Diesel pump and control module (595)

|

|

Diesel pump and control module (595)

|

Warning

Warning

|

|

As removing the fuel pump involves working on the car's fuel system, the following points must be observed:

|

|

|

|

|

|

|

•

|

Ensure good ventilation! If there is approved ventilation for extraction of fuel fumes then this must be used.

|

|

•

|

Wear protective gloves! Prolonged exposure of the hands to fuel can cause irritation of the skin.

|

|

•

|

Have a fire extinguisher class BE at hand! Be aware of the risk for sparks, i.e. in connection with breaking circuits, short-circuiting, etc.

|

|

Important

|

|

ESD-SENSITIVE COMPONENT

|

|

Earth yourself by touching the car body before plugging in / unplugging components.

Do not touch the component pins

. Read

Before removing a control module

before changing a control module.

|

|

|

|

1.

|

Undo the expansion tank cap to release any overpressure.

|

|

3.

|

Remove the front right wheel.

|

|

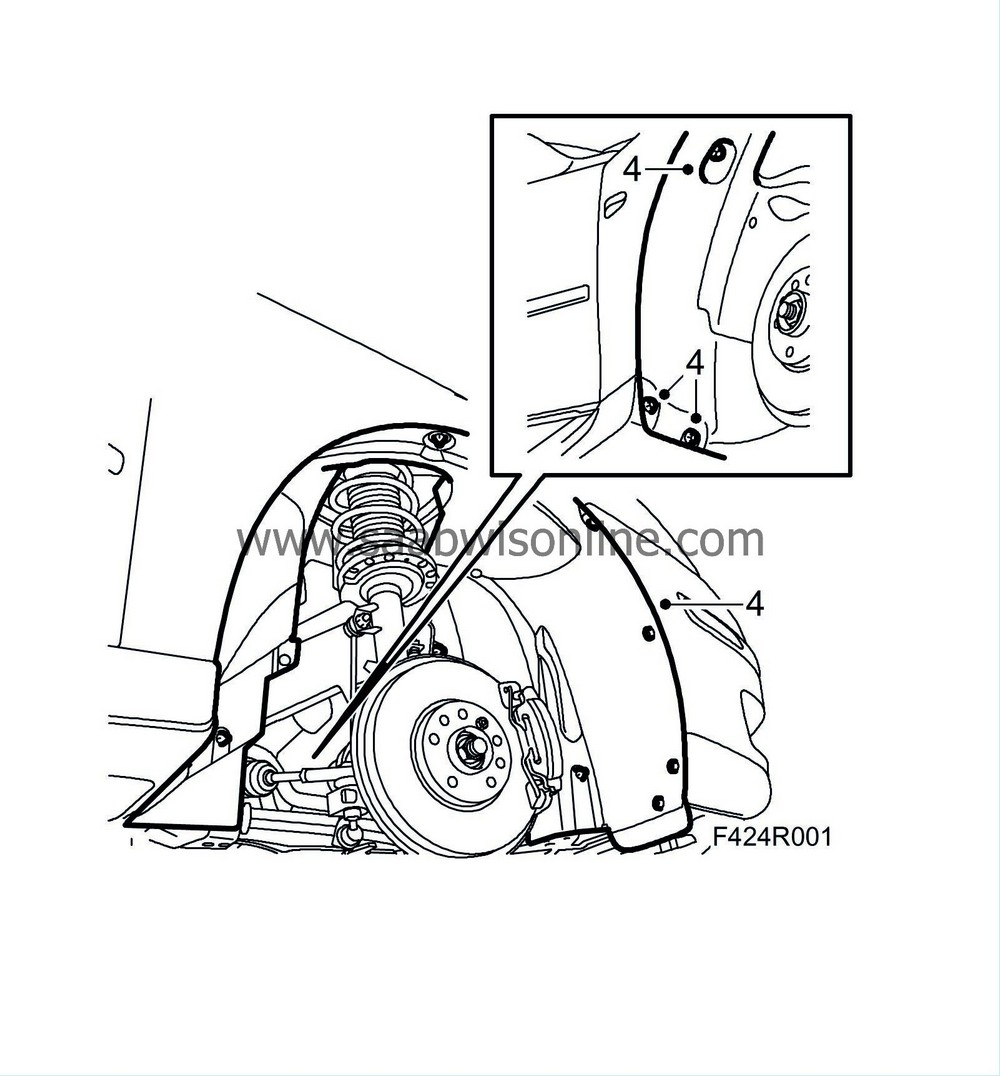

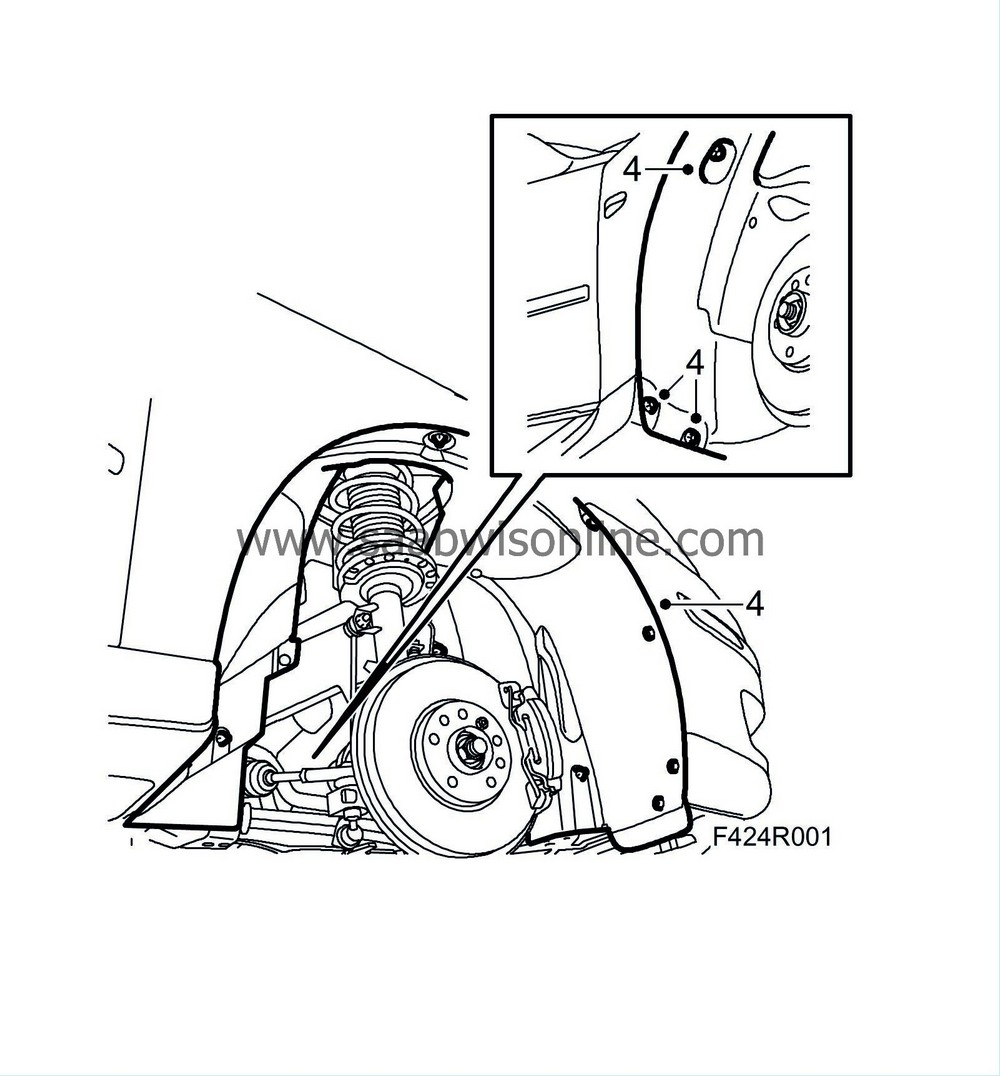

4.

|

Remove the right-hand wing liner.

|

|

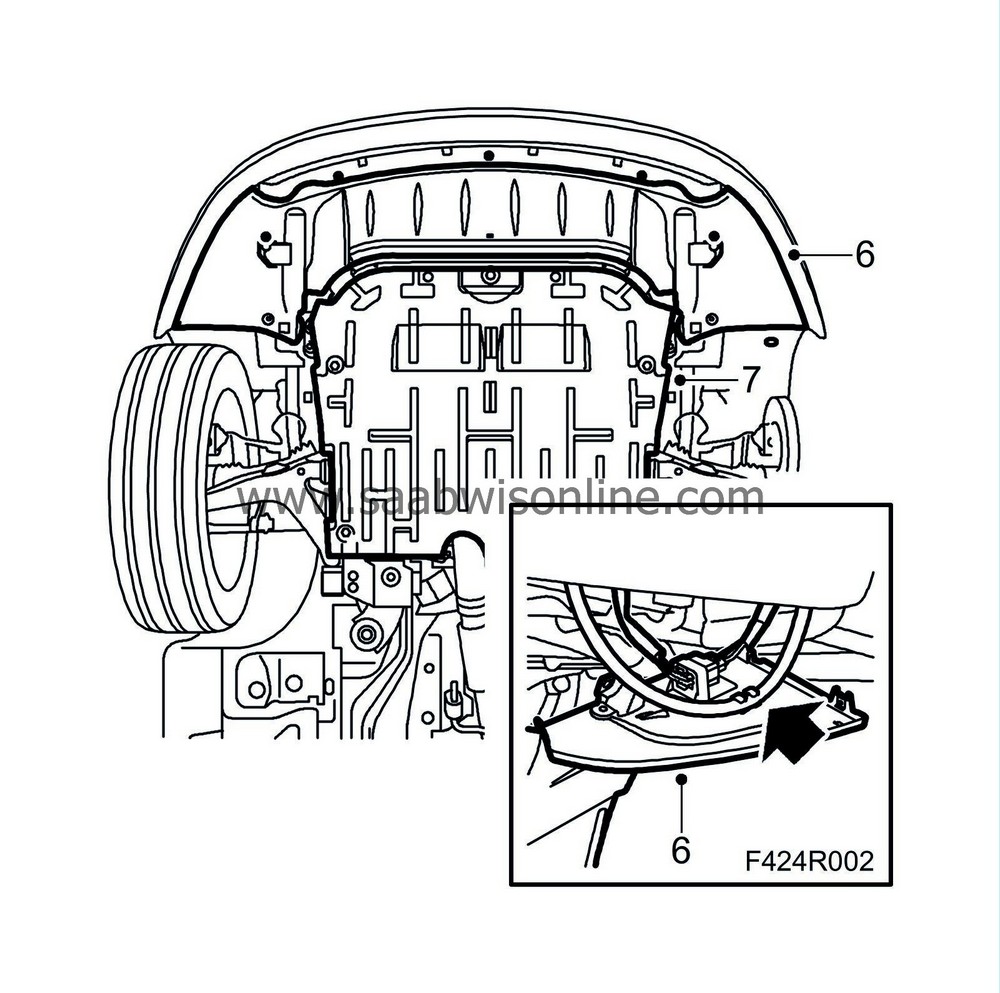

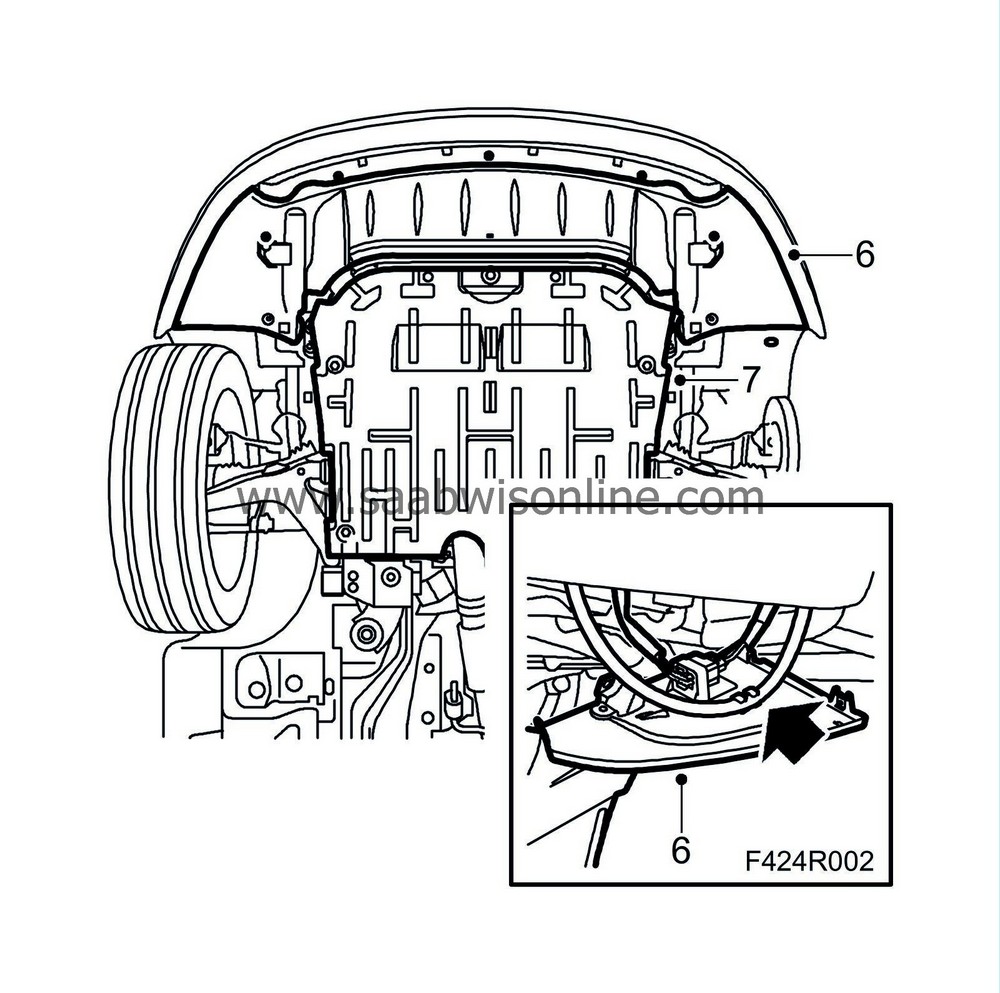

6.

|

Remove the front spoiler shield. Disconnect the headlight washer hose and unplug and remove the connector.

|

|

7.

|

Remove the lower engine cover.

