Bumper and spoiler, deep scratches and cracks

| Bumper and spoiler, deep scratches and cracks |

| 1. |

Clean the component. It is important to insure that there is no gravel or other particles in the welding area.

|

|

| 2. |

Clean the area to be repaired with Teroson FL cleaner.

|

|

| 3. |

Identify the type of plastic. See

Plastic codes, temperature and welding wire

or

Plastic code table

.

|

|

| 4. |

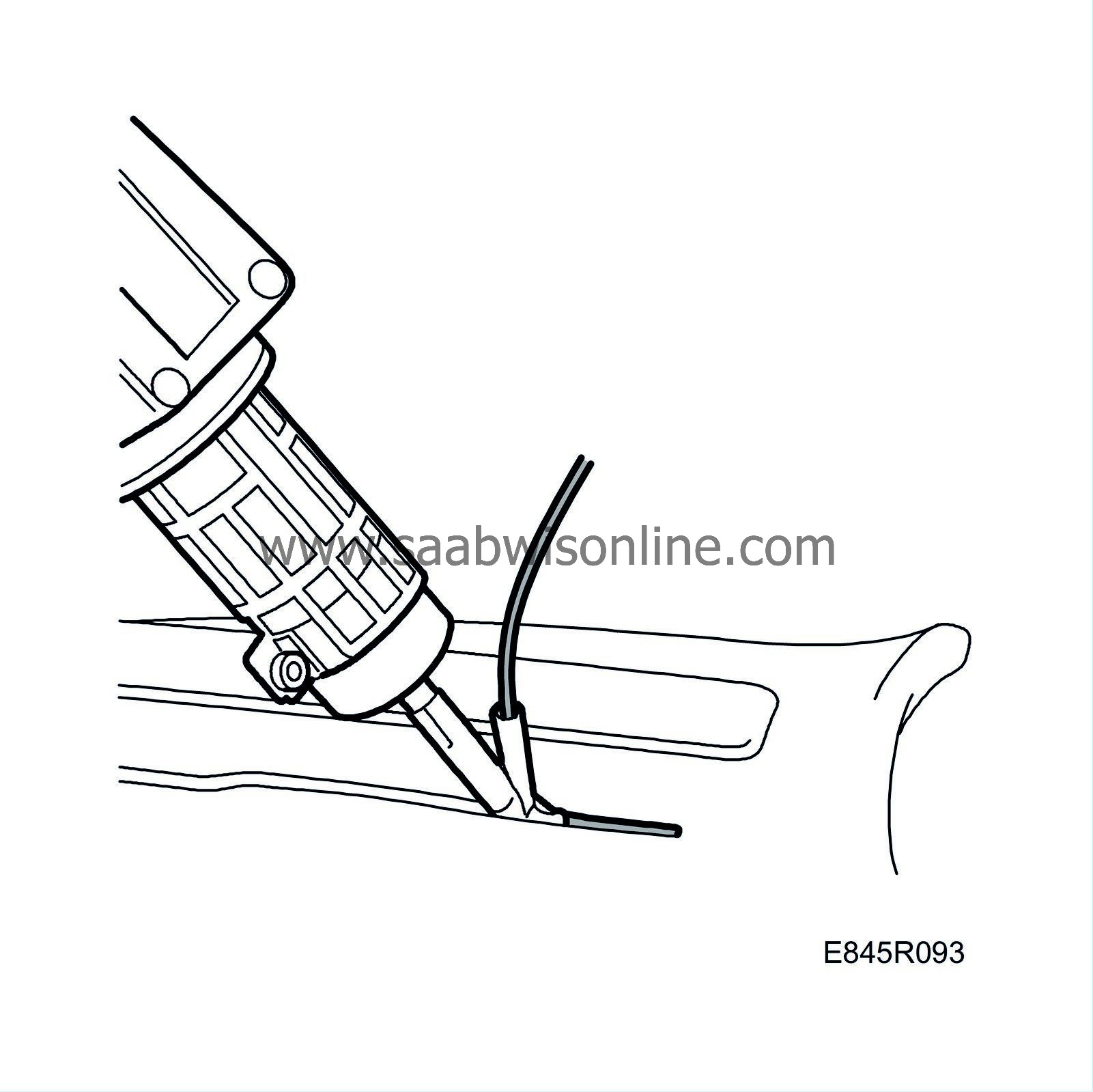

Select the correct welding wire and set the welding gun to an operating temperature appropriate for the plastic type. See

