ADJUSTMENT

| ADJUSTMENT |

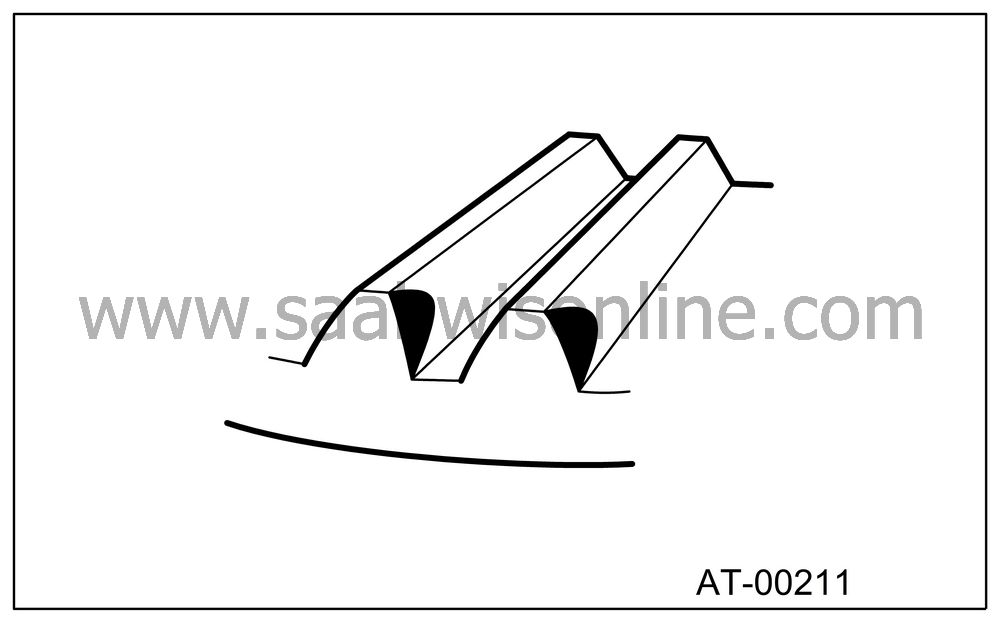

Thoroughly remove the liquid gasket from the case mating surface beforehand.

Install the oil pump housing assembly to the converter case, and secure evenly by tightening four bolts.

| Note | ||

|

Use an old gasket or an aluminum washer so as not to damage the mating surface of the housing. |

Tightening torque:

41 Nm (4.2 kgf-m, 30.4 ft-lb)

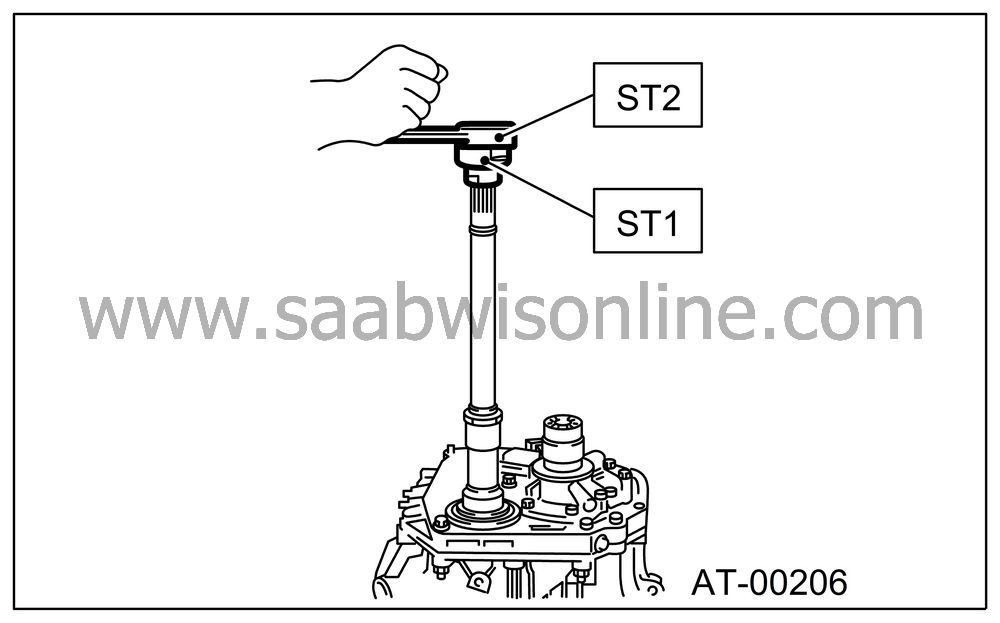

ST1 32005120 HOLDER

ST2 32005154 WRENCH

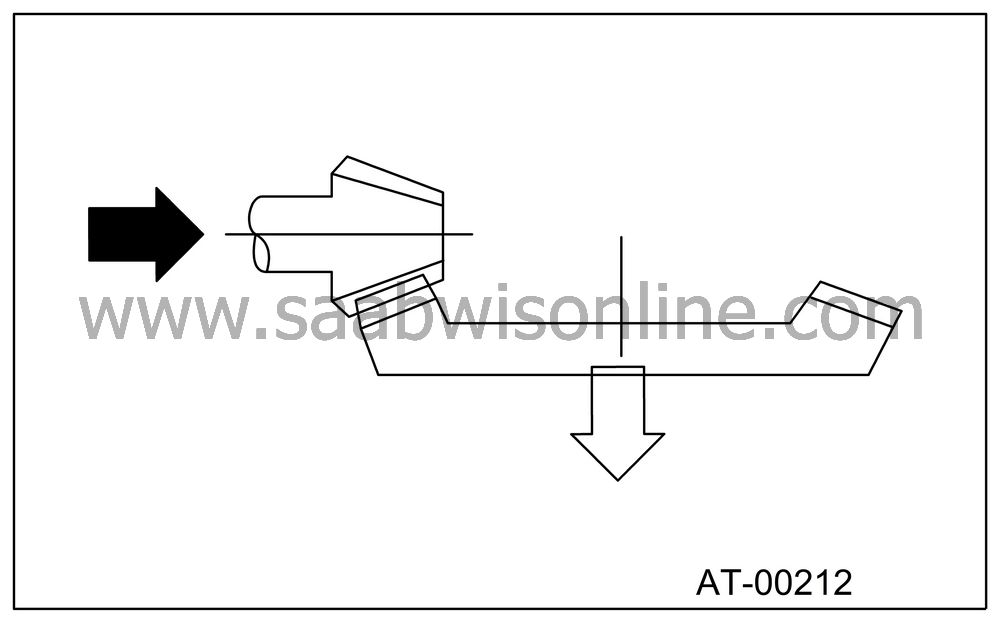

Adjust the backlash between drive pinion and hypoid driven gear.

