ASSEMBLY

| ASSEMBLY |

| HIGH CLUTCH, REVERSE CLUTCH |

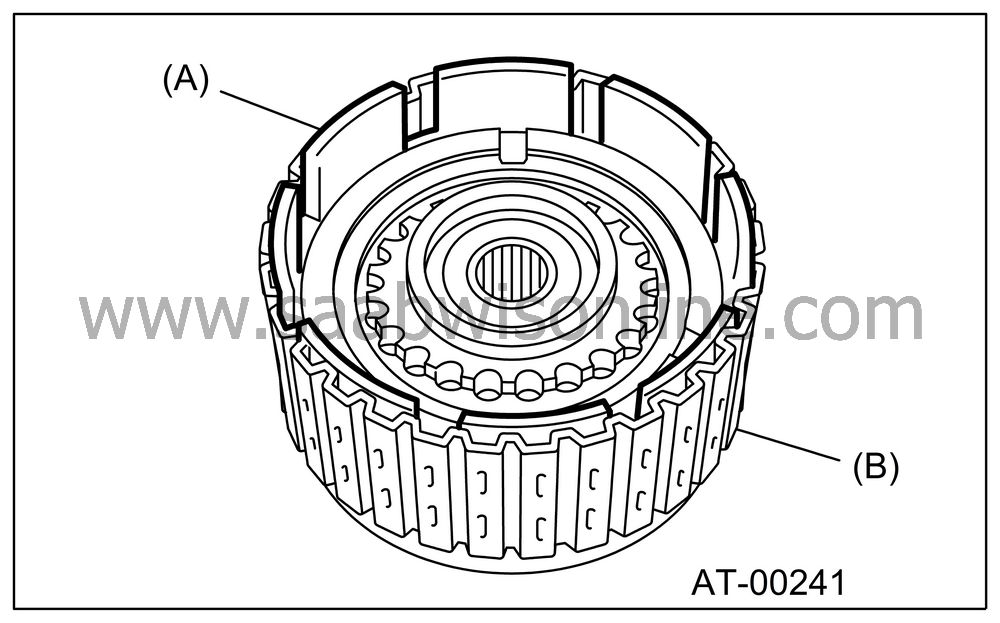

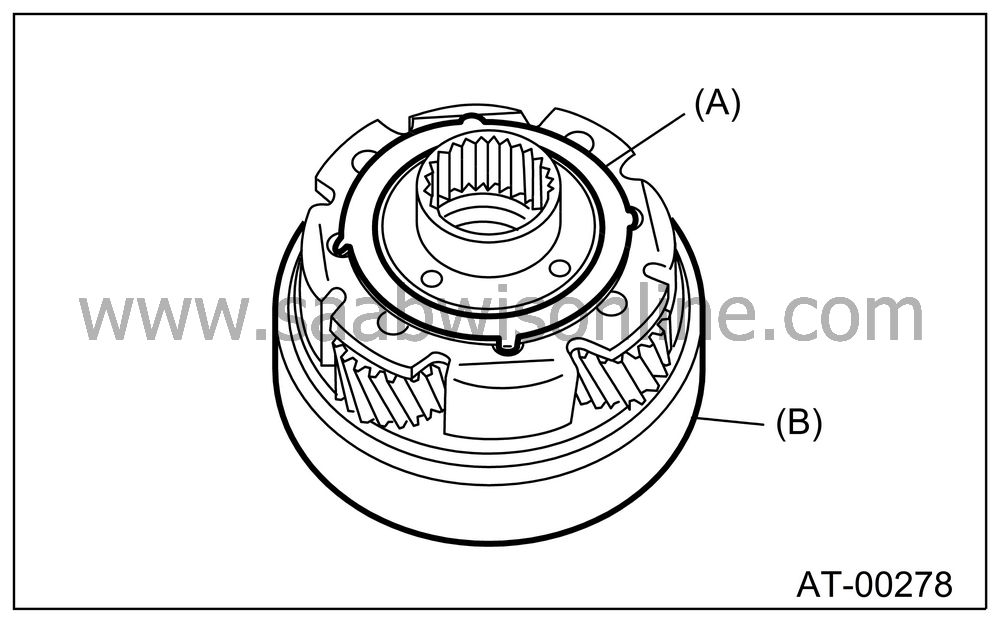

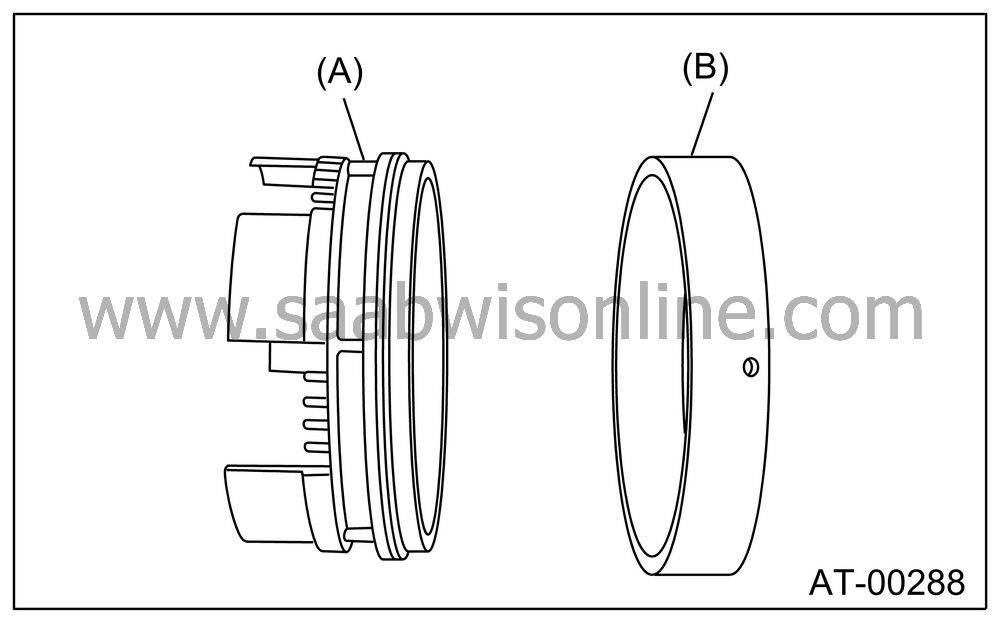

Install seal rings and lip seal to high clutch piston and reverse clutch piston.

Install high clutch piston to reverse clutch piston.

|

(A)

|

High clutch

piston

|

|

(B)