|

|

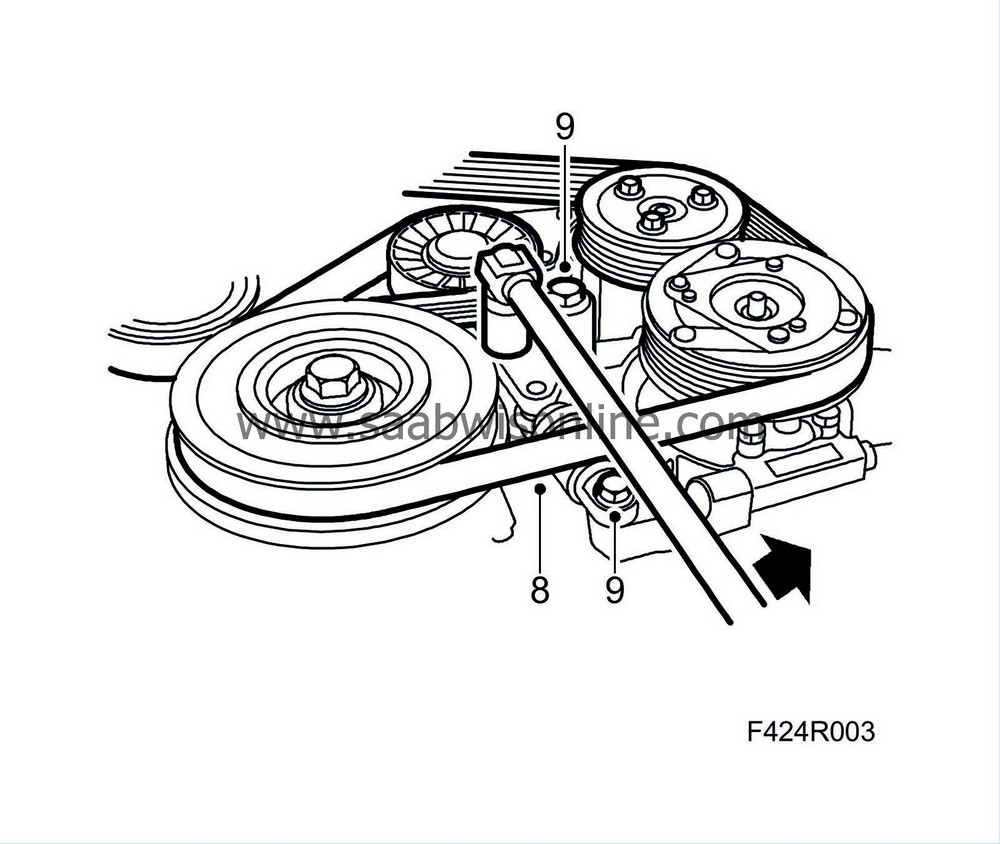

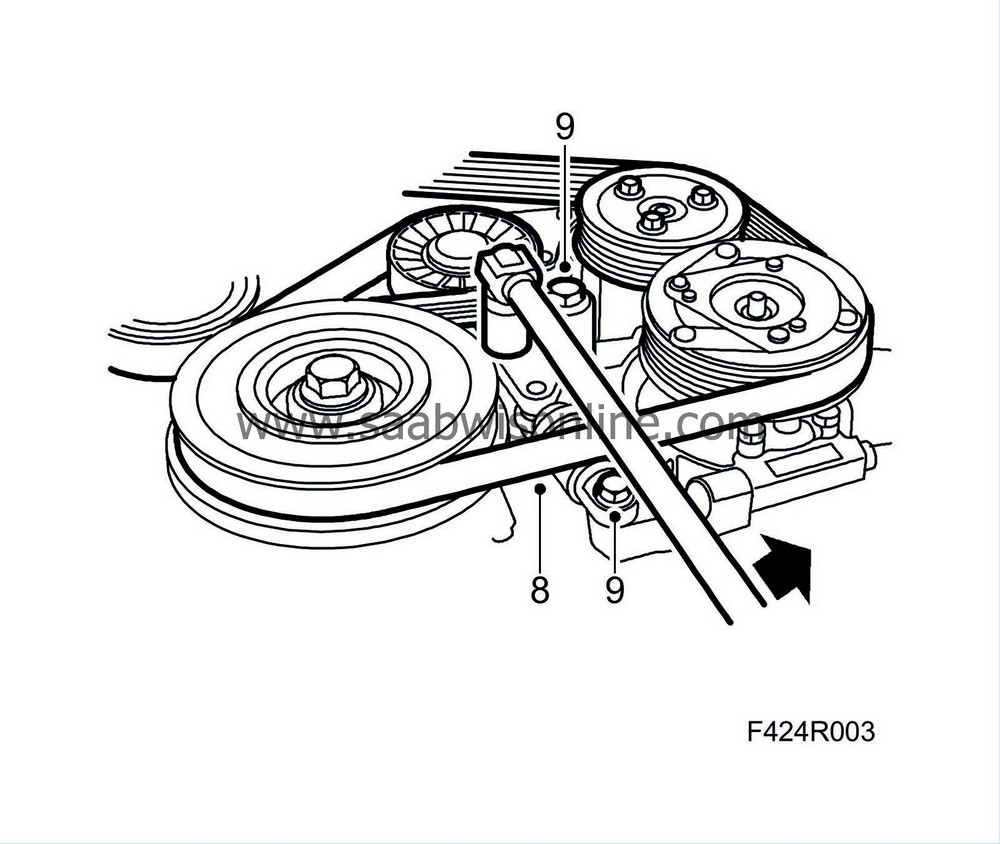

8.

|

Mark the belt's direction of rotation. Detension and remove the poly-V-belt.

|

|

9.

|

Remove the belt tensioner. Place the belt tensioner standing upright as marked.

|

|

10.

|

Place a receptacle under the car, connect a hose and drain the cooling system.

|

|

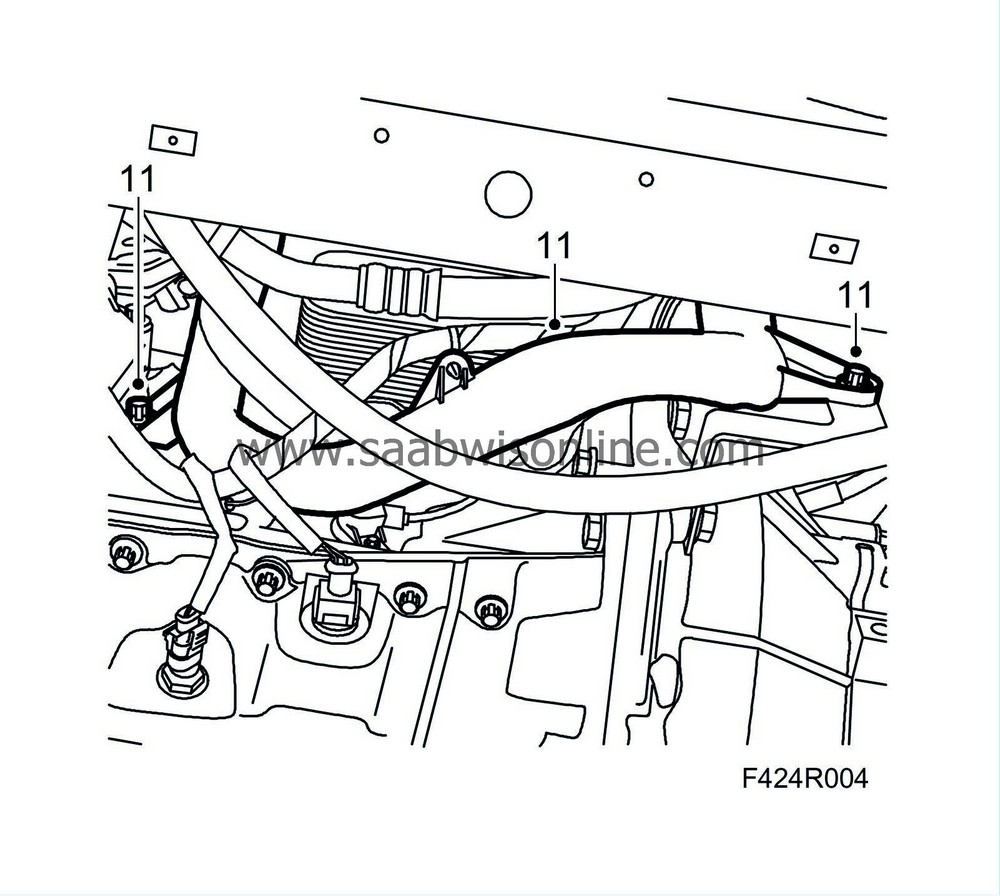

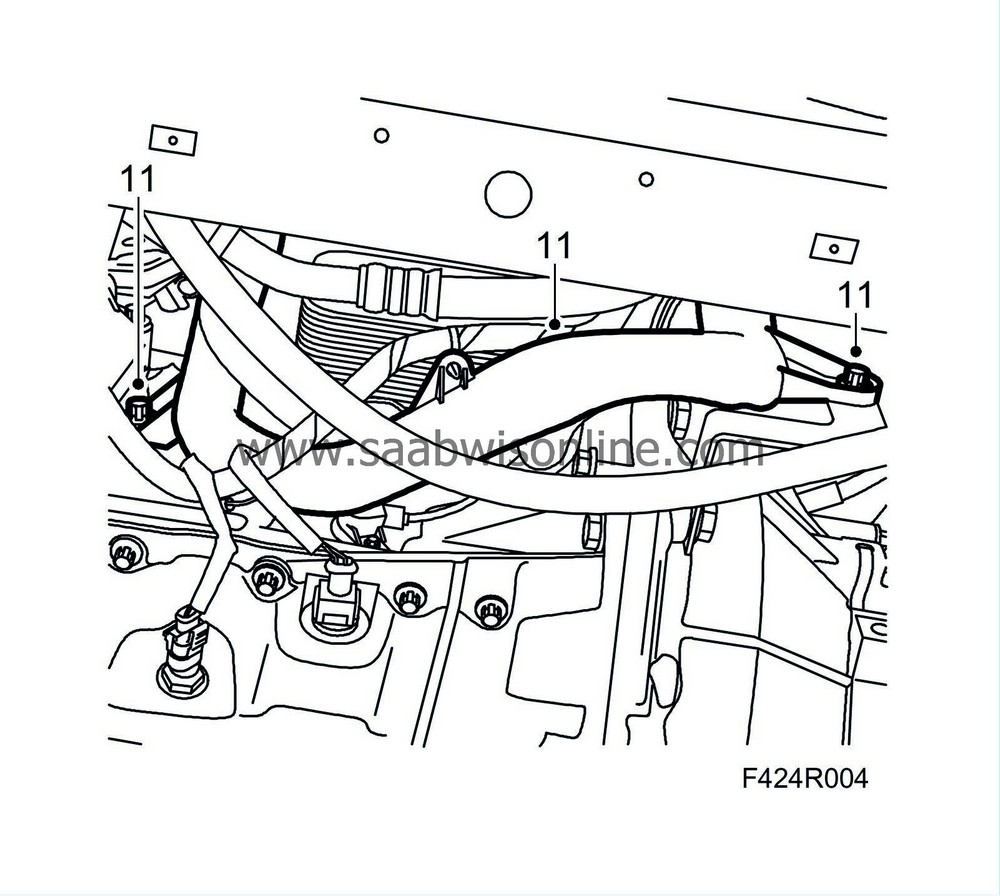

11.

|

Undo the bolts securing the coolant pipe.

|

|

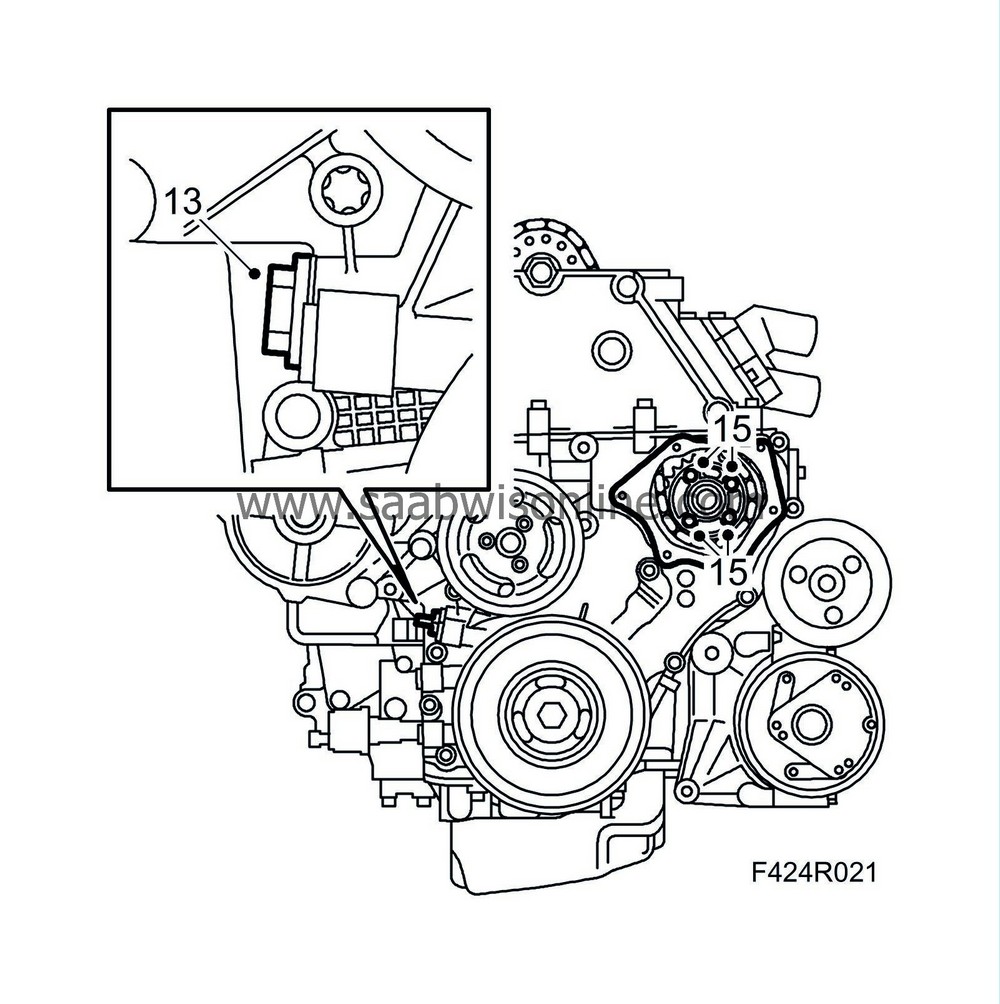

13.

|

Remove the upper engine cover.

