INSPECTION

| INSPECTION |

| Important | ||

|

Inspection and adjustment of valve clearance should be performed while engine is cold. |

||

Set the vehicle on a lift.

Lift-up the vehicle.

Remove the under cover.

Lower the vehicle.

Disconnect the ground cable from battery.

When inspecting #1 and #3 cylinders:

Disconnect the spark plug cords from spark plugs RH side.

Disconnect the PCV hose from rocker cover (RH).

Remove the bolts, then remove the rocker cover (RH).

When inspecting #2 and #4 cylinders:

Disconnect the spark plug cords from spark plugs (LH Side).

Disconnect the PCV hose from rocker cover (LH).

Remove the bolts, then remove the rocker cover (LH).

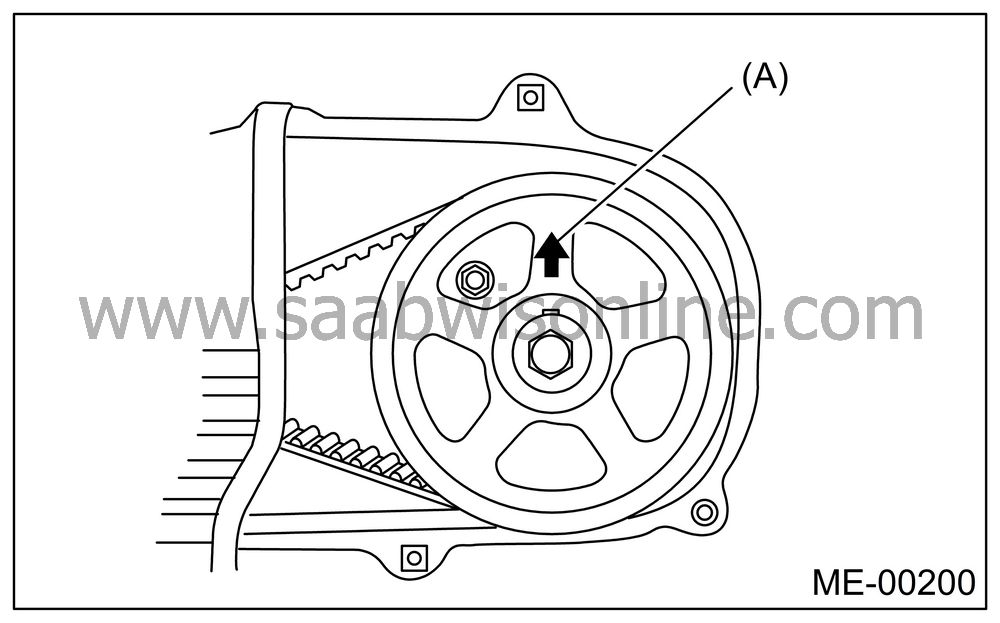

Set #1 cylinder piston to top dead center of compression stroke by rotating the crank pulley clockwise using the socket wrench.

| Note | ||

|

When the arrow mark (A) on cam sprocket (LH) comes exactly to the top, #1 cylinder piston is brought to the top dead center of compression stroke. |

