Camshaft

| Camshaft |

(In car)

| To remove |

| 1. |

Make a note of the radio code, if applicable, and position the car on a lift.

|

|

| 2. |

Put covers over the wings and detach the negative cable from the battery.

|

|

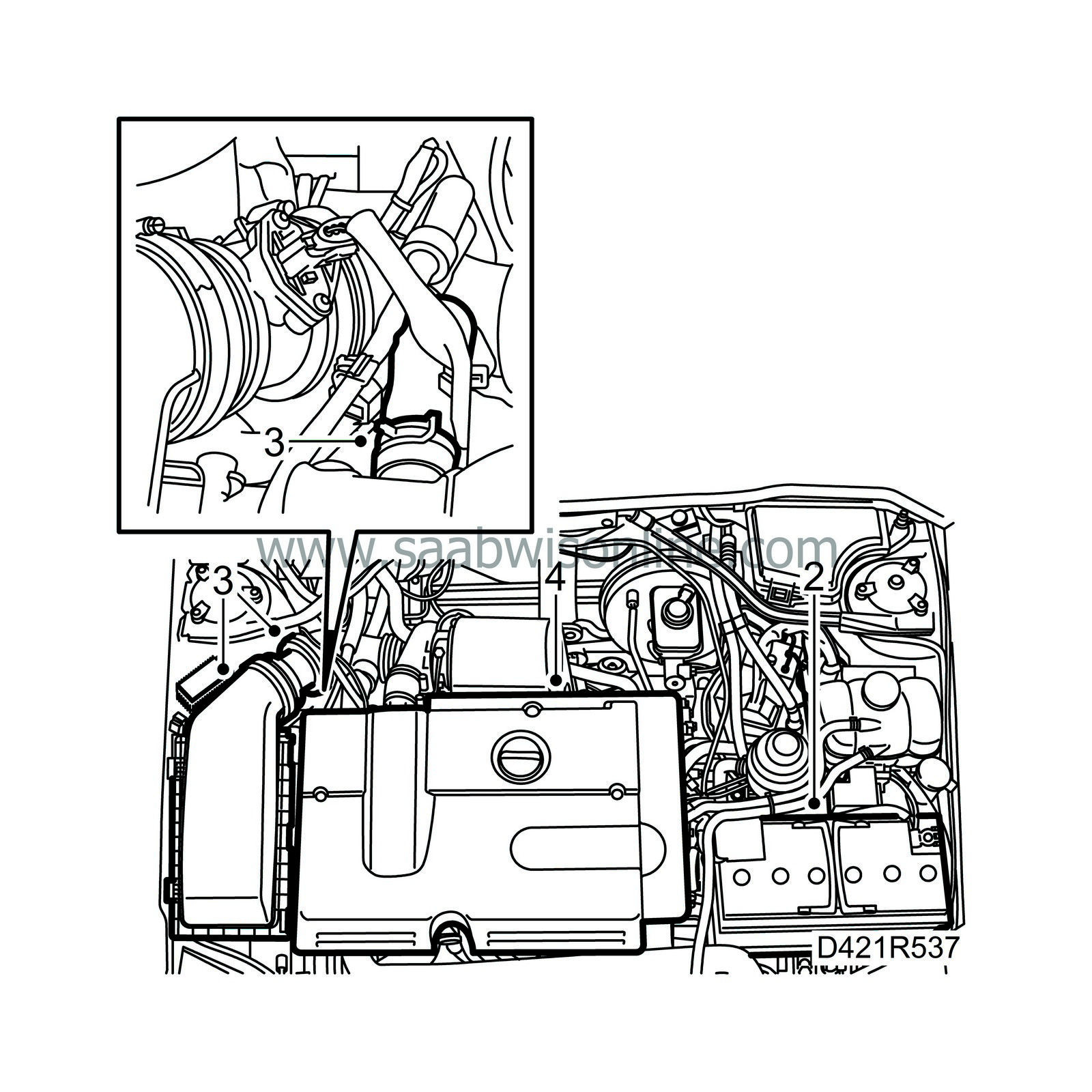

| 3. |

Remove the air cleaner with mass air flow sensor and hoses from the turbocharger and camshaft cover.

|

|

| 4. |

Remove the engine cover.

|

|

| 5. |

Remove the charge air pipe (2 bolts under the wiring harness) and seal the hoses.

|

|

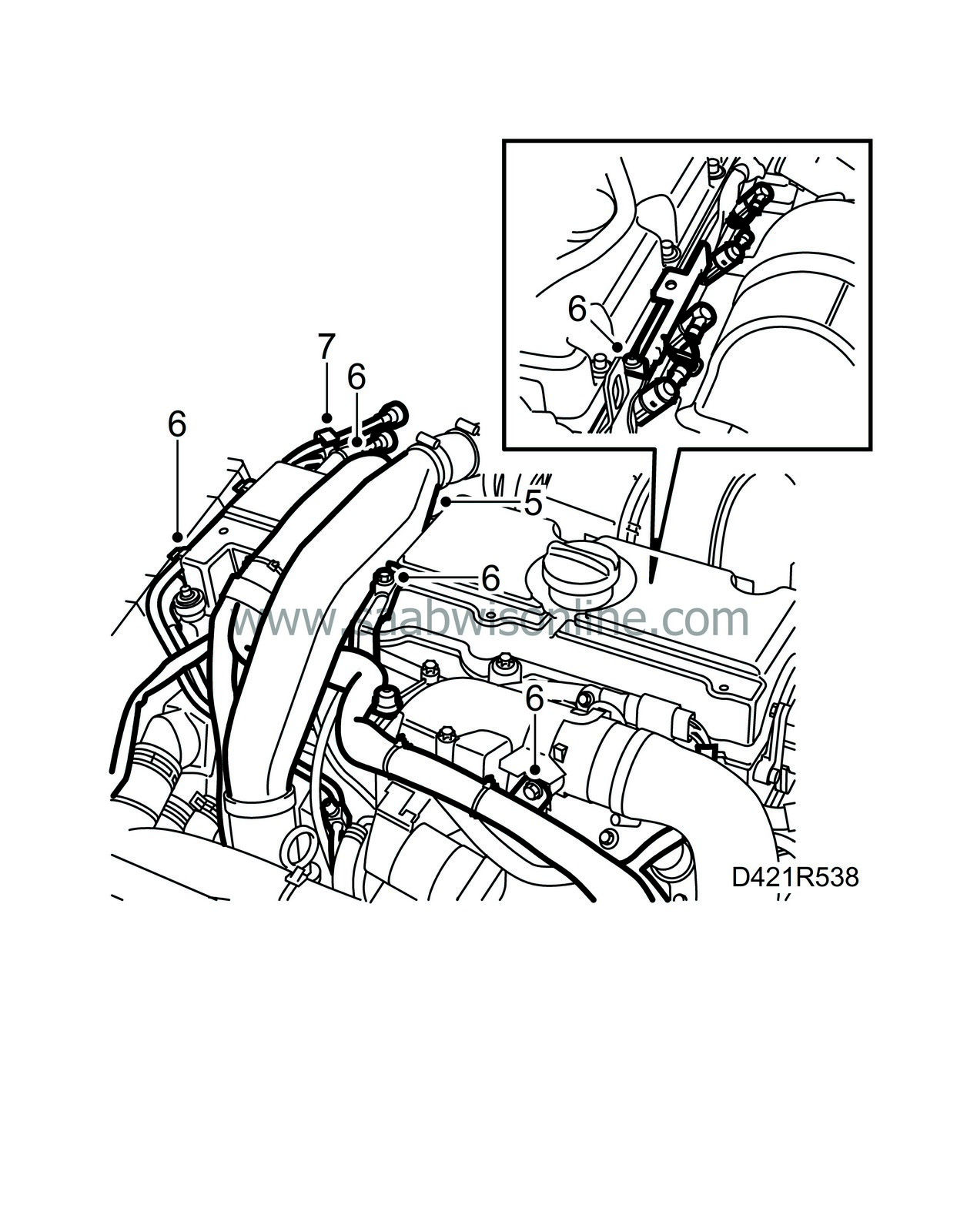

| 6. |

Remove the wiring harness duct from the cylinder head, cut the mountings and disconnect the fuel line mountings from the camshaft cover. Remove the wiring harness and bracket from the engine mounting.

|

|

| 7. |

Disconnect the fuel lines using

83 95 261 Fuel line tool

and seal the hoses.

|

|

| 8. |

Remove the cable mountings from the valve cover and throttle body.

|

|

| 9. |

Unplug the pressure/temperature sensor.

