Adjusting valve timing

| Adjusting valve timing |

| Inspection gauge 83 95 337 does not fit into the fuel distribution pump recess |

| 1. |

Zero the engine, see

step 1-20. The crankshaft must be locked with inspection gauge 83 95 352.

step 1-20. The crankshaft must be locked with inspection gauge 83 95 352.

|

|

| 2. |

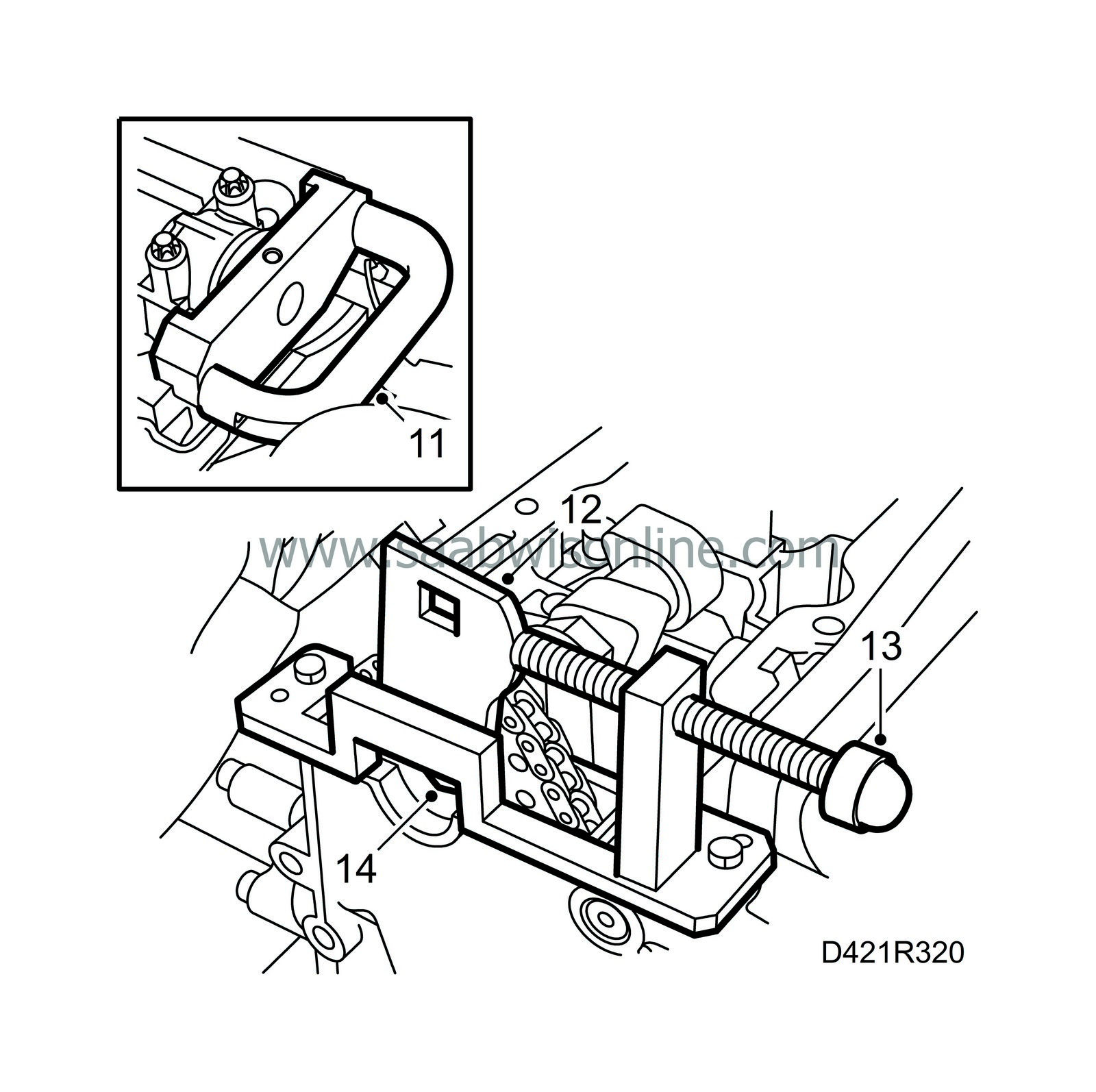

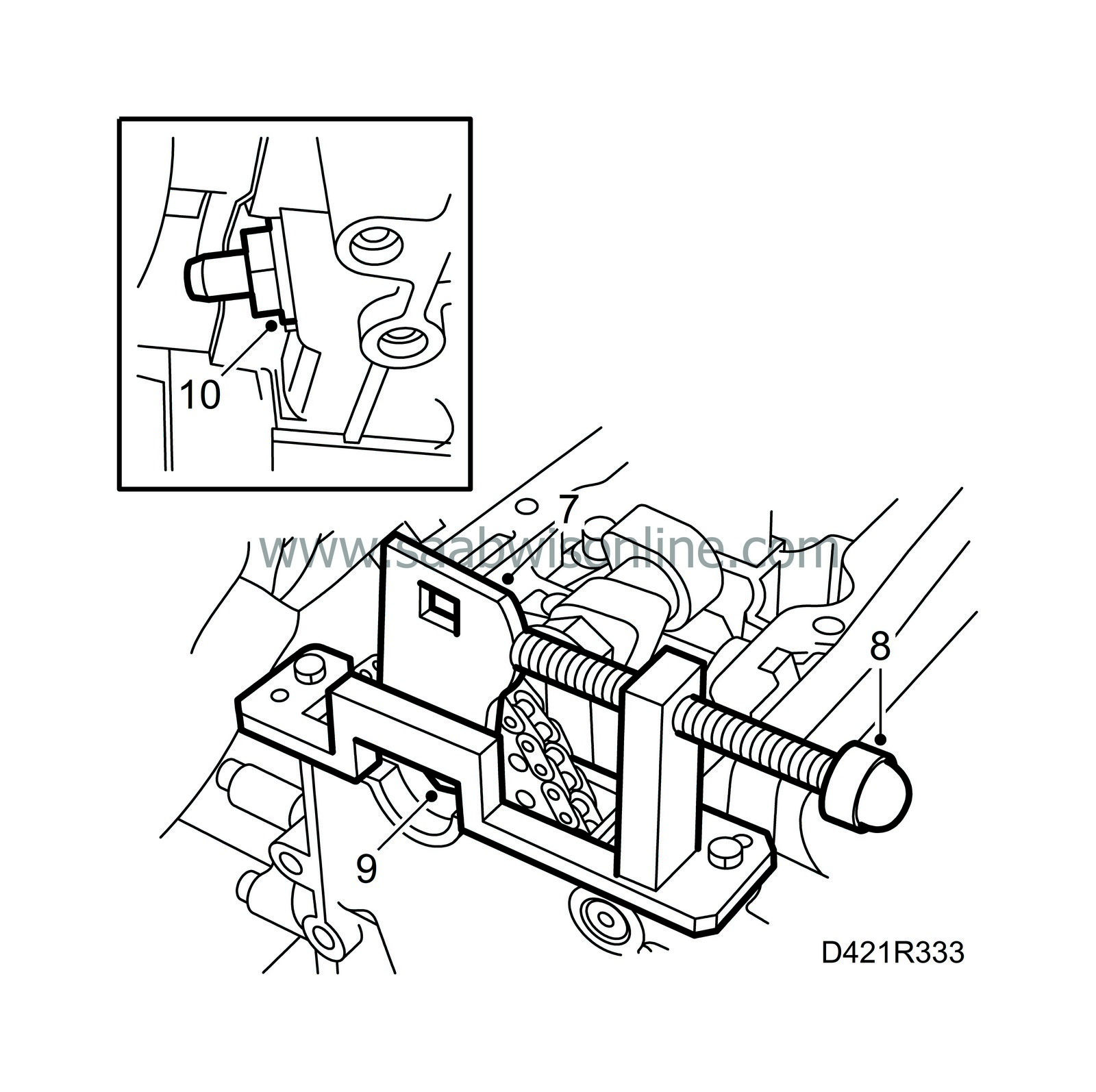

Note the position of the upper timing chain tensioner and remove it.

|

|

| 3. |

Note the position of the lower timing chain tensioner and remove it.

