ADJUSTMENT

| ADJUSTMENT |

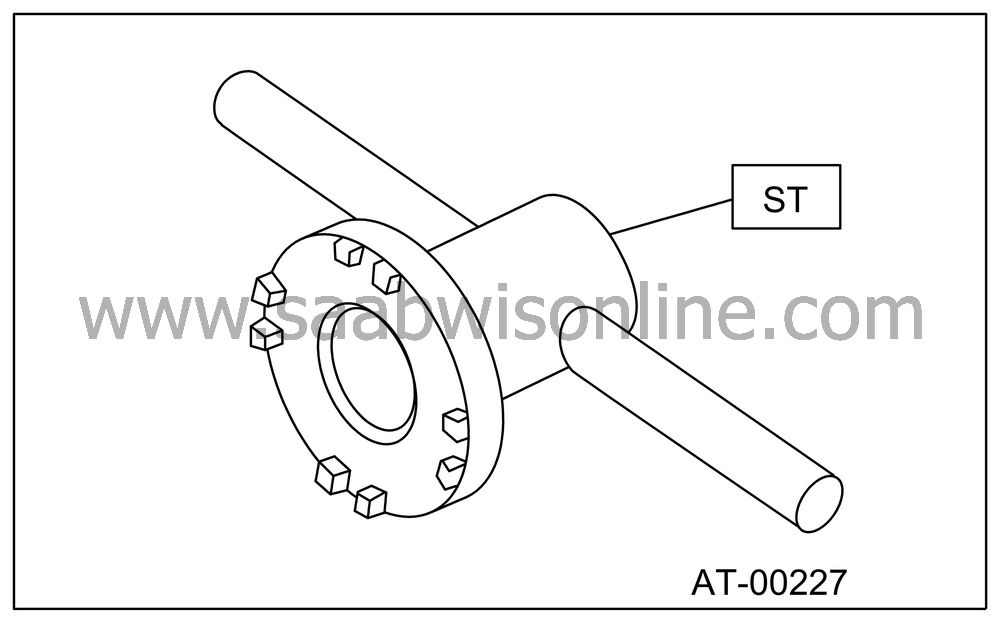

Using ST, screw in the retainer until light contact is felt.

| Note | ||

|

Screw in the RH side slightly deeper than the LH side. |

ST 32005023 WRENCH ASSY

Thoroughly remove the liquid gasket from the case mating surface beforehand.

Install the oil pump housing assembly to the converter case, and secure evenly by tightening four bolts.

| Note | ||

|

Use an old gasket or an aluminum washer so as not to damage the mating surface of the housing. |

Tightening torque:

41 Nm (4.2 kgf-m, 30.4 ft-lb)

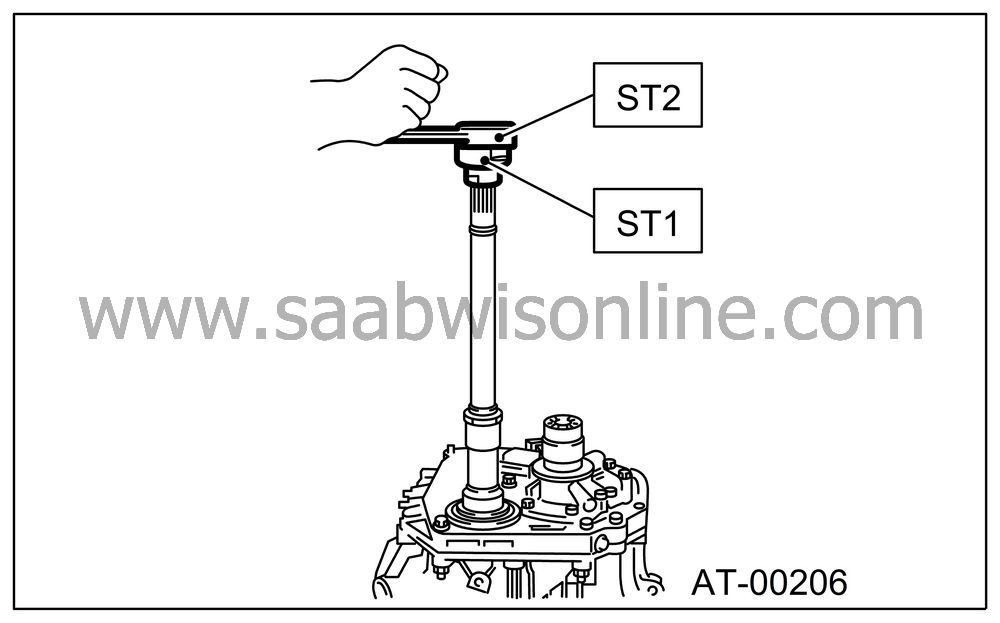

Rotate the drive pinion several times with ST1 and ST2.