|

|

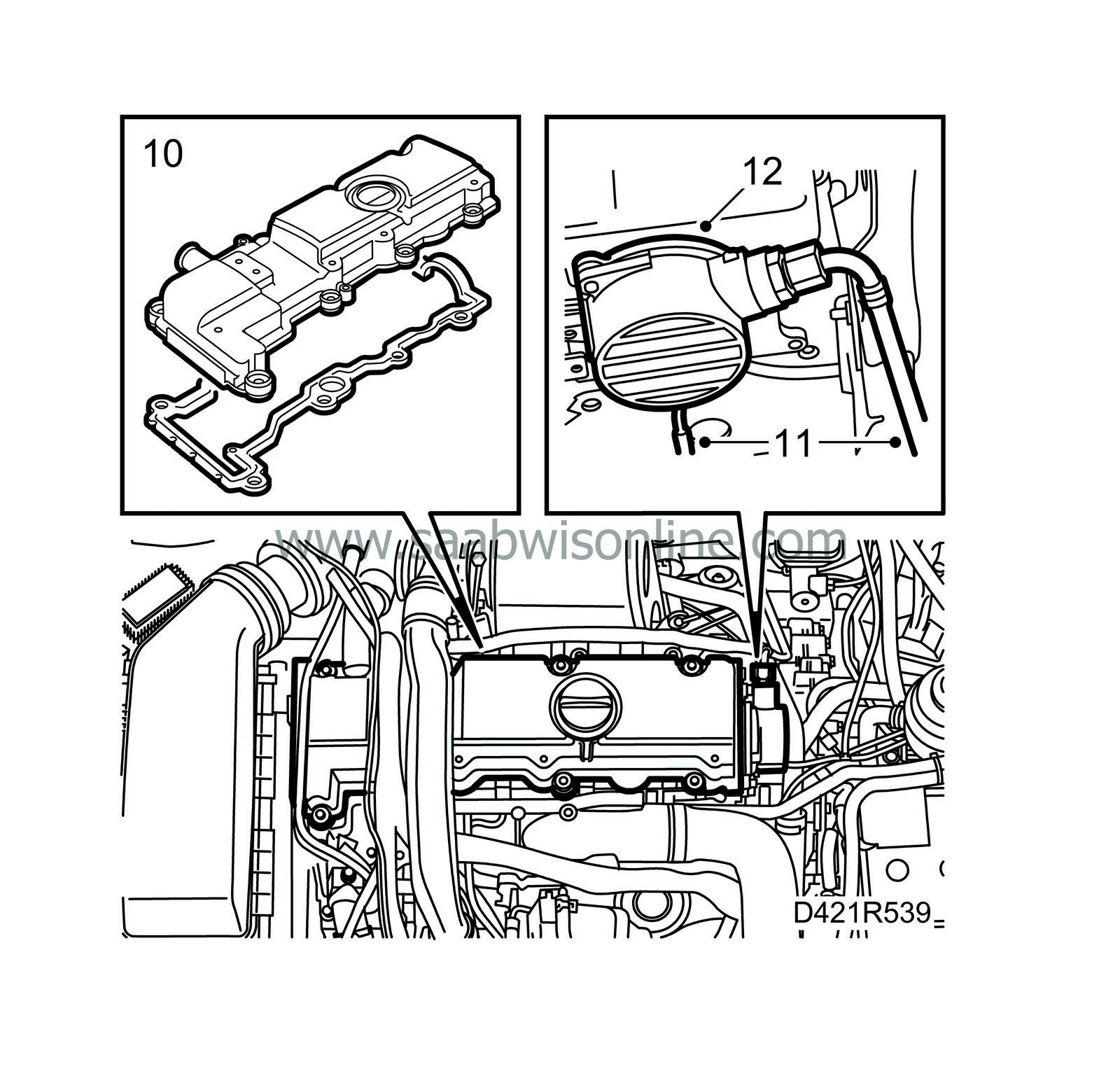

| 10. |

Remove the camshaft cover.

|

|

| 11. |

Detach the vacuum hose to the brake servo and the vacuum hose connected to the bottom of the vacuum pump.

|

|

| 12. |

Remove the four vacuum pump retaining bolts and carefully lift away the vacuum pump and its adapter.

