INSTALLATION

| INSTALLATION |

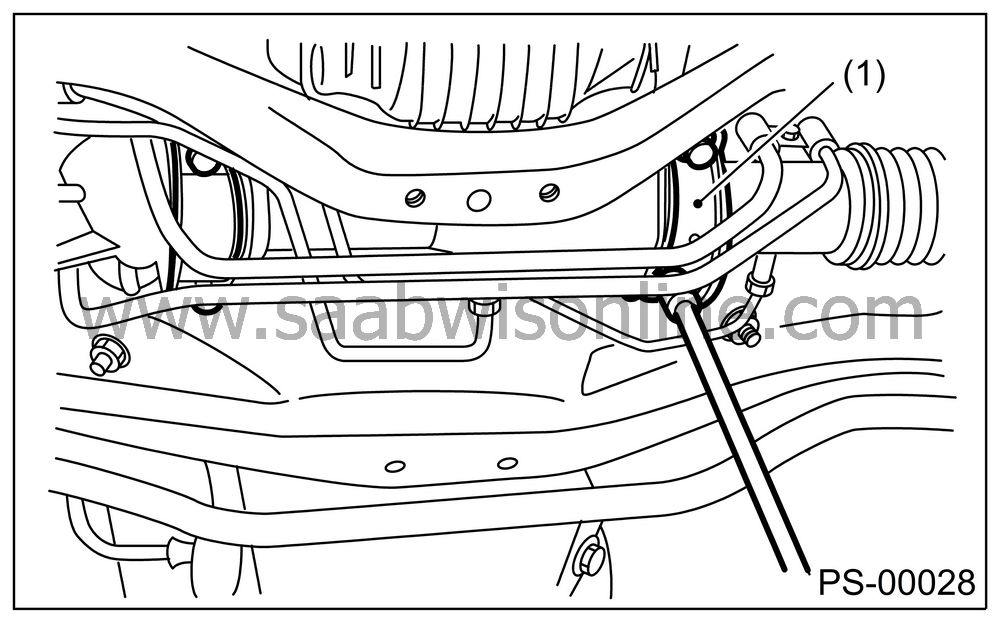

Insert the gearbox into crossmember, being careful not to damage the gearbox boot.

Tighten the gearbox to crossmember bracket via clamp with bolts to specified torque.

Tightening torque:

59 Nm (6.0 kgf-m, 43.4 ft-lb)

|

(1)

|

Clamp

|

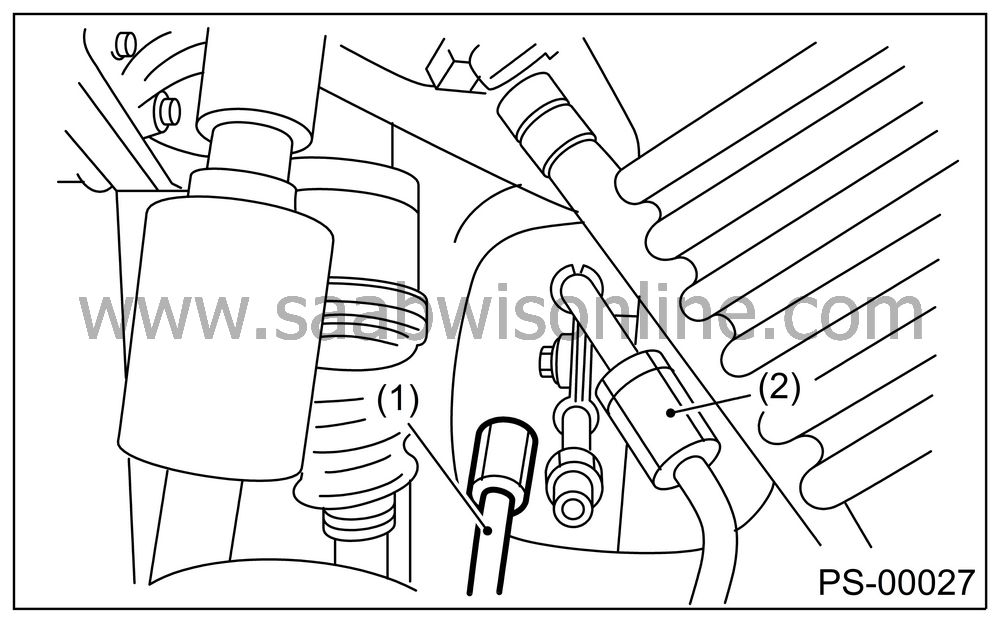

Connect the pipe D first to gear box, and pipe C second.

Tightening torque:

15 Nm (1.5 kgf-m, 10.8 ft-lb)

|

(1)

|

Pipe C

|

|

(2)

|

Pipe D

|

Install the universal joint.