Plastic codes, temperature and welding wire

|

|

| 5. |

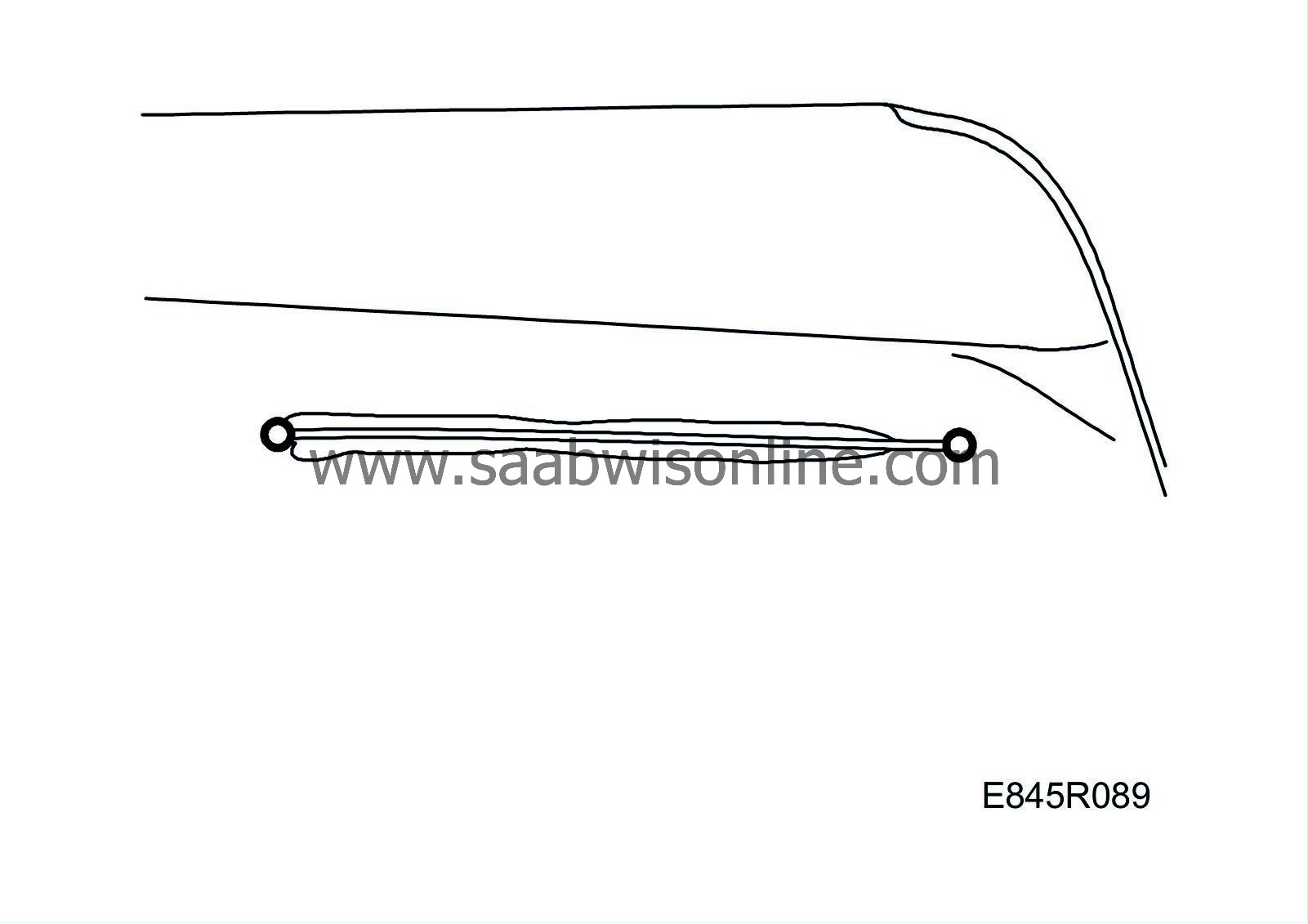

If the damage is a crack, first drill at the ends so the crack does not spread. Use a 3.5 mm bit to drill a hole at each end of the crack.