|

|

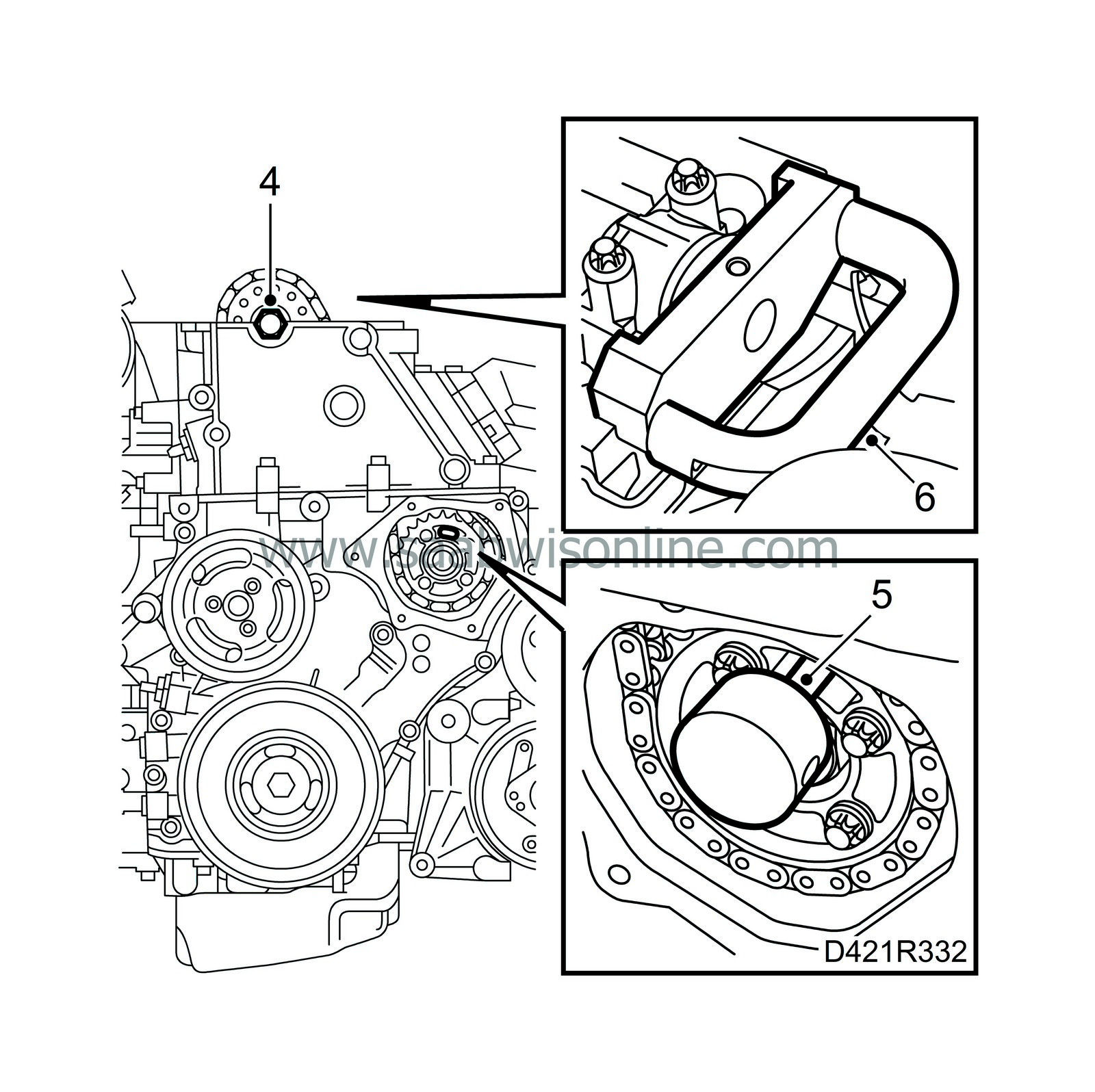

| 4. |

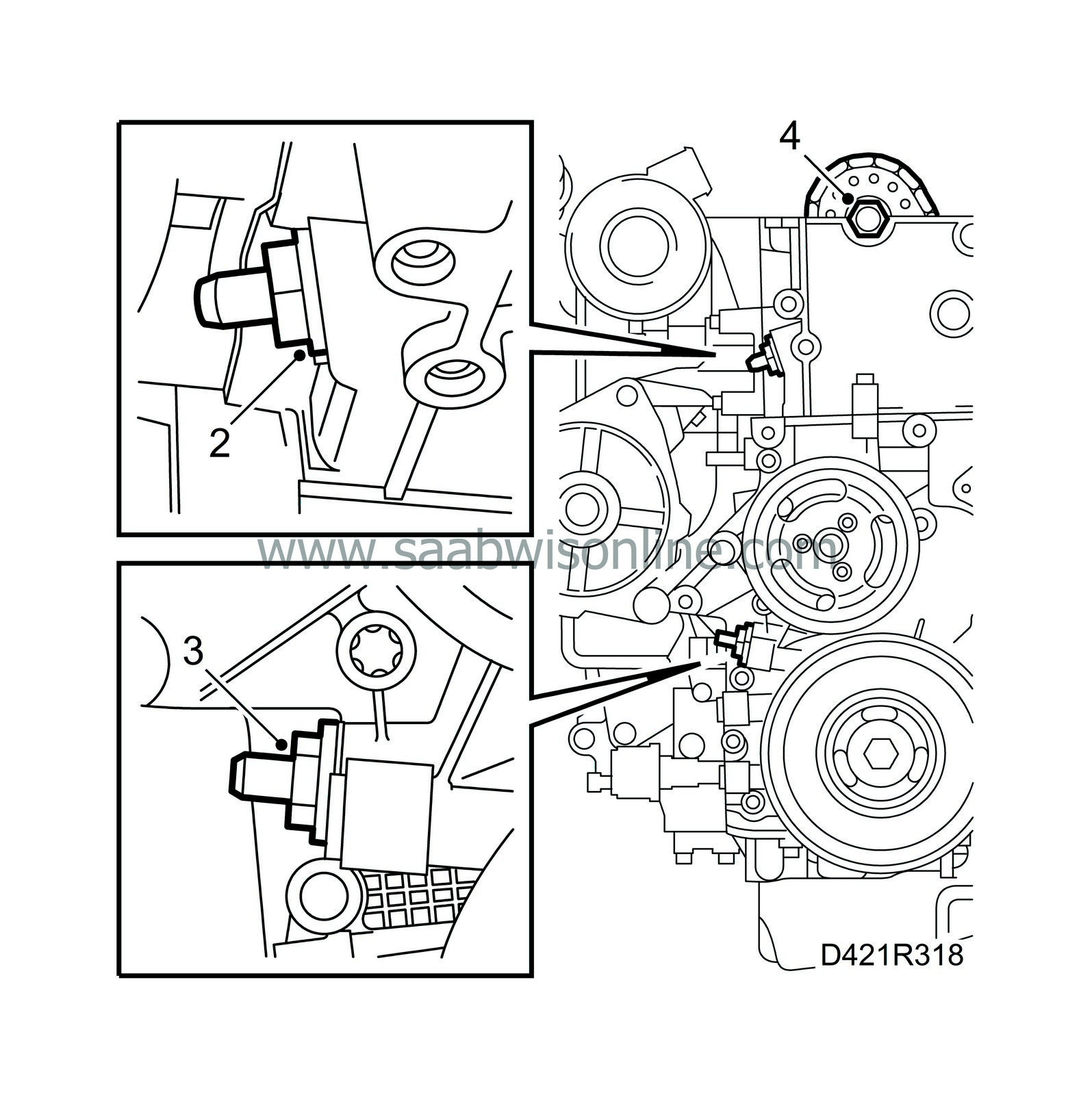

Dismantle the camshaft gear using an open spanner in the hexagonal recess on the camshaft as a backstop.

|

|

| 5. |

Position the camshaft gear so that is runs easily on the camshaft and fit it with a new bolt. Tighten by hand.

|

|

| 6. |

Undo the four bolts on the fuel distribution pump sprocket.

|

||||||||||

| 7. |

Position inspection gauge 83 95 337 in the recess in the fuel distribution pump.

|

|

| 8. |

Fit the chain tensioner for the lower timing chain with a new gasket.

Tightening torque: 60 Nm (44 lbf ft). |

|

| 9. |

Remove the inspection gauge from the fuel distribution pump and tighten the bolts on the sprocket.

Tightening torque: 20 Nm (15 lbf ft). |

|

| 10. |

Reposition the inspection gauge 83 95 337 in the recess on the fuel distribution pump.