|

|

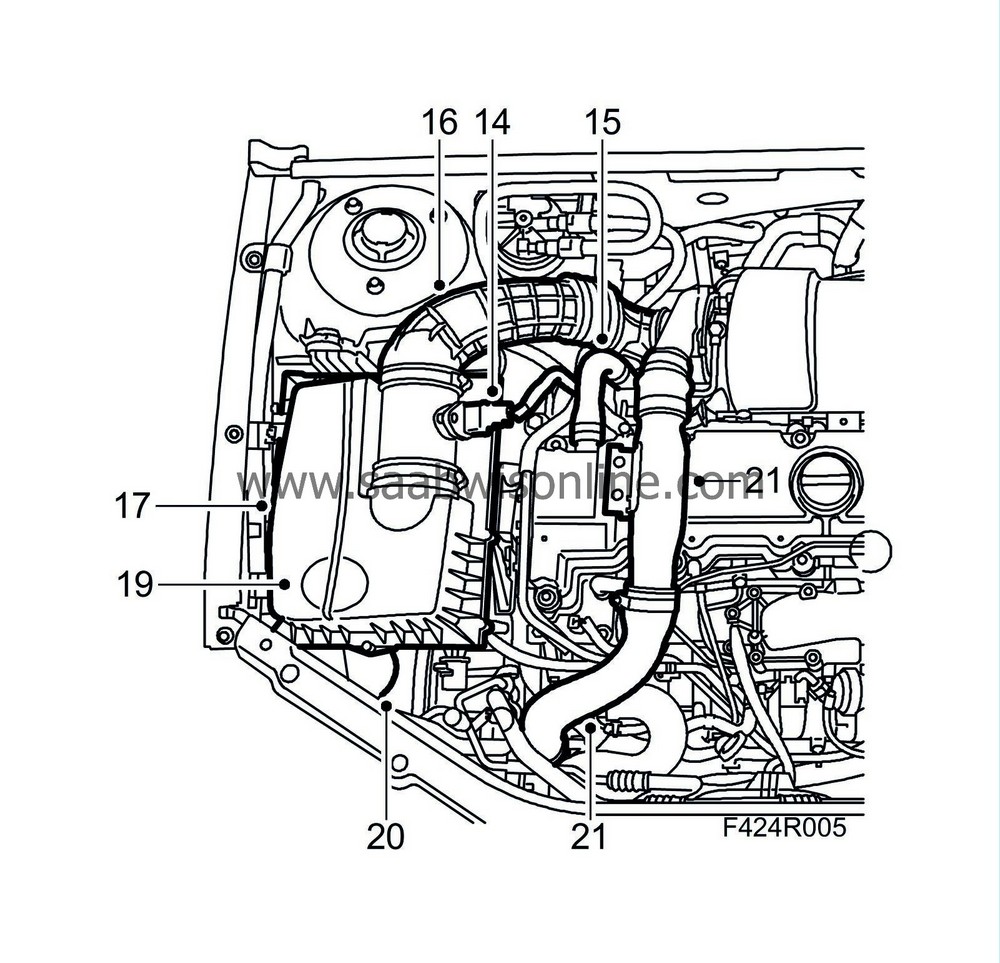

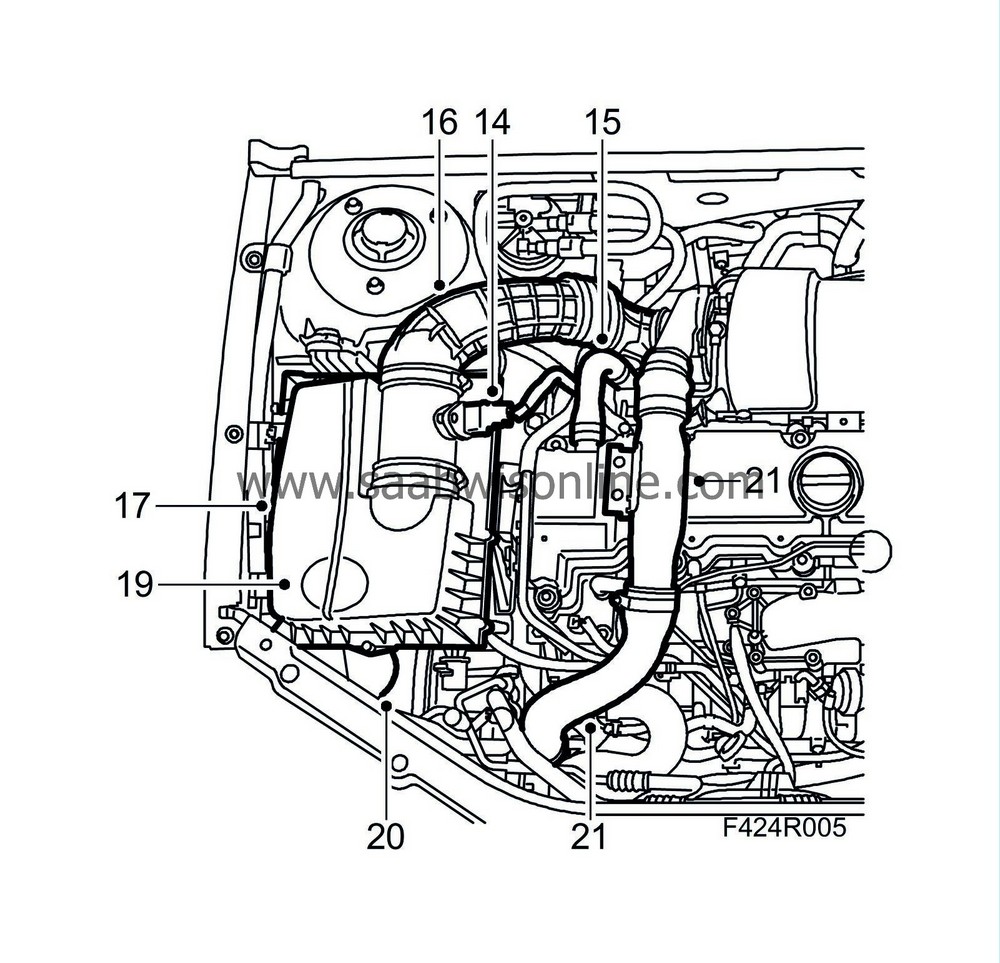

14.

|

Unplug the mass air flow sensor.

|

|

15.

|

Disconnect the hose from the crankcase ventilation.

|

|

16.

|

Disconnect the intake hose from the turbocharger. Cover the inlet on the turbocharger.

|

|

17.

|

Remove the cover on the air cleaner casing.

|

|

18.

|

Remove the filter element.

|

|

19.

|

Detach the inlet air hose from the air cleaner casing.

|

|

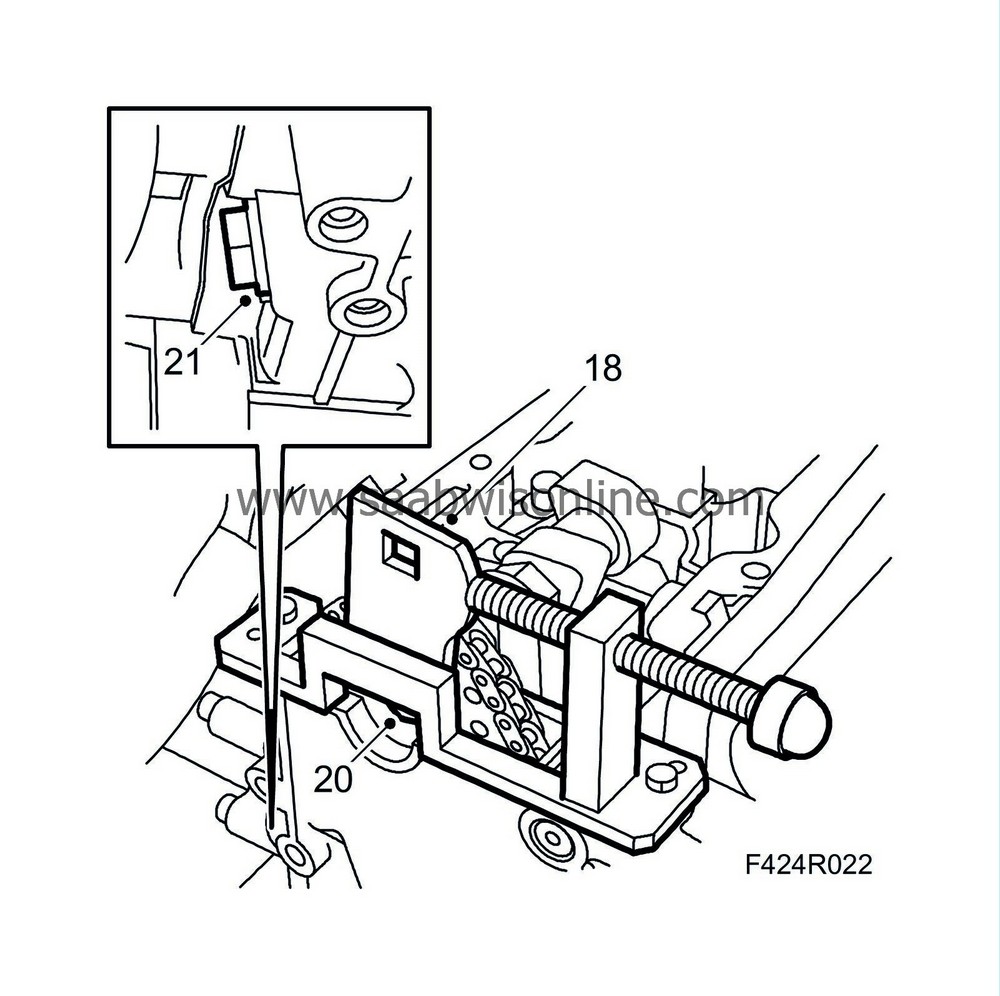

20.

|

Remove the air filter housing. Be careful not to damage the A/C pressure sensor.

|

|

21.

|

Remove the charge air hose and charge air pipe from the turbocharger and the charge air pipe from the fan cowling. Plug the connections.

|

|

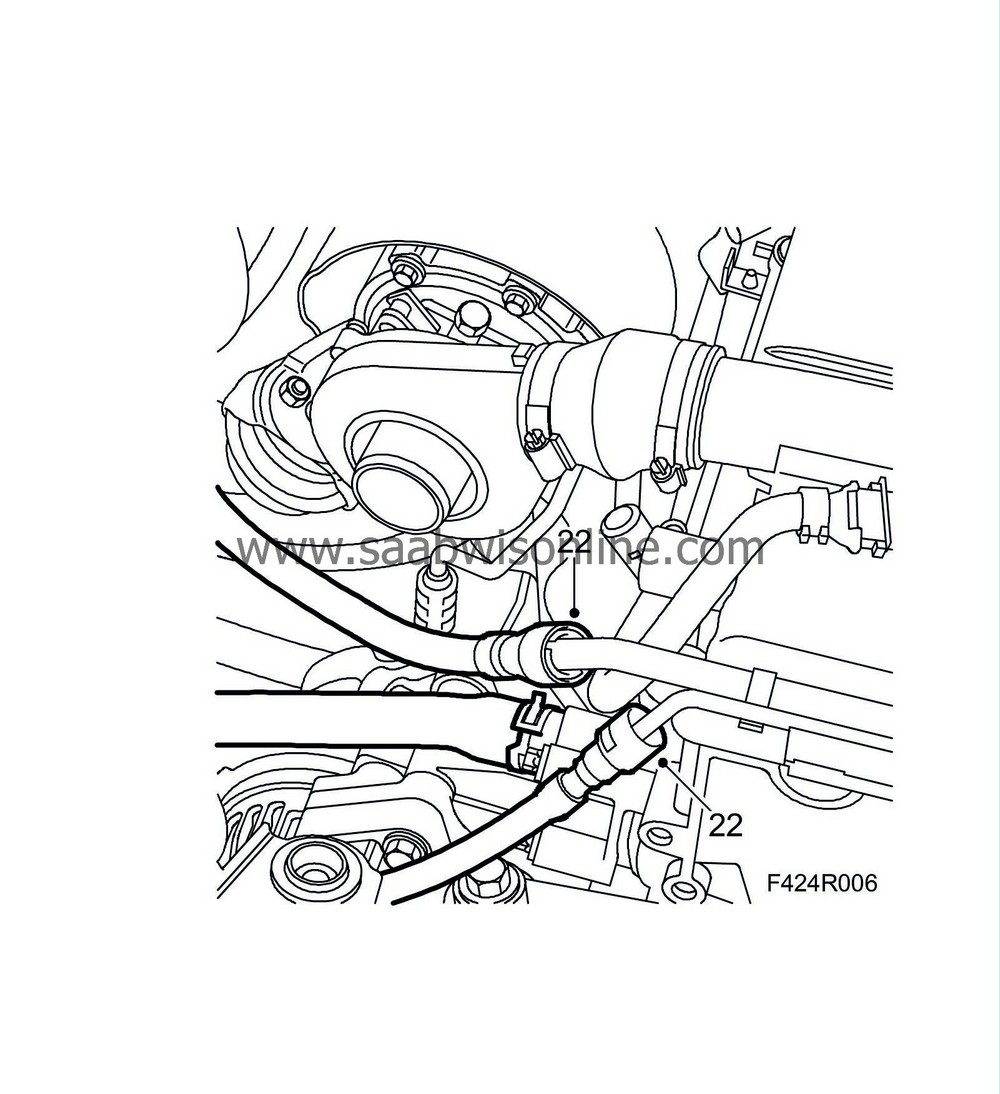

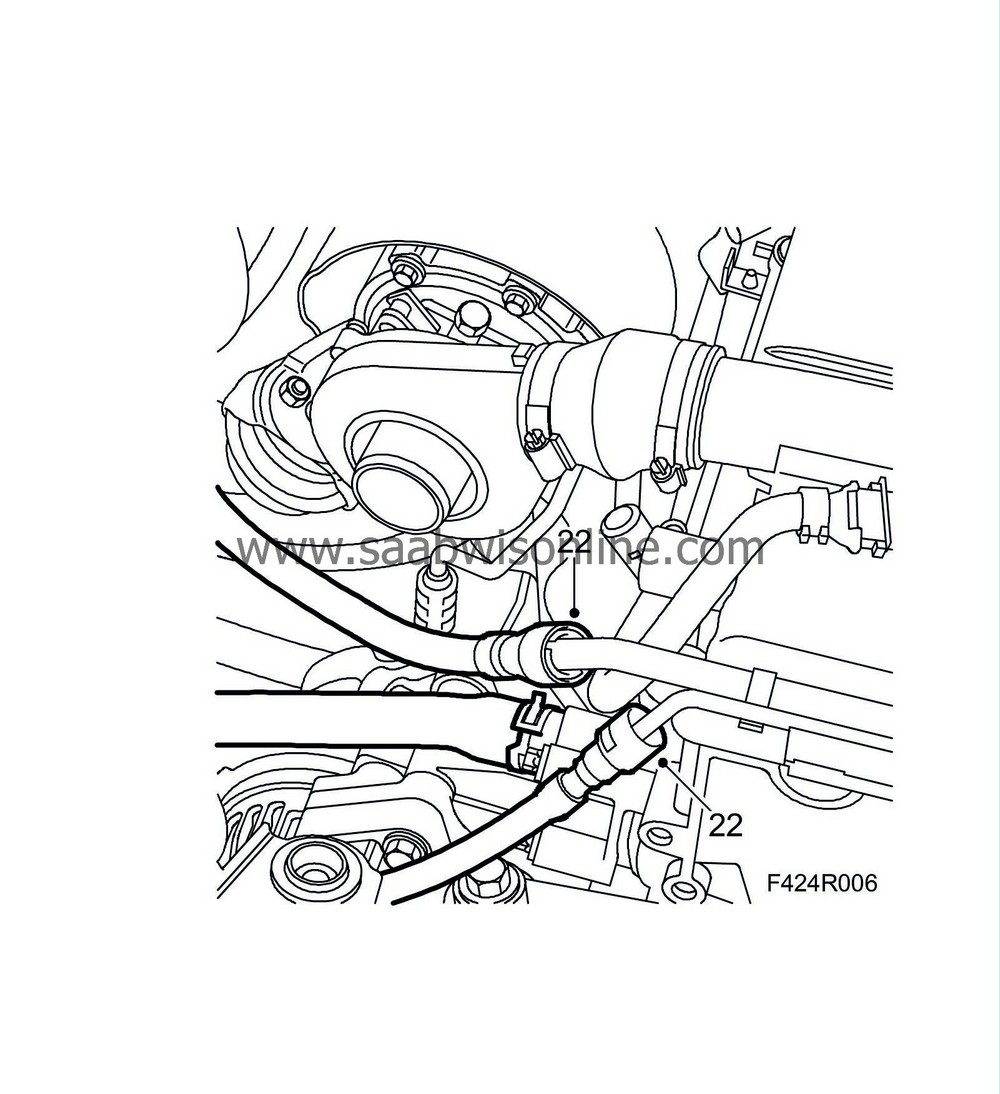

22.