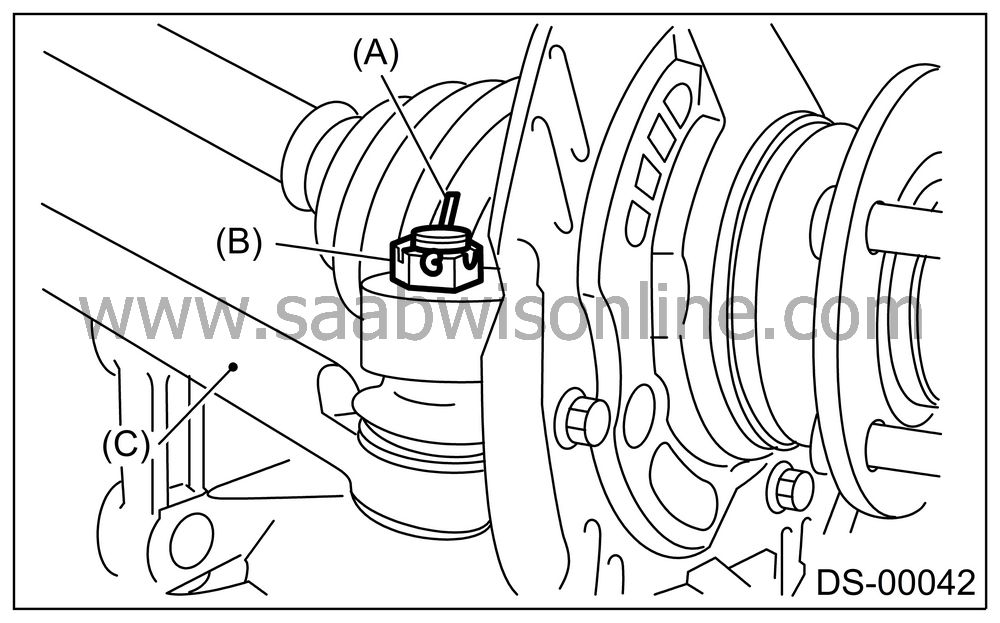

Connect the tie-rod end and knuckle arm, and tighten with castle nut.

Castle nut tightening torque:

27 Nm (2.75 kgf-m, 19.9 ft-lb)

| Important | ||

|

When connecting, do not hit the cap at bottom of tie-rod end with hammer. |

||

After tightening the castle nut to specified torque, tighten it further within 60° until cotter pin hole is aligned with the slot in nut, and then bend the cotter pin to lock.

|

(A)

|

Cotter

pin

|

|

(B)

|

Castle

nut

|

|

(C)

|

Tie-rod

end

|

Install the front stabilizer to vehicle.

Install the front exhaust pipe assembly.

Install the sub frame.

Install the under cover.

Align the center of roll connector.

Install the steering wheel.

Install the front wheels.

Tighten the wheel nuts to specified torque.

Tightening torque:

90 Nm (9.1 kgf-m, 65.8 ft-lb)

Connect the battery ground cable to battery.

Pour fluid into the oil tank, and bleed air.

Check for fluid leaks.

Install the jack-up plate.

Lower the vehicle.

Check the fluid level in oil tank.

After adjusting the toe-in and steering angle, tighten the lock nut on tie-rod end.

Tightening torque:

83 Nm (8.5 kgf-m, 61.5 ft-lb)

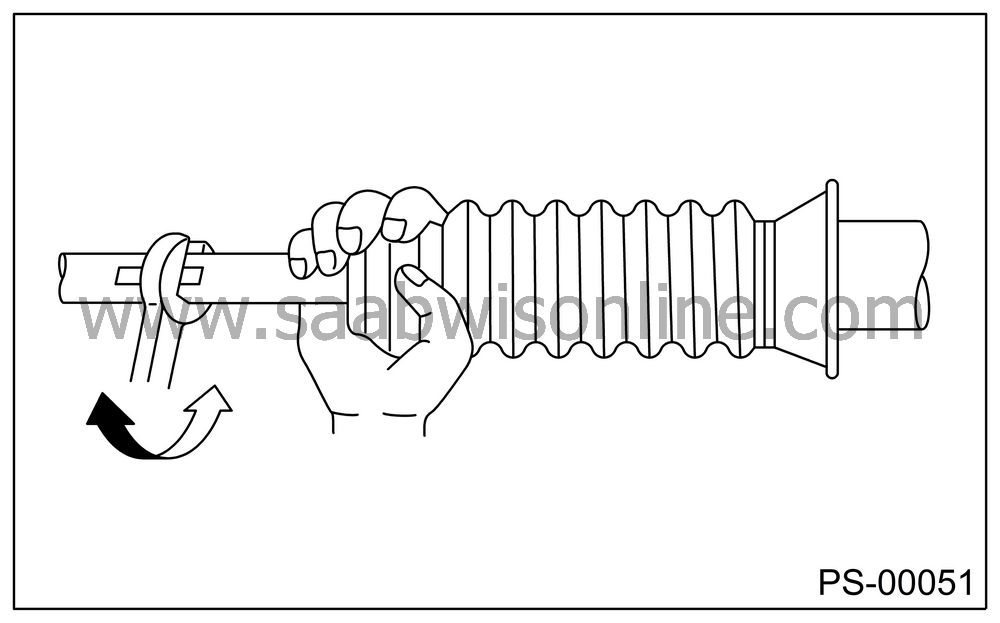

| Note | ||

|

When adjusting the toe-in, hold boot as shown to prevent it from being rotated or twisted. If twisted, straighten it. |