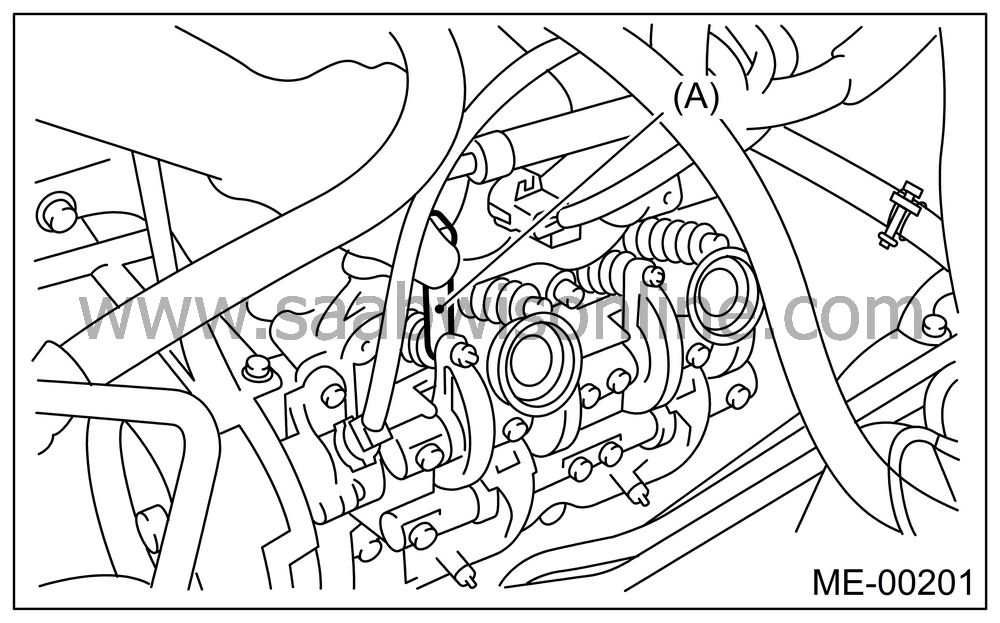

Measure #1 cylinder valve clearance using thickness gauge.

| Important | ||

| • |

Insert the thickness gauge (A)

in as horizontally as possible with respect to the valve stem end

face.

|

|

| • |

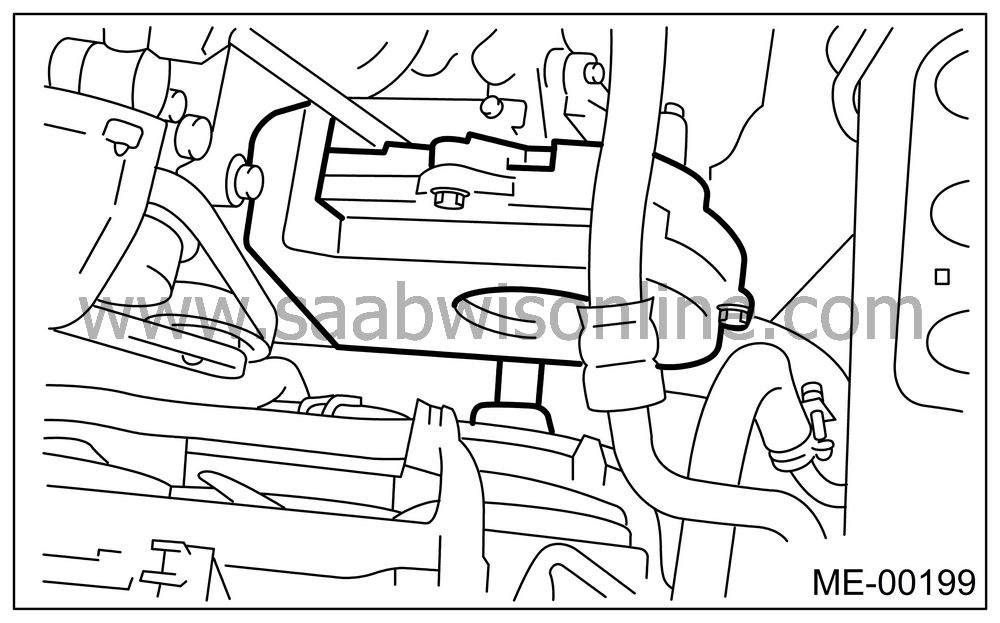

Measure the exhaust valve clearances while lifting-up

the vehicle.

|

|

Valve clearance (Standard):

Intake:

0.20±0.04 mm (0.0079±0.0016 in)Exhaust:

0.25±0.04 mm (0.0098±0.0016 in)

If necessary, adjust the valve clearance.

Measure the valve clearance in #3, #2 and #4 cylinder in the same measurement procedure as #1 cylinder.

| Note | ||

| • |

Be sure to set the cylinder pistons to their respective

top dead centers on compression stroke before measuring valve clearances.

|

|

| • |

By rotating the crank pulley clockwise every 180° from

the state that #1 cylinder piston is on the top dead center

of compression stroke, #3, #2 and #4 cylinder

pistons come to the top dead center of compression stroke in this

order.

|

|

After inspection, install the related parts in the reverse order of removal.