|

Split the fuel hoses using

83 95 261 Fuel line tool

and seal them. Be ready to catch and mop up any fuel spills with a rag.

|

|

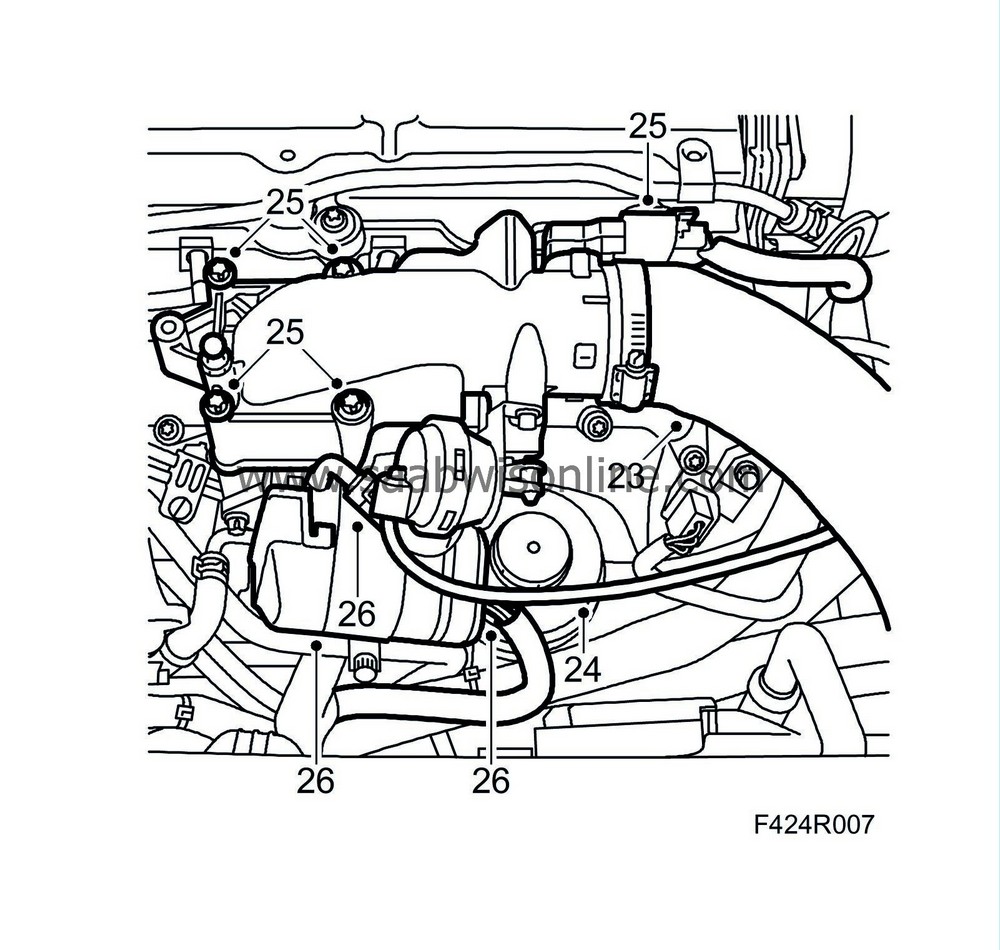

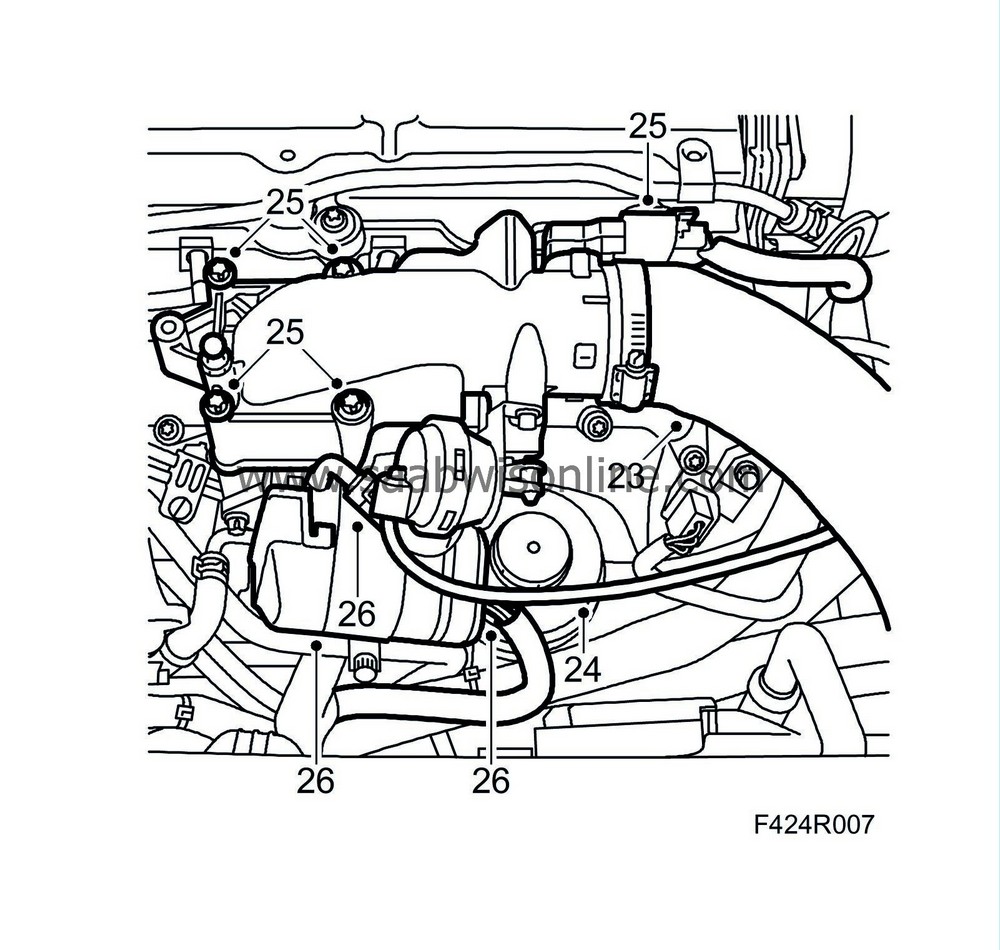

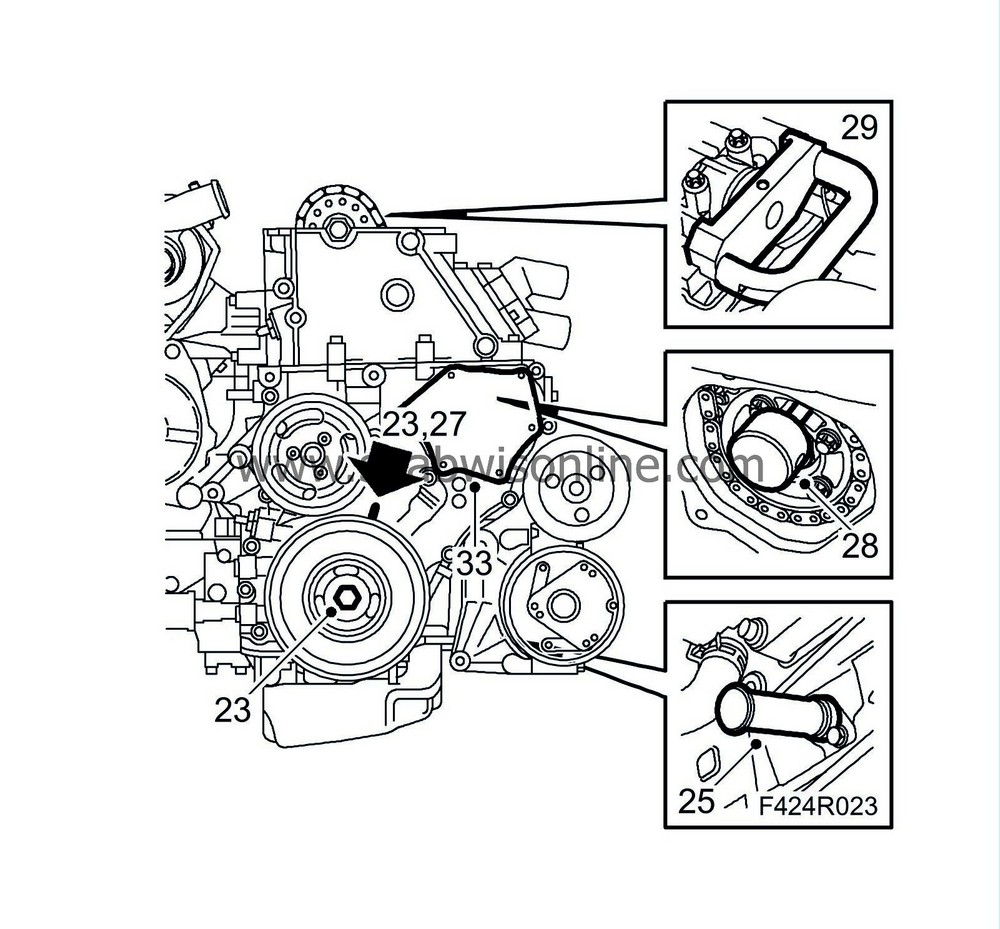

23.

|

Remove the charge air hose from the throttle body and bend it aside.

|

|

24.

|

Remove the vacuum hose from the throttle body.

|

|

25.

|

Remove the throttle body.

|

|

26.

|

Unplug the EGR valve and disconnect the cooling hose. Remove the EGR valve from the intake manifold.

|

|

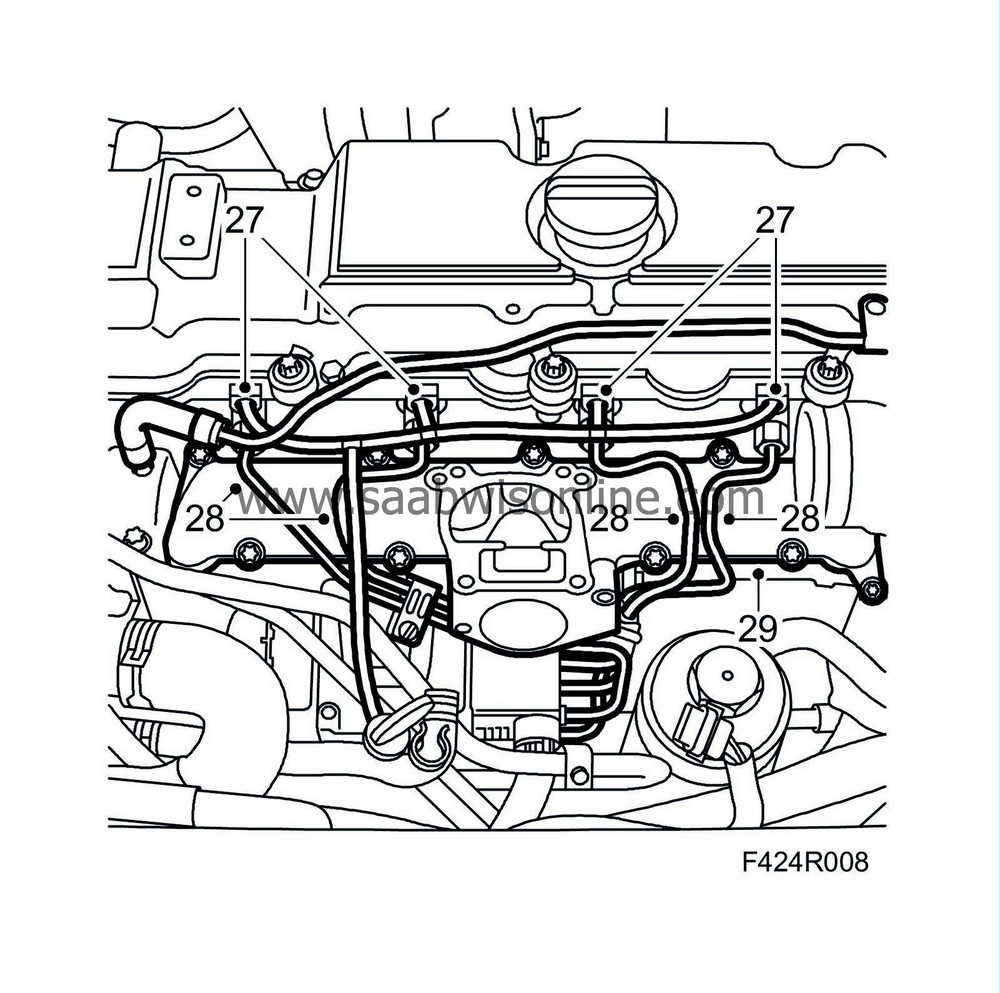

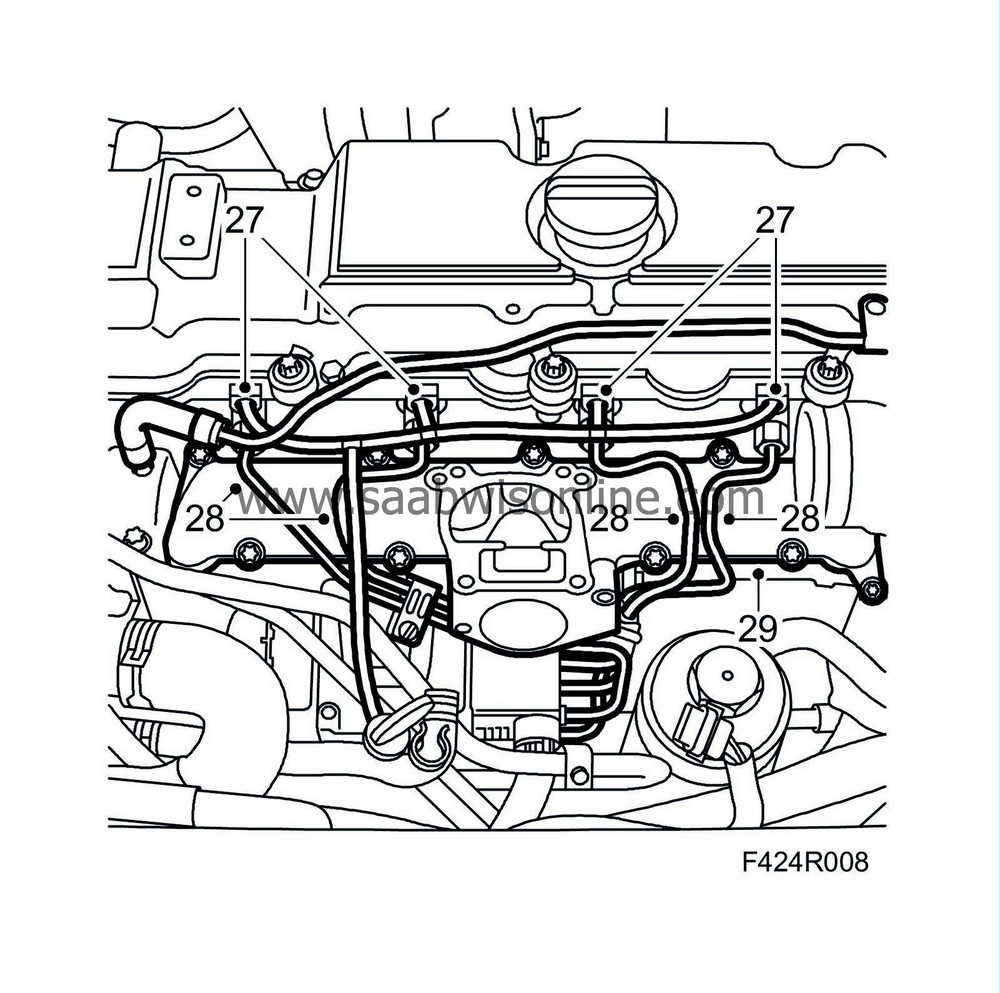

27.

