Stop Performance

|

|

P2122

|

Throttle/Pedal

Position Sensor/Switch “D” Circuit Low

Input

|

|

P2123

|

Throttle/Pedal

Position Sensor/Switch “D” Circuit High

Input

|

|

P2127

|

Throttle/Pedal

Position Sensor/Switch “E” Circuit Low

Input

|

|

P2128

|

Throttle/Pedal

Position Sensor/Switch “E” Circuit High

Input

|

|

P2135

|

Throttle/Pedal

Position Sensor/Switch “A” / “B” Voltage

Rationality

|

|

P2138

|

Throttle/Pedal

Position Sensor/Switch “D” / “E” Voltage

Rationality

|

|

P2227

|

Atmospheric

Pressure Sensor Circuit Range/Performance

|

|

P2228

|

Atmospheric

Pressure Sensor Circuit Malfunction (Low Input)

|

|

P2229

|

Atmospheric

Pressure Sensor Circuit Malfunction (High Input)

|

| PREPARATION FOR THE INSPECTION MODE |

Make sure the fuel remains approx. half amount [20 — 40 litres (5.3 — 10.6 US gal, 4.4 — 8.8 Imp gal)] and the battery voltage is 12 V or more.

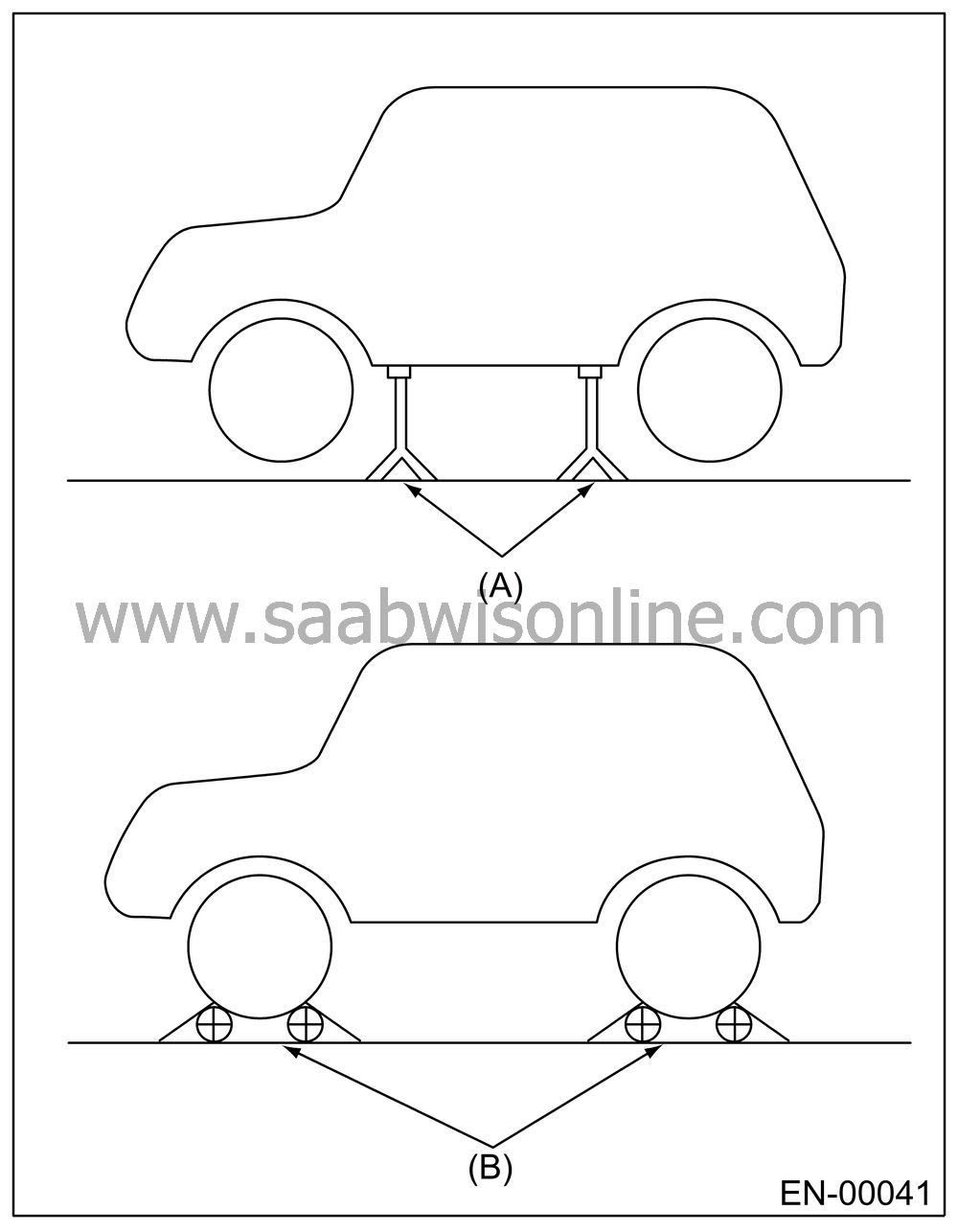

Raise the vehicle using a garage jack and place on rigid racks or drive the vehicle onto free rollers.

| Vehicle Diagnostic Interface |

After clearing the memory, check for any remaining unresolved trouble data.

Warm up the engine.

Prepare the Vehicle Diagnostic Interface kit.

Connect the diagnosis cable to Vehicle Diagnostic Interface.