|

||||||||||

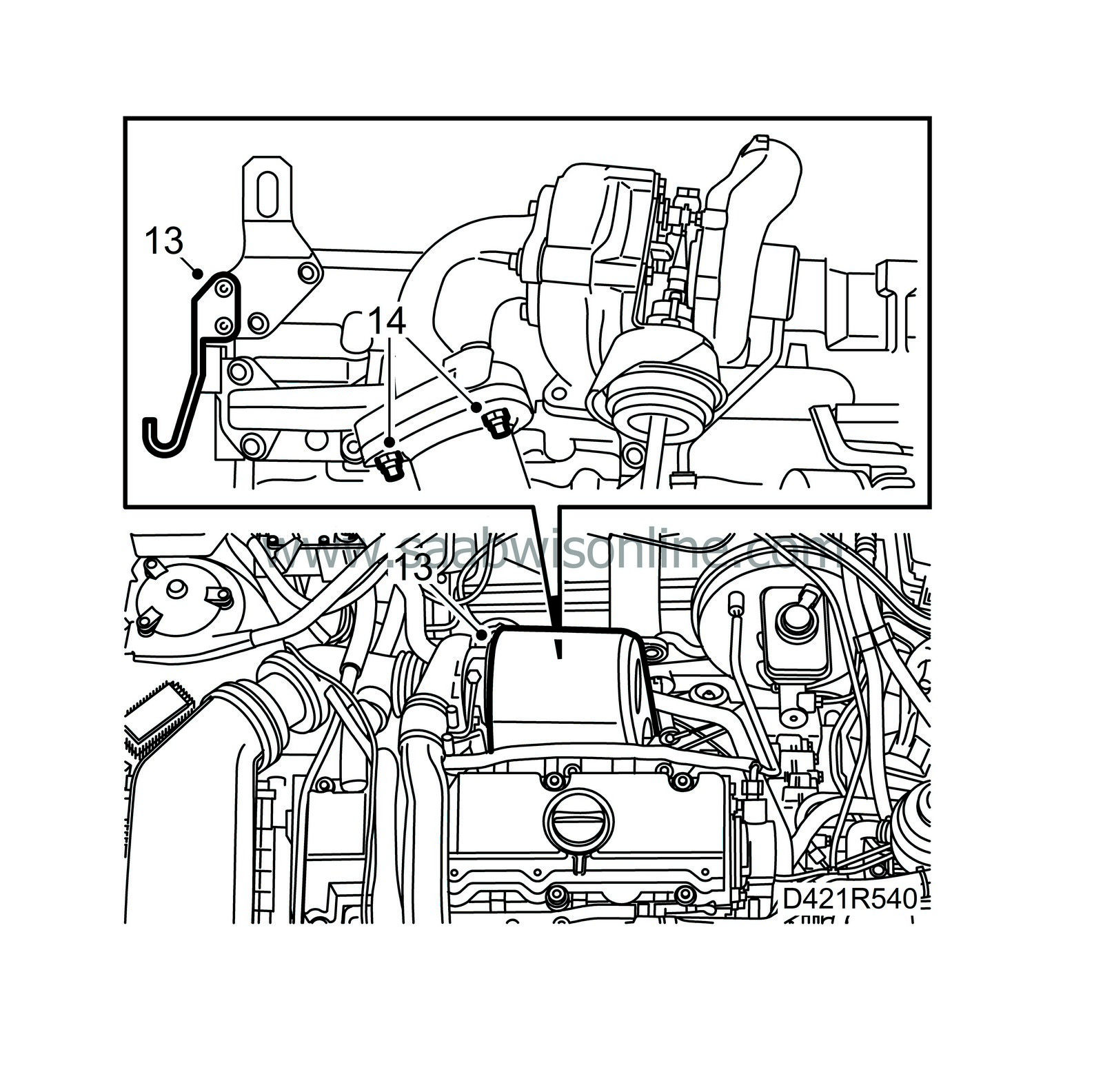

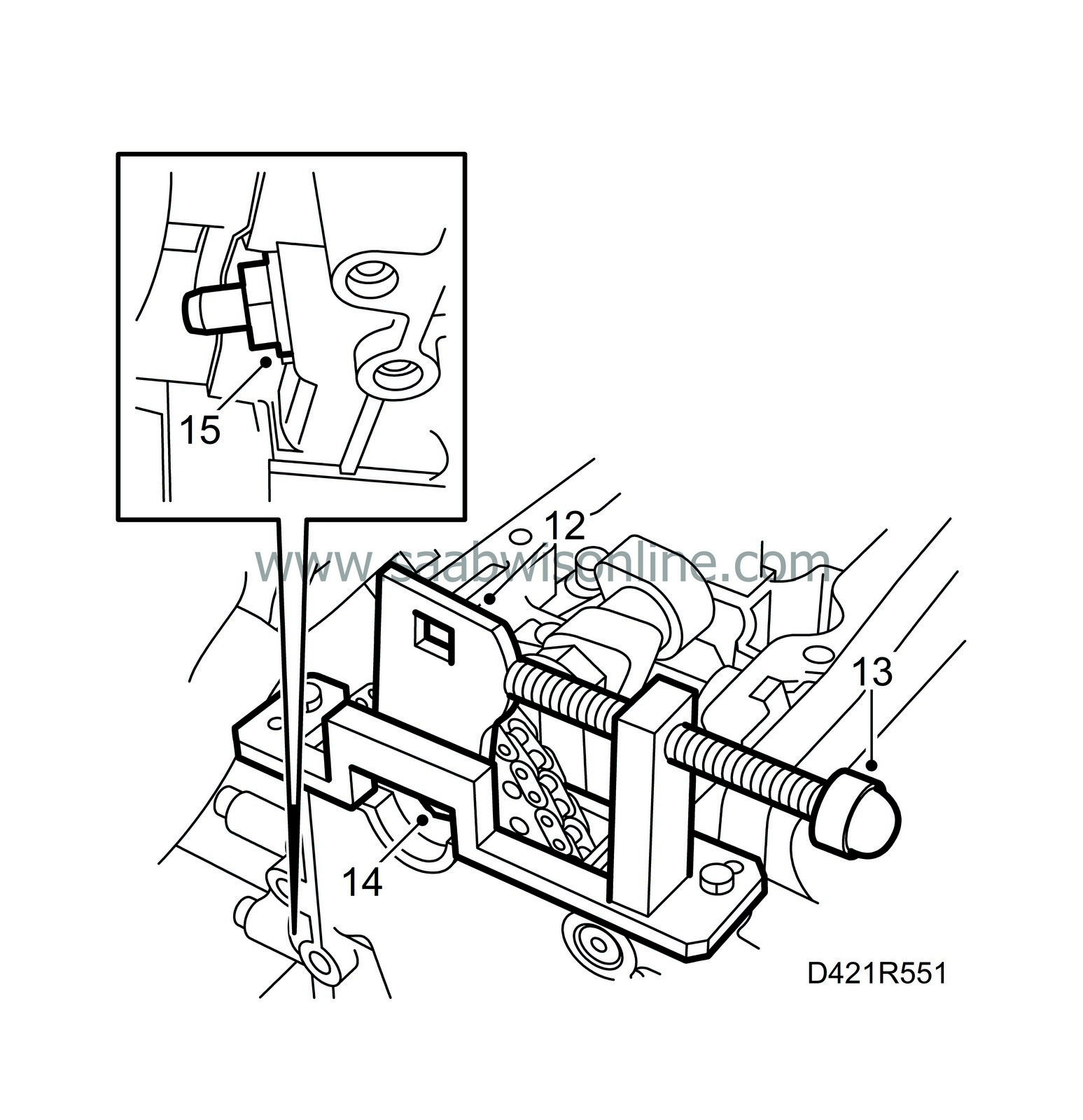

| 13. |

Remove the heat shields from over the turbocharger and exhaust manifold. Undo the bolt securing the lifting eye.

|

|

| 14. |

Remove the nuts from connection between the front exhaust and the turbocharger.