|

Reverse

clutch piston

|

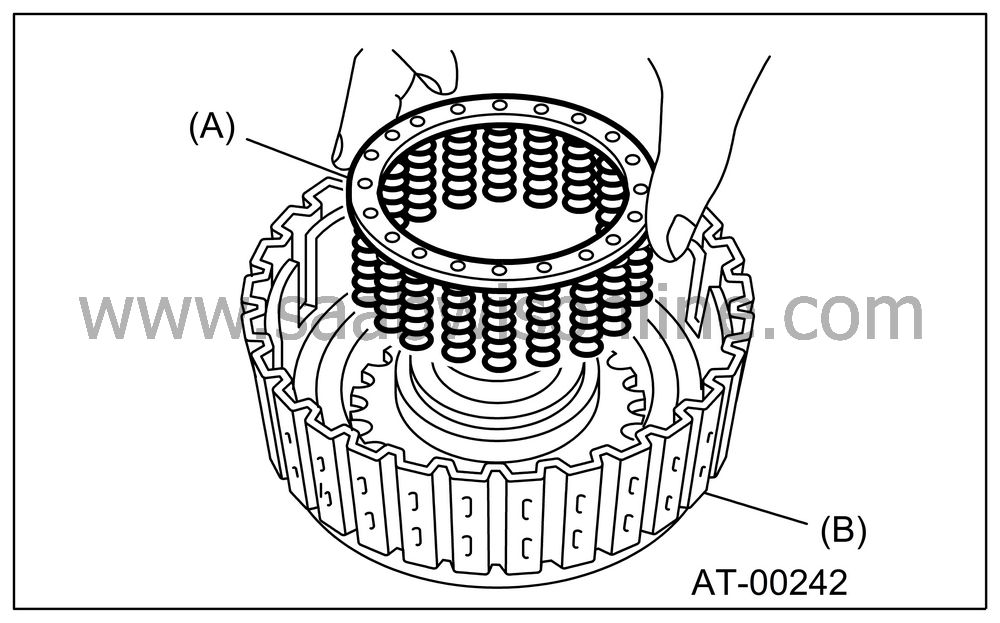

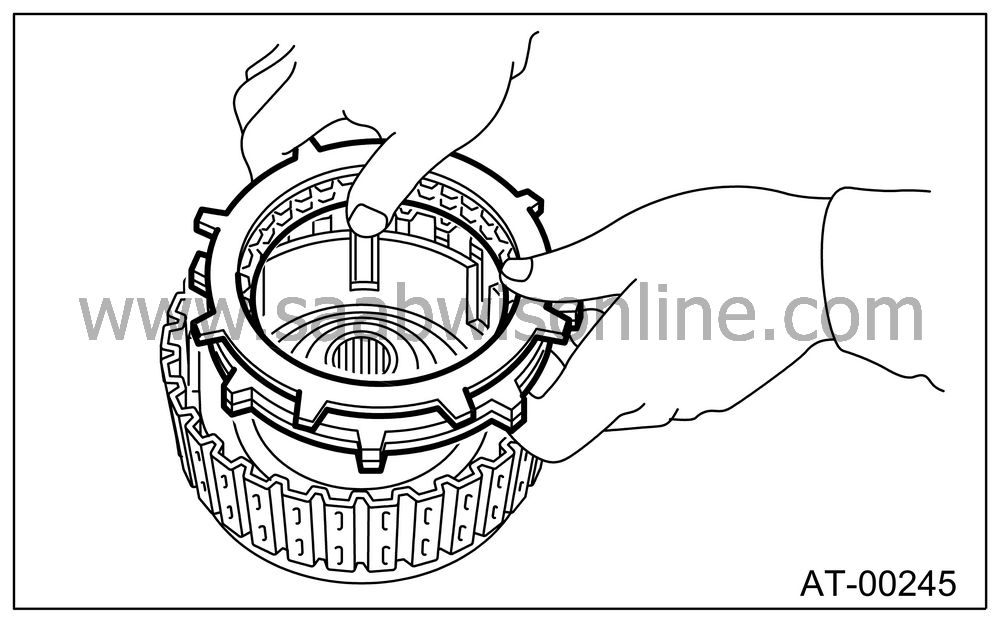

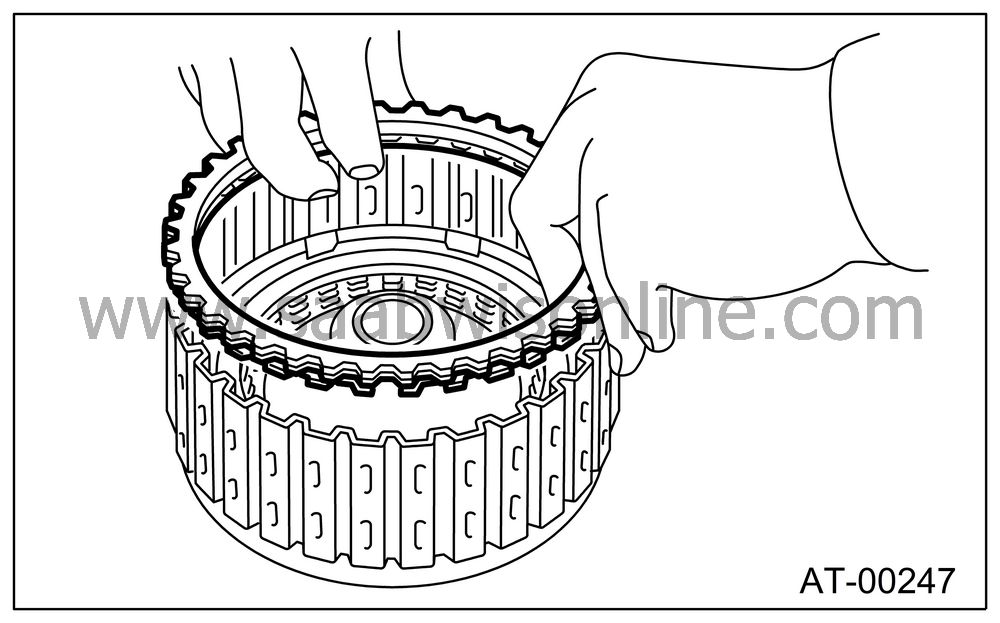

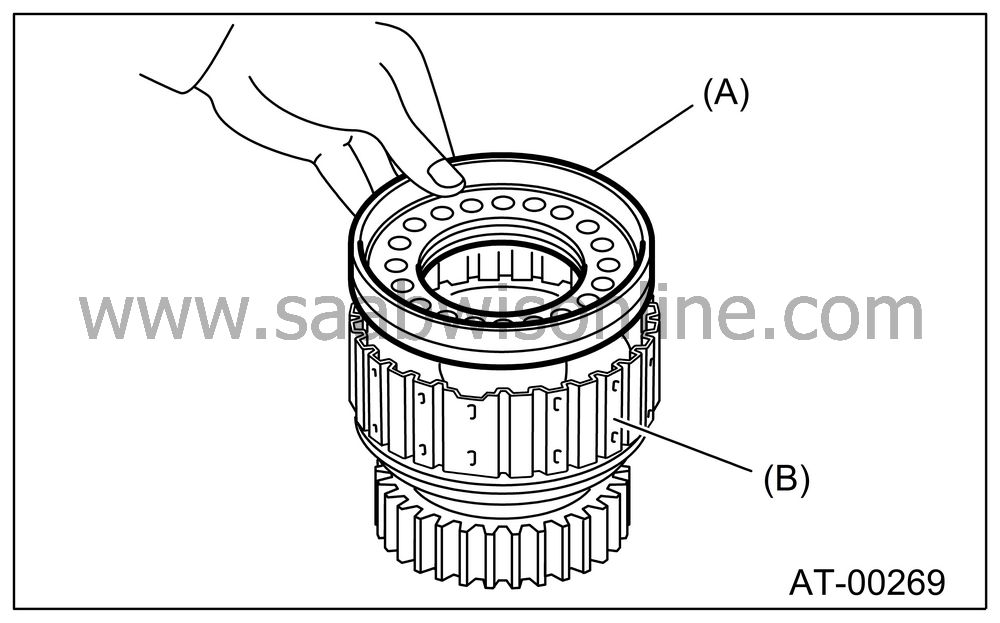

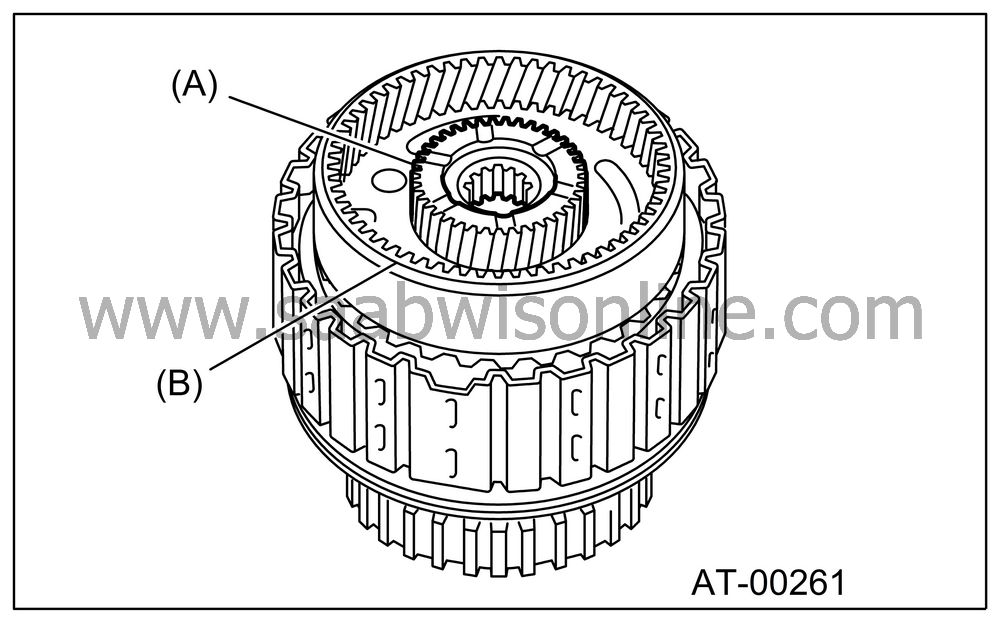

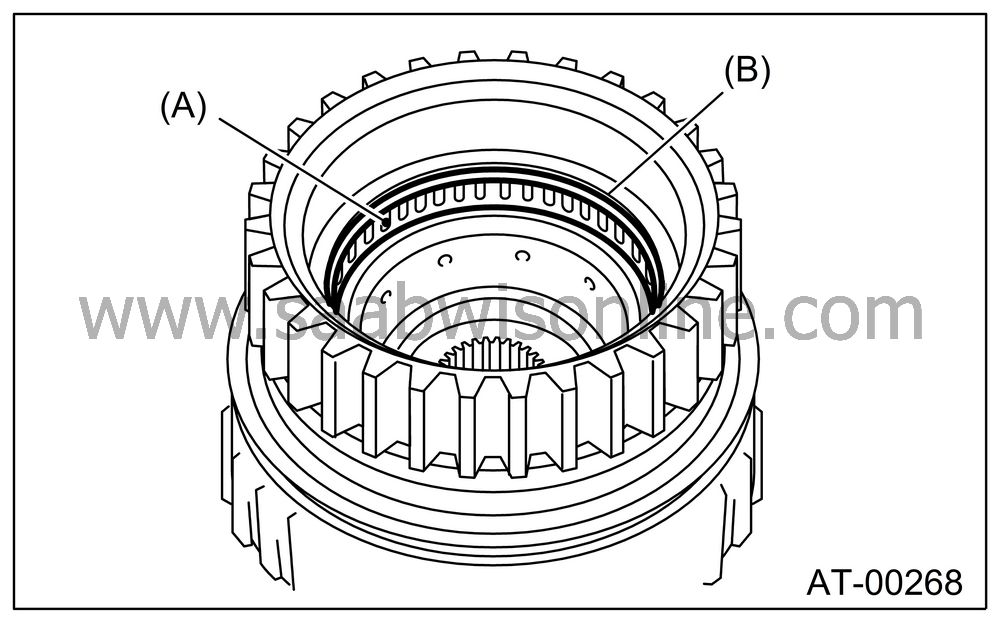

Install reverse clutch to high clutch drum.