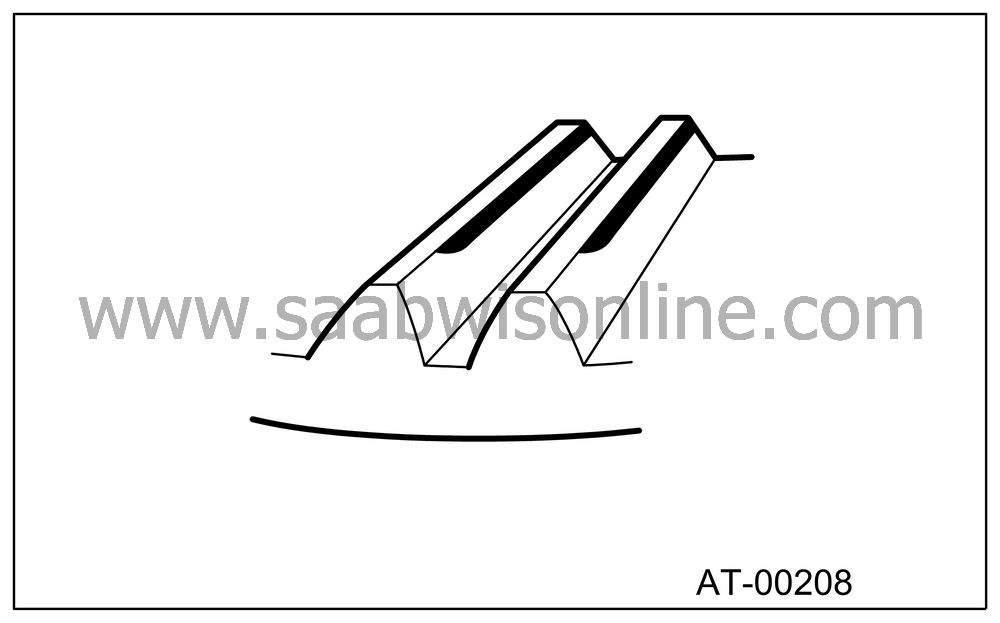

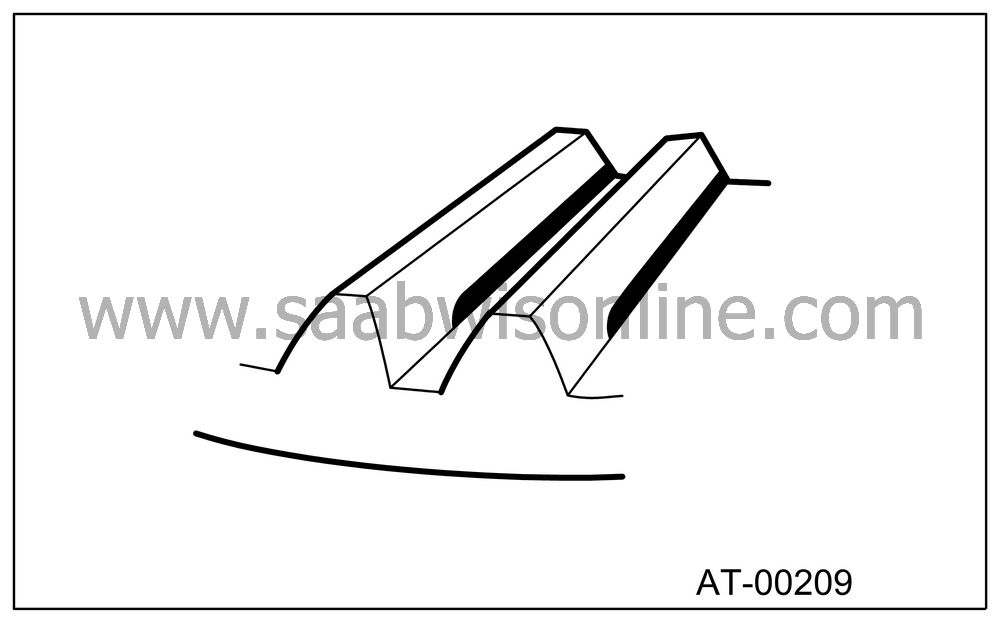

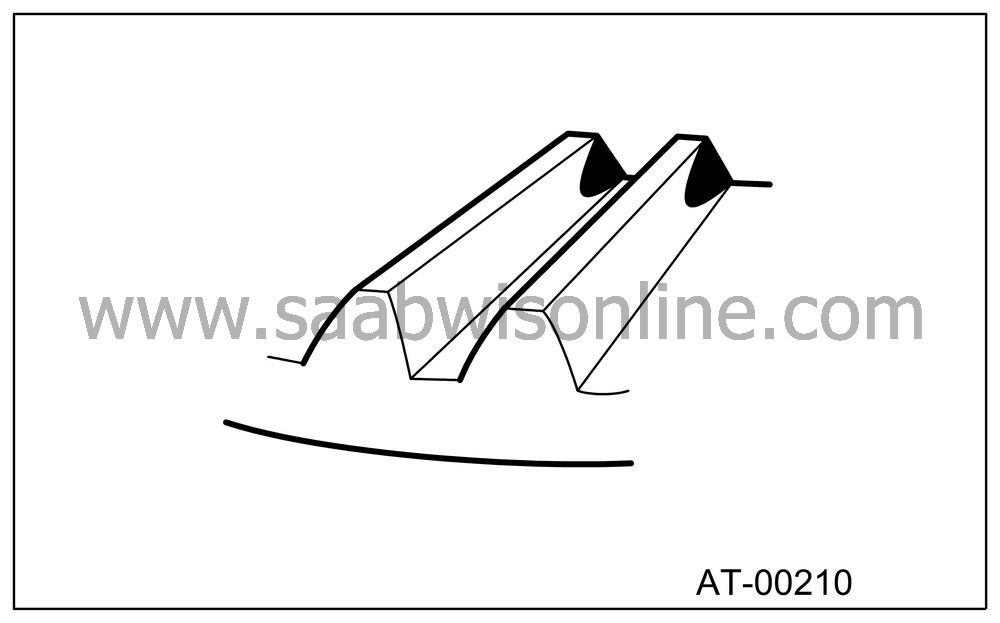

Apply red lead evenly to the surfaces of three or four teeth of the hypoid driven gear. Rotate the drive pinion in the forward and reverse directions several times. Then remove the oil pump housing, and check the tooth contact pattern.

If tooth contact is improper, readjust the backlash or shim thickness.

| • |

Tooth

contact