|

|

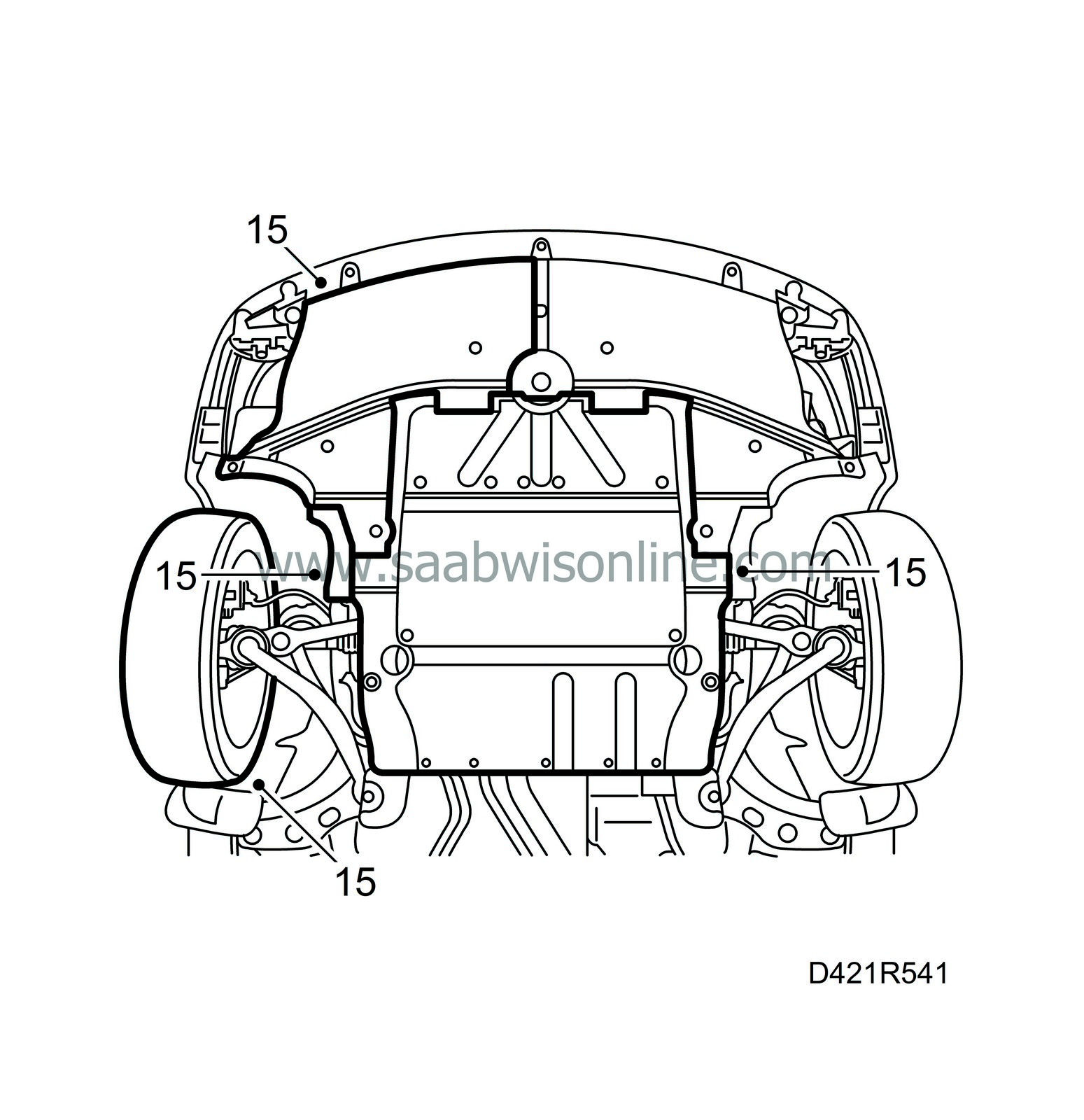

| 15. |

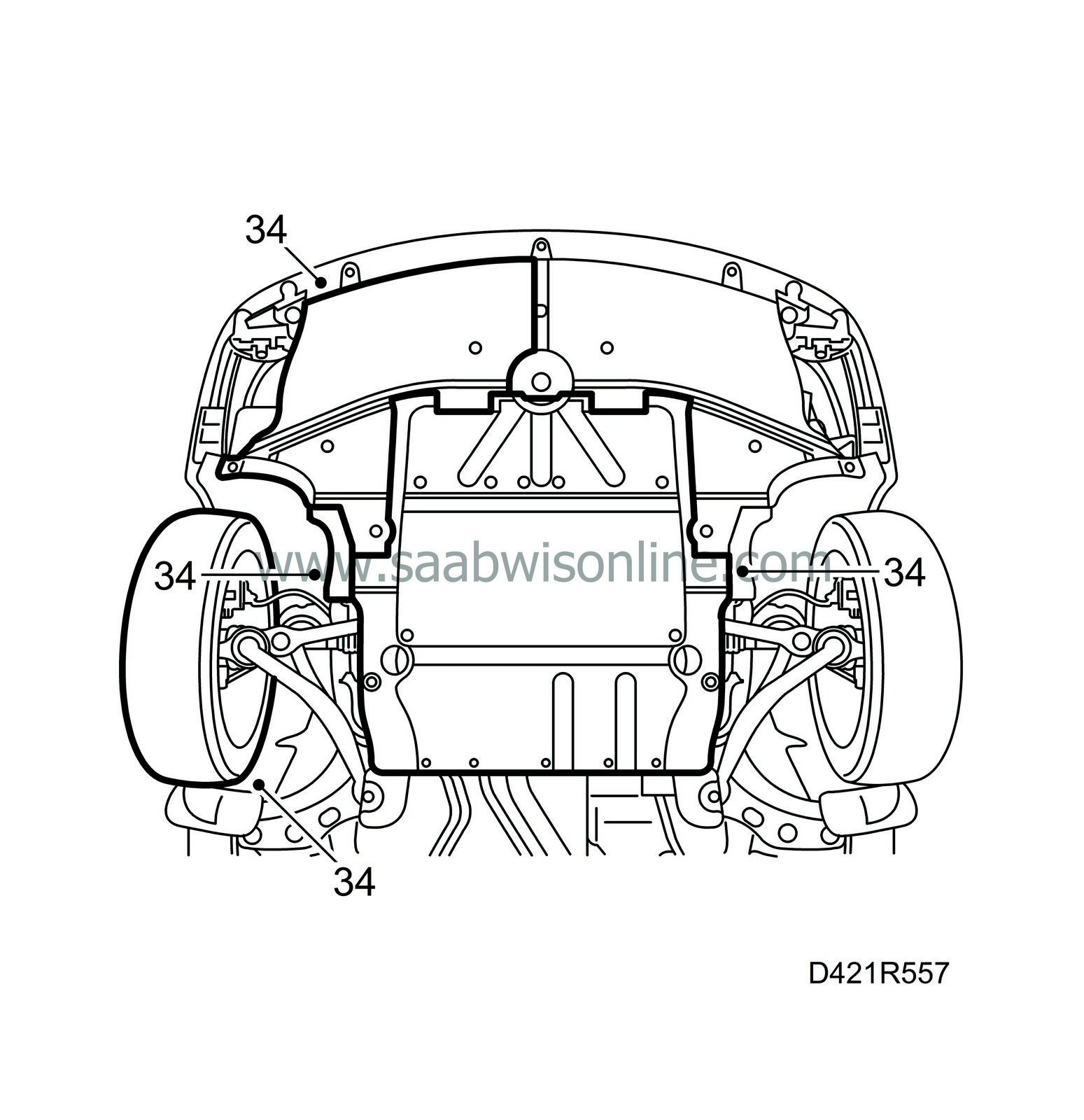

Raise the car and remove the lower engine cover, the right-hand air shield, the cover in the right-hand wheel housing and the front right wheel.

|

|

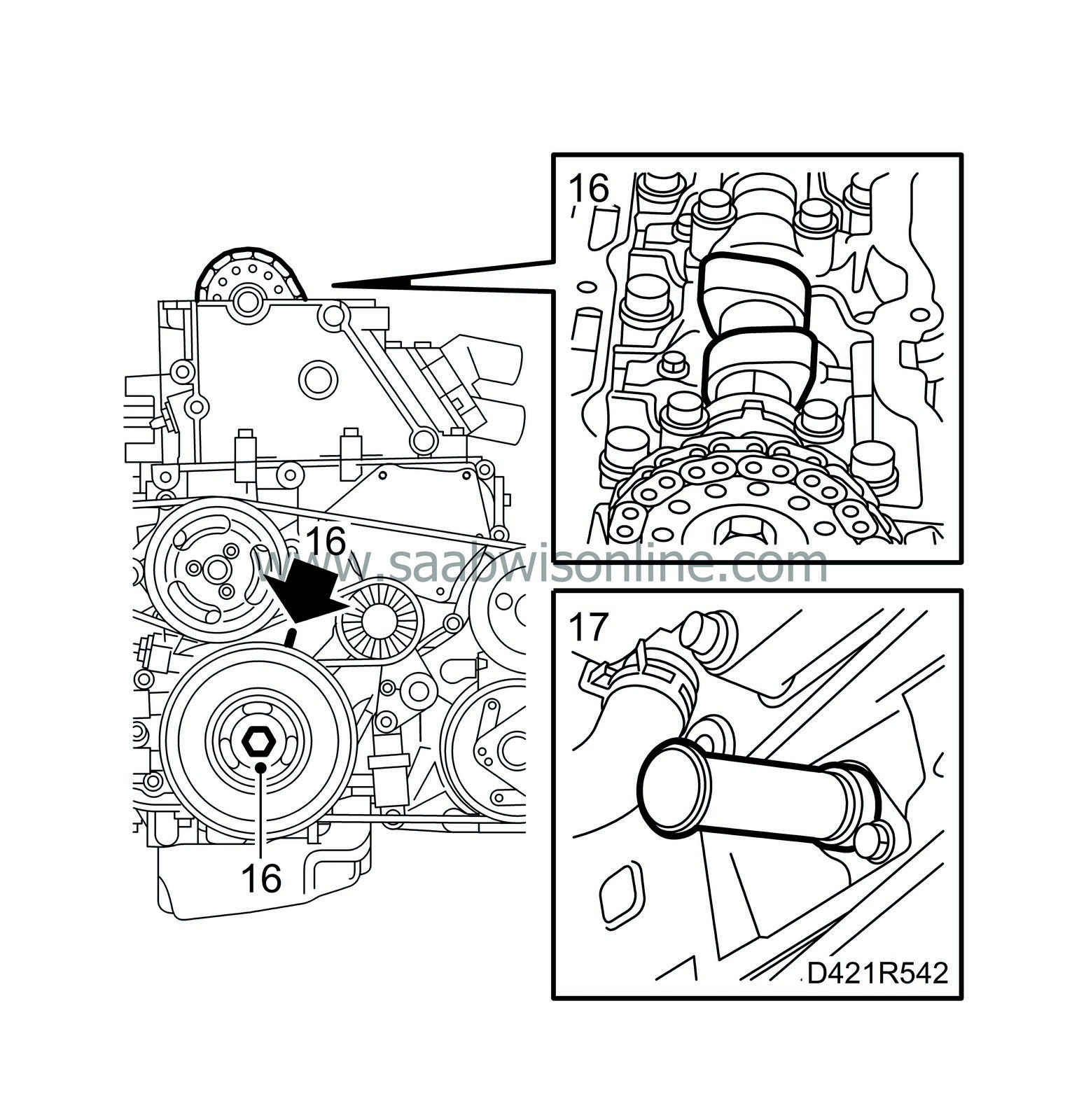

| 16. |

Turn the crankshaft with the centre bolt on the pulley two revolutions until it reaches the mark for top dead centre in cylinder 1. Make sure both cams for cylinder 1 point upwards.

|

|

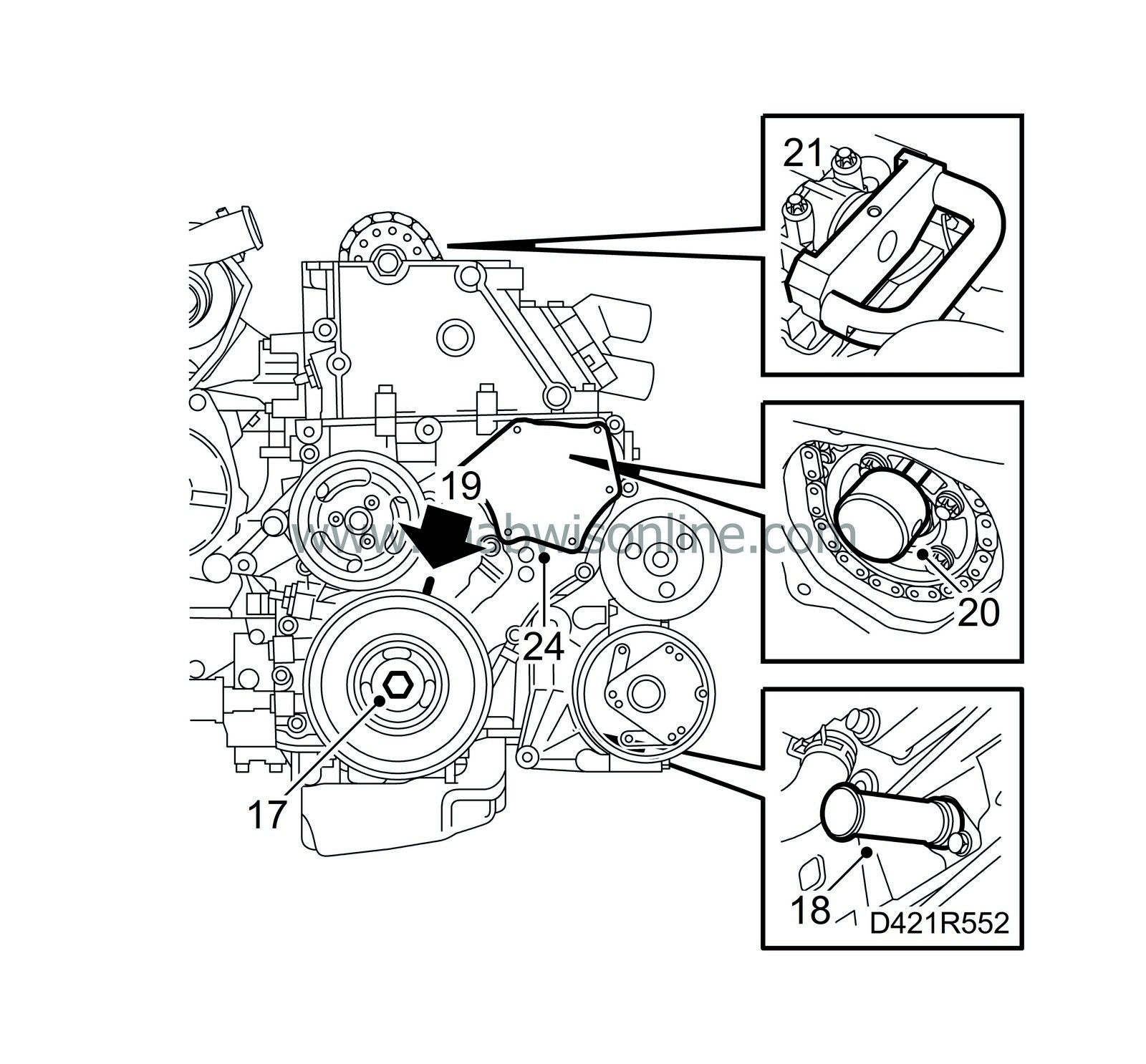

| 17. |

Remove the crankshaft position sensor and O-ring and insert

83 95 352 Adjustment tool, crankshaft

into the hole. Push the tool somewhat inward at the same time as turning the crankshaft to its zero point. The tool will then go into a recess in the crankshaft and lock it.