Align the groove on the reverse clutch piston with the groove on the high clutch drum during installation.

|

(A)

|

Reverse

clutch piston

|

|

(B)

|

High clutch

drum

|

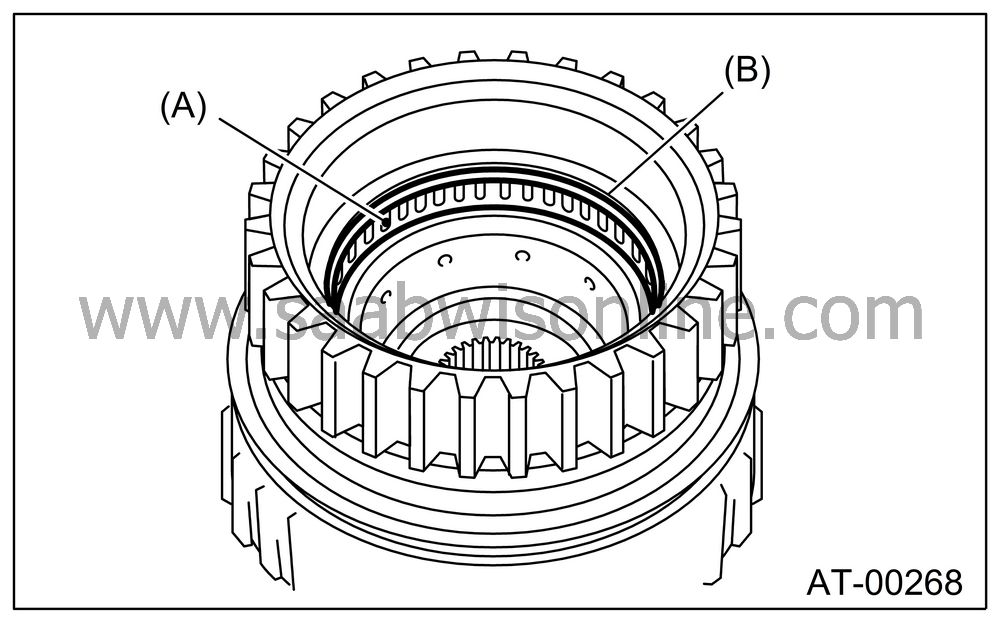

Install spring retainer to high clutch piston.

|

(A)

|

Return

spring

|

|

(B)

|

High clutch

drum

|

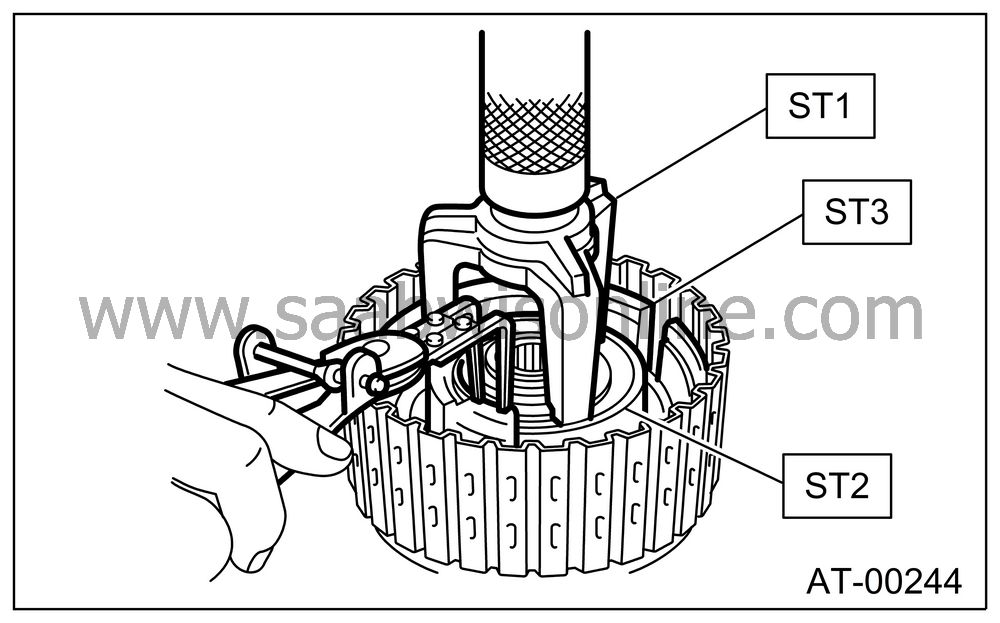

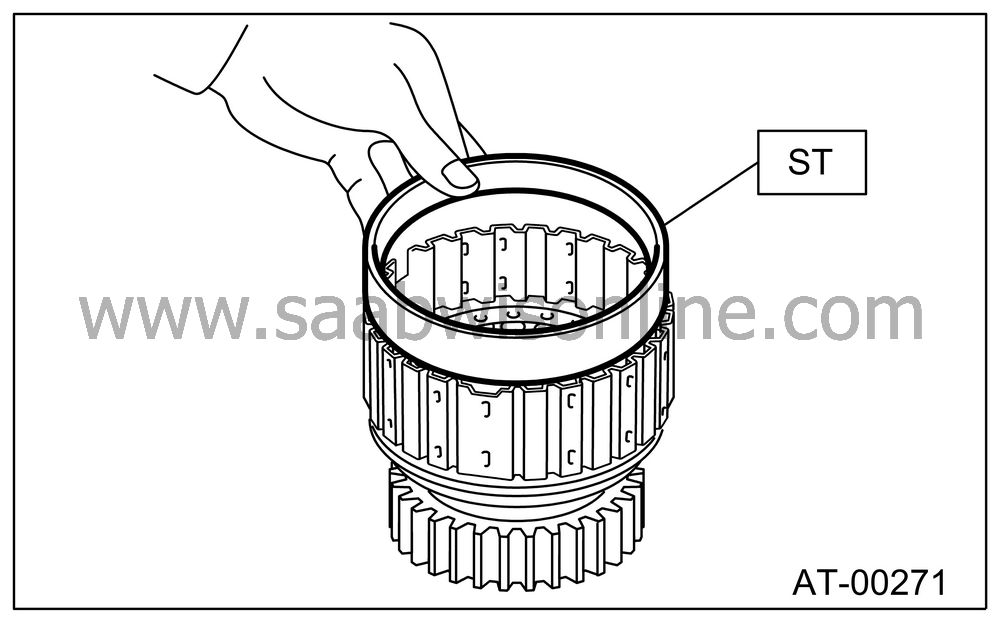

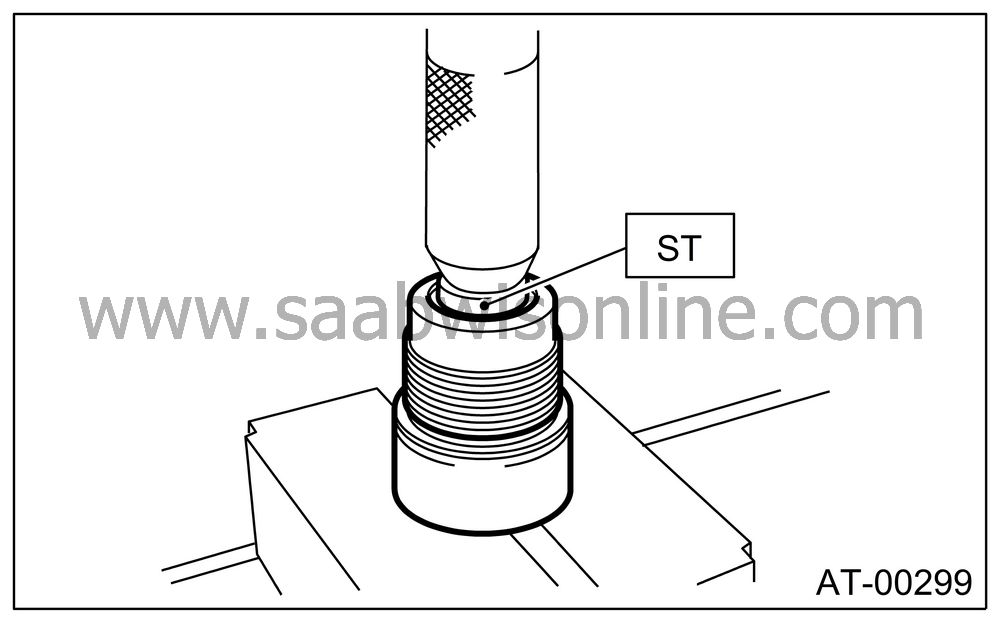

Install ST to high clutch piston.

ST 32005102 HIGH CLUTCH PISTON GUIDE

Avoid folding the high clutch piston seal, when installing the cover to high clutch piston.

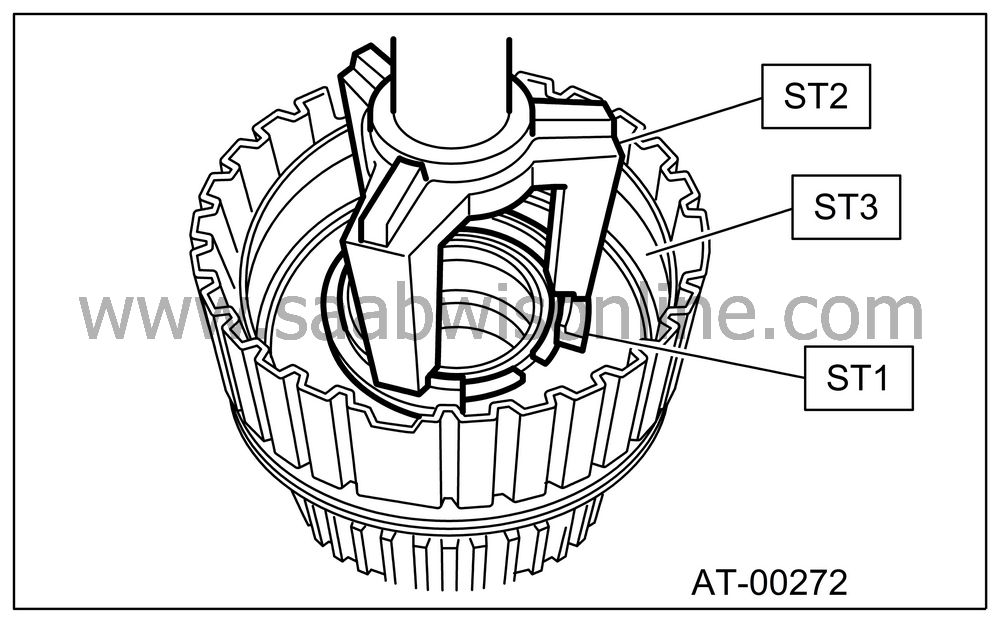

Using ST1 and ST2, install snap ring.