ST1 32005120 HOLDER

ST2 32005154 WRENCH

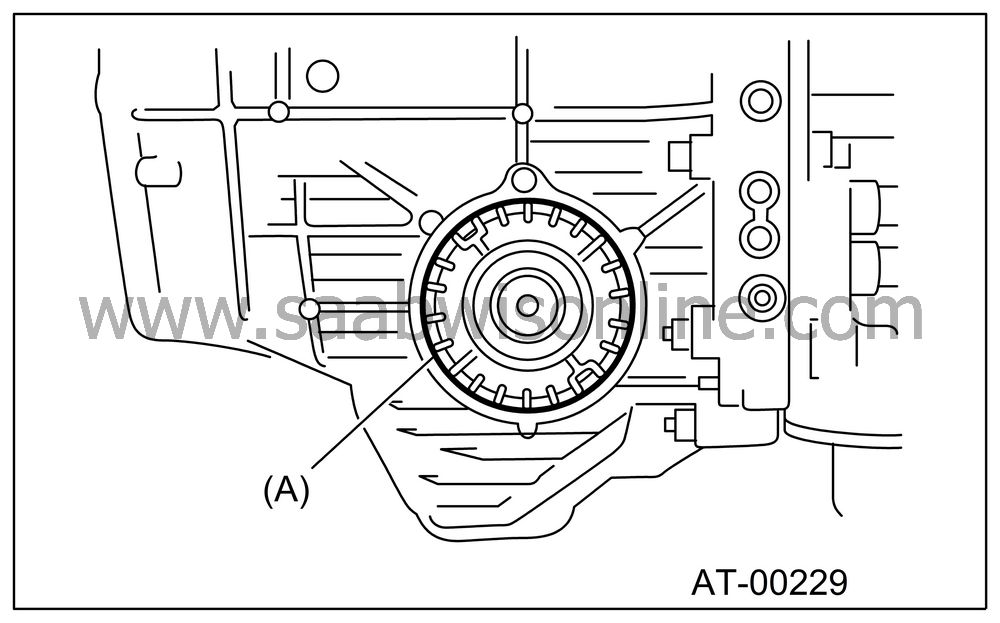

Tighten the LH retainer until contact is felt while rotating the shaft. Then loosen the RH retainer. Keep tightening the LH retainer and loosening the RH retainer until the pinion shaft can no longer be turned. This is the “zero” state.

|

(A)

|

Retainer

|

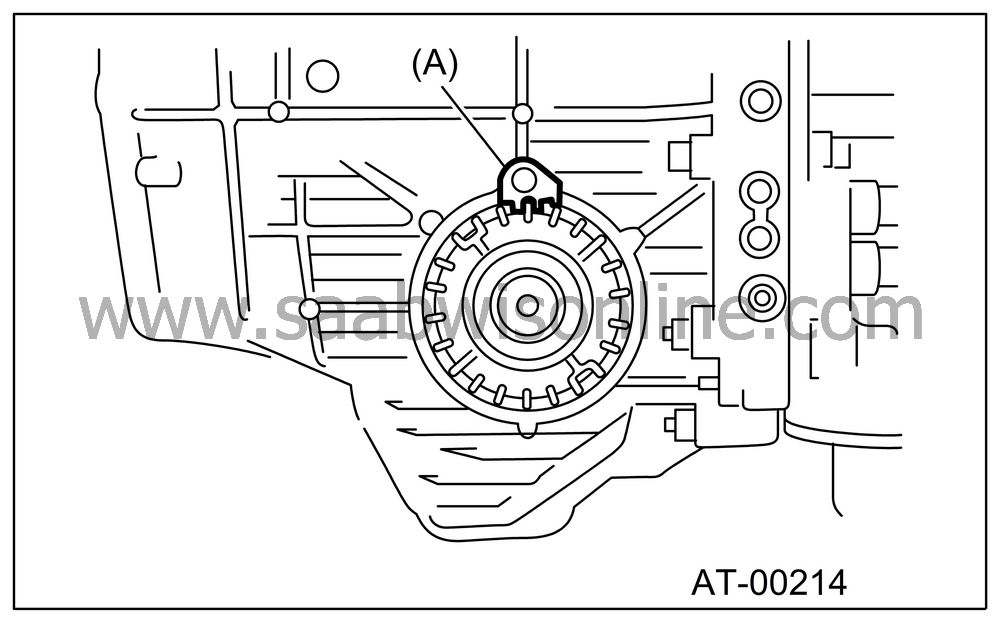

After the “zero” state is established, back off the LH retainer 3 notches and secure it with the lock plate. Then back off the RH retainer and retighten until it stops. Rotate drive pinion a few times. Tighten the RH retainer 1-3/4 notches further. This sets the preload. Finally, secure the retainer with its lock plate.