|

|

| 18. |

Relieve the tension on the belt tensioner by turning it anticlockwise (towards the rear of the car) with a 19 mm spanner and lift off the belt.

|

|

| 19. |

Remove the belt tensioner. Lower the car.

|

|

| 20. |

Place a jack with a wood block under the oil sump, raise the engine until the strain is off the right-hand engine mounting and dismantle the right-hand engine mounting.

|

|

| 21. |

Remove the engine mounting (the lower bolt does not need to be removed completely). Undo the nut on the rear engine pad.

|

|

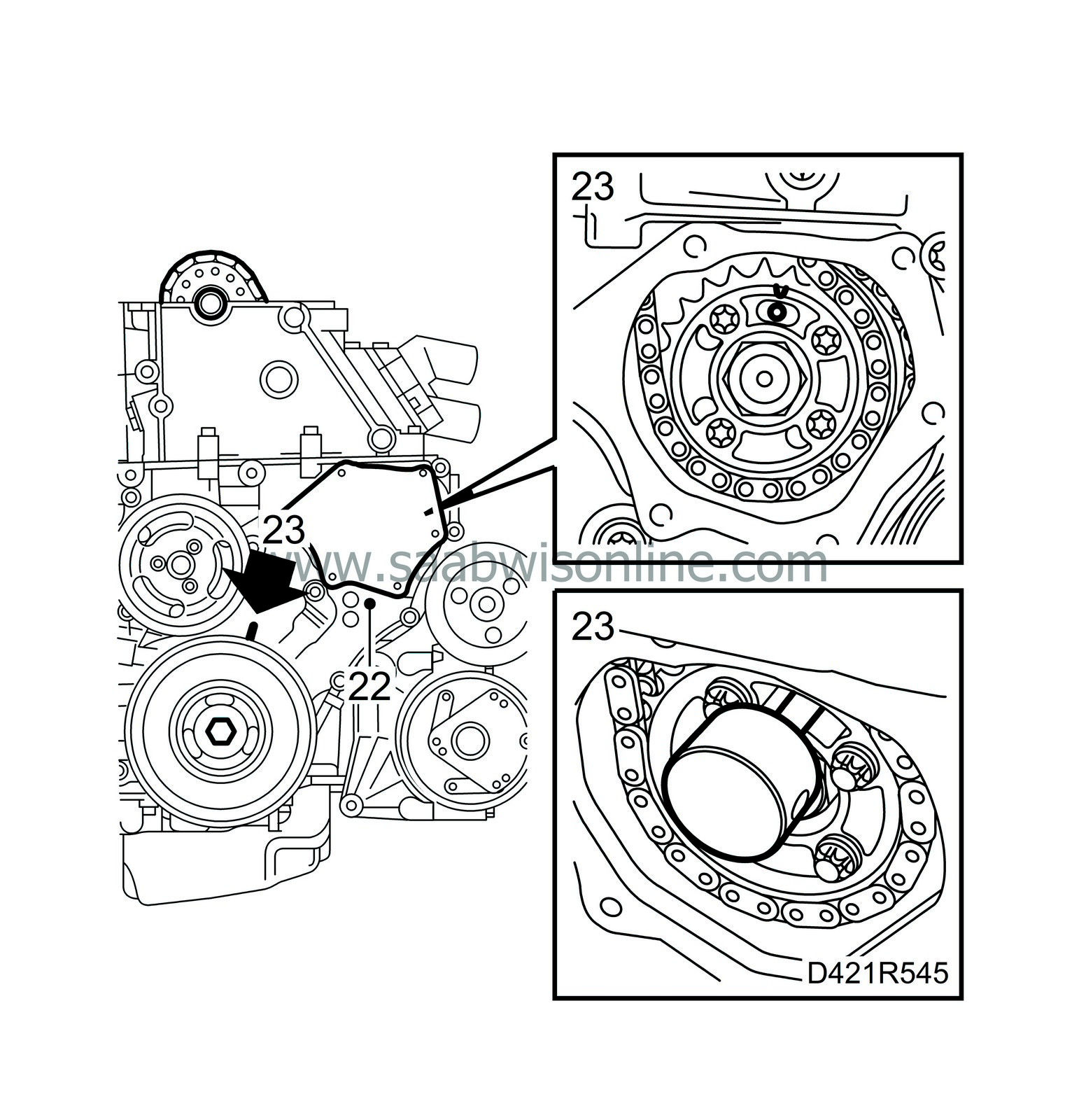

| 22. |

Remove the bolts on the cover, carefully insert a spatula behind the cover and prise it off.

|

||||||||||

| 23. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must also be aligned with the recess in the pump. Fit

83 95 337 Adjustment tool, fuel pump

into the hole.

|

|

| 24. |

Remove all the inspection gauges.

|

|

| 25. |

Dismantle the upper timing chain tensioner.

|

|

| 26. |

Fasten the camshaft chain to the gear.

|

|

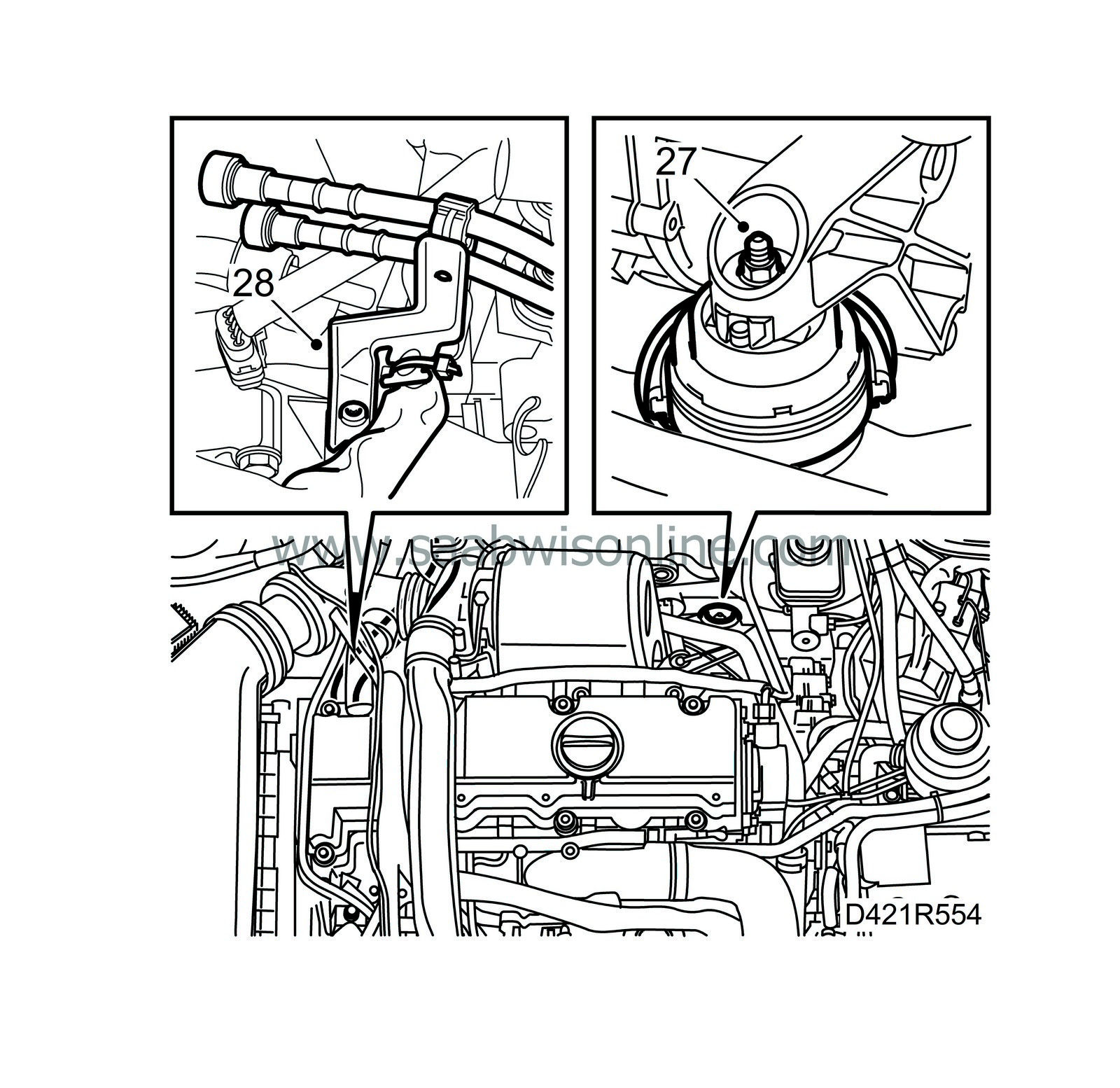

| 27. |

Dismantle the camshaft gear using an open spanner in the hexagonal recess on the camshaft as a backstop.