ST1 32005075 COMPRESSOR

ST2 32005112 SEAT

ST3 32005102 HIGH CLUTCH PISTON GUIDE

Selection of high clutch retaining plate (Saab 9-2X 2.0T Aero)

Install the thickest driven plate to piston side, and then install the driven plate, drive plate, retaining plate to high clutch drum.

Install snap ring to high clutch drum.

Apply compressed air intermittently to check for operation.

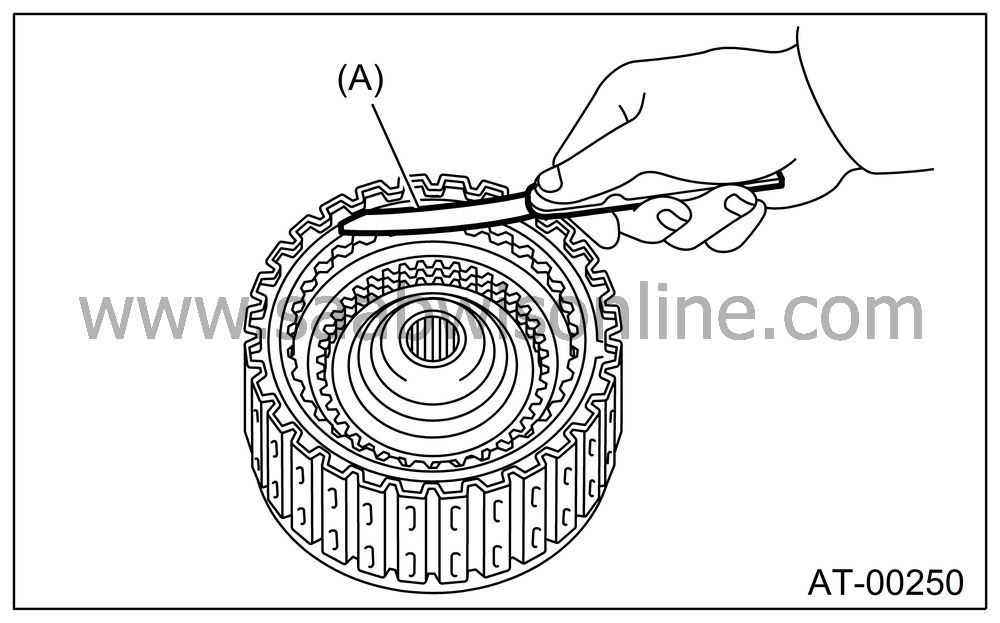

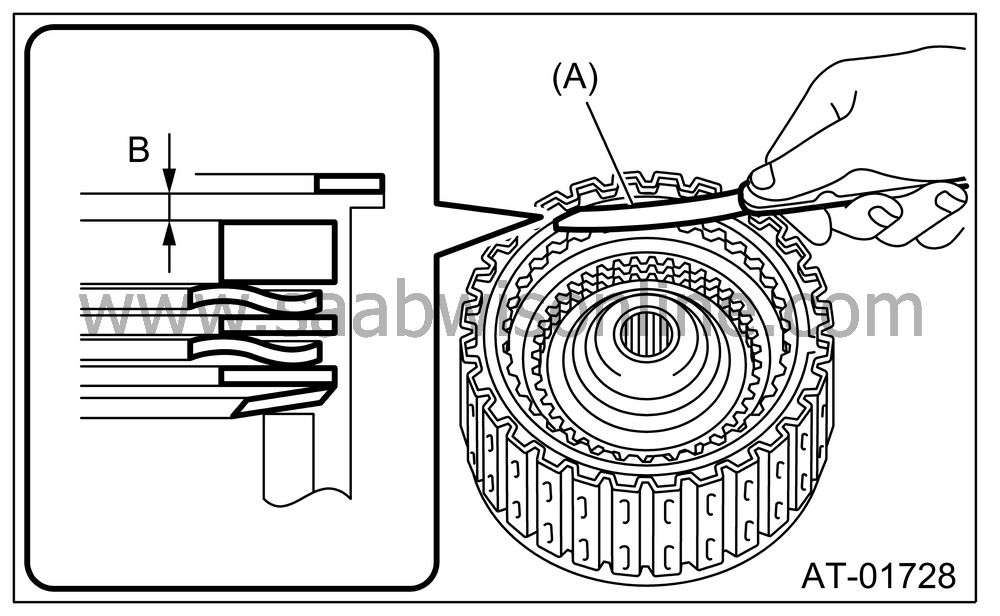

Measure the clearance between the retaining plate and snap ring. (High clutch) At this time, do not press down retaining plate.

Initial standard:

0.8 — 1.1 mm (0.031 — 0.043 in)

Limit thickness:

1.5 mm (0.059 in)

|

(A)

|

Thickness

gauge

|

If specified tolerance limits are exceeded, select a suitable high clutch retaining plate. If it exceeds the service limit, replace the drive plate with a new one and adjust it within the specification.

| High clutch retaining plate | |

| Part No. | Thickness mm (in) |

|

32006504

|

4.7

(0.185)

|

|

32006505

|

4.8

(0.189)

|

|

32006506

|

4.9

(0.193)

|

|

32006507

|

5.0

(0.197)

|

|

32006500

|

5.1

(0.201)

|

|

32006501

|

5.2

(0.205)

|

|

32006502

|

5.3

(0.209)

|

|

32006503

|

5.4

(0.213)

|

Selection of high clutch retaining plate (Saab 9-2X 2.5i Linear)

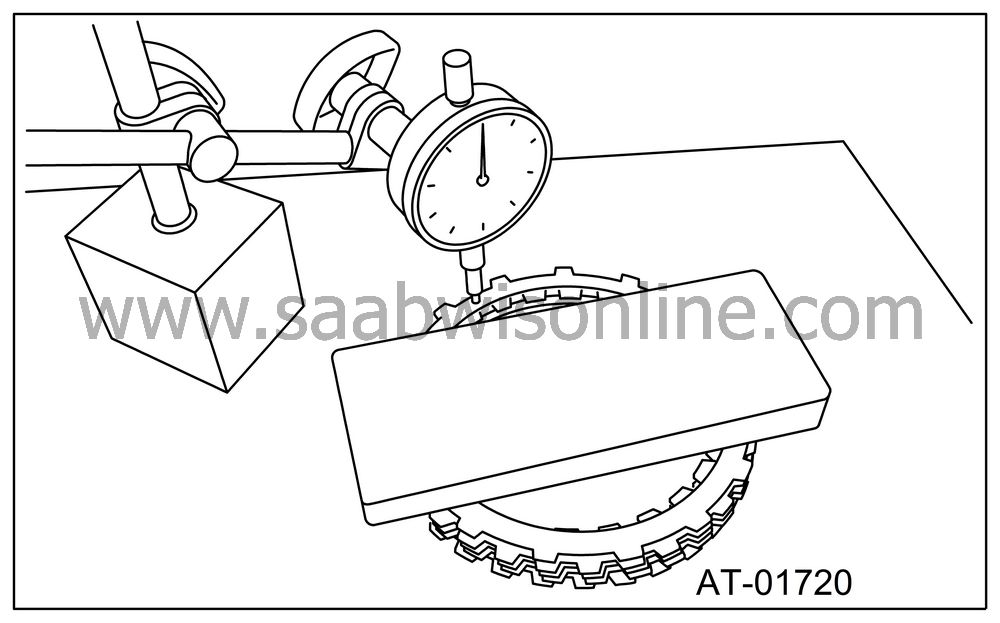

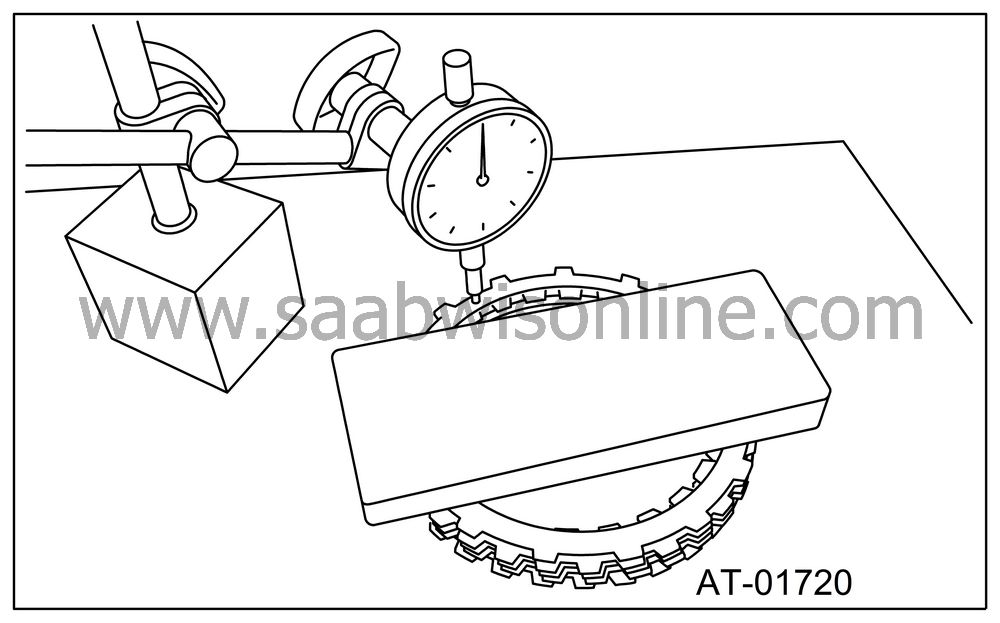

Place the dish plate, driven plate, drive plate and retaining plate neatly in this order on surface table.