|

|

| 12. |

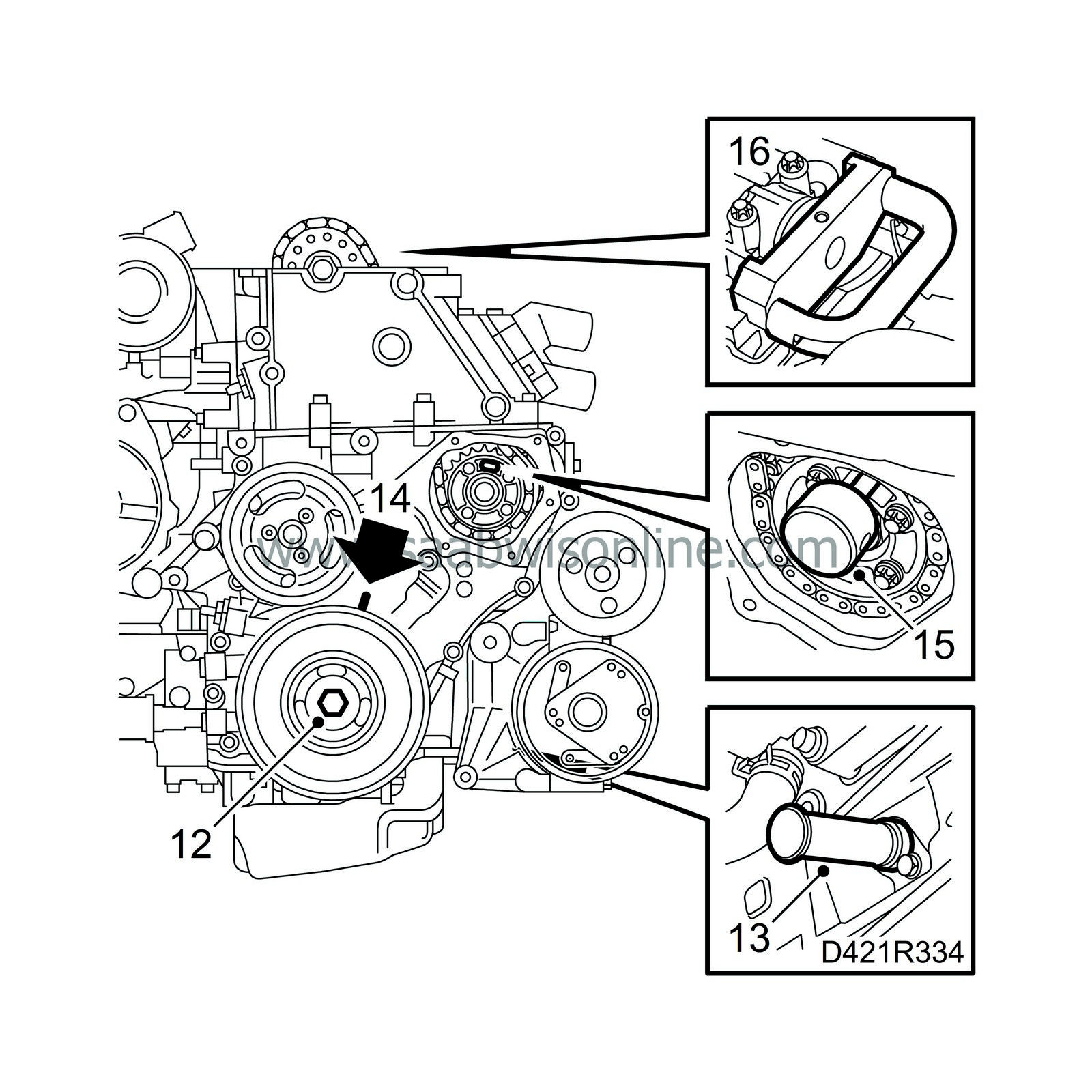

Fit the adapter for the timing chain adjuster 83 95 394 on the camshaft gear and the timing chain adjuster on the cylinder head.

|

|

| 13. |

Secure the position of the adapter on the camshaft gear by turning it slightly anticlockwise with a ratchet handle. Tighten the adjuster screw on the tool.

|

||||||||||

| 14. |

Tighten the bolts on the camshaft gear.

Tightening torque: 90 Nm (66.5 lbf ft) + 60°. |

|

| 15. |

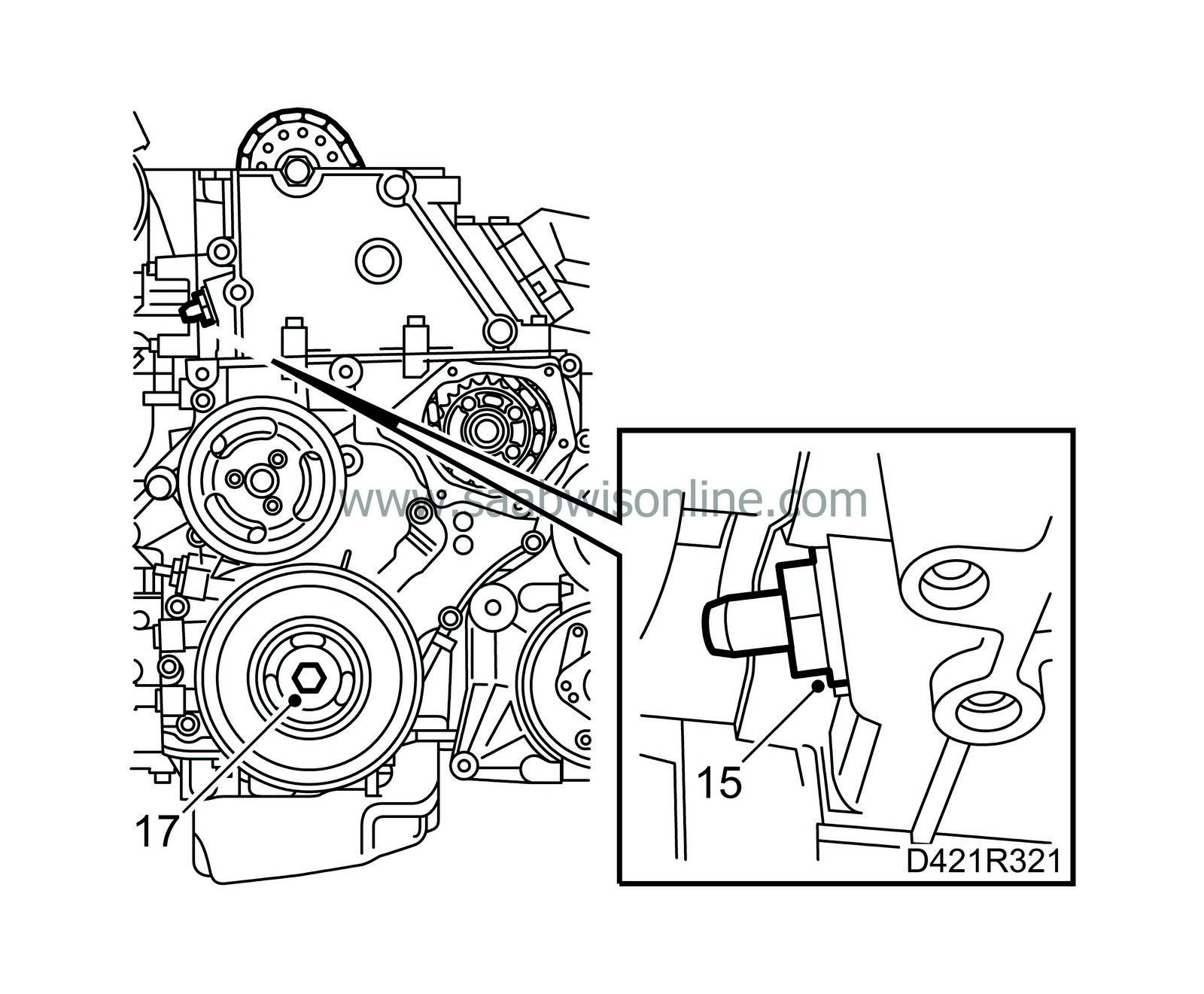

Fit the chain tensioner for the upper timing chain with a new gasket.

Tightening torque: 60 Nm (44 lbf ft). |

|

| 16. |

Remove all tools and gauges.

|

|

| 17. |

Turn the crankshaft with the centre bolt on the pulley two revolutions until it reaches the mark for top dead centre in cylinder 1. Make sure both cams for cylinder 1 are point up.

|

|

| 19. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must also be aligned with the recess in the pump.

|

|

| 20. |

Position inspection gauge 83 95 337 in the recess in the fuel distribution pump.