|

Place a suitable receptacle under the car to catch fuel spills. Remove the fuel return hoses from the fuel bridges.

|

|

28.

|

Mark the position of the fuel distribution pipes and clamps and remove the pipes.

|

|

29.

|

Remove the upper section of the intake manifold.

|

|

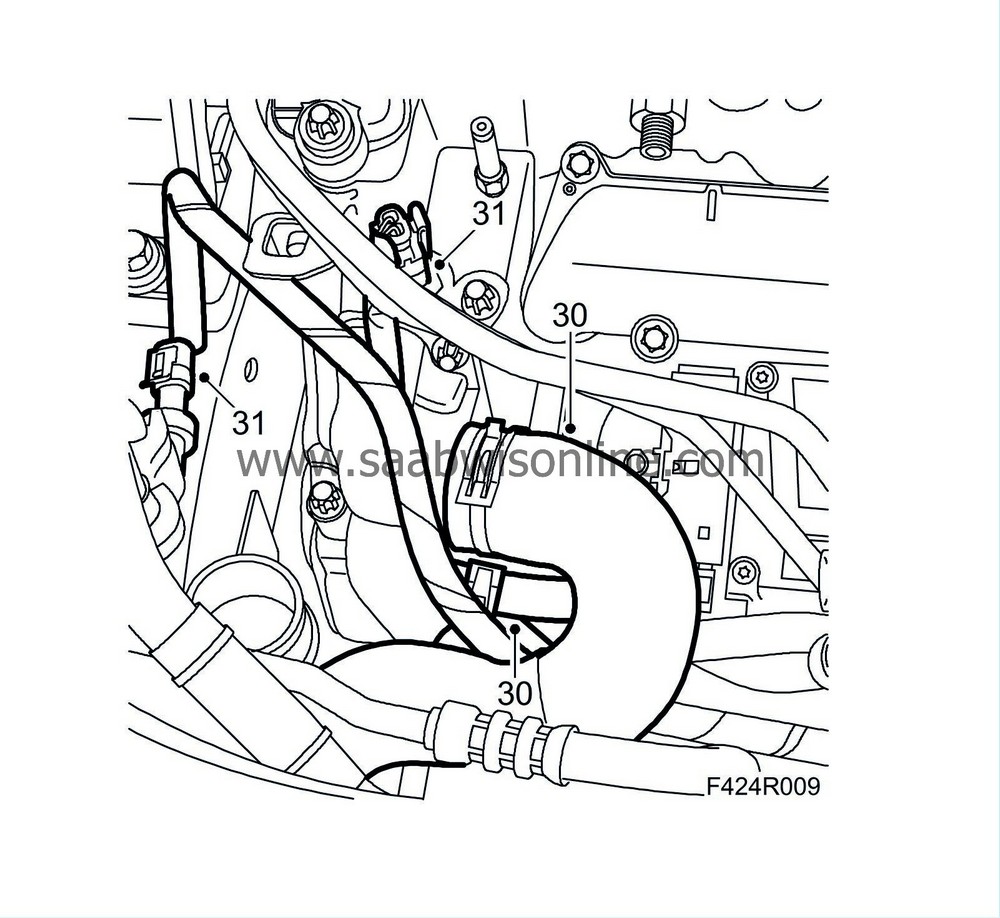

30.

|

Remove the hoses from the thermostat housing.

|

Important

|

|

Take care when releasing the locking mechanism on the connector so as not to damage the connector. Pull the halves straight apart to avoid bending the pins. For further information regarding connectors, refer to

Connectors, handling and inspection

.

|

|

|

|

|

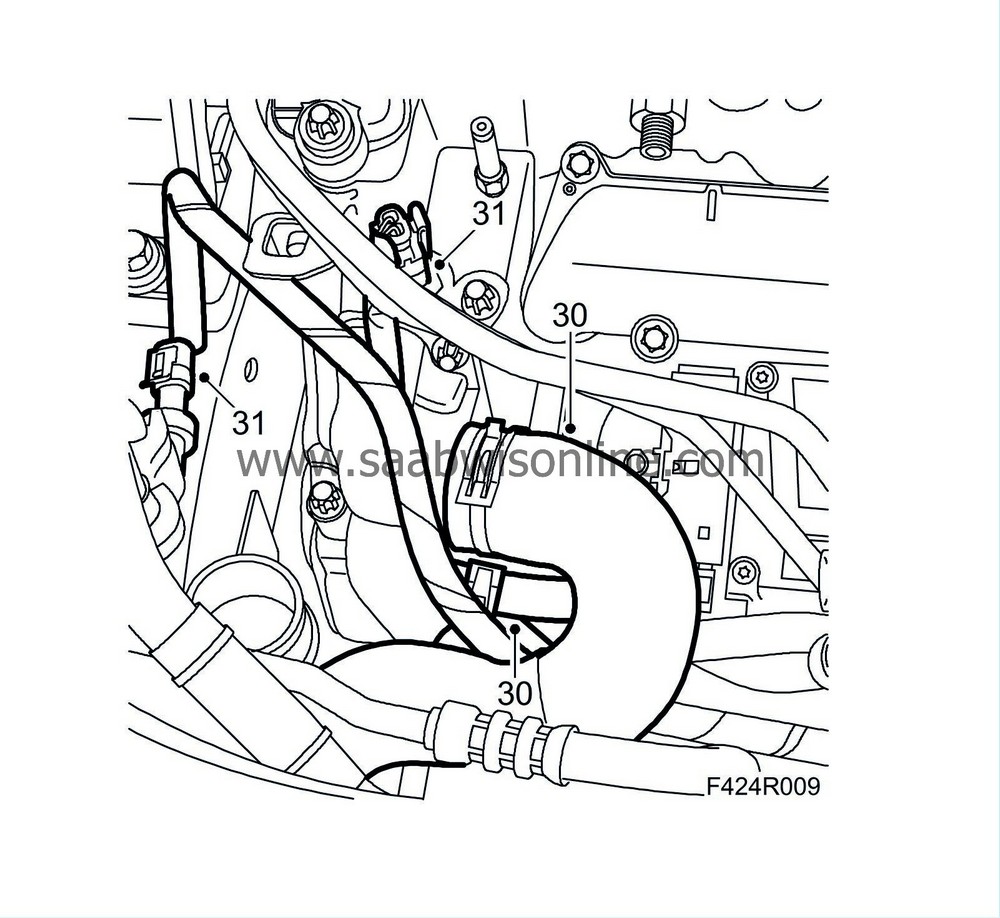

31.

|

Unplug the connectors from the A/C pressure sensor, coolant temperature sensor and engine control module.

|

|

32.

|

Cut the cable tie that secures the coolant pipe. Move aside the wiring from the engine control module.

|

|

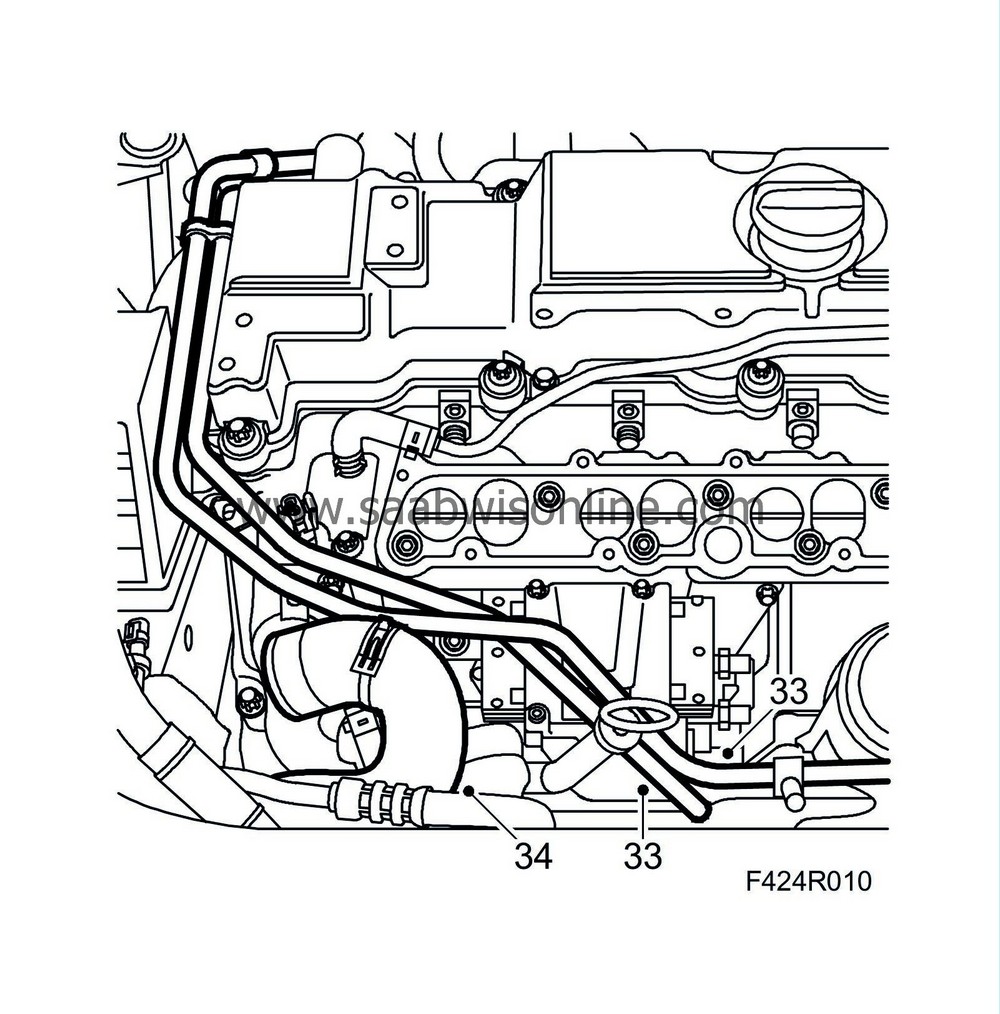

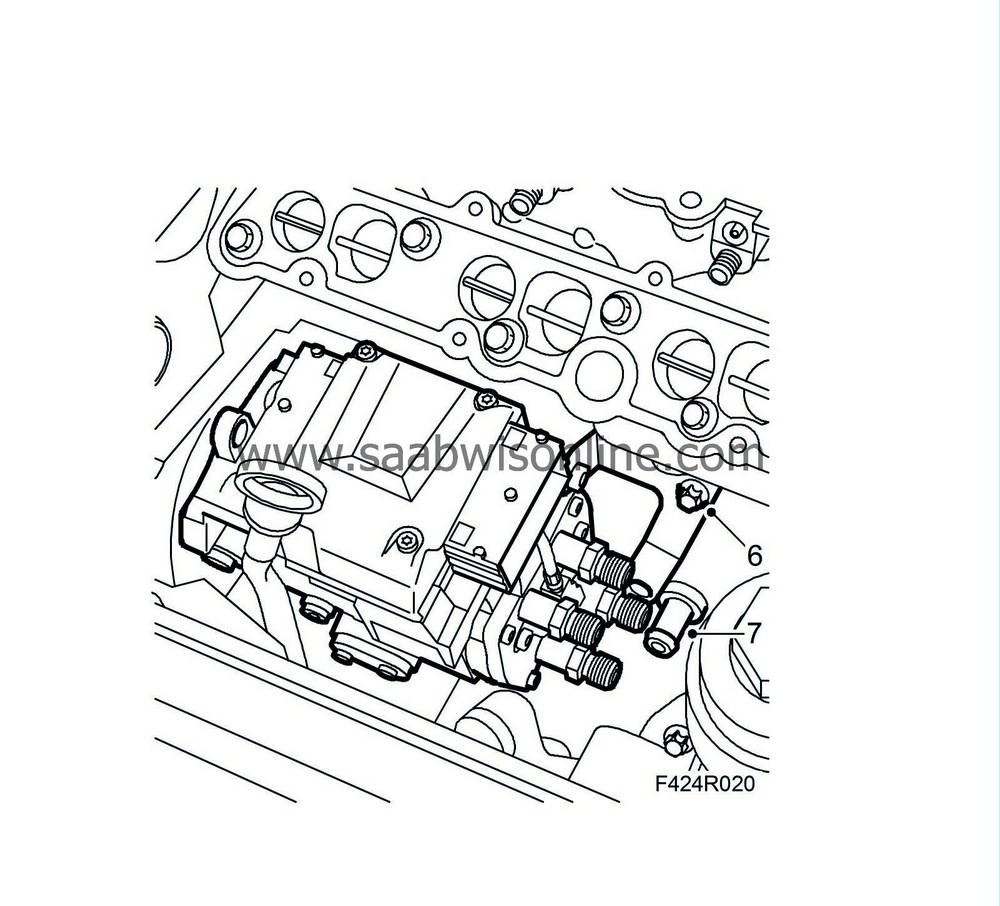

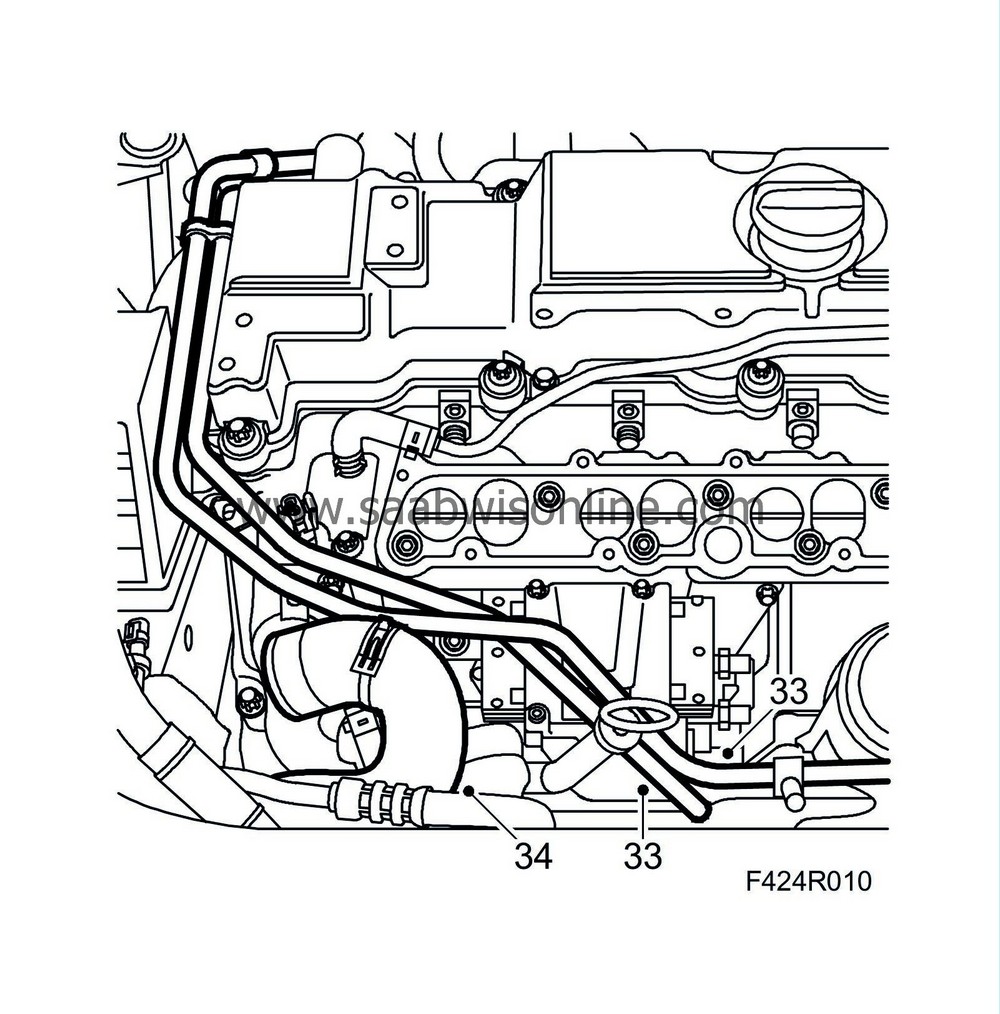

33.