Set the micro gauge to clutch, and read its scale.

| Note | ||

|

The value, which is read in the gauge at this time, is zero point. |

Scale and record the weight “Z” of a flat board which will be put on plates.

| Note | ||

| • |

Use a stiff flat board which does not bend against load.

|

|

| • |

Use a flat board of its weight less than 250 N (25.5

kgf, 56.2 lb).

|

|

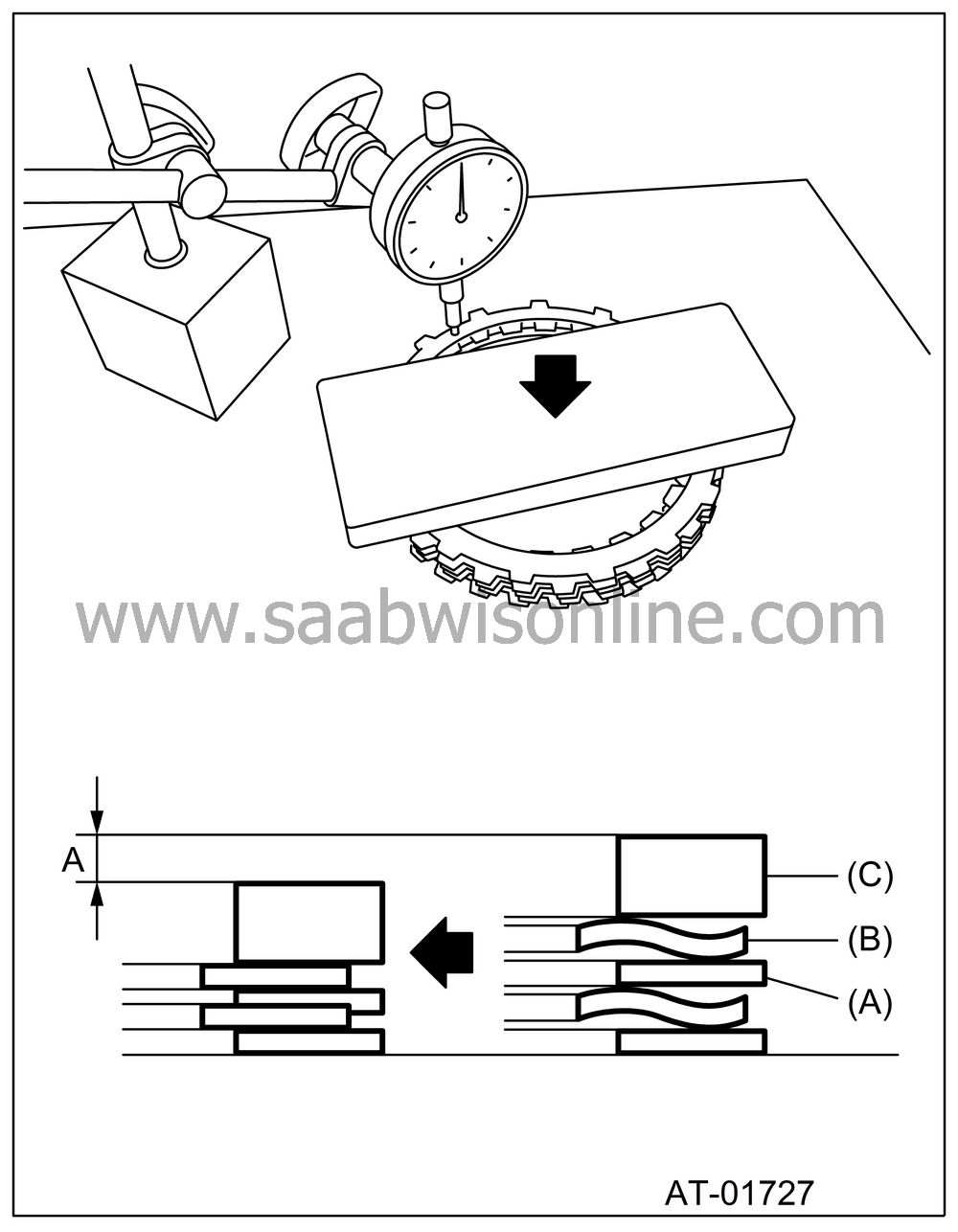

Put the flat board on retaining plate.

Using the following formula, calculate “N” indicated on the push/pull gauge.

N = 250 N (25.5 kgf, 56.2 lb) − Z

N: Value indicated on push/pull gauge

250 N (25.5 kgf, 56.2 lb): Load applied to clutch plate

Z: Flat board weight

Press the center of retaining plate applying force of N with push/pull gauge, and then measure and record the height A. Make more than three measurements at even distance and take the average value.

| Note | ||

|

If three points, measure the height every 120°. If four points, measure the height every 90°. |

|

(A)

|

Driven

plate

|

|

(B)

|

Drive plate

|

|

(C)

|

Retaining

plate

|

Install the thickest driven plate to piston side, and then install the driven plate, drive plate, retaining plate to high clutch drum.

Install the snap ring to high clutch drum.

Apply compressed air intermittently to check for operation.

Measure and record the clearance B between the retaining plate and snap ring. (High clutch)

At this time, do not press down the retaining plate.

|

(A)

|

Thickness

gauge

|

Piston stroke calculation

Select the retaining plate within the specification by calculating with A and B dimensions which have been recorded before. If the calculated value exceeds the usage limit, replace the drive plate with a new one and adjust it within the specitication.

T = A + B

T: Piston stroke

A: Collapse amount of drive plate

B: Clearance between retaining plate and snap ring

Initial standard:

2.0 — 2.3 mm (0.079 — 0.091 in)

Limit thickness:

2.6 mm (0.102 in)

| High clutch retaining plate | |

| Part number | Thickness mm (in) |

|

32006500

|

5.1

(0.201)

|

|

32006501

|

5.2

(0.205)

|

|

32006502

|

5.3

(0.209)

|

|

32006503

|

5.4

(0.213)

|

|

32006504

|

5.5

(0.217)

|

|

32006505

|

5.6

(0.220)

|

|

32006506

|

5.7

(0.224)

|

|

32006507

|

5.8

(0.228)

|

Selection of reverse clutch retaining plate (Saab 9-2X 2.0T Aero)

Install driven plate, drive plate, retaining plate and snap ring.

Apply compressed air intermittently to check for operation.

Measure the clearance between the retaining plate and snap ring. (Reverse clutch) At this time, do not press down retaining plate.

Initial standard:

0.5 — 0.8 mm (0.020 — 0.031 in)

Limit thickness:

1.2 mm (0.047 in)

|

(A)

|

Thickness

gauge

|

If specified tolerance limits are exceeded, select a suitable high clutch retaining plate.

If it exceeds the service limit, replace the drive plate with a new one and adjust it within the specification.

| Reverse clutch retaining plate | |

| Part No. | Thickness mm (in) |

|

32006513

|

4.0

(0.157)

|

|

32006514

|

4.2

(0.165)

|

|

32006515

|

4.4

(0.173)

|

|

32006516

|

4.6

(0.181)

|

|

32006517

|

4.8

(0.189)

|

|

32006518

|

5.0

(0.197)

|

|

32006519

|

5.2

(0.205)

|

|

32006520

|

5.4

(0.213)

|

Selection of reverse clutch retaining plate (Saab 9-2X 2.5i Linear)

Place the dish plate, driven plate, drive plate and retaining plate neatly in this order on surface table.

Set the micro gauge to clutch, and read its scale.

| Note | ||

|

The value, which is read in the gauge at this time, is zero point. |

Scale and record the weight “Z” of a flat board which will be put on plates.

| Note | ||

| • |

Use a stiff flat board which does not bend against load.

|

|

| • |

Use a flat board of its weight less than 150 N (15.3

kgf, 33.7 lb).

|

|

Put the flat board on retaining plate.

Using the following formula, calculate “N” indicated on the push/pull gauge.

N = 150 N (15.3 kgf, 33.7 lb) − Z

N: Value indicated on push/pull gauge

150 N (15.3 kgf, 33.7 lb): Load applied to clutch plate

Z: Flat board weight

Press the center of retaining plate applying force of N with push/pull gauge, and then measure and record the height A. Make more than three measurements at even distance and take the average value.

| Note | ||

|

If three points, measure the height every 120°. If four points, measure the height every 90°. |

|

(A)

|

Driven

plate

|

|

(B)

|

Drive plate

|

|

(C)

|

Retaining

plate

|

Install the driven plate, drive plate, retaining plate and snap ring.

