INSPECTION

| INSPECTION |

| SHIFT LOCK OPERATION |

CHECK SHIFT LOCK.

Turn the ignition switch ON.Move the select lever to “P” range.

While the brake pedal is not depressed, can select lever move from “P” range to other ranges?

| Yes |

Inspect “SELECT LEVER

SHIFT LOCK CANNOT BE RELEASED”.

| No |

CHECK SHIFT LOCK.

While the brake pedal is depressed, can select lever move from “P” range to other ranges?

| Yes |

| No |

Inspect “SELECT LEVER

CANNOT BE SHIFT LOCKED”.

CHECK KEY INTERLOCK.

When the select lever is in other than “P” range, does ignition switch turn to “LOCK” position?

| Yes |

Inspect “KEY INTERLOCK DOES

NOT BE LOCKED OR RELEASED.

| No |

CHECK KEY INTERLOCK.

When the select lever is in “P” range, does ignition switch turn to “LOCK” position?

| Yes |

AT shift lock system is normal.

| No |

Inspect “KEY INTERLOCK DOES

NOT BE LOCKED OR RELEASED.

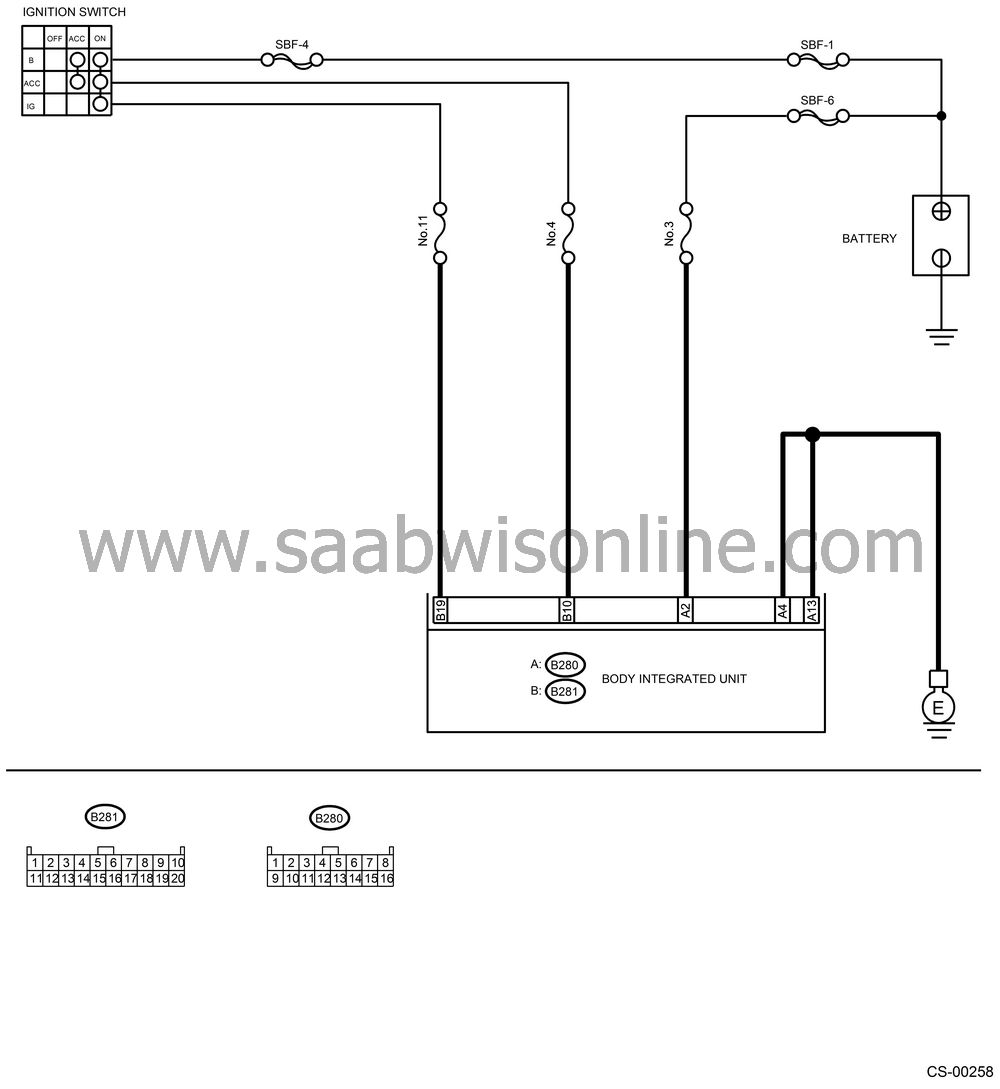

| BODY INTEGRATED UNIT POWER SUPPLY AND GROUND LINE |

CHECK FUSE.

Remove the fuse (No. 3, 4 and 11).Is the fuse (No. 3, 4 or 11) blown out?

| Yes |

Replace the fuse (No. 3, 4 or 11). If the replaced fuse (No. 3, 4 or 11) has blown out easily, repair short circuit in harness between fuse and body integrated unit.

| No |

CHECK HARNESS CONNECTOR BETWEEN BODY INTEGRATED UNIT AND BODY GROUND.

Turn the ignition switch to OFF.Measure the resistance of harness between body integrated unit and chassis ground.