|

|

| 21. |

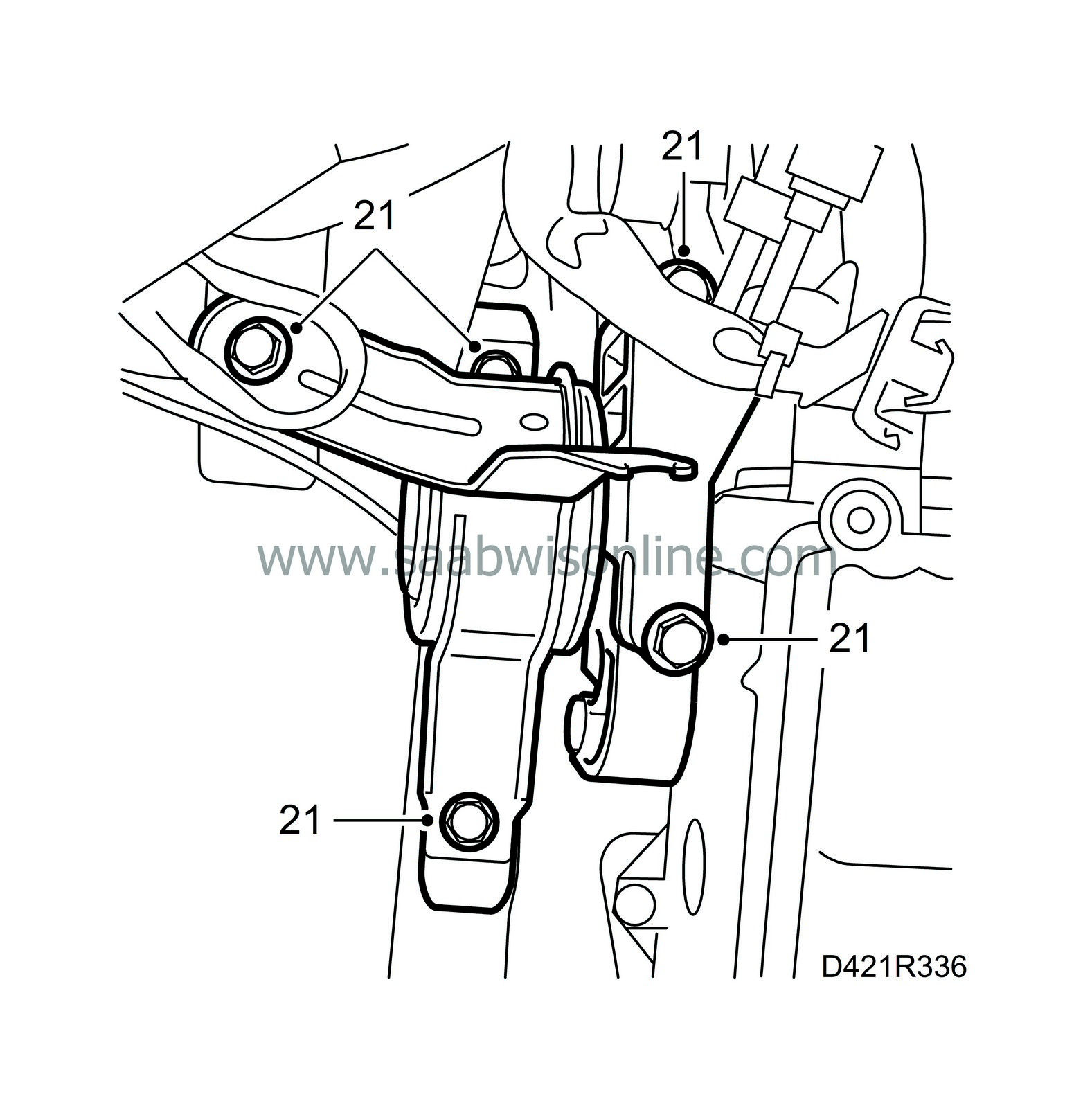

Position inspection gauge 83 95 386 on the camshaft and the cylinder head.

|

|

| 22. |

Remove all the inspection gauges.

|

|

| 23. |

Cover the opening in the timing cover with a lint-free cloth and remove any remains from the old gasket from the sealing surface. Clean also the sealing surface on the cap.

|

|

| 24. |

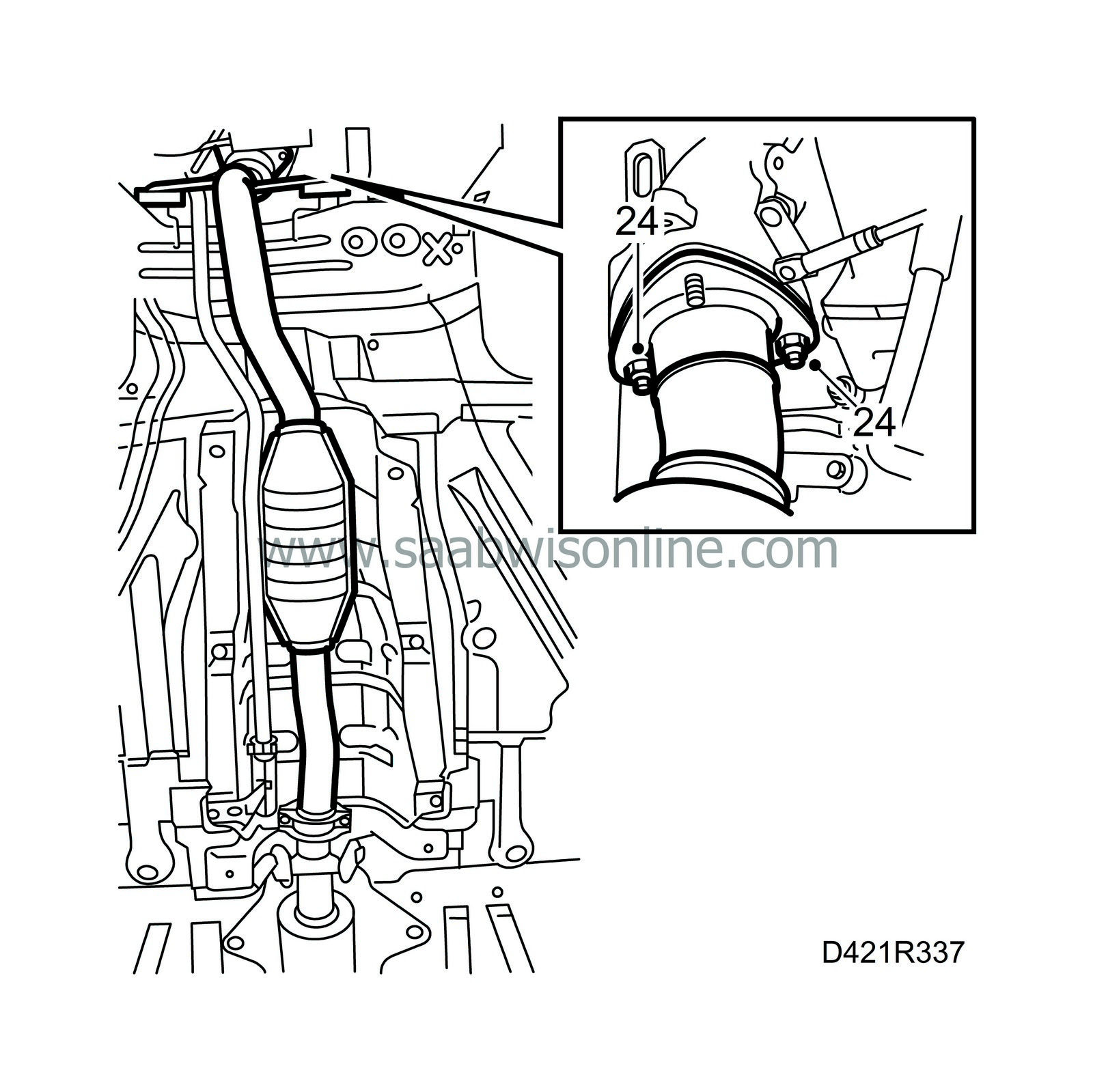

Apply a string of silicone sealant about 2 mm thick on the cap, remove the cloth from the timing cover and fit the cap.