Apply compressed air intermittently to check for operation.

Measure and record the clearance B between the retaining plate and snap ring. (Reverse clutch)

At this time, do not press down the retaining plate.

|

(A)

|

Thickness

gauge

|

Piston stroke calculation

Select the retaining plate within the specification by calculating with A and B dimensions which have been recorded before. If the calculated value exceeds the usage limit, replace the drive plate with a new one and adjust it within the specification.

T = A + B

T: Piston stroke

A: Collapse amount of drive plate

B: Clearance between retaining plate and snap ring

Initial standard:

1.1 — 1.4 mm (0.043 — 0.055 in)

Limit thickness:

1.6 mm (0.063 in)

| Reverse clutch retaining plate | |

| Part number | Thickness mm (in) |

|

32006513

|

4.0

(0.157)

|

|

32006514

|

4.2

(0.165)

|

|

32006515

|

4.4

(0.173)

|

|

32006516

|

4.6

(0.181)

|

|

32006517

|

4.8

(0.189)

|

|

32006518

|

5.0

(0.197)

|

|

32006519

|

5.2

(0.205)

|

|

32006520

|

5.4

(0.213)

|

| PLANETARY GEAR, LOW CLUTCH |

Install D-ring to low clutch piston.

Fit the low clutch piston to the low clutch drum.

|

(A)

|

Low clutch

piston

|

|

(B)

|

Low clutch

drum

|

Install spring retainer to low clutch piston.

|

(A)

|

Spring

retainer

|

|

(B)

|

Low clutch

drum

|

Install ST to low clutch drum.

ST 32005103 LOW CLUTCH PISTON GUIDE

Set the cover on the piston with a press using ST1 and ST2, and attach the snap ring. At this time, be careful not to fold cover seal during installation.

ST1 32005112 SEAT

ST2 32005075 COMPRESSOR

ST3 32005103 LOW CLUTCH PISTON GUIDE

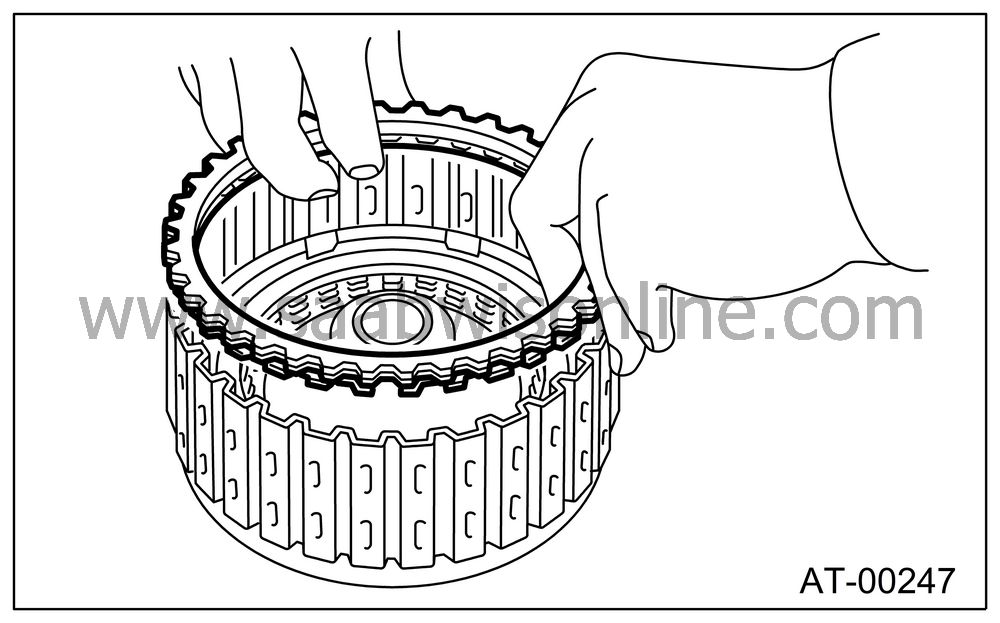

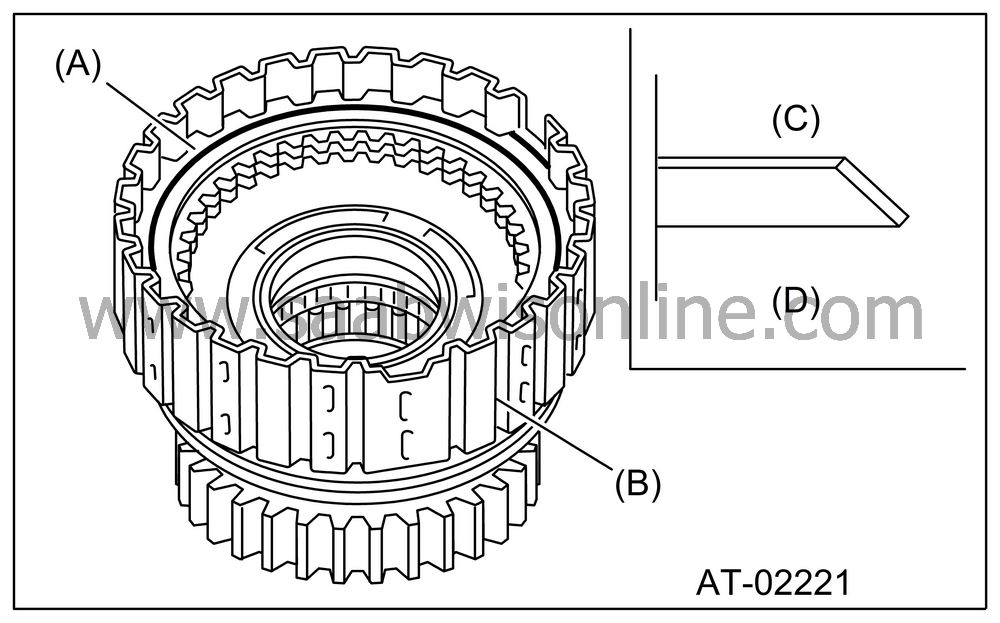

Install the dish plate, driven plates, drive plates, and retaining plate, and secure with the snap ring.

|

(A)

|

Snap ring

|

|

(B)

|

Low clutch

drum

|

|

(C)

|

Dish plate

|

|

(D)

|

Low clutch

piston side

|

Check the low clutch for operation.

Remove one-way clutch.

Set the one-way clutch inner race, and apply compressed air for checking.

|

(A)

|

Apply compressed

air

|

|

(B)

|

Low clutch

drum

|

Checking low clutch clearance.

Place the same thickness of shim on both sides to prevent retaining plate from tilting.

Inspect clearance between retaining plate and operation of the low clutch.

Initial standard:

0.7 — 1.1 mm (0.028 — 0.043 in)

Limit thickness:

1.6 mm (0.063 in)

|

(A)

|

Thickness

gauge

|

|

(B)

|

Low clutch

drum

|

If the clearance is out of the specified range, select a proper retaining plate so that the standard clearance can be obtained.

If it exceeds the service limit, replace the drive plate with a new one and adjust it to the specification.

|

Available retaining plate

|

|

|

Part

No.

|

Thickness

mm (in)

|

|

32006508

|

3.8

(0.150)

|

|

32006509

|

4.0

(0.157)

|

|

32006510

|

4.2

(0.165)

|

|

32006511

|

4.4

(0.173)

|

|

32006512

|

4.6

(0.181)

|

Install washer to rear internal gear.

|

(A)

|

Rear internal

gear

|

|

(B)

|

Washer

|

Install rear internal gear.

|

(A)

|

Rear internal

gear

|

|

(B)

|

Low clutch

drum

|

Install thrust needle bearing in the correct direction.

|

(A)

|

Thrust

needle bearing

|

|

(B)

|

Low clutch

drum

|

Install the washer by aligning protrusion of washer and hole of rear planetary carrier.

|

(A)

|

Washer

|

|

(B)

|

Rear planetary

carrier

|

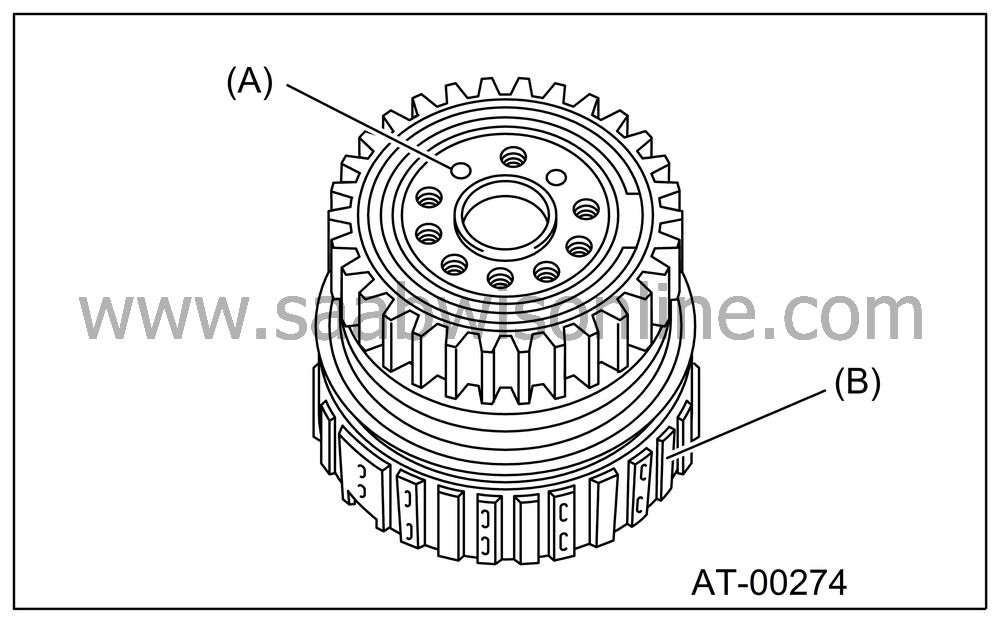

Install rear planetary carrier to low clutch drum.

|

(A)

|

Rear planetary

carrier

|

|

(B)

|

Low clutch

drum

|

Install thrust needle bearing in the correct direction.