Connector & terminal

(B280) No. 4 — Chassis ground:

(B280) No. 13 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit in harness between body integrated unit and body ground.

CHECK BATTERY POWER SUPPLY.

Turn the ignition switch to ON (engine OFF).Measure the voltages between body integrated unit and chassis ground.

Connector & terminal

(B280) No. 2 (+) — Chassis ground (−):

Is the voltage more than 9 V?

| Yes |

| No |

Repair the open circuit harness between battery and body integrated unit, and poor contact in coupling connector.

CHECK IGNITION POWER SUPPLY CIRCUIT.

Turn the ignition switch to ACC.Measure the voltage between body integrated unit and chassis ground.

Connector & terminal

(B281) No. 10 (+) — Chassis ground (−):

Is the voltage more than 9 V?

| Yes |

| No |

Repair the open circuit harness between battery and body integrated unit, and poor contact in coupling connector.

CHECK IGNITION POWER SUPPLY CIRCUIT.

Turn the ignition switch to ON (engine OFF).Measure the voltage between body integrated unit and chassis ground.

Connector & terminal

(B281) No. 19 (+) — Chassis ground (−):

Is the voltage more than 9 V?

| Yes |

| No |

Repair the open circuit harness between battery and body integrated unit, and poor contact in coupling connector.

CHECK POOR CONTACT.

Is there poor contact in connector?

| Yes |

Repair the poor contact.

| No |

Replace the body integrated unit.