Tightening torque: 6 Nm (4.5 lbf ft). |

|

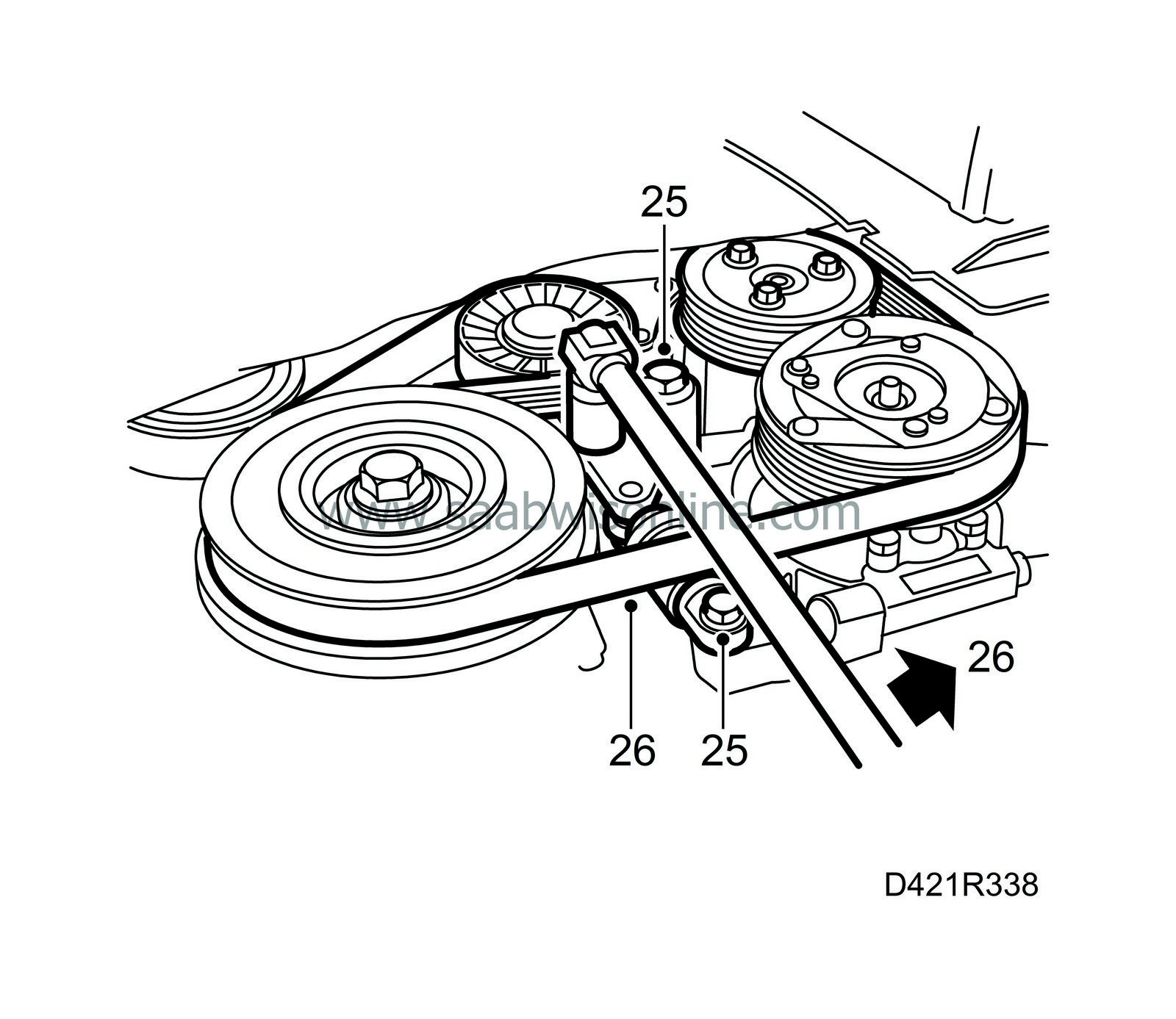

| 25. |

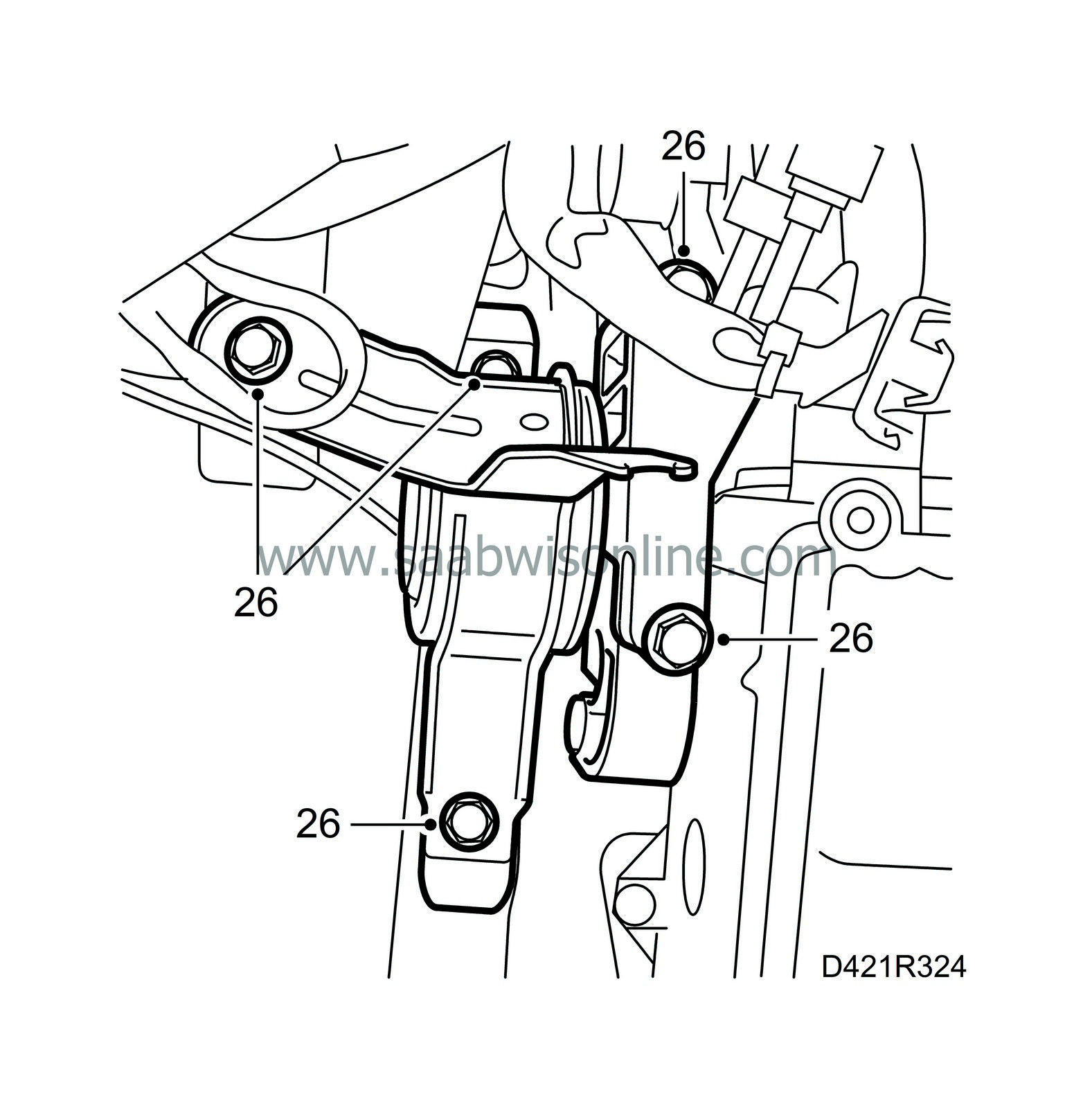

Fit the right-hand engine mounting bracket on the engine and tighten the engine mounting on the engine.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 26. |

Lower the engine and tighten the right-hand engine mounting on the body.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 27. |

Raise the car and fit the crankshaft position sensor with a new O-ring.

Tightening torque: 8 Nm (6 lbf ft). |

|

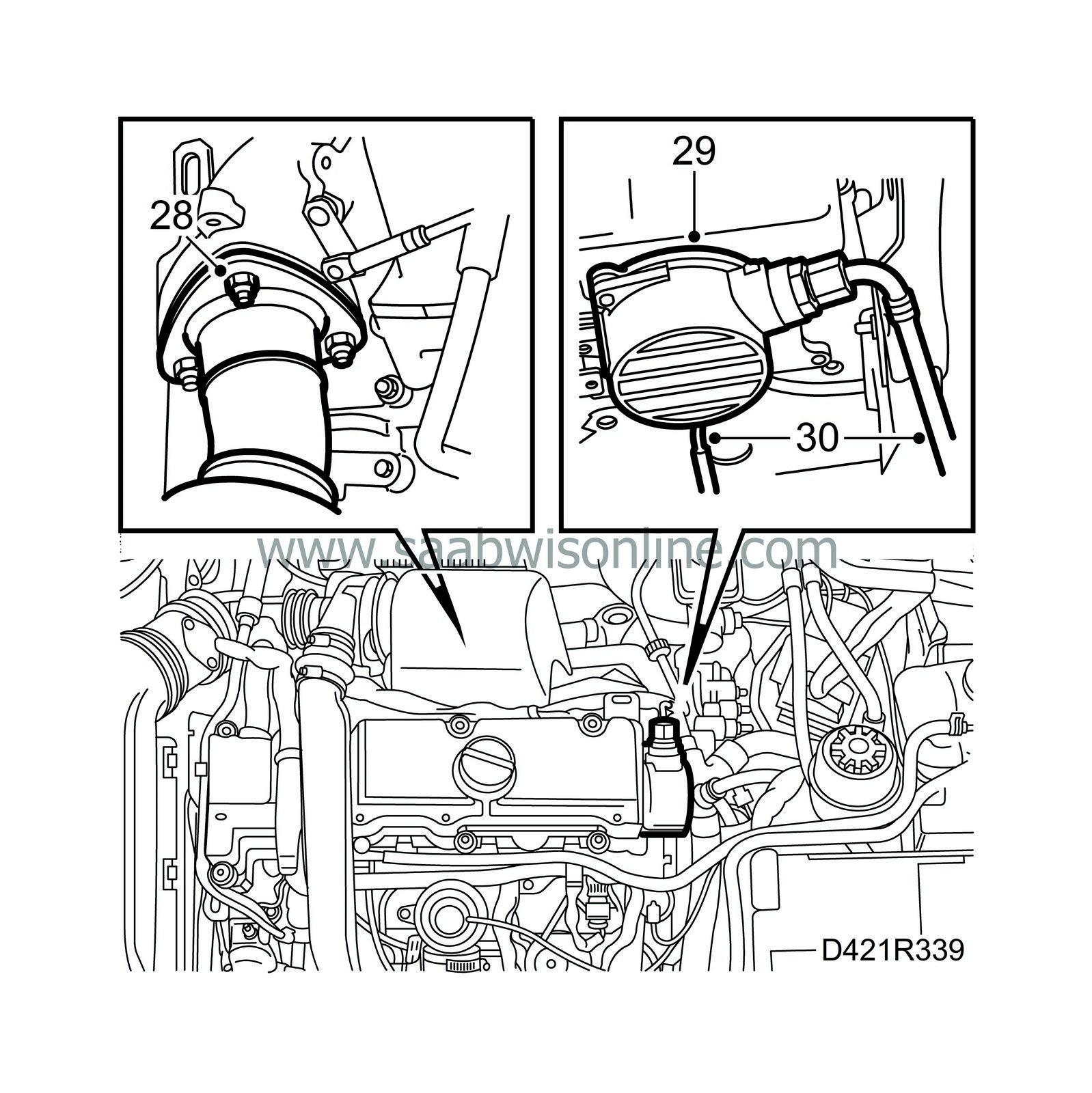

| 28. |

Apply Molycote 1000 to the studs on the turbocharger, position the front part of the exhaust pipe with a new gasket and mount new nuts.