Install the rear sun gear in proper direction.

|

(A)

|

Rear sun

gear

|

|

(B)

|

Rear planetary

carrier

|

Install the thrust needle bearing in proper direction.

|

(A)

|

Thrust

needle bearing

|

|

(B)

|

Front planetary

carrier

|

|

(C)

|

Rear sun

gear side

|

|

(D)

|

Front planetary

carrier side

|

Install front planetary carrier to low clutch drum.

|

(A)

|

Front planetary

carrier

|

|

(B)

|

Low clutch

drum

|

Install snap ring to low clutch drum.

|

(A)

|

Snap ring

|

|

(B)

|

Front planetary

carrier

|

Install the needle bearing, and secure with the snap ring.

|

(A)

|

Needle

bearing

|

|

(B)

|

Snap ring

|

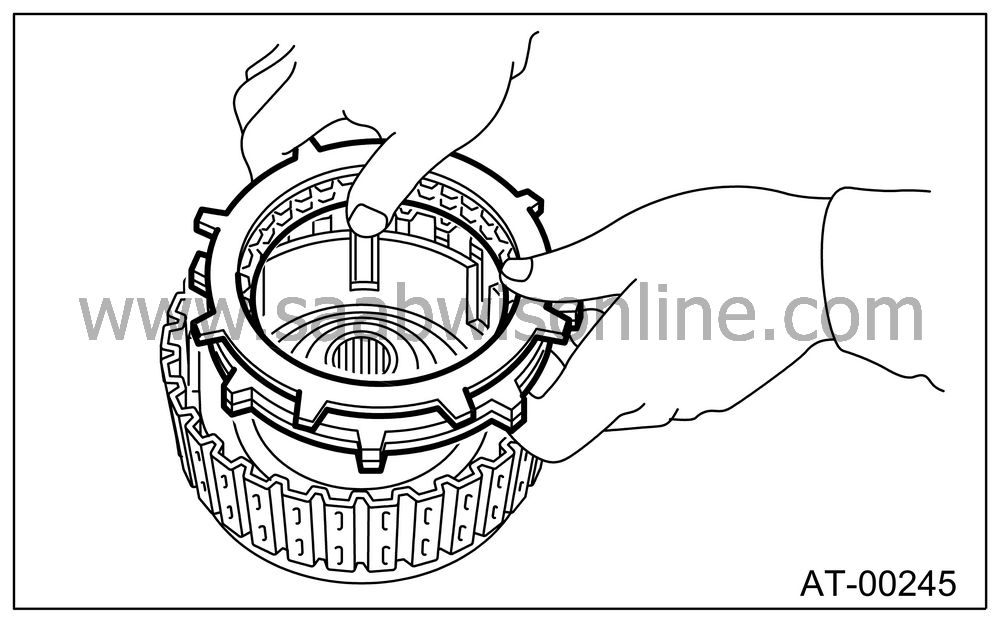

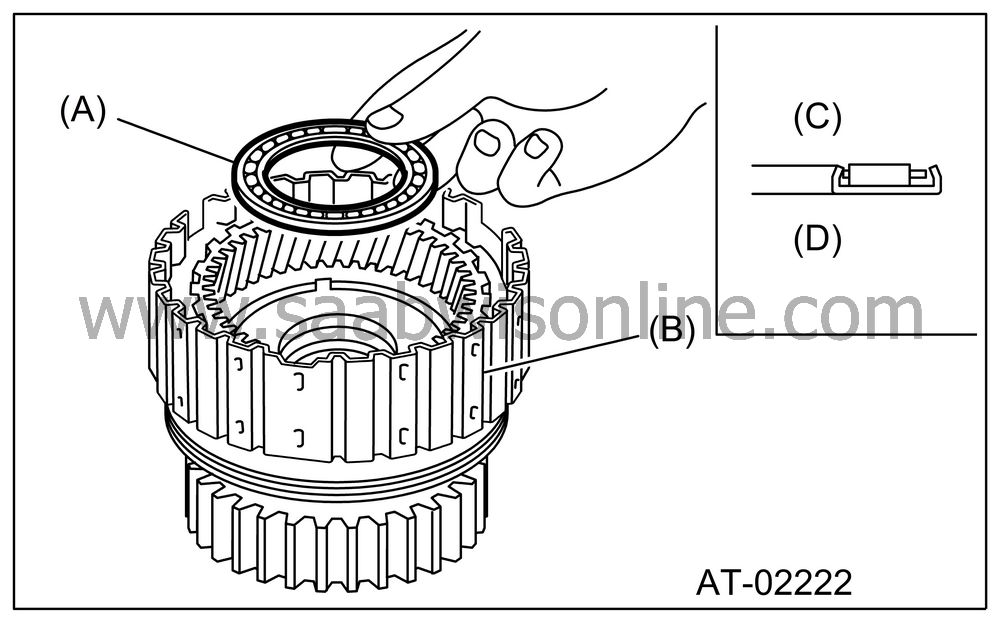

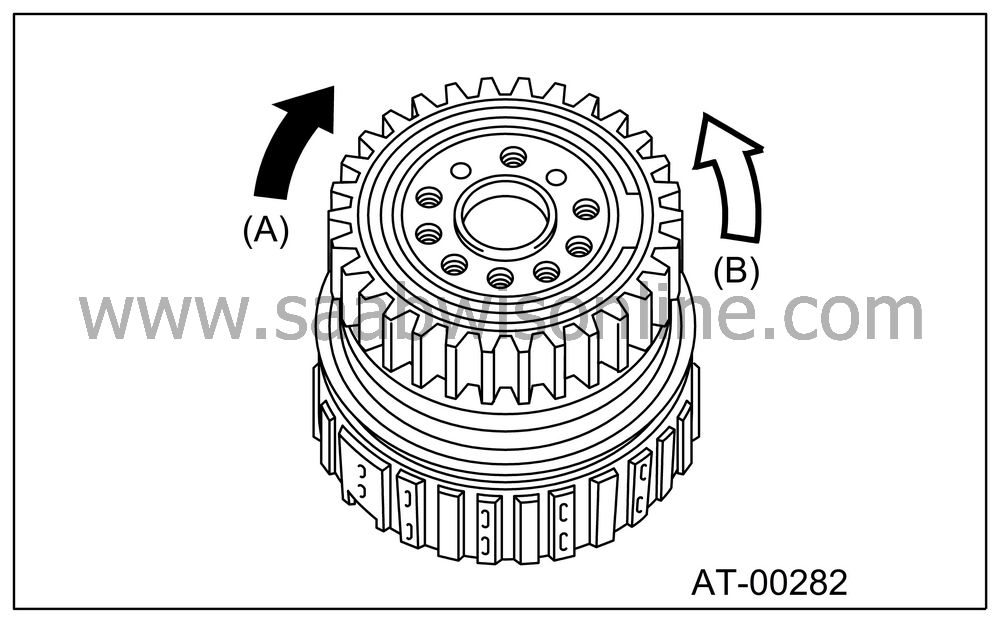

Install the one-way clutch, one-way clutch inner race and plate, and secure with the snap ring.

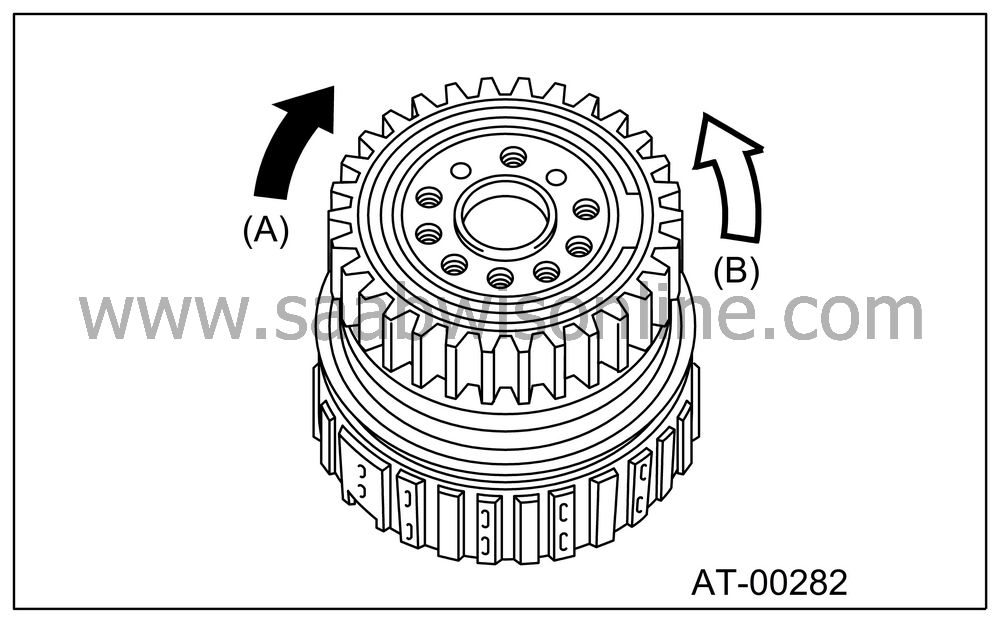

Set the inner race. Make sure that the clutch is locked in the clockwise direction and free in the counterclockwise direction.

|

(A)

|

Locked

|

|

(B)

|

Free

|

| 2-4 BRAKE |

Apply ATF to new D-ring, and install it to 2-4 brake piston.