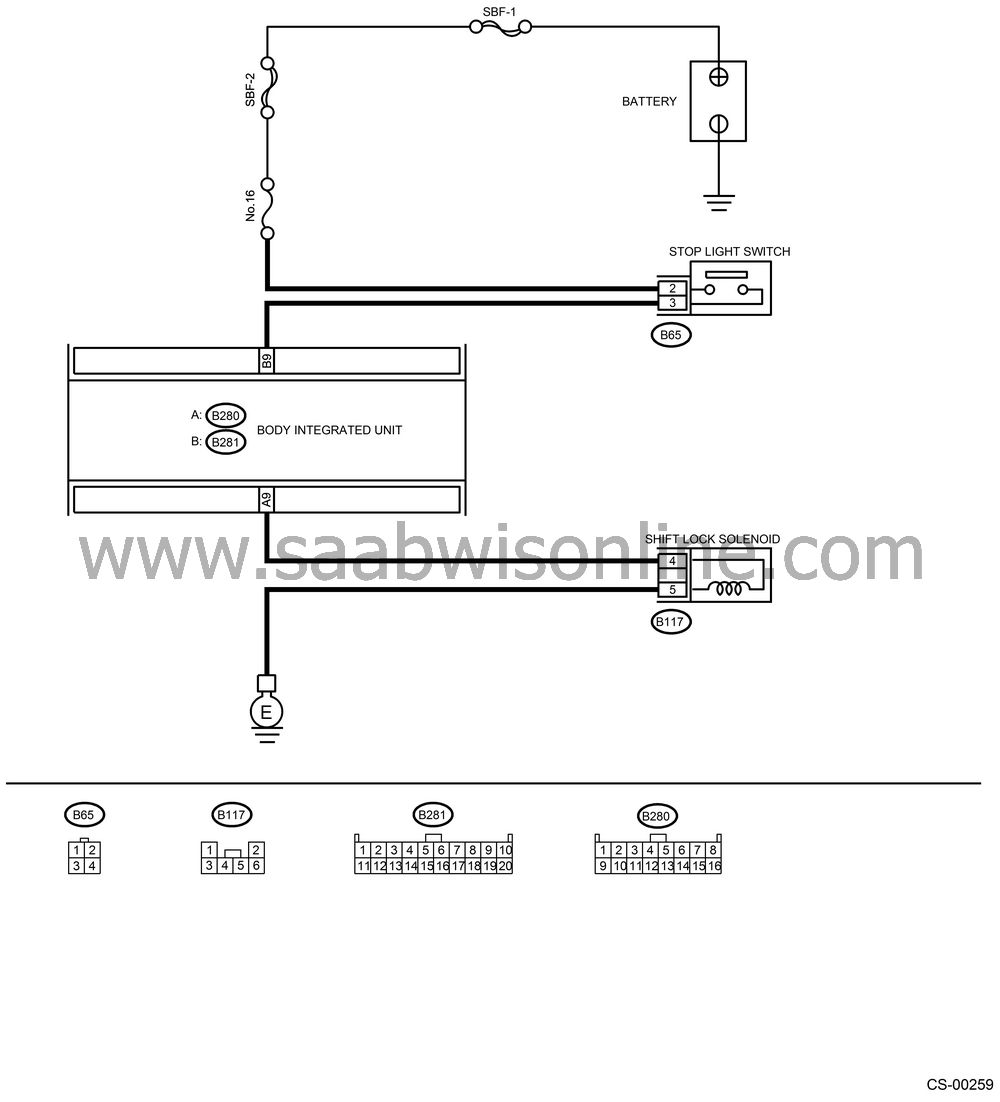

| SELECT LEVER CANNOT BE SHIFT LOCKED |

CHECK STOP LIGHT SWITCH.

Depress the brake pedal.Does the stop light turn on?

| Yes |

| No |

Inspect the stop light system.

CHECK HARNESS BETWEEN STOP LIGHT SWITCH AND BODY INTEGRATED UNIT.

Turn the ignition switch to OFF.Disconnect the body integrated unit and stoplight switch connector.

Measure the resistance of harness between stop light switch and body integrated unit.

Connector & terminal

(B65) No. 3 — (B281) No. 9:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and stop light switch.

| No |

CHECK HARNESS BETWEEN STOP LIGHT SWITCH AND BODY INTEGRATED UNIT.

Measure the resistance of harness between stop light switch and chassis ground.Connector & terminal

(B65) No. 3 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

Repair the short circuit in harness between body integrated unit and stop light switch.

| No |

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND SHIFT LOCK SOLENOID.

Disconnect the shift lock solenoid connector.Measure the resistance of harness between body integrated unit and shift lock solenoid.

Connector & terminal

(B117) No. 4 — (B280) No. 9:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and shift lock solenoid.

| No |

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND SHIFT LOCK SOLENOID.

Measure the resistance of harness between shift lock solenoid and chassis ground.Connector & terminal

(B117) No. 4 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

Repair the short circuit in harness between body integrated unit and shift lock solenoid.

| No |

CHECK HARNESS BETWEEN SHIFT LOCK SOLENOID AND CHASSIS GROUND.

Measure the resistance of harness between shift lock solenoid and chassis ground.Connector & terminal

(B117) No. 5 — Chassis ground:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between shift lock solenoid and body ground.

| No |

CHECK SHIFT LOCK SOLENOID.

Measure the resistance of shift lock solenoid connector terminals.Terminals

No. 4 — No. 5:

Is the resistance 20 — 40 Ω?

| Yes |

| No |

Replace the shift lock solenoid.

CHECK SHIFT LOCK SOLENOID.