|

|

| 28. |

Carefully place the chain on one side.

|

|

| 29. |

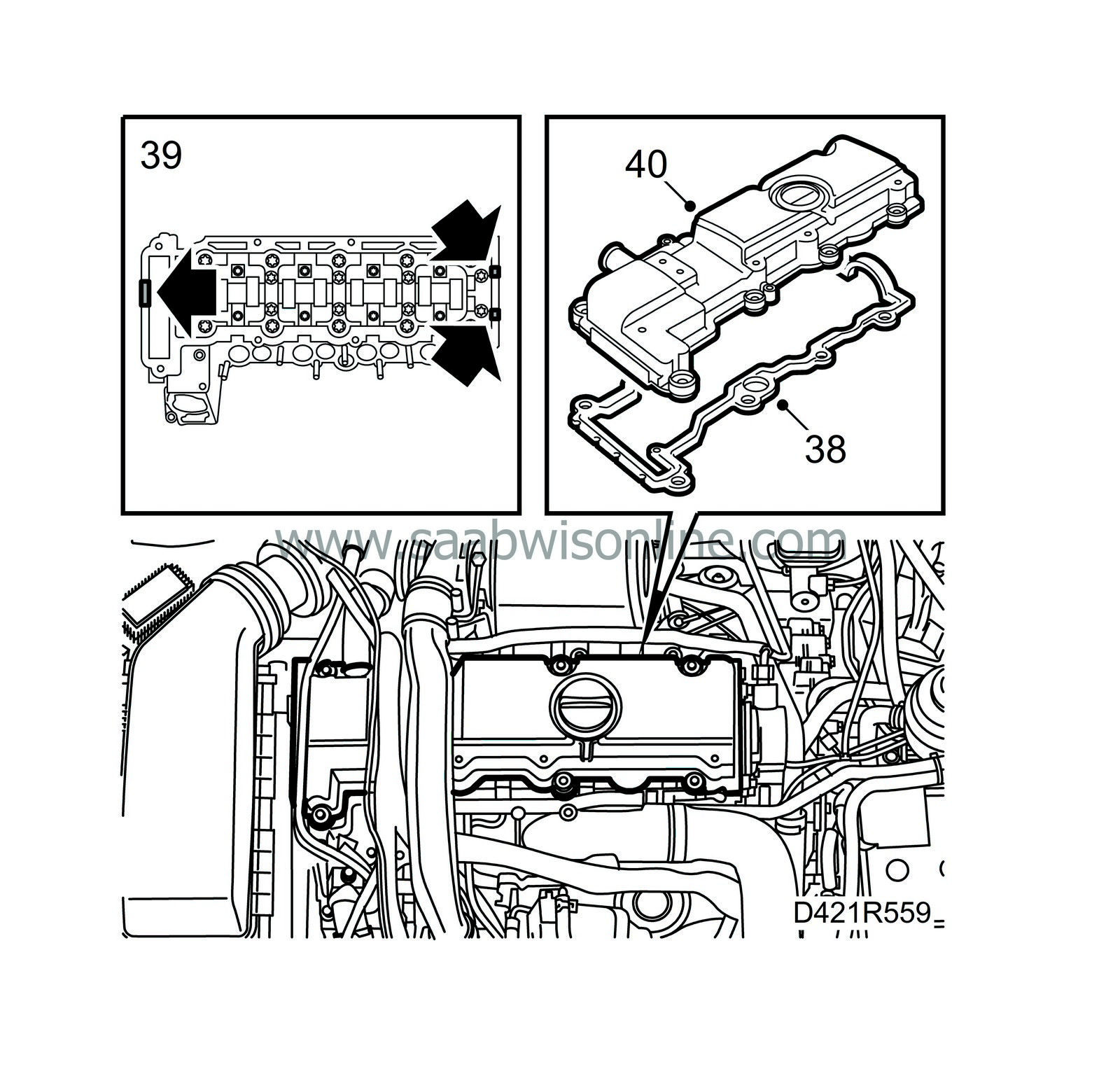

Undo the camshaft bearing cap bolts in stages, 0.5-1 turn in a spiral formation starting with cap number 1.

|

||||||||||

| 30. |

Lift off the camshaft bearing caps and remove the camshaft.

|

||||||||||

| 31. |

If the camshaft is to be changed, the valve bridges must also be replaced.

|

||||||||||

| To fit |

| 1. |

Clean off any gasket remains from the sealing surfaces.

|

|

| 2. |

Check the camshaft and bearing seats for signs of wear and replace as necessary.

|

|

| 4. |

Sparingly apply sealant 87 81 841 to the sealing surfaces of the 5th camshaft bearing cap, see illustration.

|

|

| 5. |

Lubricate the sliding surfaces on the camshaft and valve bridges.

|

|

| 6. |

Position the camshaft with both cams for cylinder 1 pointing up and lay the camshaft bearing caps in their respective positions.

|

|

| 7. |

Tighten the camshaft bearing cap bolts in stages, 0.5-1 turn in a spiral formation starting with cap number 3.

Tightening torque: 20 Nm (15 lbf ft). |

|

| 8. |

Lift up the timing chain and position the camshaft gear so that it runs freely on the camshaft, and fit it with a new bolt. Tighten by hand.

|

|

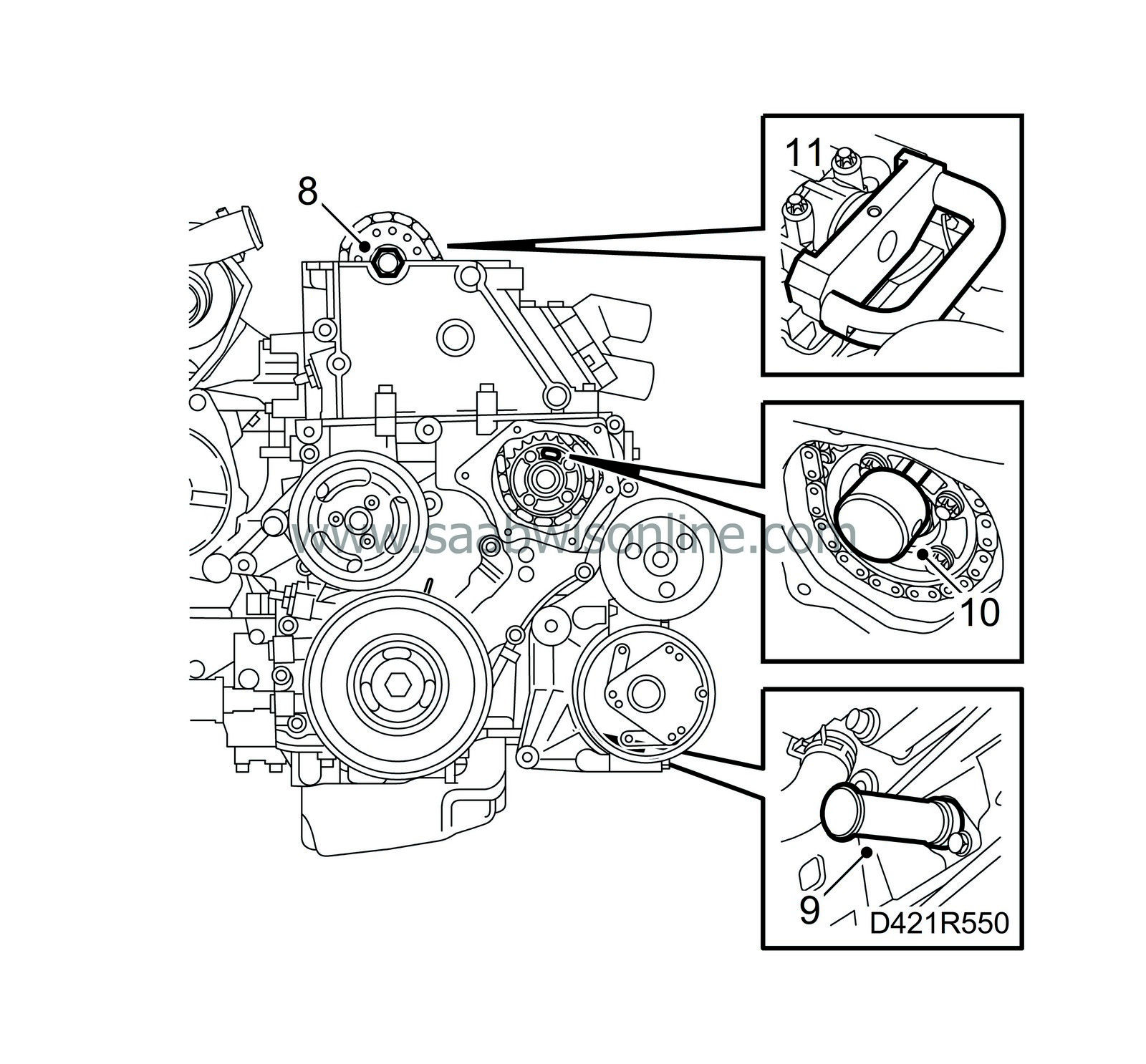

| 9. |

Insert

83 95 352 Adjustment tool, crankshaft

into the crankshaft position sensor hole.