|

Remove the delivery and return fuel lines from the fuel distribution pump.

|

|

34.

|

Disconnect the coolant hose and pipe and move it aside.

|

|

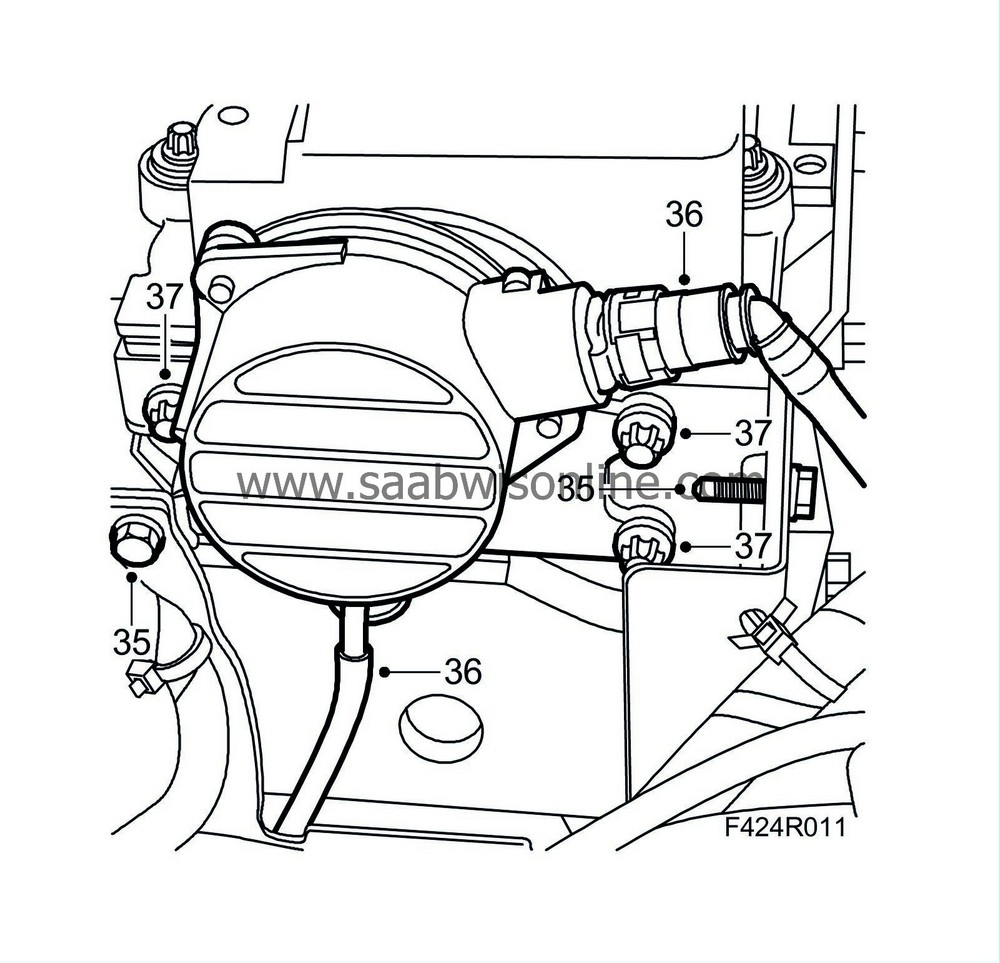

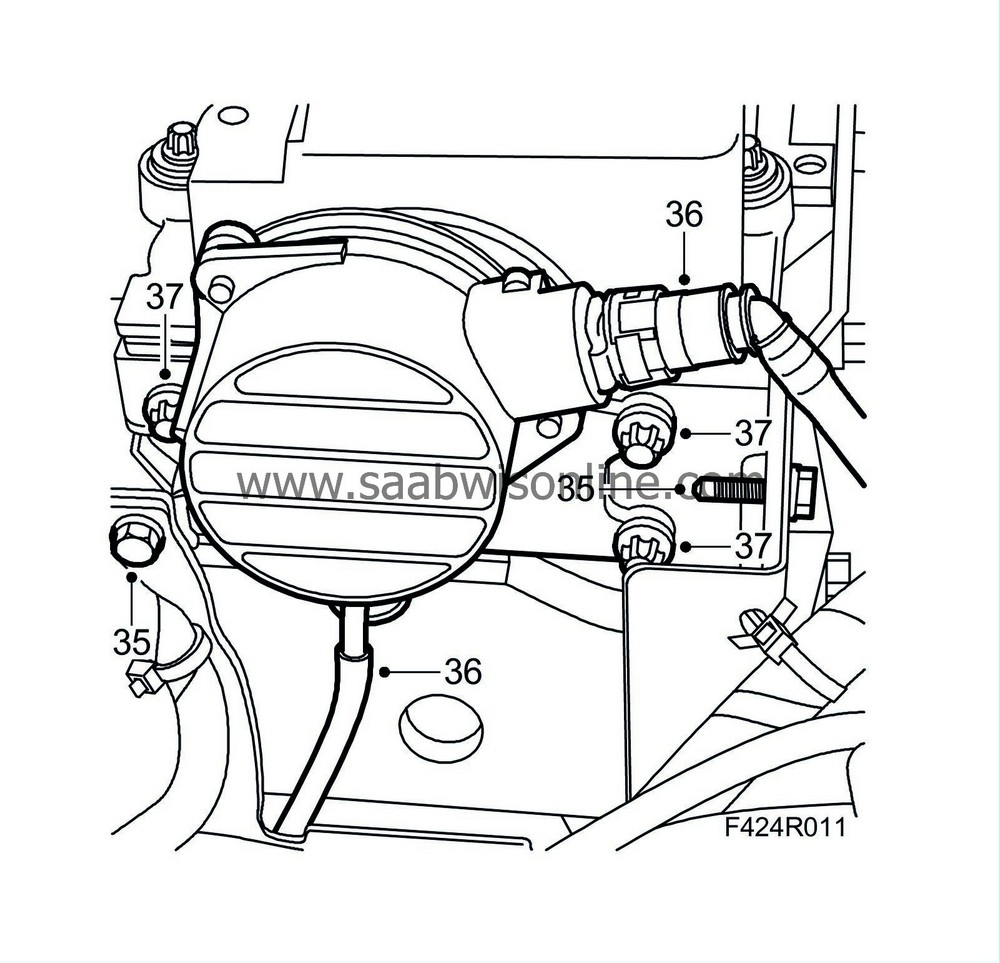

35.

|

Disconnect and move aside the cable duct.

|

|

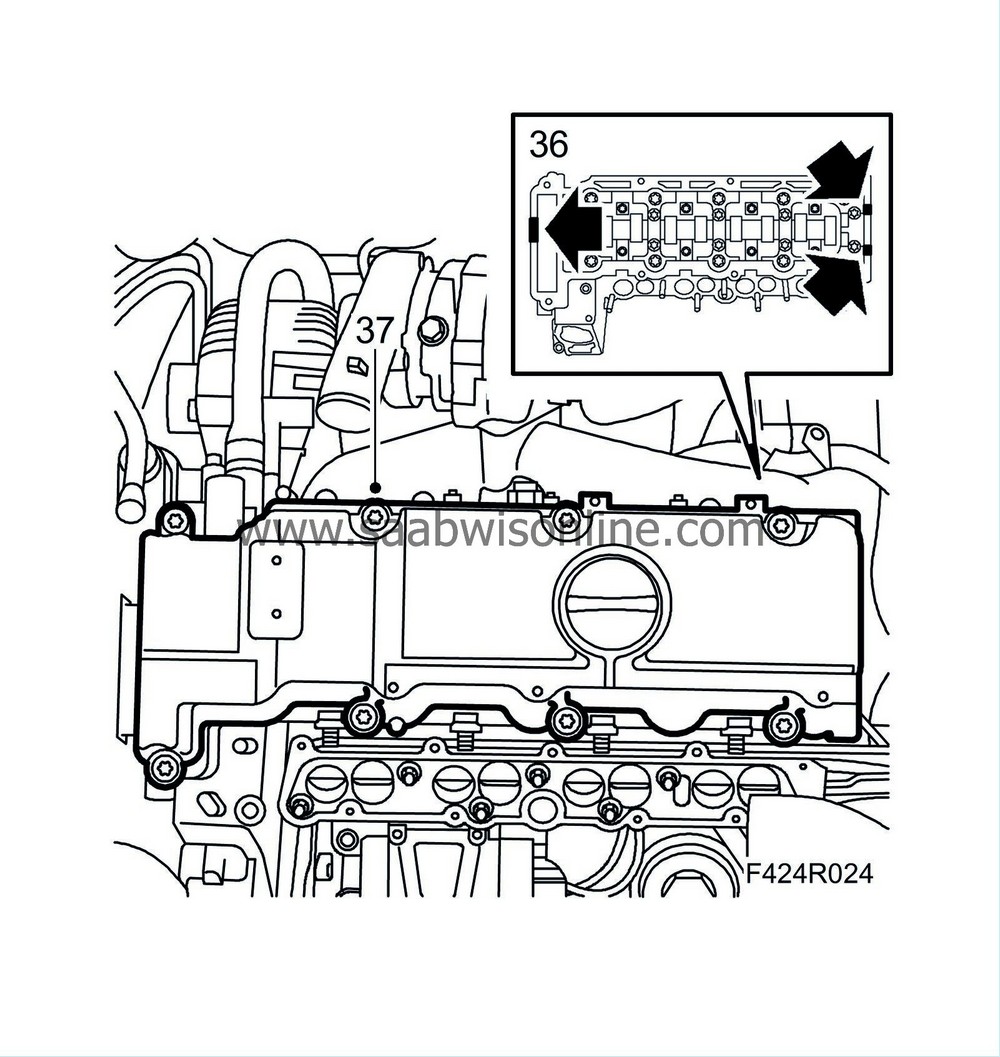

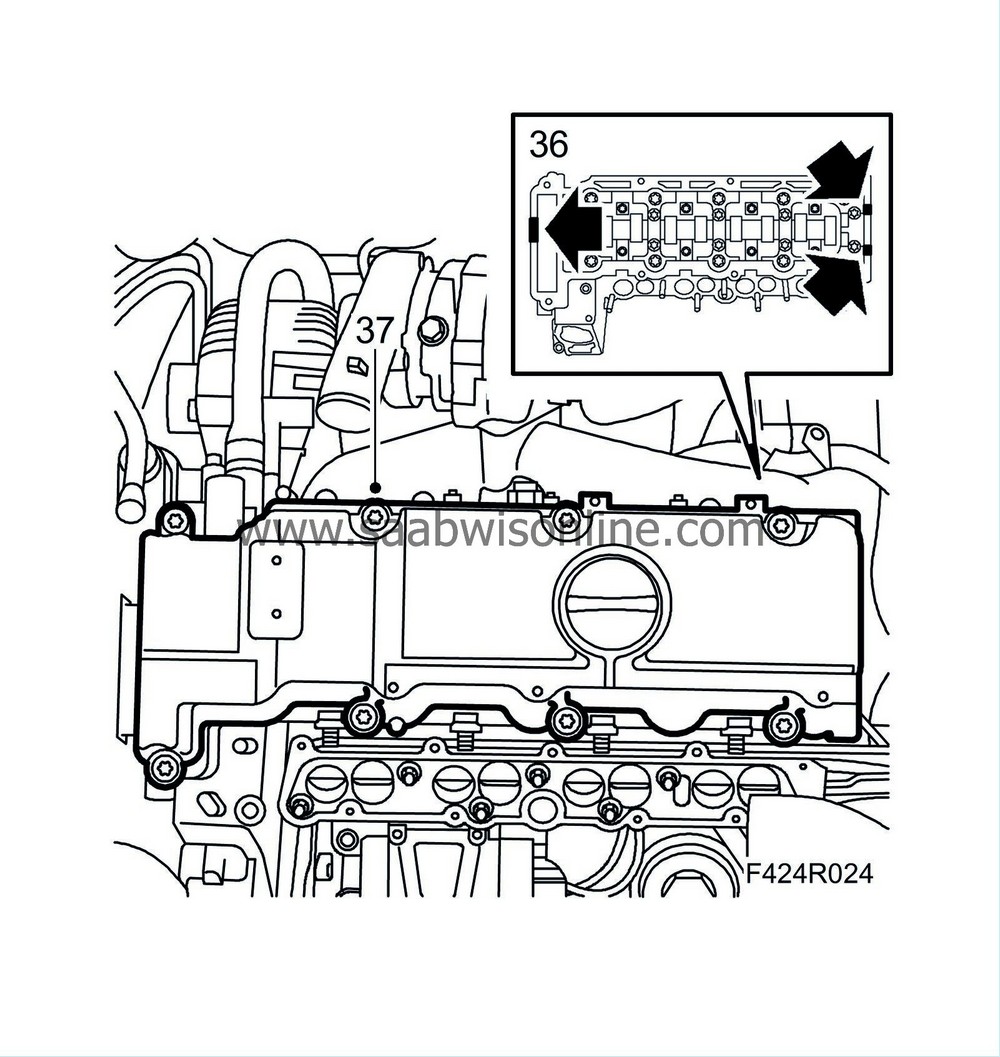

36.

|

Disconnect the vacuum hose from the brake servo and the vacuum hose connected to the bottom of the vacuum pump.

|

|

37.

|

Remove the four bolts securing the vacuum pump and carefully lift aside the vacuum pump and its adapter. Have a rag at hand to catch and mop up any oil.