|

|

| 6. |

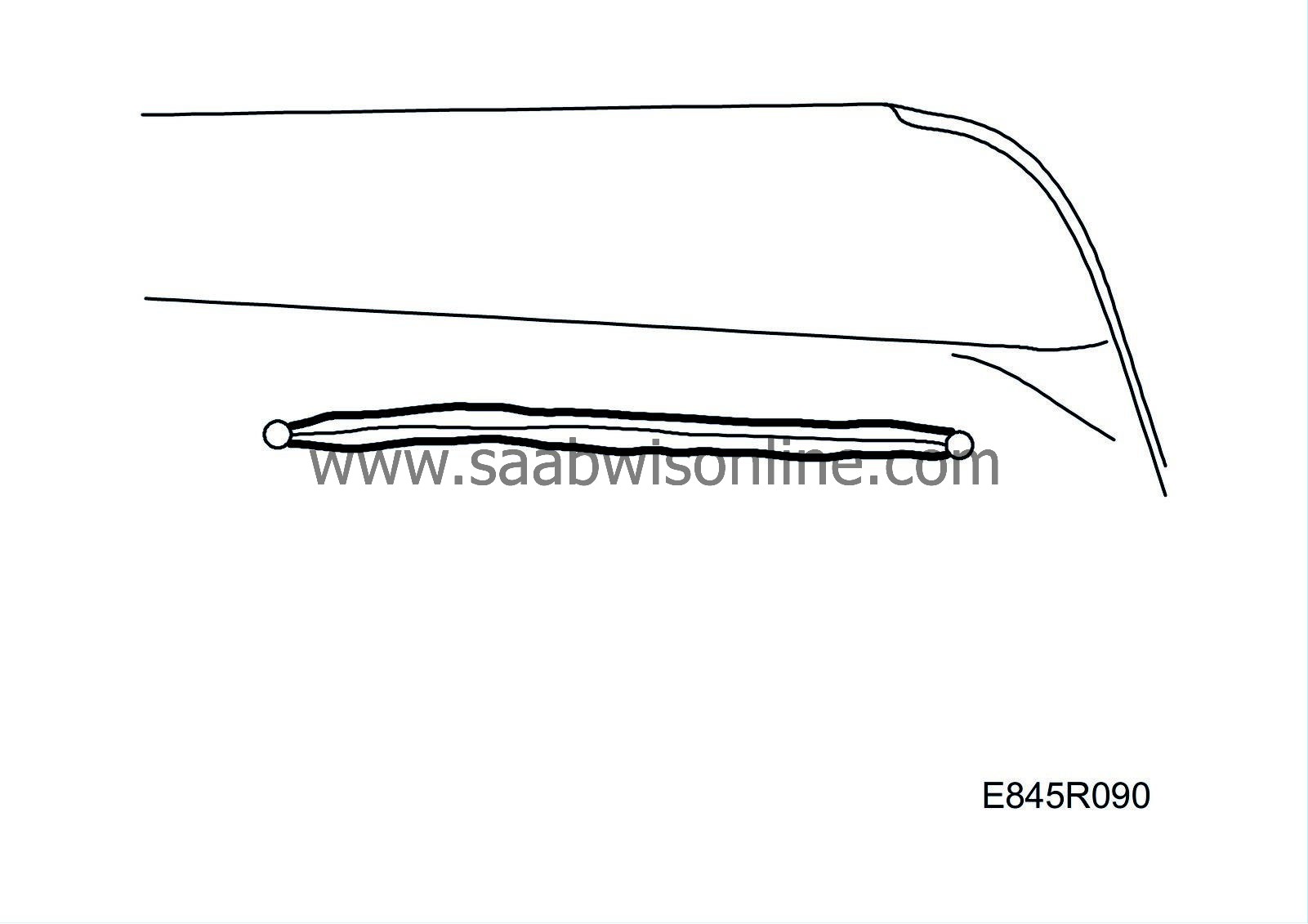

Cut a 90° V-joint on the back. Use a low-speed machine.