Connect the battery with shift lock solenoid connector terminal and operate solenoid.Terminals

No. 4 (+) — No. 5 (−):

Does the shift lock solenoid operate properly?

| Yes |

| No |

Replace the shift lock solenoid.

CHECK POOR CONTACT.

Is there poor contact in connector?

| Yes |

Repair the poor contact.

| No |

Replace the body integrated unit.

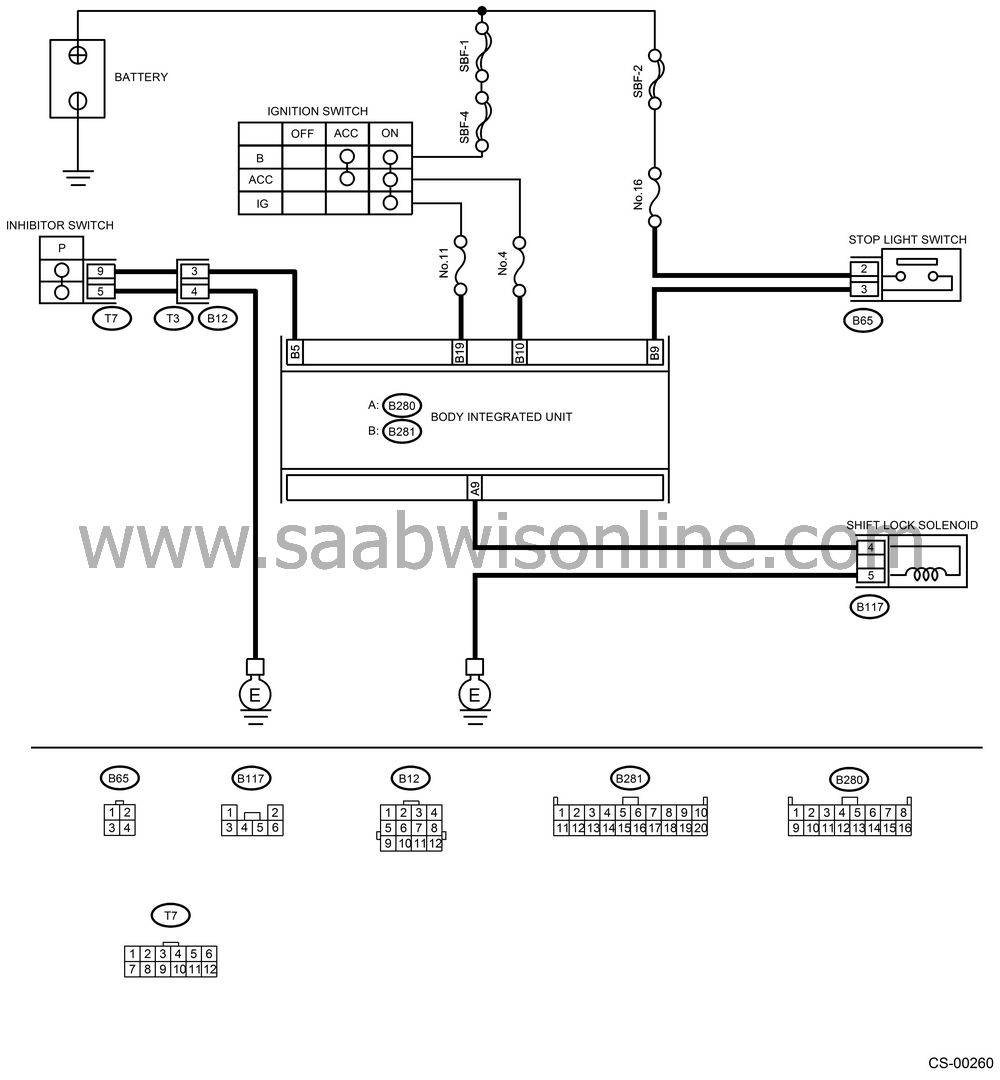

| SELECT LEVER SHIFT LOCK CANNOT BE RELEASED |

CHECK INHIBITOR SWITCH.

Turn the ignition switch to ON (engine OFF).Move the select lever from “P” to “1” range.