|

|

| 10. |

Insert

83 95 337 Adjustment tool, fuel pump

into the fuel distribution pump's recess.

|

|

| 11. |

Fit

Adjustment tool, camshaft

83 95 386 to the camshaft and cylinder head.

|

|

| 12. |

Cut the cable tie and fit the adapter for

Adjustment tool, timing chain

83 95 394 to the camshaft sprocket. Fit the adjustment tool to the cylinder head.

|

|

| 13. |

Secure the position of the adapter on the camshaft gear by turning it slightly anticlockwise with a ratchet handle. Tighten the adjuster screw on the tool.

|

||||||||||

| 14. |

Tighten the bolt for the camshaft gear using an open spanner as backstop in the hexagonal recess on the camshaft.

Tightening torque 90 Nm (66.5 lbf ft) + 60°. |

|

| 15. |

Fit the chain tensioner for the upper timing chain with a new gasket.

Tightening torque: 60 Nm (44 lbf ft). |

|

| 16. |

Remove all tools and gauges.

|

|

| 17. |

Turn the crankshaft with the centre bolt on the pulley two revolutions until it reaches the mark for top dead centre in cylinder 1. Make sure both cams for cylinder 1 point upwards.

|

|

| 18. |

Insert

83 95 352 Adjustment tool, crankshaft

into the hole for the crankshaft position sensor. Push the tool somewhat inward at the same time as turning the crankshaft to its zero point. The tool will then go into a recess in the crankshaft and lock it.

|

|

| 19. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must also be aligned with the recess in the pump.

|

|

| 20. |

Insert

83 95 337 Adjustment tool, fuel pump

into the fuel distribution pump's recess.

|

|

| 21. |

Fit

Adjustment tool, camshaft

83 95 386 to the camshaft and cylinder head. If the gauge does not fit, the engine valve timing must be adjusted. See

Adjusting valve timing.

|

|

| 22. |

Remove all the inspection gauges.

|

|

| 23. |

Cover the opening in the timing cover with a lint-free cloth and remove any remains from the old gasket from the sealing surface. Clean also the sealing surface on the pump cover.

|

|

| 24. |

Apply a string of sealing compound 87 81 841 about 2 mm thick to the pump cover, remove the cloth from the timing cover and fit the pump cover.

Tightening torque: 6 Nm (4.5 lbf ft).

|

|

| 25. |

Fit the right-hand engine mounting bracket on the engine.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 26. |

Lower the engine and tighten the right-hand engine mounting.

Tightening torque: 47 Nm (35 lbf ft). |

|

| 27. |

Tighten the nut on the rear engine mounting.

Tightening torque: 47 Nm (35 lbf ft).

|

|

| 28. |

Put back the wiring harness and fuel pipe mounting on the engine mounting bracket.

|

|

| 29. |

Apply Molycote 1000 to the turbocharger studs. Tighten the nuts.

Tightening torque 25 Nm (18 lbf ft)

|

|

| 30. |

Fit the heat shields over the turbocharger and exhaust manifold. Tighten the bolt on the lifting eye.

|

|

| 31. |

Raise the car and fit the crankshaft position sensor with a new O-ring.

Tightening torque: 8 Nm (6 lbf ft). |

|

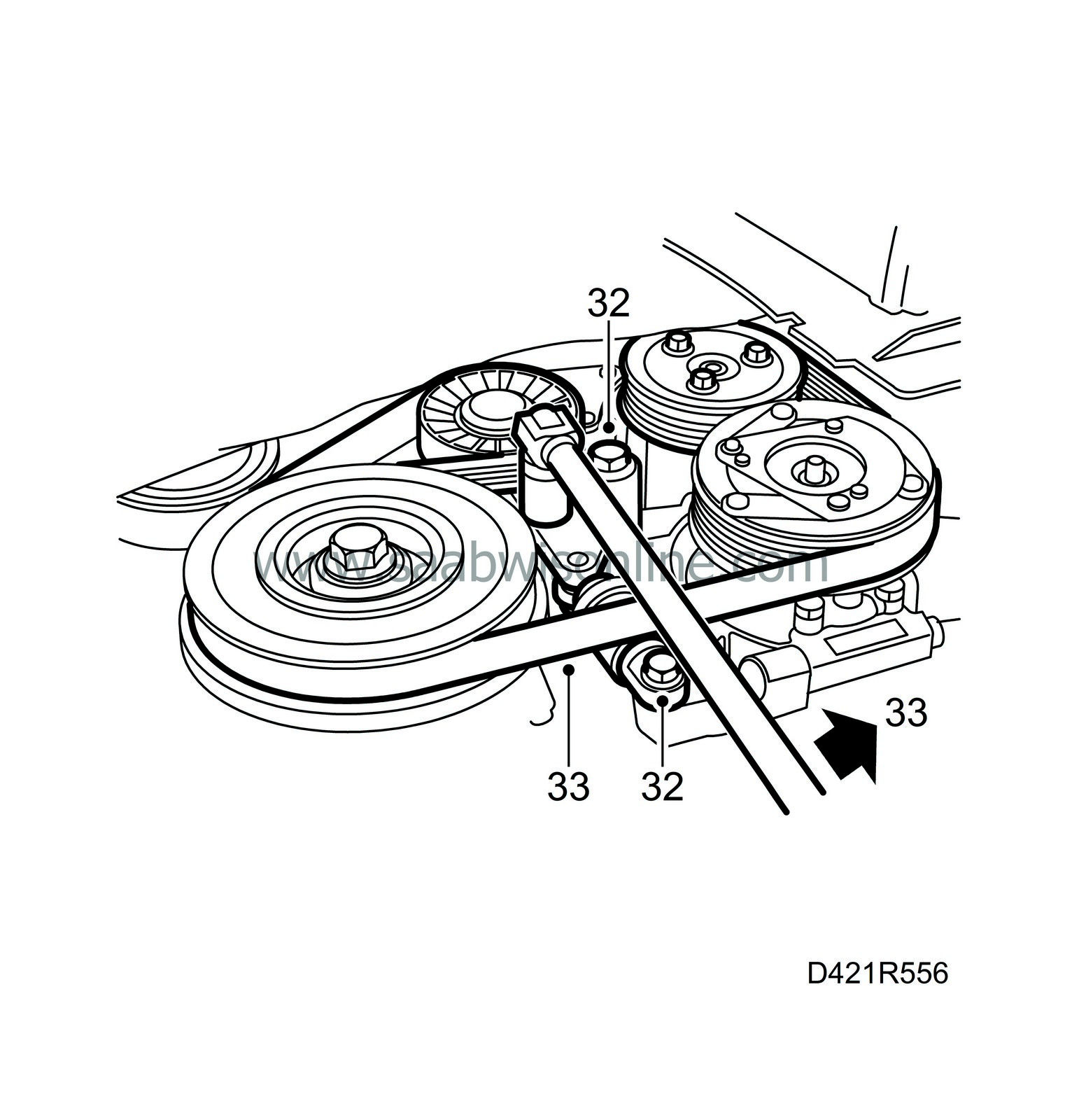

| 32. |

Fit the belt tensioner, tightening the top bolt first.

Tightening torque: 42 Nm (31 lbf ft). Tighten the bottom bolt. Tightening torque: 23 Nm (17 lbf ft).

|

|

| 33. |

Fit the multigroove V-belt on all the pulleys. Relieve the tension on the belt tensioner by turning it anticlockwise (towards the rear of the car) with a 19 mm spanner and fit the belt on its pulley. Make sure the belt is positioned correctly on all the pulleys.

|

|

| 34. |

Refit the lower engine cover and the wheel.

Tightening torque, wheels 110 Nm (81 lbf ft). Lower the car to the floor.

|

|

| 35. |

Fit a new gasket on the vacuum pump and fit the pump together with the adapter.