Install 2-4 brake piston to 2-4 brake piston retainer.

|

(A)

|

2-4 brake

piston

|

|

(B)

|

2-4 brake

piston retainer

|

| ONE-WAY CLUTCH INNER RACE |

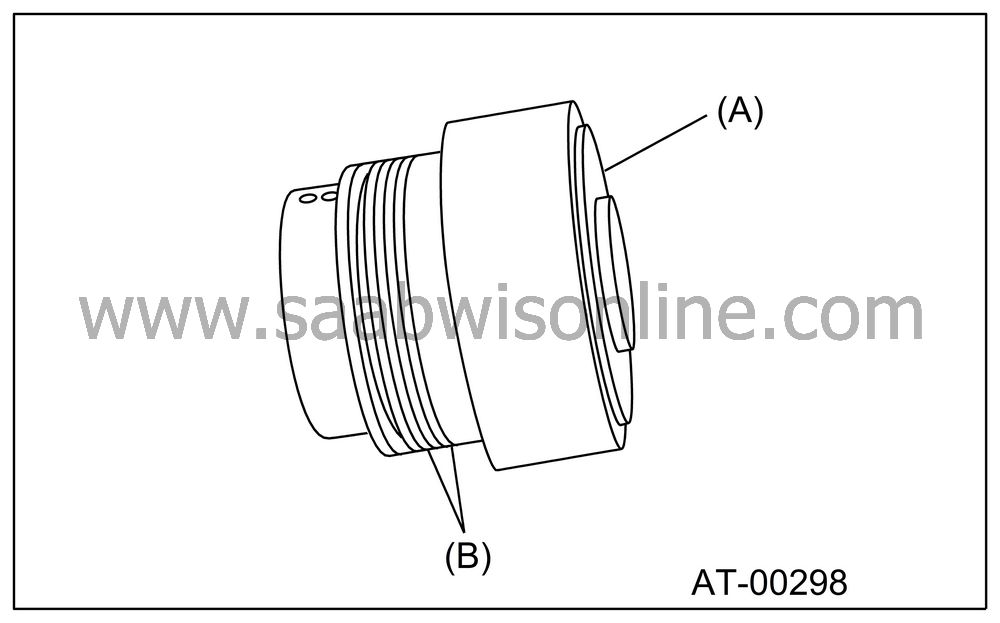

Using a press and ST, install the needle bearing to the inner race.

ST 32005065 INSTALLER

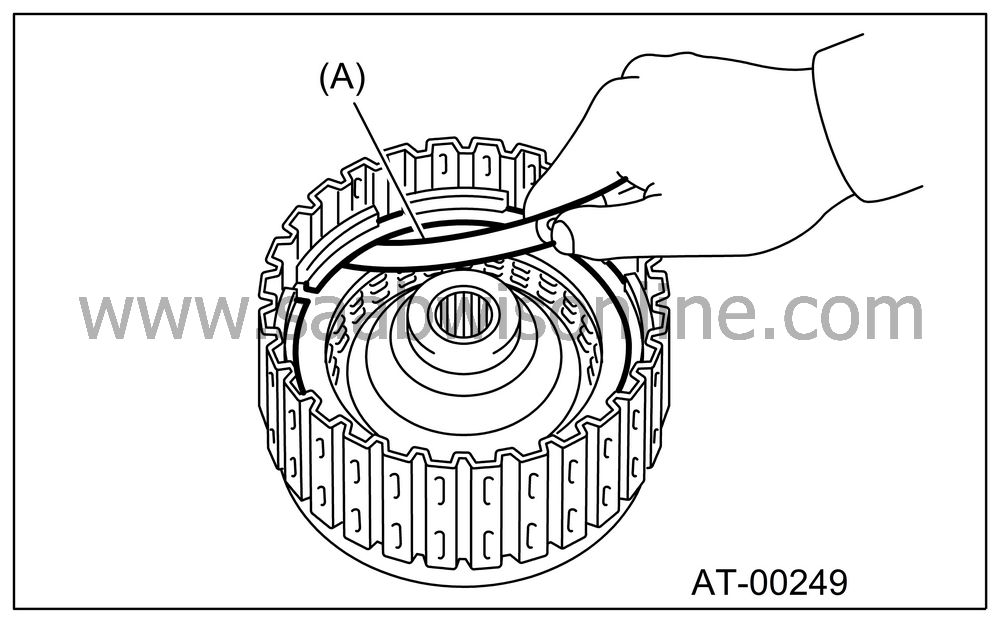

Apply vaseline to the groove of the inner race and to the seal ring.

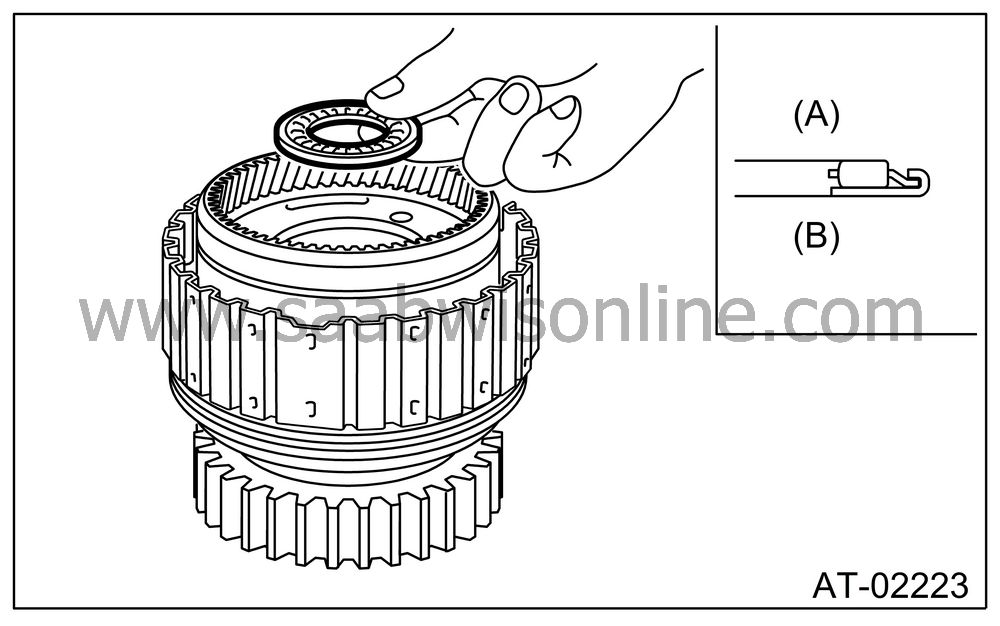

Install two seal rings to one-way clutch inner race.

|

(A)

|

One way

clutch inner race

|

|

(B)

|

Seal rings

|

| ONE-WAY CLUTCH OUTER RACE |

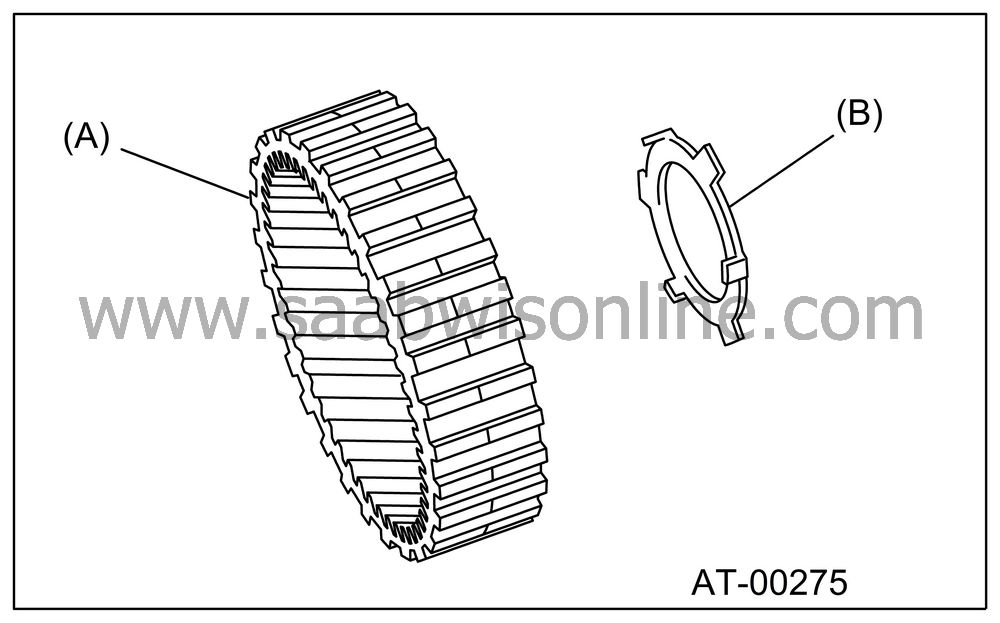

Install the needle bearing, and secure with the snap ring.

|

(A)

|

Needle

bearing

|

|

(B)

|

Snap ring

|

Install the one-way clutch, one-way clutch inner race and plate, and secure with the snap ring.

Set the inner race. Make sure that the clutch is locked in the clockwise direction and free in the counterclockwise direction.

|

(A)

|

Locked

|

|

(B)

|

Free

|