Are combination meter indicator light and select lever “P”, “R”, “N”, “3”, “2” and “1” correctly matched?

| Yes |

| No |

Adjust the inhibitor switch and select cable.

CHECK HARNESS BETWEEN INHIBITOR SWITCH AND BODY INTEGRATED UNIT.

Turn the ignition switch to OFF.Disconnect the connector of transmission harness and body integrated unit.

Measure the resistance of harness between body integrated unit and chassis ground.

Connector & terminal

(B281) No. 5 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

Repair the short circuit in harness between body integrated unit and transmission connector.

| No |

CHECK HARNESS BETWEEN INHIBITOR SWITCH AND BODY INTEGRATED UNIT.

Measure the resistance of harness between body integrated unit and inhibitor switch.Connector & terminal

(B12) No. 3 — (B281) No. 5:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and transmission connector

| No |

CHECK HARNESS BETWEEN INHIBITOR SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between body integrated unit and chassis ground.Connector & terminal

(B12) No. 4 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit in harness between body integrated unit and chassis ground.

CHECK INHIBITOR SWITCH.

Move the select lever to “P” range.Measure the resistance of transmission harness connector terminals.

Connector & terminal

(T3) No. 3 — No. 4:

Is the resistance more than 1 MΩ?

| Yes |

Repair or replace the inhibitor switch.

| No |

CHECK OUTPUT SIGNAL FOR BODY INTEGRATED UNIT.

Connect all connectors.Turn the ignition switch to ON.

Measure the voltage between body integrated unit and chassis ground.

Connector & terminal

(B281) No. 5 (+) — Chassis ground (−):

Is the voltage 9 — 16 V?

| Yes |

| No |

CHECK STOP LIGHT SWITCH.

Depress the brake pedal.Does the stop light turn on?

| Yes |

| No |

Inspect the stop light system.

CHECK HARNESS BETWEEN STOP LIGHT SWITCH AND AT SHIFT LOCK CONTROL MODULE.

Depress the brake pedal.Measure the voltage between body integrated unit and chassis ground.

Connector & terminal

(B281) No. 9 (+) — Chassis ground (−):

Is the voltage more than 9 V?

| Yes |

| No |

Repair the open or short circuit in harness between body integrated unit and stop light switch.

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND SHIFT LOCK SOLENOID.

Turn the ignition switch to OFF.Disconnect the connector from shift lock solenoid and body integrated unit.

Measure the resistance of harness between body integrated unit and shift lock solenoid.

Connector & terminal

(B280) No. 9 — (B117) No. 4:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and shift lock solenoid.

| No |

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND SHIFT LOCK SOLENOID.

Measure the resistance of harness between shift lock solenoid and chassis ground.Connector & terminal

(B280) No. 9 — Chassis ground:

Is the resistance less than 10 Ω?

| Yes |

Repair the short circuit in harness between body integrated unit and shift lock solenoid.

| No |

CHECK HARNESS BETWEEN SHIFT LOCK SOLENOID AND CHASSIS GROUND.

Measure the resistance of harness between shift lock solenoid and chassis ground.Connector & terminal

(B117) No. 5 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit in harness between shift lock solenoid and chassis ground.

CHECK SHIFT LOCK SOLENOID.

Measure the resistance of shift lock solenoid connector terminals.Terminals

No. 4 — No. 5:

Is the resistance 20 — 40 Ω?

| Yes |

| No |

Replace the shift lock solenoid.

CHECK SHIFT LOCK SOLENOID.

Connect the battery with shift lock solenoid connector terminal and operate solenoid.Terminals

No. 4 (+) — No. 5 (−):

Is the shift lock solenoid operating properly?

| Yes |

| No |

Replace the shift lock solenoid.

CHECK OUTPUT SIGNAL FOR AT SHIFT LOCK CONTROL MODULE.

Turn the ignition switch to ON (engine OFF).Measure the voltage between body integrated unit and chassis ground.

Connector & terminal

(B280) No. 9 (+) — Chassis ground (−):

Is the voltage more than 8.5 V?

| Yes |

| No |

Replace the body integrated unit.