|

|

| 29. |

Tighten the front exhaust pipe to the turbocharger.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

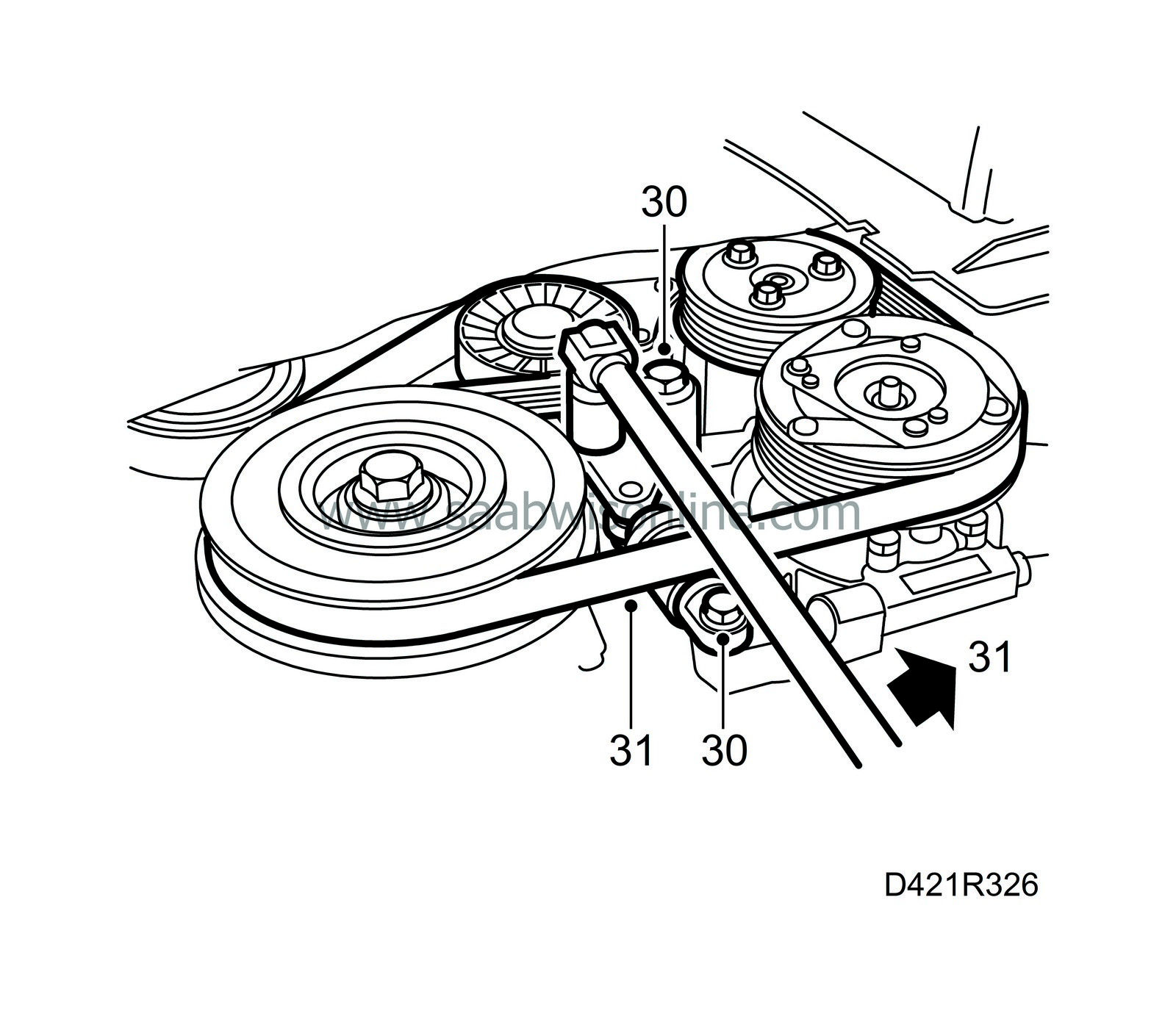

| 30. |

Fit the belt tensioner, tightening the top bolt first.

Tightening torque: 42 Nm (31 lbf ft). Tighten the bottom bolt. Tightening torque: 23 Nm (17 lbf ft). |

|

| 31. |

Fit the multigroove V-belt on all the pulleys. Relieve the tension on the belt tensioner by turning it anticlockwise (towards the rear of the car) with a 19 mm spanner and fit the belt on its pulley. Make sure the belt is positioned correctly on all the pulleys.

|

|

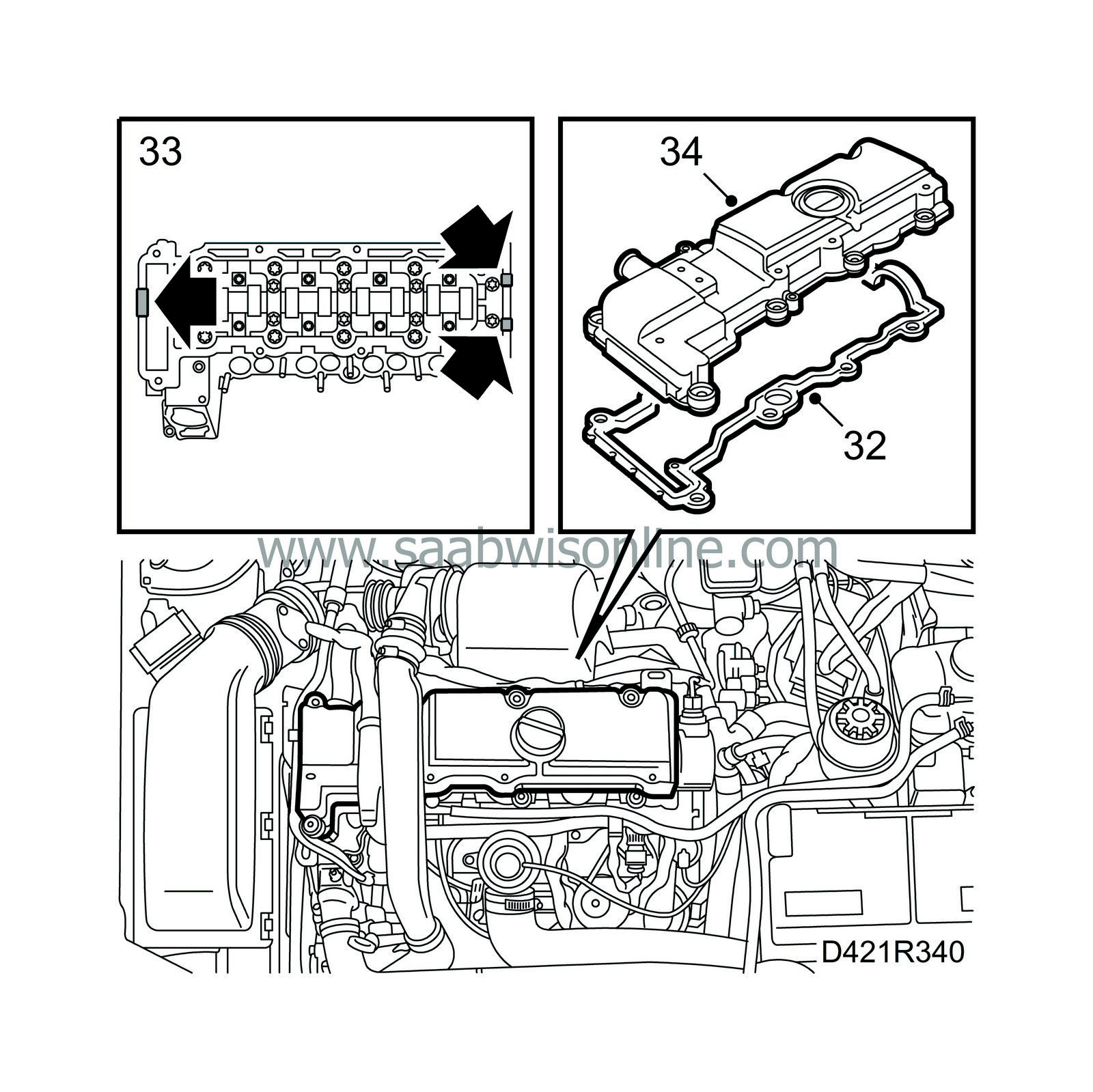

| 32. |

Refit the lower engine cover, the cover in the right-hand wheel housing and the front right wheel.