|

|

| 7. |

Set the welding gun to an operating temperature appropriate for the plastic type. See

|

|

| 8. |

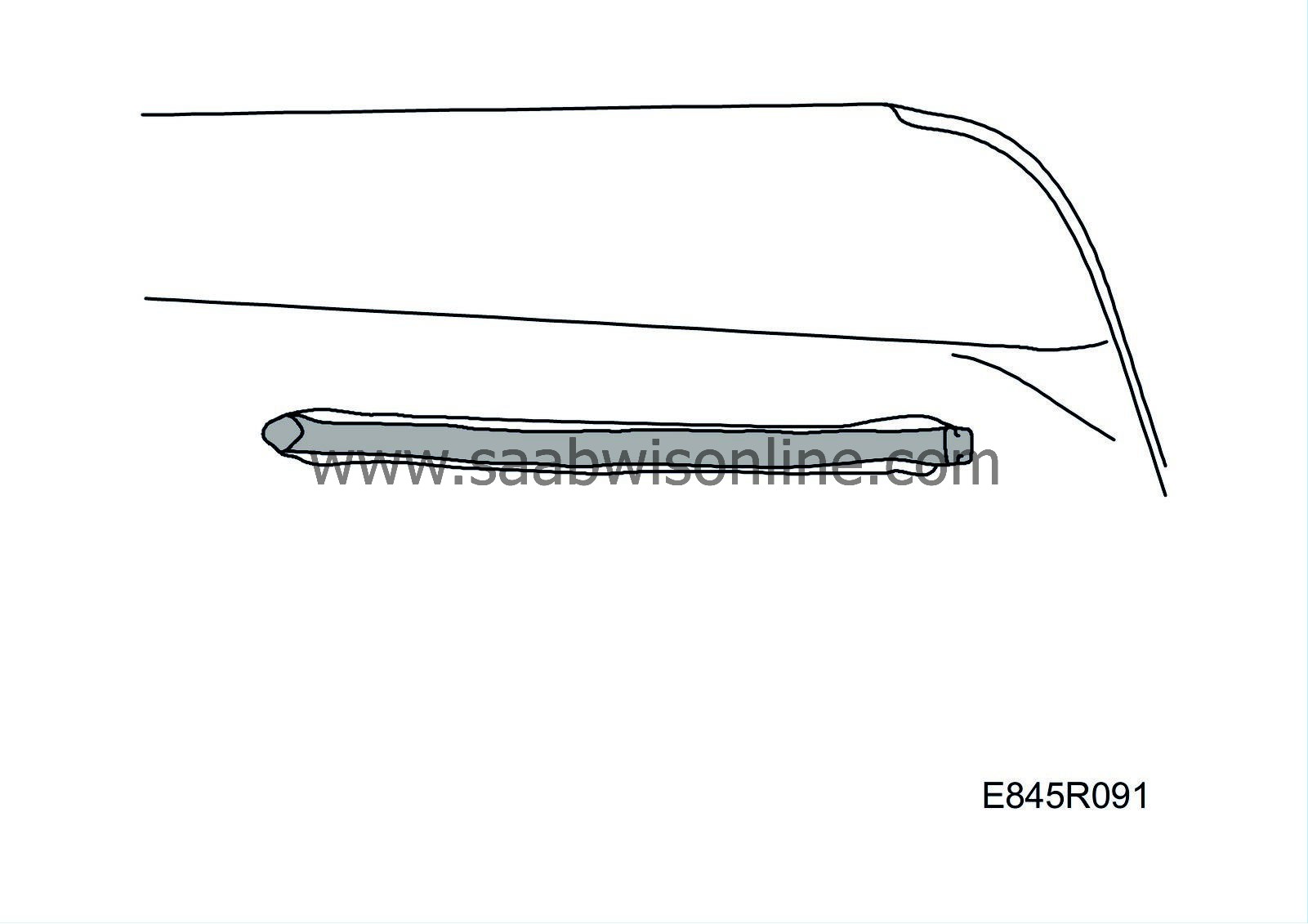

Weld the crack on the back.

|

|

| 9. |

Grind away any paint around the damaged area on the front.

|

|

| 10. |

Check the operating temperature of the gun.

|

|

| 11. |

Weld the front using welding wire.

|

|

| 12. |

Allow the welded area to cool.

|

|

| 13. |

Grind away excess welding material from the welded area.

|

|

| 14. |

Carry out final steps 1 - 10. See

Bumper, scratches and scrapes

.

|

|