CHECK POOR CONTACT.

Is there poor contact in connector?

| Yes |

Repair the poor contact.

| No |

Replace the body integrated unit.

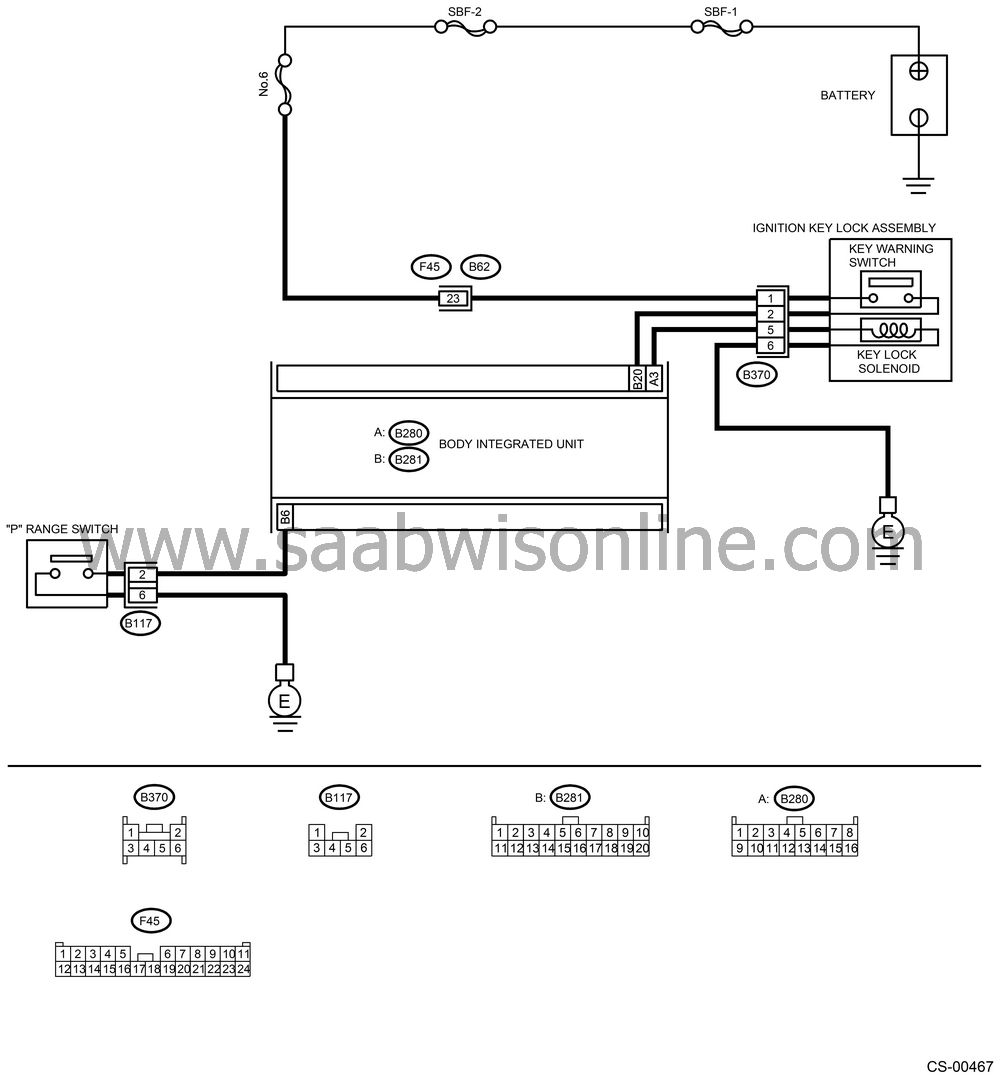

| KEY INTERLOCK DOES NOT LOCK OR RELEASE |

CHECK HARNESS BETWEEN BATTERY AND KEY WARNING SWITCH.

Disconnect the connector key warning switch.Measure the voltage of harness between key warning switch and chassis ground.

Connector & terminal

(B370) No. 1 (+) — Chassis ground (−):

Is the voltage 9 — 16 V?

| Yes |

| No |

Repair the open or short circuit in harness between battery and key warning switch.