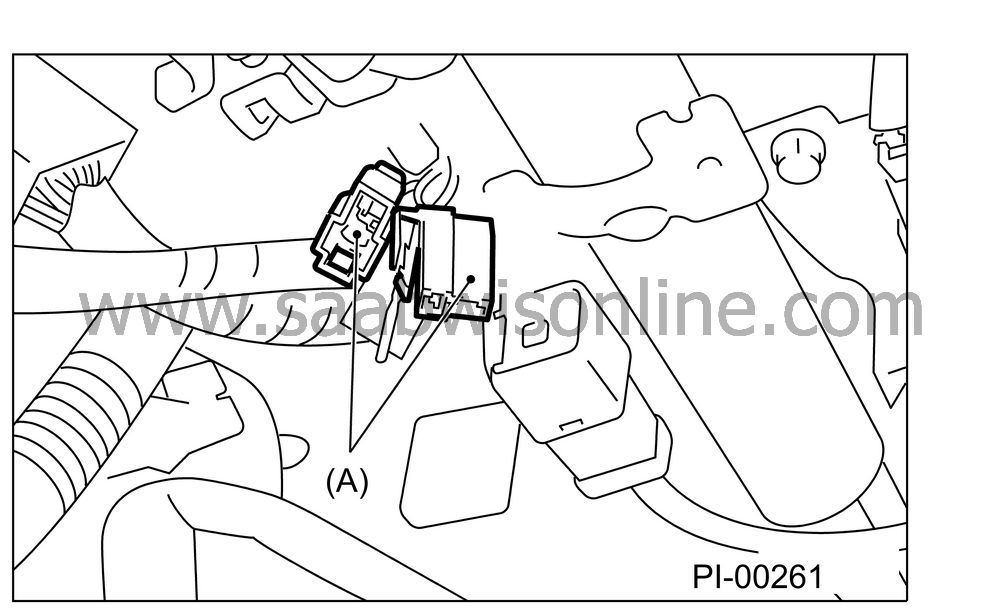

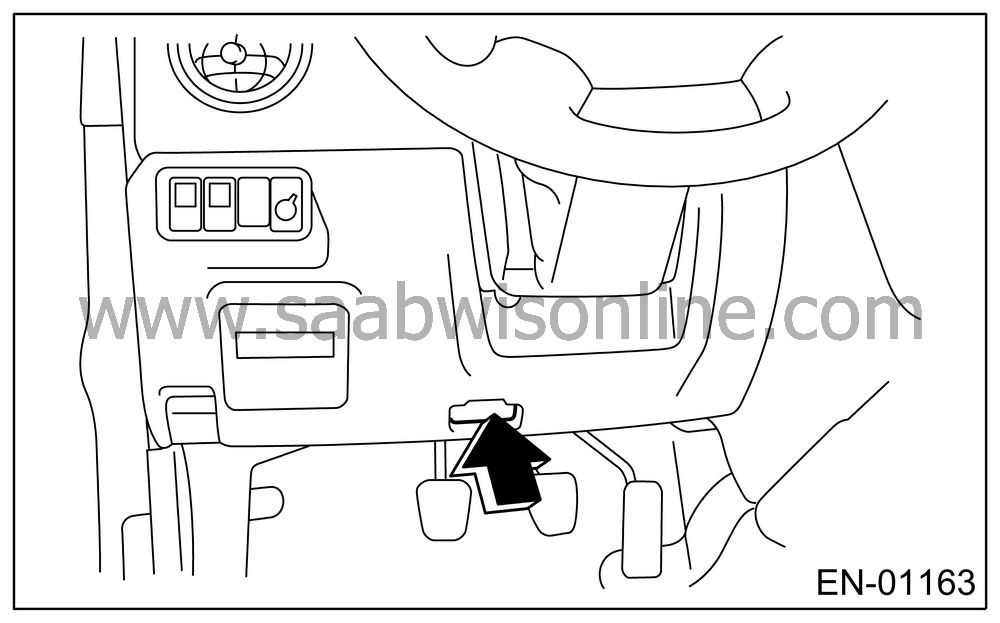

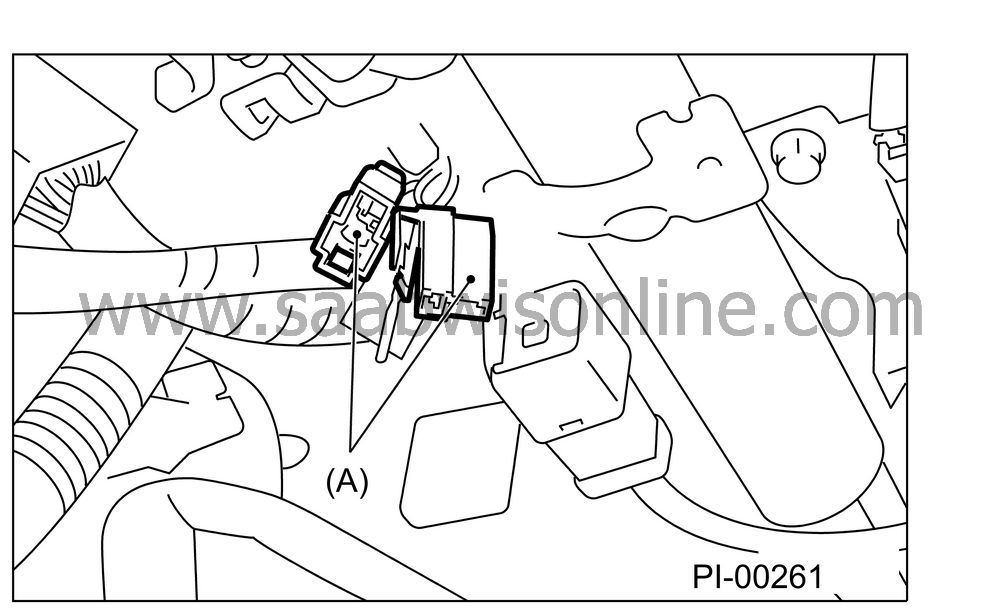

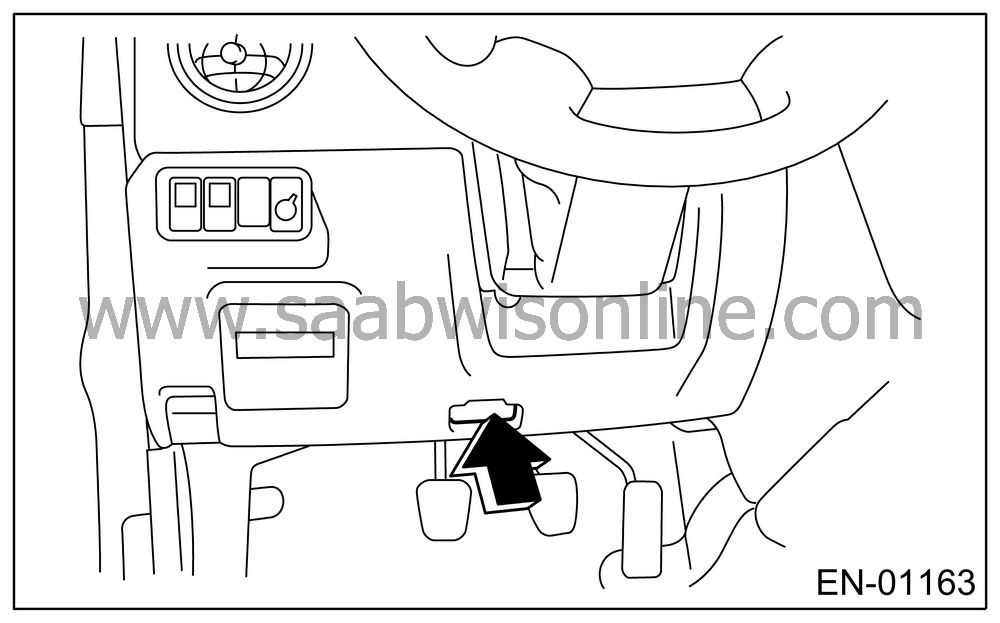

Connect the test mode connector (A) at the lower portion of instrument panel (on driver’s side).

Data link connector is located in the lower portion of the instrument panel (on the driver’s side).

Connect the diagnosis cable to data link connector.

| Important | ||

|

Do not connect the scan tools except for Vehicle Diagnostic Interface and OBD-II general scan tool. |

||

Turn the ignition switch to ON (engine OFF), and start the Vehicle Diagnostic Interface.

On «Main Menu» display screen, select the {2. Each System Check}.

On «System Selection Menu» display screen, select the {Engine Control System}.

Select the {OK} after the information of engine type is displayed.

On «Engine Diagnosis» display screen, select the {Dealer Check Mode Procedure}.