|

|

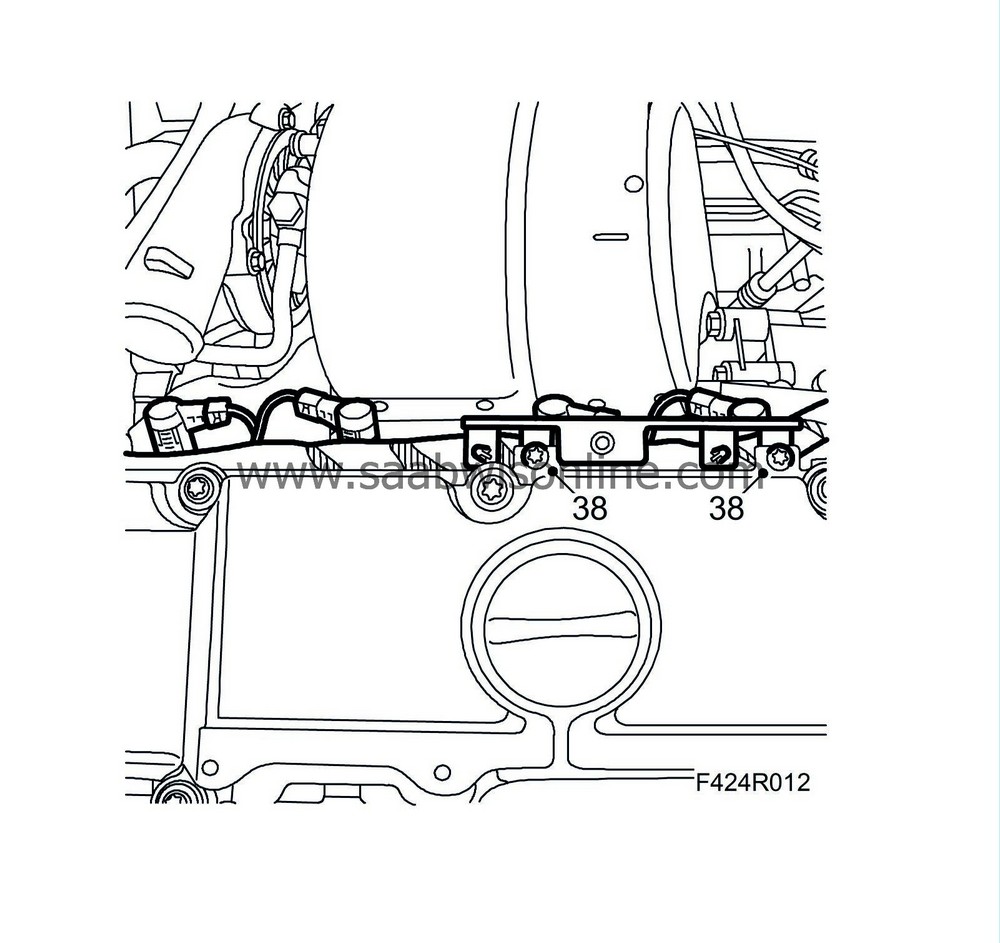

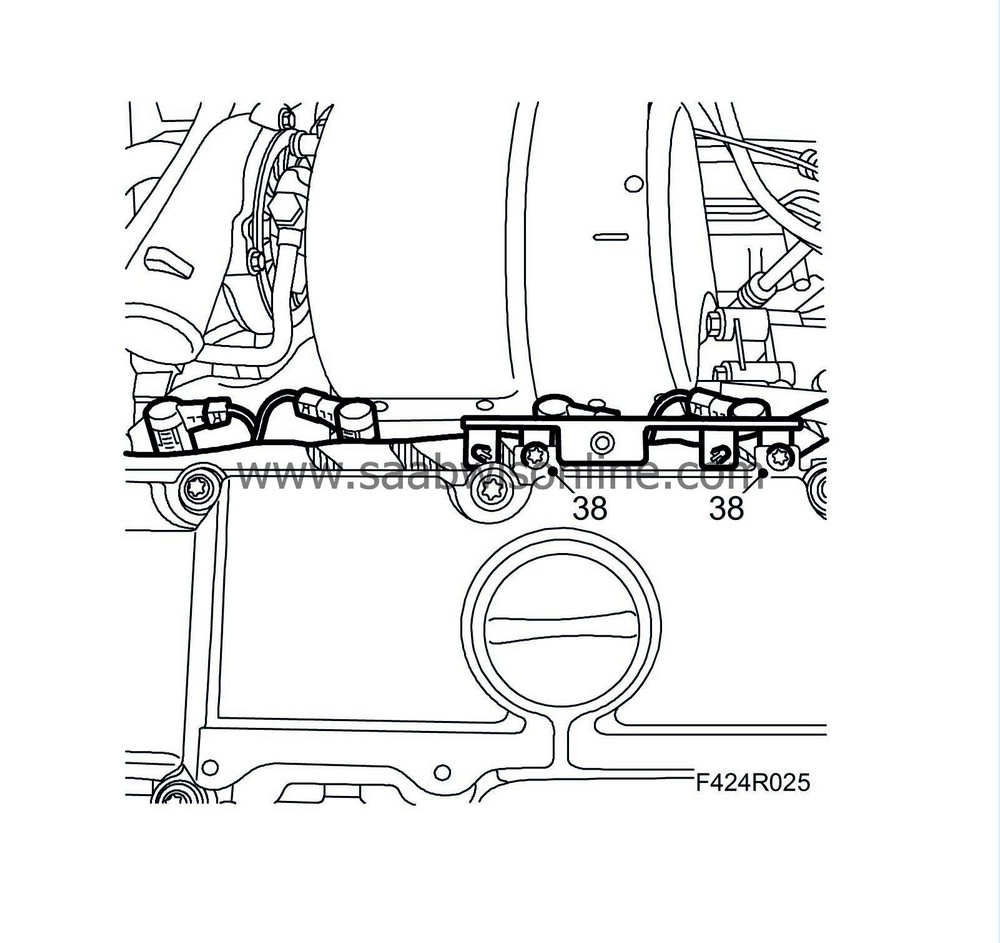

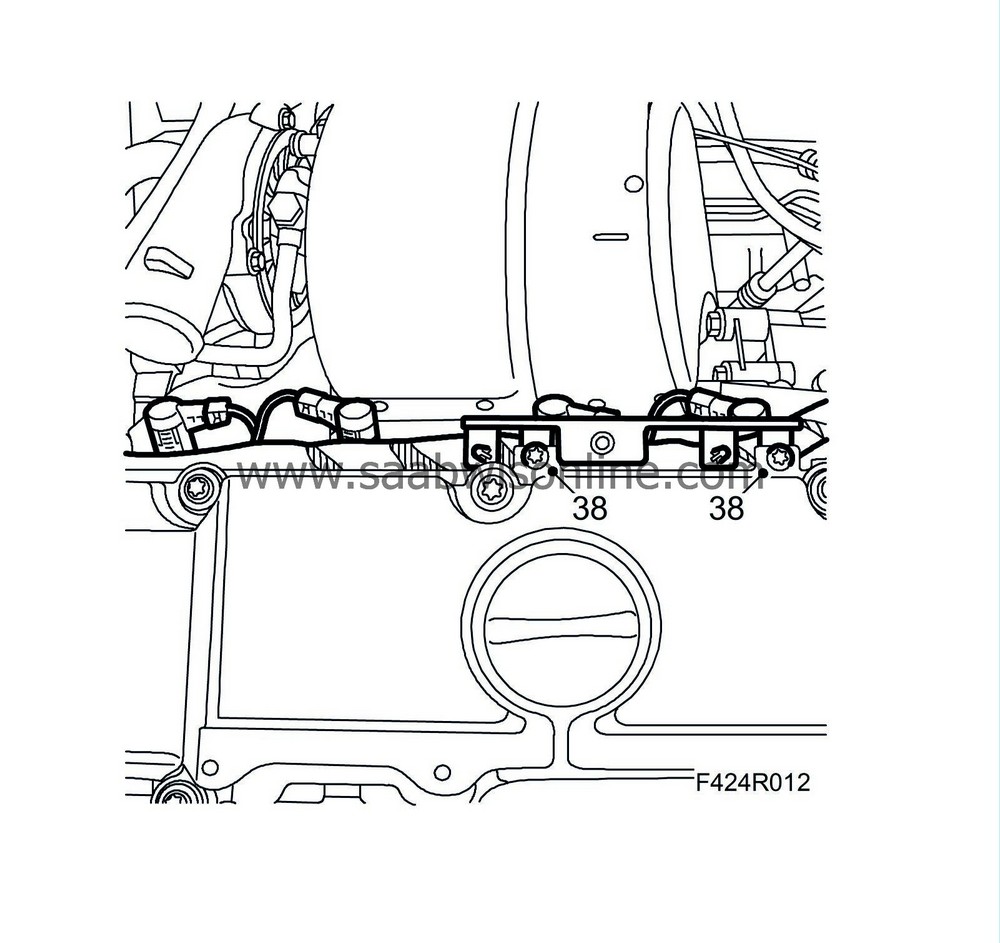

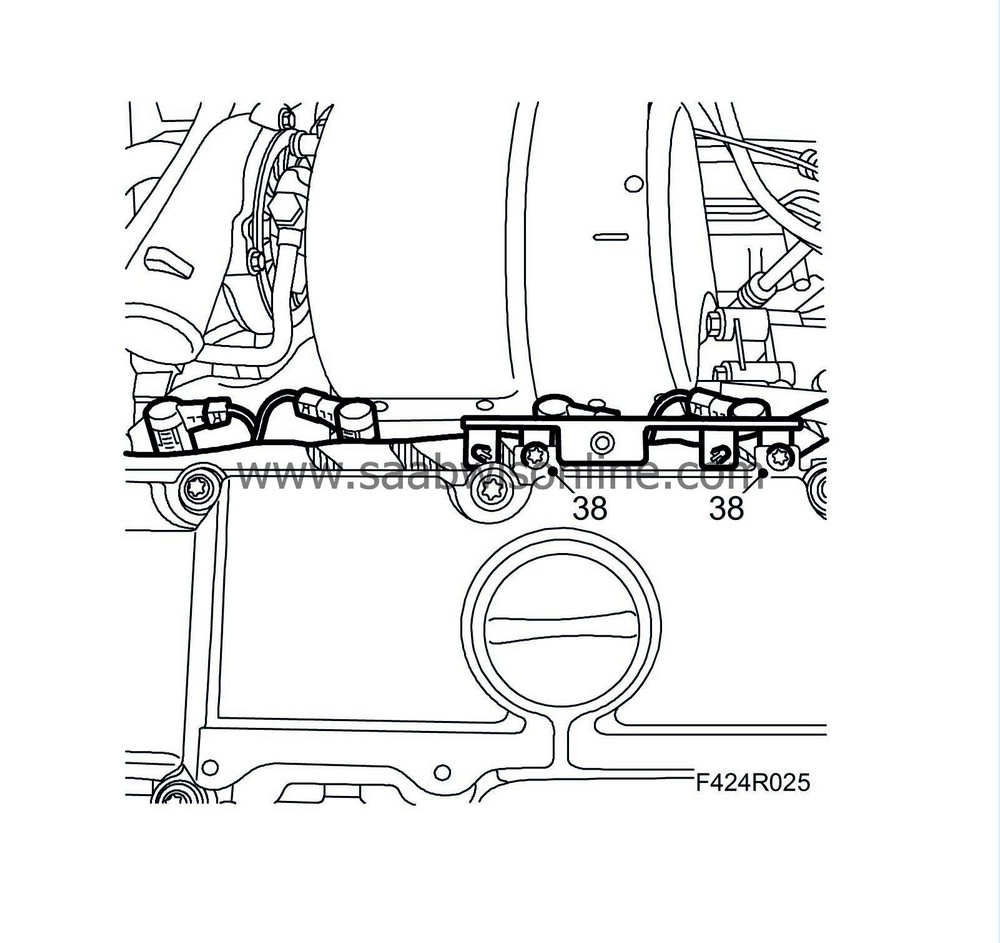

38.

|

Undo the rear wiring harness mounting from the camshaft cover.