CHECK KEY WARNING SWITCH.

Measure the resistance of key warning switch connector terminals.Terminals

No. 1 — No. 2:

Is the resistance more than 1 MΩ?

| Yes |

Replace the key warning switch.

| No |

CHECK KEY WARNING SWITCH.

Remove the key.Measure the resistance of key warning switch connector terminals.

Terminals

No. 1 — No. 2:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Replace the key warning switch.

CHECK HARNESS BETWEEN AT SHIFT LOCK CONTROL MODULE AND KEY WARNING SWITCH.

Disconnect the body integrated unit connector.Measure the voltage of harness body integrated unit and chassis ground.

Connector & terminal

(B281) No. 20 (+) — Chassis ground (−):

Is the voltage more than 9 V?

| Yes |

| No |

Repair the open circuit in harness between body integrated unit and key warning switch.

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND KEY LOCK SOLENOID.

Disconnect the connector of key lock solenoid.Measure the resistance of harness between body integrated unit and key lock solenoid.

Connector & terminal

(B370) No. 5 — (B280) No. 3:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and key lock solenoid.

| No |

CHECK HARNESS BETWEEN BODY INTEGRATED UNIT AND KEY LOCK SOLENOID.

Measure the resistance of harness between body integrated unit and chassis ground.Connector & terminal

(B280) No. 3 — Chassis ground:

Is the resistance more than 1 Ω?

| Yes |

| No |

Repair the short circuit in harness between body integrated unit and key lock solenoid.

CHECK HARNESS BETWEEN KEY LOCK SOLENOID AND CHASSIS GROUND.

Measure the resistance of harness between key lock solenoid and chassis ground.Connector & terminal

(B370) No. 6 — Chassis ground:

Is the resistance less than 10 Ω?

| Yes |

| No |

Repair the open circuit in harness between key lock solenoid and chassis ground.

CHECK KEY LOCK SOLENOID.

Measure the resistance of key lock solenoid connector terminals.Terminals

No. 5 — No. 6:

Is the resistance 4 — 8 Ω?

| Yes |

| No |

Replace the key lock solenoid.

CHECK HARNESS BETWEEN “P” RANGE SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between “P” range switch and chassis ground.Connector & terminal

(B117) No. 2 — Chassis ground:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the short circuit in harness between “P” range switch and body integrated unit.

CHECK HARNESS BETWEEN AT SHIFT LOCK CONTROL MODULE AND “P” RANGE SWITCH.

Disconnect the connector from “P” range switch.Measure the resistance of harness between body integrated unit and “P” range switch.

Connector & terminal

(B117) No. 2 — (B281) No. 6:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between body integrated unit and “P” range switch.

| No |

CHECK HARNESS BETWEEN “P” RANGE SWITCH AND CHASSIS GROUND.

Measure the resistance of harness “P” range switch and chassis ground.Connector & terminal

(B117) No. 6 — Chassis ground:

Is the resistance more than 1 MΩ?

| Yes |

Repair the open circuit in harness between “P” range switch and chassis ground.

| No |

CHECK “P” RANGE SWITCH.

Move the select lever to “P” range.Measure resistance between “P” range switch connector terminals.

Terminals

No. 2 — No. 6:

Is the resistance less than 1 Ω?

| Yes |

| No |

Replace the “P” range switch.

CHECK “P” RANGE SWITCH.

Move the select lever to other than “P” range.Measure resistance between “P” range switch connector terminals.

Terminals

No. 2 — No. 6:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Replace the “P” range switch.

CHECK OUTPUT SIGNAL FOR BODY INTEGRATED UNIT.

Connect all connectors.Turn the ignition switch to ON (engine OFF).

Move the select lever to “P” range.

Press the brake pedal.

Measure the voltage between body integrated unit connector and chassis ground.

Connector & terminal

(B280) No. 3 (+) — Chassis ground (−):

Is the voltage 7.5 — 16 V?

| Yes |

| No |

Replace the body integrated unit.

CHECK POOR CONTACT.

Is there poor contact in connector?

| Yes |

Repair the poor contact.

| No |

Replace the body integrated unit.