Tightening torque, wheel 110 Nm (81 lbf ft). |

|

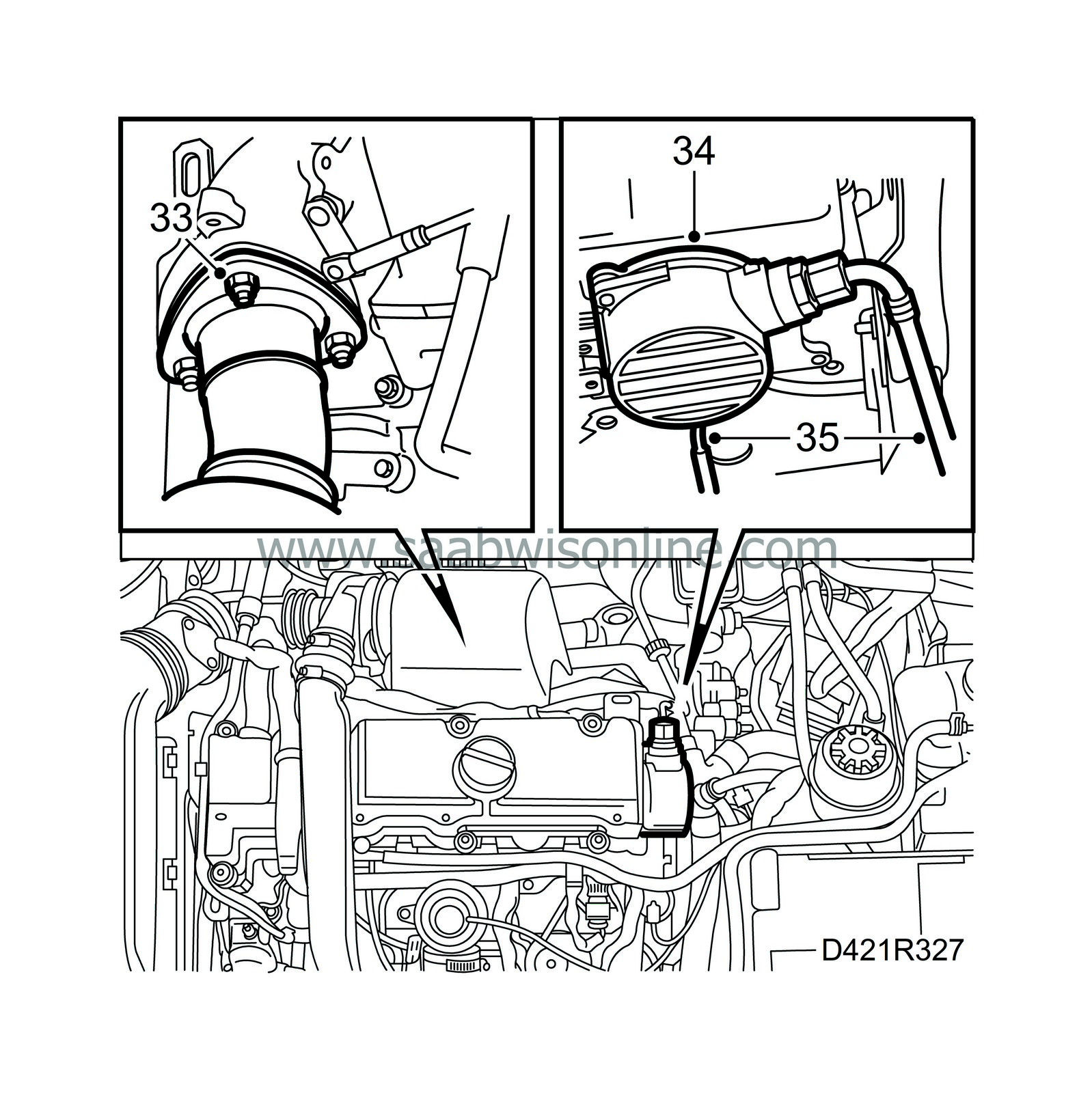

| 33. |

Lower the car and tighten the remaining nuts between the turbocharger and the front exhaust pipe.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 34. |

Fit a new gasket on the vacuum pump and fit the pump together with the adapter.

Tightening torque: 8 Nm (6 lbf ft). |

||||||||||

| 35. |

Connect the vacuum hose for the brake servo to the vacuum pump.

Tightening torque: 18 Nm (13 lbf ft). Connect the vacuum hose to the bottom of the vacuum pump. |

|

| 36. |

Clean off any gasket remains from the sealing surfaces.