After the “Perform Inspection (Dealer Check) Mode?” is shown on display screen, select the {OK}.

Perform subsequent procedures as instructed on display screen.

| • |

If trouble

still remains in memory, the corresponding DTC appears on display

screen.

|

||||||||||||||||

| OBD-II GENERAL SCAN TOOL |

After clearing memory, check for any remaining unresolved trouble data:

Warm up the engine.

Connect the test mode connector (A) at the lower side of instrument panel (on the driver’s side).

Connect the OBD-II general scan tool to its data link connector.

| Important | ||

|

Do not connect the scan tools except for Vehicle Diagnostic Interface and OBD-II general scan tool. |

||

Start the engine.

| Note | ||

| • |

Ensure the selector lever is placed in “P” position before

starting. (AT models)

|

|

| • |

Depress the clutch pedal when starting engine. (MT models)

|

|

Using the selector lever or shift lever, turn the “P” position switch and “N” position switch to ON.

Depress the brake pedal to turn brake switch ON. (AT models)

Keep the engine speed in 2,500 — 3,000 rpm range for 40 seconds.

Place the selector lever or shift lever in “D” position (AT models) or “1st” gear (MT models) and drive the vehicle at 5 to 10 km/h (3 to 6 MPH).

| Note | ||

| • |

On AWD vehicles, release the parking brake.

|

|

| • |

The speed difference between front and rear wheels may

light ABS warning light, but this indicates no malfunctions. When

the engine control diagnosis is finished, perform the ABS memory clearance

procedure of self-diagnosis system.

|

|

Using the OBD-II general scan tool, check for DTC and record the result(s).

| Note | ||

| • |

For detailed operation procedures, refer to the OBD-II

General Scan Tool Instruction Manual.

|

|

| • |

For details concerning DTC, refer to the List of Diagnostic

Trouble Code (DTC).

|

|

Warning

Warning