Checking item:Tooth contact pattern is slightly shifted toward to toe side under no-load rotation. [When loaded, contact pattern moves toward heel.]

|

|||||

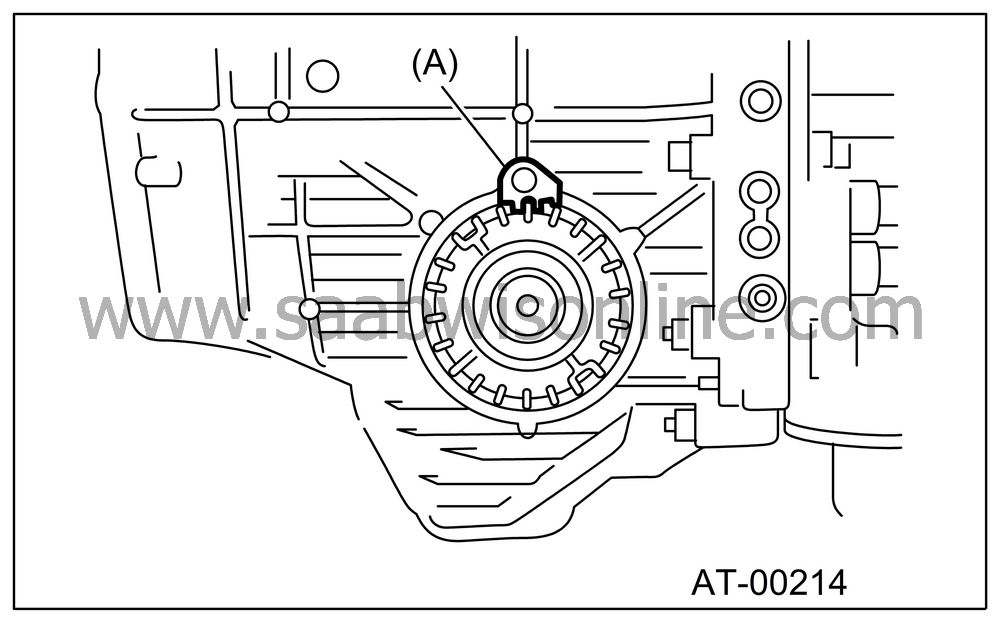

If tooth contact is correct, mark the retainer position and loosen it. After fitting a new O-ring and oil seal, screw in the retainer to the marked position. Then tighten the lock plate to the specified torque.

Tightening torque:

25 Nm (2.5 kgf-m, 18.1 ft-lb)

|

(A)

|

Lock plate

|