|

|

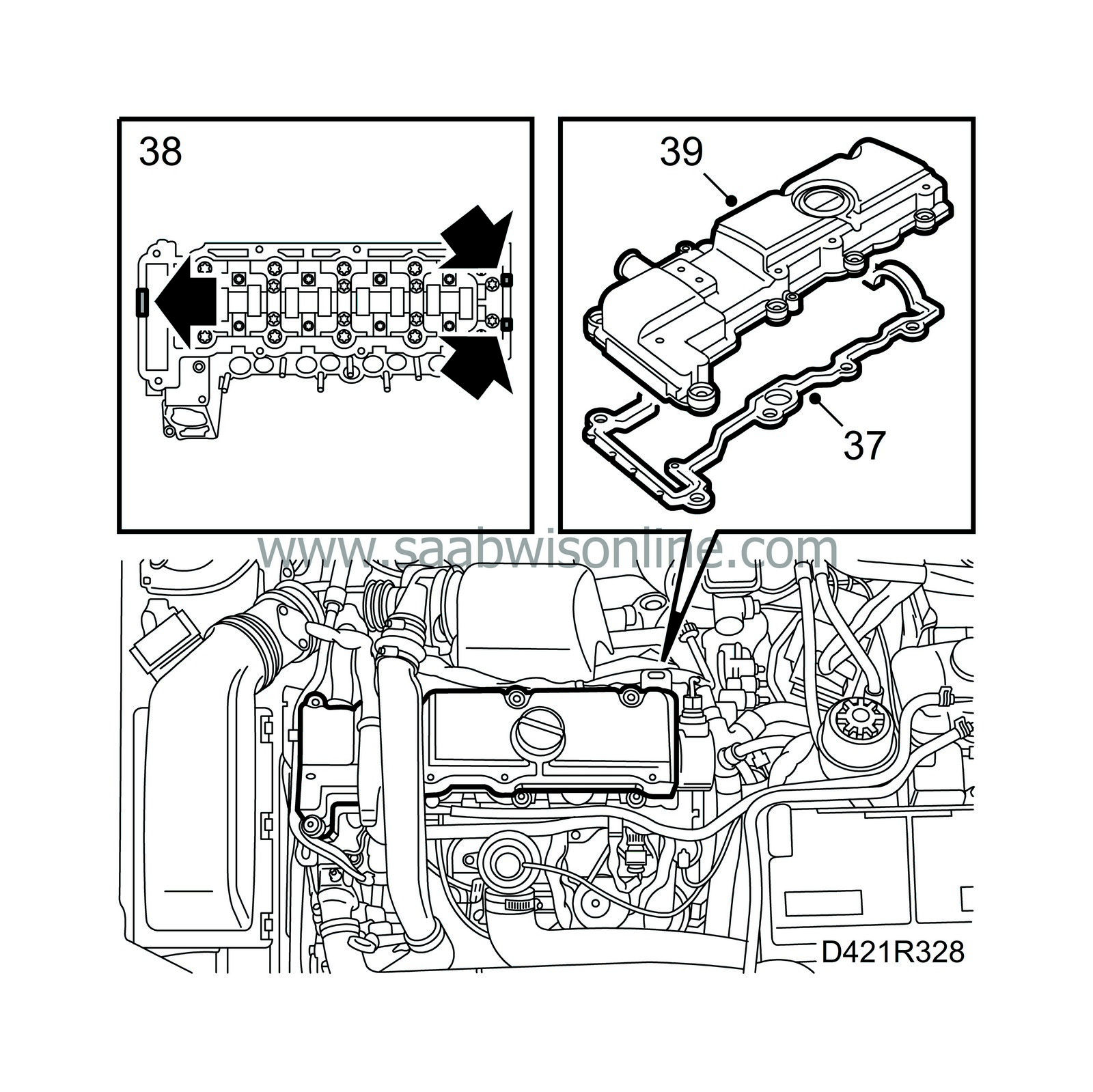

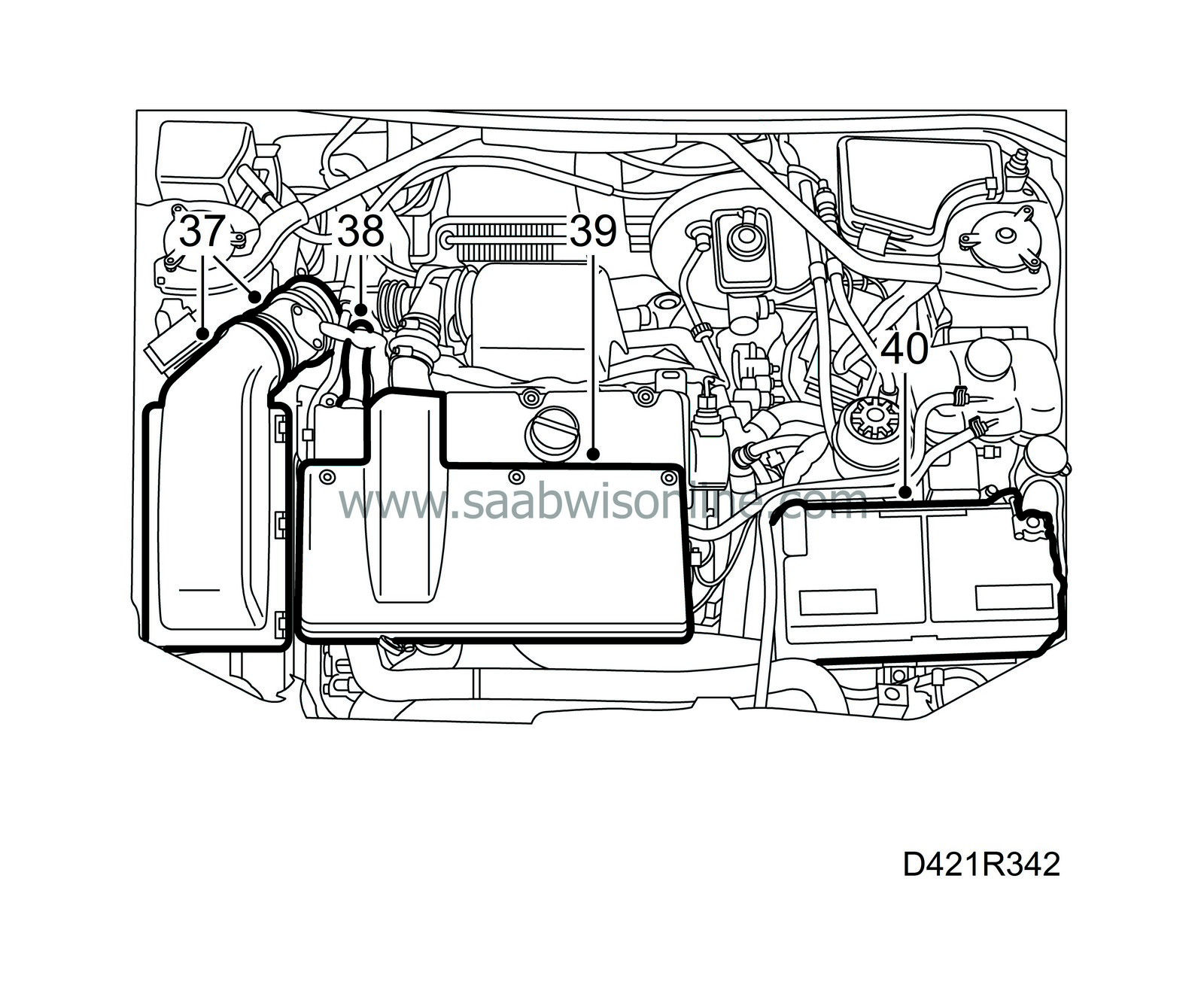

| 37. |

Position a new gasket on the camshaft cover. There are sleeves on the bolts on which the gasket fits.

|

|

| 38. |

Apply sealing compound 87 81 841 to the sealing surface, see illustration.

|

|

| 39. |

Position the transmission cover on the cylinder head and tighten the bolts.

Tightening torque: 8 Nm (6 lbf ft). |

|

| 40. |

Press the fuel lines back into their fastenings and fit the wiring harness channel on the cylinder head.

|

|

| 41. |

Refit the turbo delivery pipe with a new O-ring.

|

|

| 42. |

Refit the air cleaner with mass air flow sensor and hoses.

|

|

| 43. |

Connect the crankcase ventilation hose to the camshaft cover.

|

|

| 44. |

Refit the engine cover.

|

|

| 45. |

Connect the battery.

|

|

| Inspection gauge 83 95 386 does not fit into the camshaft recess |

| 1. |

Zero the engine, see

step 1-20. The crankshaft must be locked with inspection gauge 83 95 352.

step 1-20. The crankshaft must be locked with inspection gauge 83 95 352.

|

|

| 2. |

Note the position of the upper timing chain tensioner and remove it.

|

|

| 3. |

Dismantle the camshaft gear using an open spanner in the hexagonal recess on the camshaft as a backstop.

|

|

| 4. |

Position the camshaft gear so that is runs easily on the camshaft and fit it with a new bolt. Tighten by hand.

|

|

| 5. |

Position inspection gauge 83 95 337 in the recess in the fuel distribution pump.

|

|

| 6. |

Position inspection gauge 83 95 386 on the camshaft and cylinder head. The camshaft can be turned slightly if necessary with an open spanner in the hexagonal recess on the camshaft at the same time as the gauge is put into the correct position.

|

|

| 7. |

Fit the adapter for the timing chain adjuster 83 95 394 on the camshaft gear and the timing chain adjuster on the cylinder head.

|

|

| 8. |

Secure the position of the adapter on the camshaft gear by turning it slightly anticlockwise with a ratchet handle. Tighten the adjuster screw on the tool.

|

||||||||||

| 9. |

Tighten the bolts on the camshaft gear.

Tightening torque: 90 Nm (66.5 lbf ft) + 60°. |

|

| 10. |

Fit the chain tensioner for the upper timing chain with a new gasket.

Tightening torque: 60 Nm (44 lbf ft). |

|

| 11. |

Remove all tools and gauges.

|

|

| 12. |

Turn the crankshaft with the centre bolt on the pulley two revolutions until it reaches the mark for top dead centre in cylinder 1. Make sure both cams for cylinder 1 are point up.

|

|

| 13. |

Position inspection gauge 83 95 352 inside the hole for the crankshaft position sensor. Press the tool inwards slightly at the same time as the crankshaft is turned to the zero mark. The tool will then enter a recess in the crankshaft and secure it.

|

|

| 14. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must also be aligned with the recess in the pump.

|

|

| 15. |

Position inspection gauge 83 95 337 in the recess in the fuel distribution pump.

|

|

| 16. |

Position inspection gauge 83 95 386 on the camshaft and the cylinder head.

|

|

| 17. |

Remove all the inspection gauges.

|

|

| 18. |

Cover the opening in the timing cover with a lint-free cloth and remove any remains from the old gasket from the sealing surface. Clean also the sealing surface on the cap.

|

|

| 19. |

Apply a string of silicone sealant about 2 mm thick on the cap, remove the cloth from the timing cover and fit the cap.

Tightening torque: 6 Nm (4.5 lbf ft). |

|

| 20. |

Fit the right-hand engine mounting bracket on the engine and tighten the engine mounting on the engine.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 21. |

Lower the engine and tighten the right-hand engine mounting on the body.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 22. |

Raise the car and fit the crankshaft position sensor with a new O-ring.

Tightening torque: 8 Nm (6 lbf ft). |

|

| 23. |

Apply Molycote 1000 to the studs on the turbocharger, position the front part of the exhaust pipe with a new gasket and mount new nuts.

|

|

| 24. |

Tighten the front exhaust pipe to the turbocharger.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 25. |

Fit the belt tensioner, tightening the top bolt first.

Tightening torque: 42 Nm (31 lbf ft). Tighten the bottom bolt. Tightening torque: 23 Nm (17 lbf ft). |

|

| 26. |

Fit the multigroove V-belt on all the pulleys. Relieve the tension on the belt tensioner by turning it anticlockwise (towards the rear of the car) with a 19 mm spanner and fit the belt on its pulley. Make sure the belt is positioned correctly on all the pulleys.

|

|

| 27. |

Refit the lower engine cover, the cover in the right-hand wheel housing and the front right wheel.

Tightening torque, wheel 110 Nm (81 lbf ft). |

|

| 28. |

Lower the car and tighten the remaining nuts between the turbocharger and the front exhaust pipe.

Tightening torque: 25 Nm (18.5 lbf ft). |

|

| 29. |

Fit a new gasket on the vacuum pump and fit the pump together with the adapter.

Tightening torque: 8 Nm (6 lbf ft). |

||||||||||

| 30. |

Connect the vacuum hose for the brake servo to the vacuum pump.

Tightening torque: 18 Nm (13 lbf ft). Connect the vacuum hose to the bottom of the vacuum pump. |

|

| 31. |

Clean off any gasket remains from the sealing surfaces.

|

|

| 32. |

Position a new gasket on the camshaft cover. There are sleeves on the bolts on which the gasket fits.

|

|

| 33. |

Apply sealing compound 87 81 841 to the sealing surface, see illustration.

|

|

| 34. |

Position the transmission cover on the cylinder head and tighten the bolts.

Tightening torque: 8 Nm (6 lbf ft). |

|

| 35. |

Press the fuel lines back into their fastenings and fit the wiring harness channel on the cylinder head.

|

|

| 36. |

Refit the turbo delivery pipe with a new O-ring.

|

|

| 37. |

Refit the air cleaner with mass air flow sensor and hoses.

|

|

| 38. |

Connect the crankcase ventilation hose to the camshaft cover.

|

|

| 39. |

Refit the engine cover.

|

|

| 40. |

Connect the battery.

|

|