|

(A)

|

Lock plate

|

| Note | ||

|

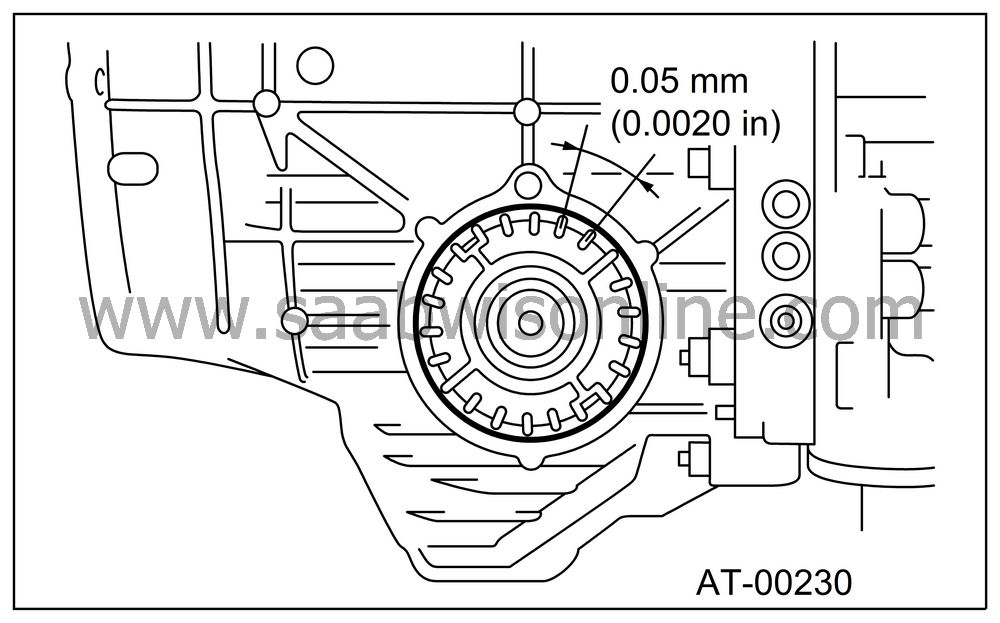

Turning the retainer by one tooth changes the backlash about 0.05 mm (0.0020 in). |

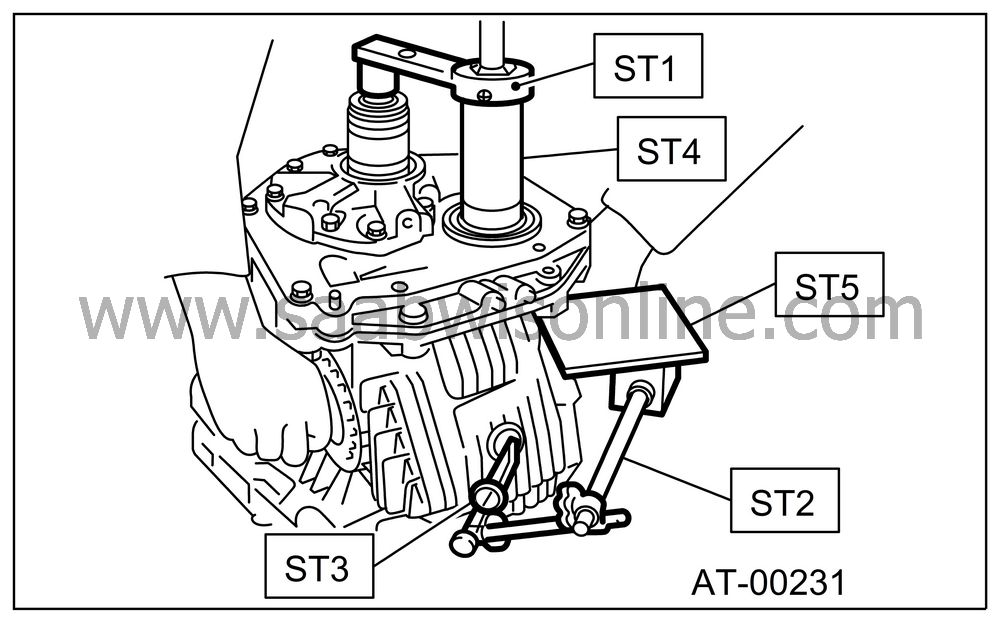

Turn the drive pinion several rotations with ST1 and check to see if the backlash is within the standard value with ST2, ST3, ST4 and ST5.

ST1 32005154 WRENCH

ST2 32005094 MAGNET BASE

ST3 32005095 DIAL GAUGE

ST4 32005153 ADAPTER

ST5 32005096 PLATE

Backlash:0.13 — 0.18 mm (0.0051 — 0.0071 in)

Adjust the tooth contact between front differential and drive shaft.