Tightening torque: 8 Nm (6 lbf ft). |

||||||||||

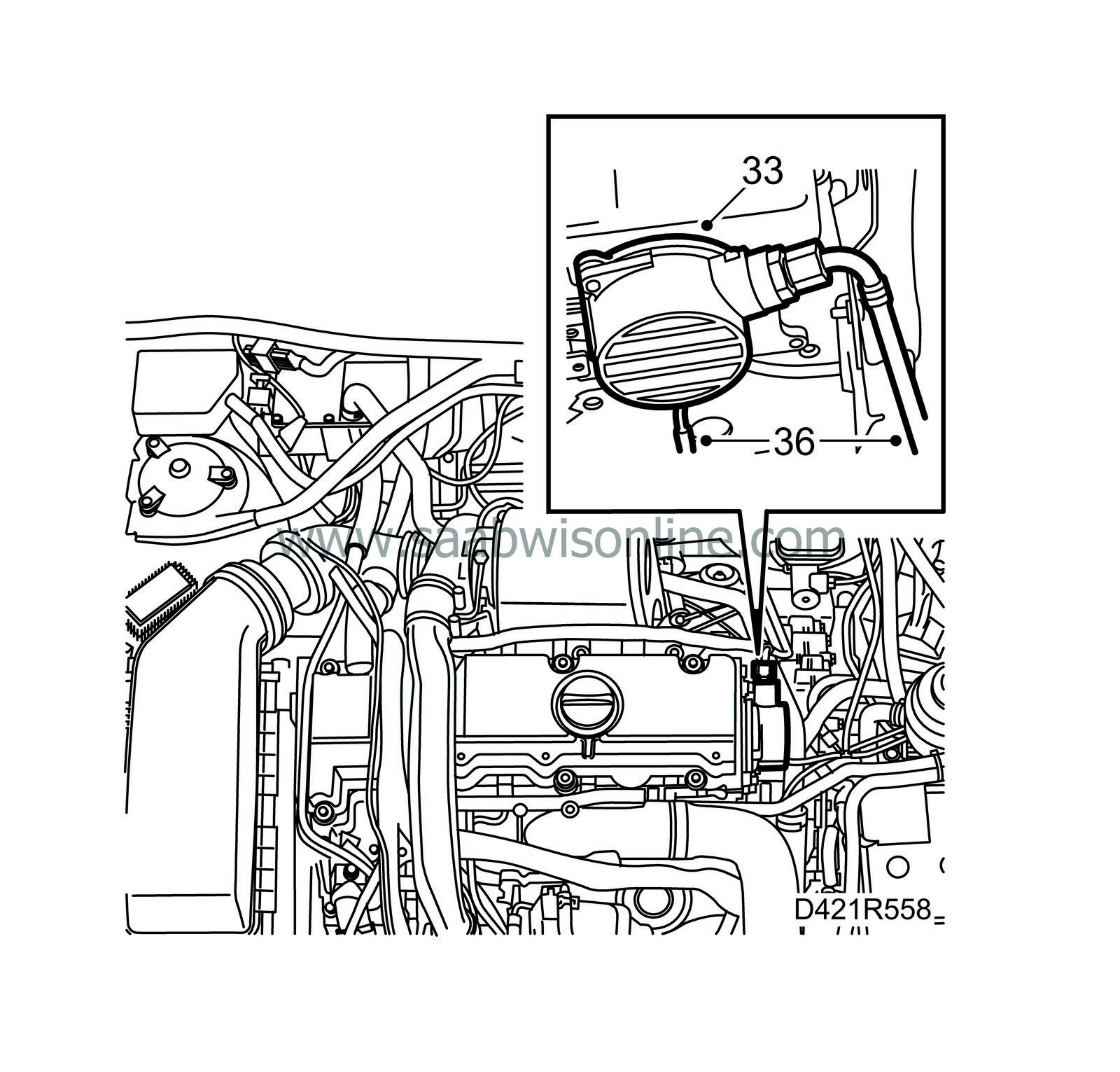

| 36. |

Connect the vacuum hose for the brake servo to the vacuum pump.

Tightening torque: 18 Nm (13 lbf ft). Connect the hose on the bottom of the vacuum pump.

|

|

| 37. |

Clean any gasket remains from the sealing surfaces on the camshaft cover.

|

|

| 38. |

Fit a new gasket to the camshaft cover.

|

|

| 39. |

Apply sealing compound 87 81 841 to the sealing surface, see illustration.

|

|

| 40. |

Position the transmission cover on the cylinder head and tighten the bolts.

Tightening torque: 8 Nm (6 lbf ft). |

|

| 41. |

Fit the bracket to the camshaft cover.

|

|

| 42. |

Press the fuel lines back into their mountings on the cylinder head and fit the wiring harness duct to the throttle body.

|

|

| 43. |

Plug in the pressure/temperature sensor and the timing sensor.

|

|

| 44. |

Fit the charge air pipe.

|

|

| 45. |

Connect the hose to the throttle body.

|

|

| 46. |

Fit the air cleaner along with the mass air flow sensor and hoses. Plug in the mass air flow sensor.

|

|

| 47. |

Connect the crankcase ventilation hose to the camshaft cover.

|

|

| 48. |

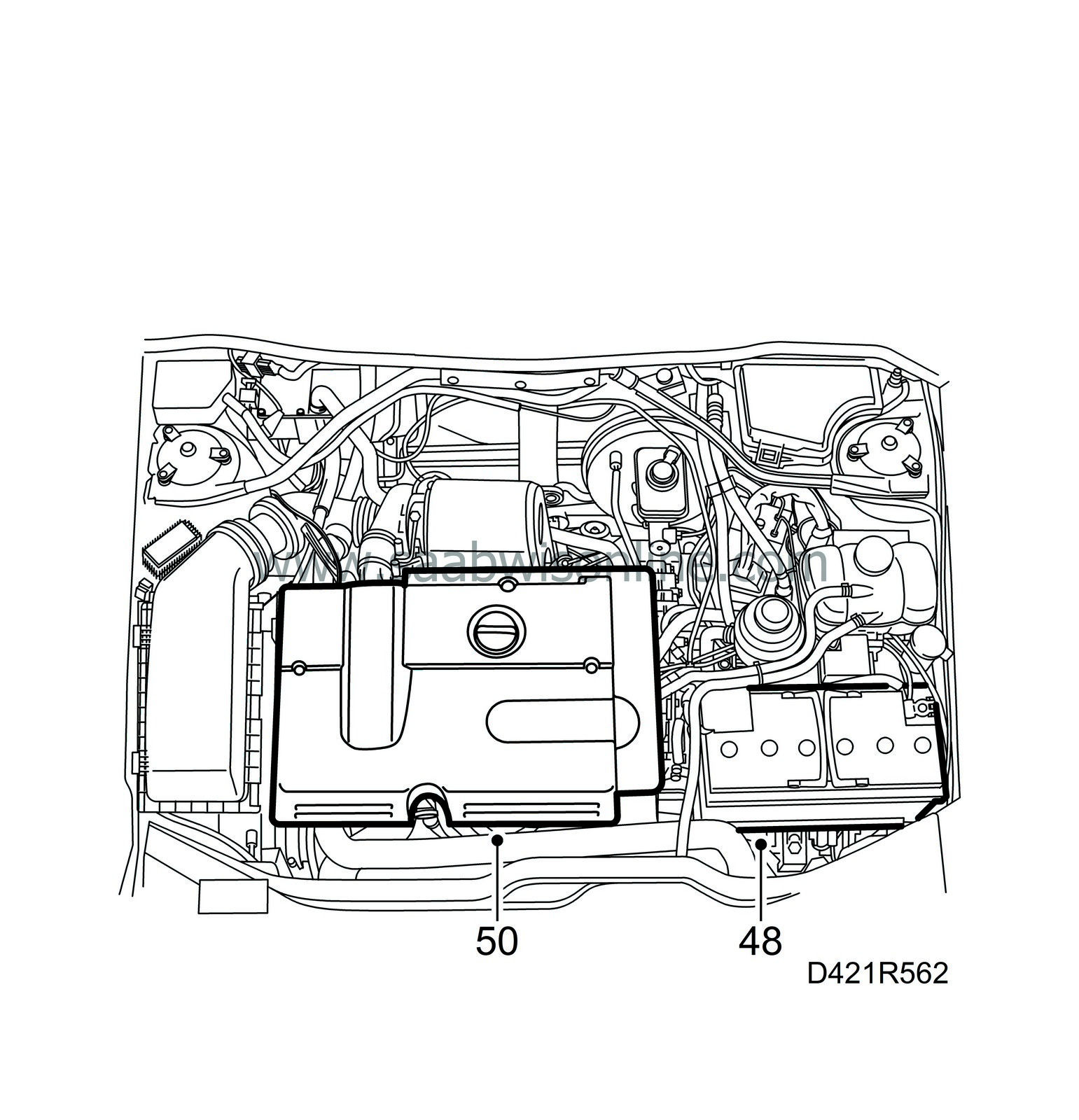

Connect the fuel lines.

|

|

| 49. |

Connect the negative cable to the battery.

|

|

| 50. |

Restore the engine bay to its original condition. Bleed the fuel system as described under

Bleeding the fuel lines

|

|

| 51. |

Refit the engine cover.

|

|

| 52. |

Adjust the clock in the car and press 5 times on the remote control lock/unlock button.

|

|

| 53. |

Enter the radio code, if applicable.

|

|