|

|

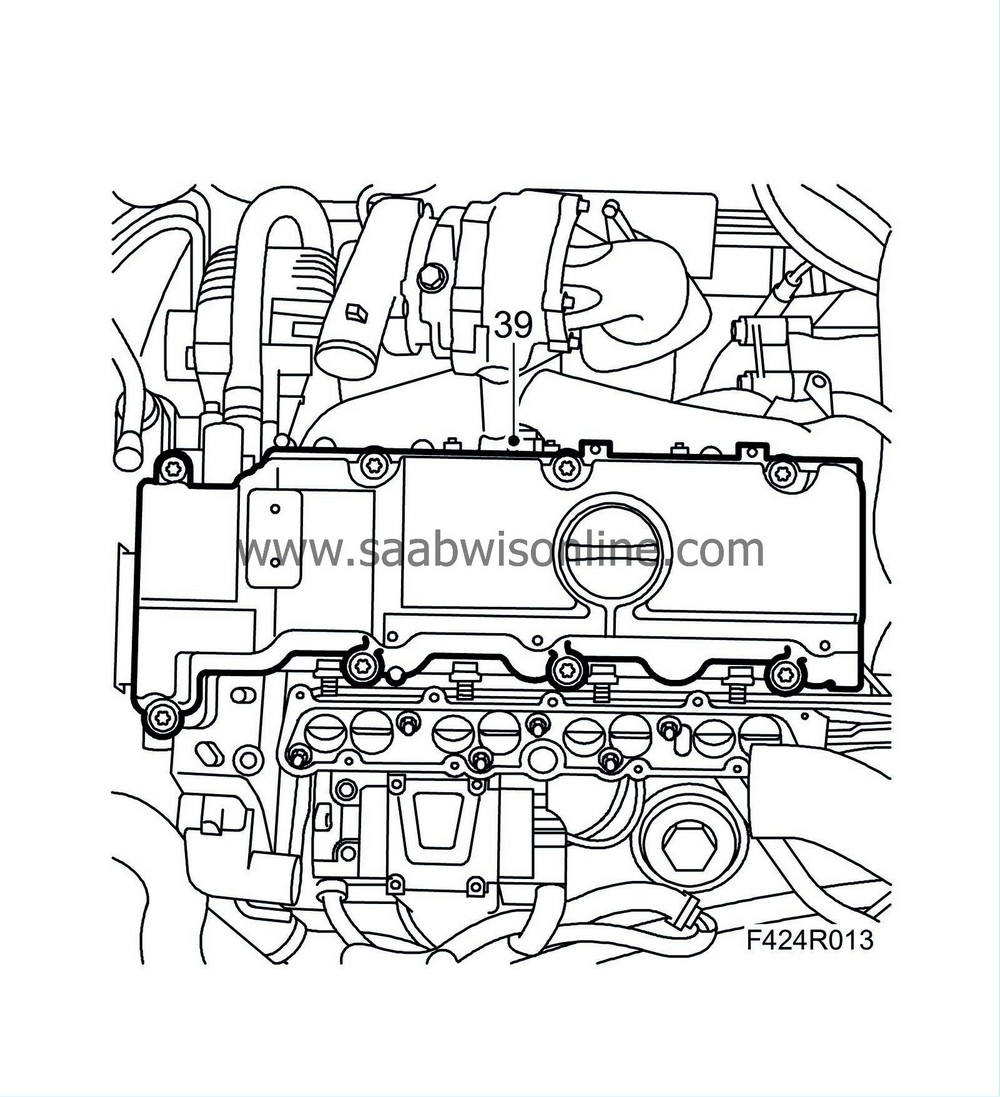

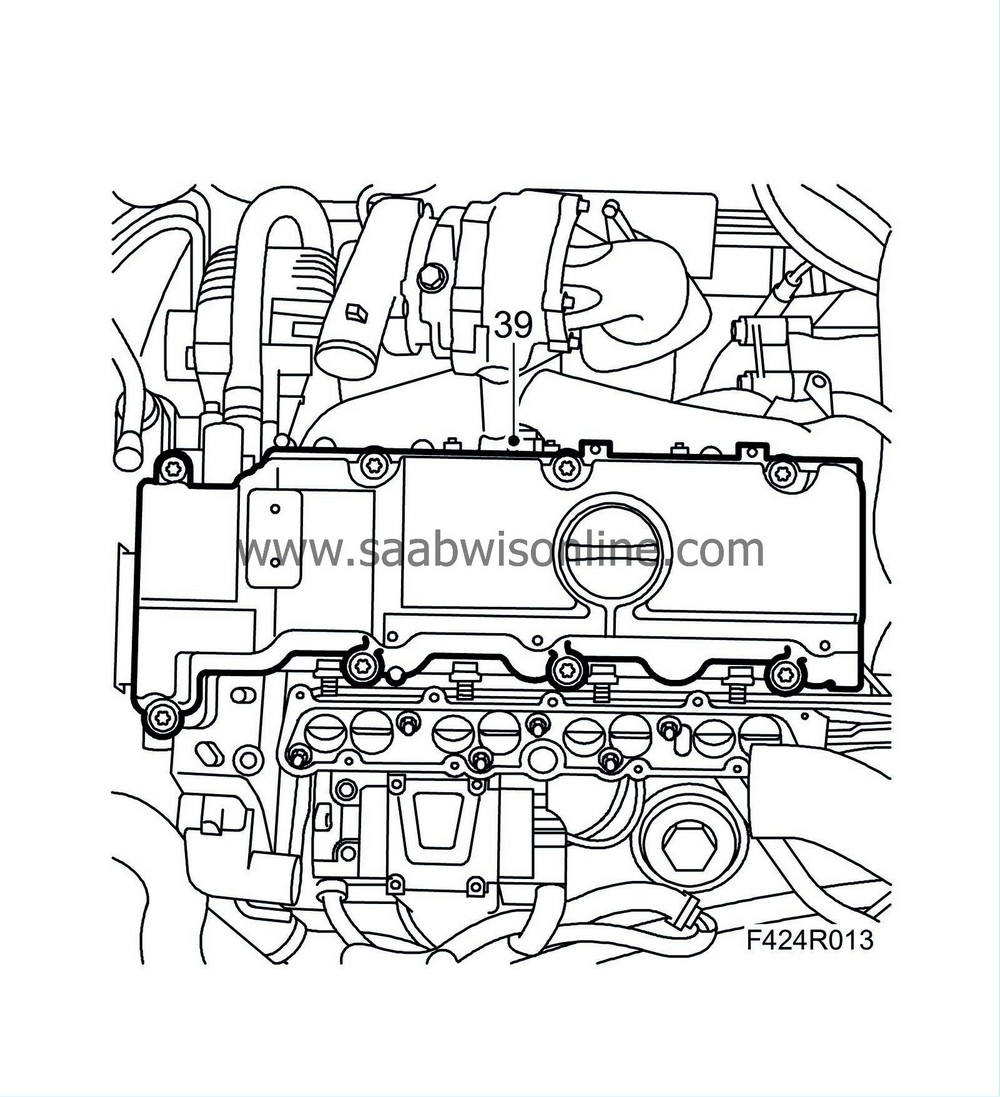

39.

|

Remove the camshaft cover.

|

|

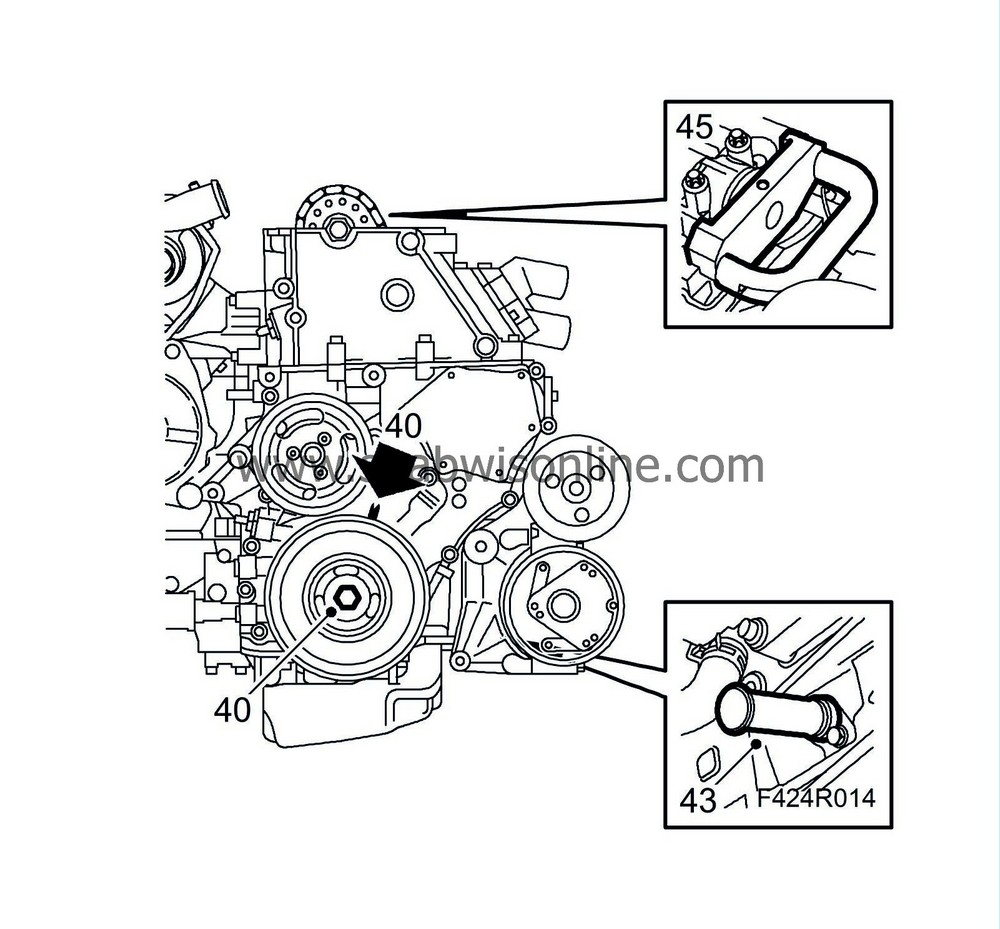

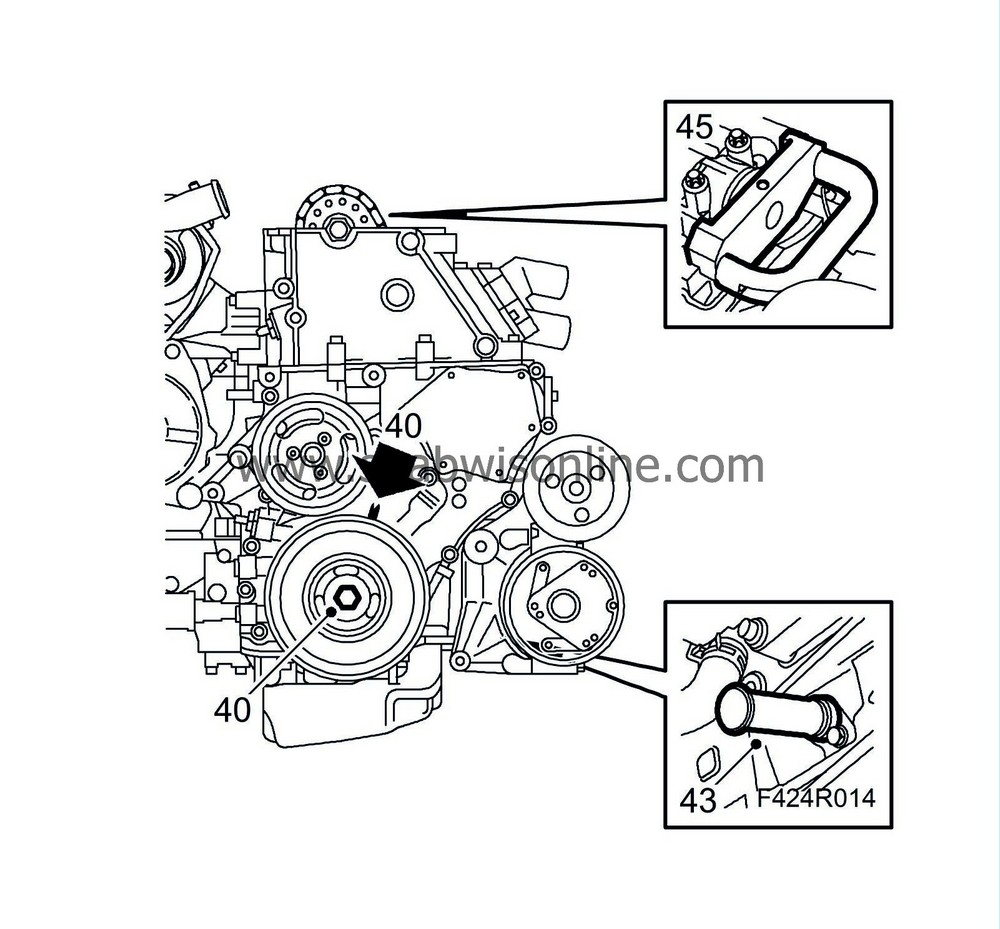

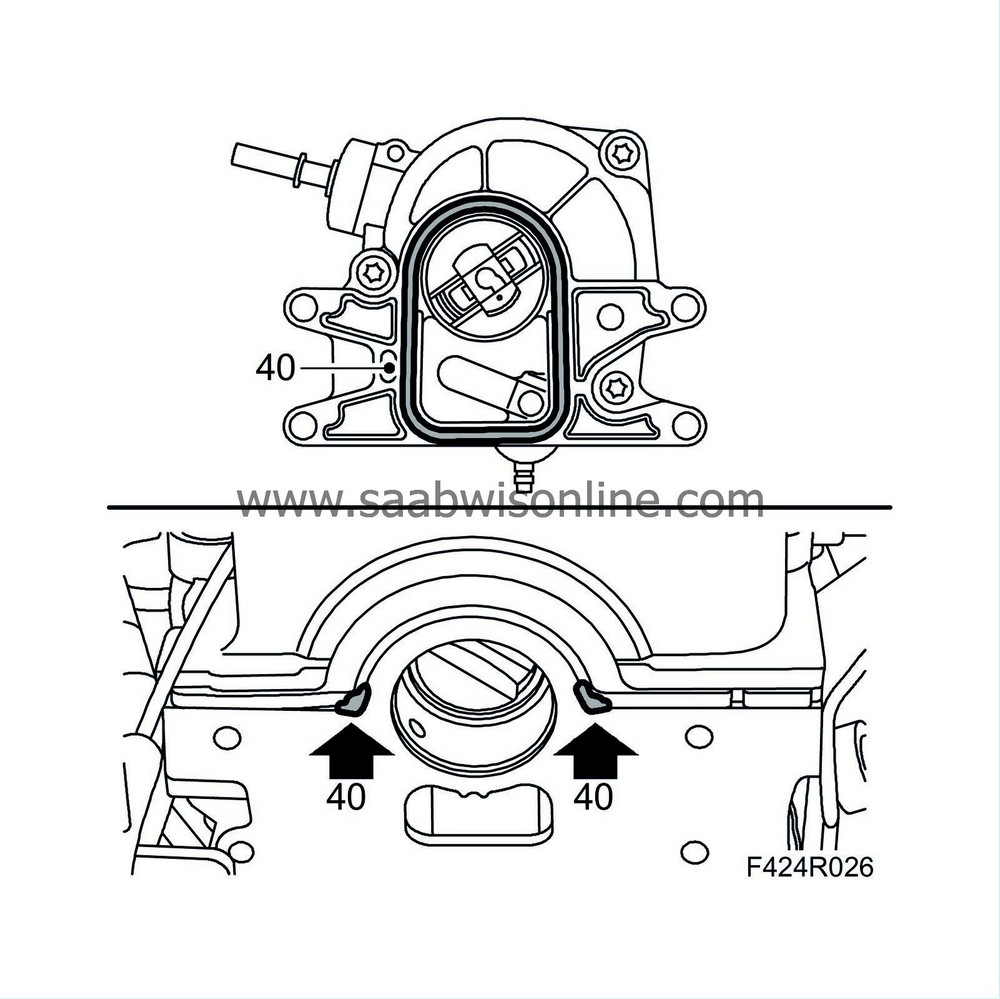

40.

|

Turn the crankshaft to just before the mark for TDC for cylinder 1. Check that both the cams for cylinder 1 are pointing obliquely upward.

|

|

42.

|

Remove the crankshaft position sensor.

|

|

43.

|

Insert

83 95 352 Adjustment tool, crankshaft

into the hole for the crankshaft position sensor. Press the tool in while turning the crankshaft to zero. The tool should enter a recess in the crankshaft and lock it.

|

|

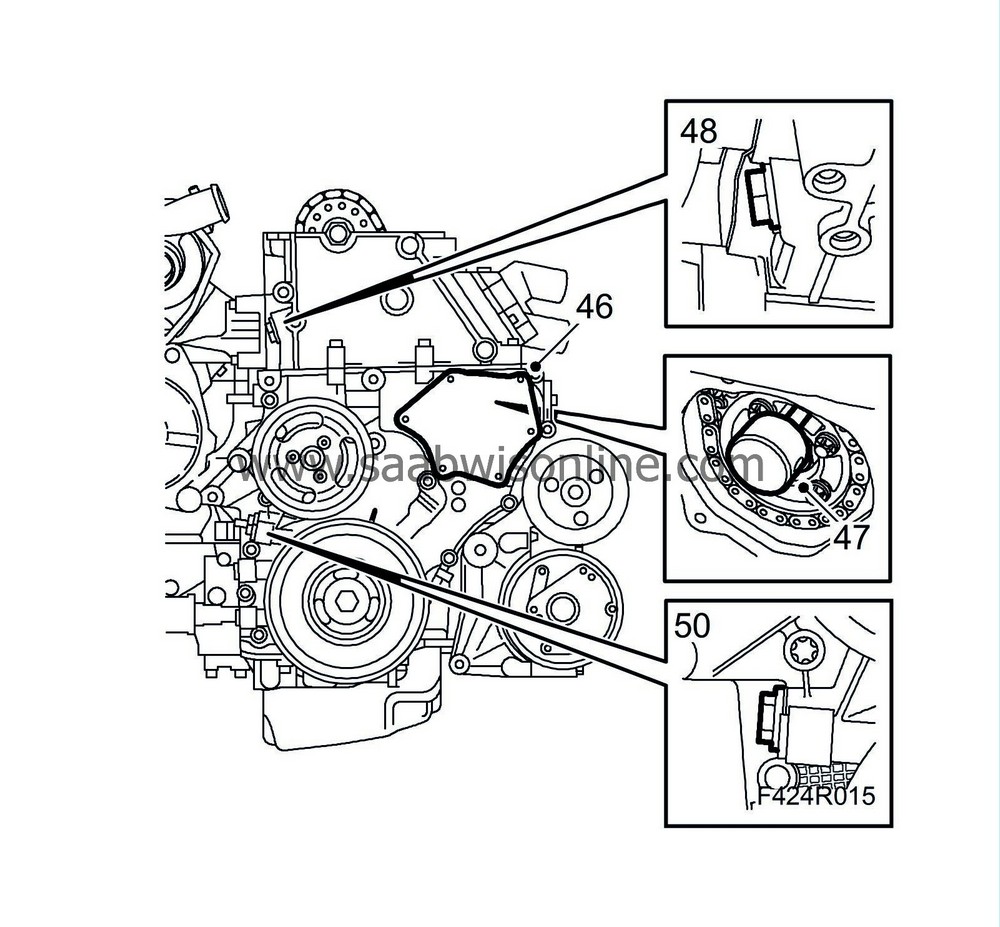

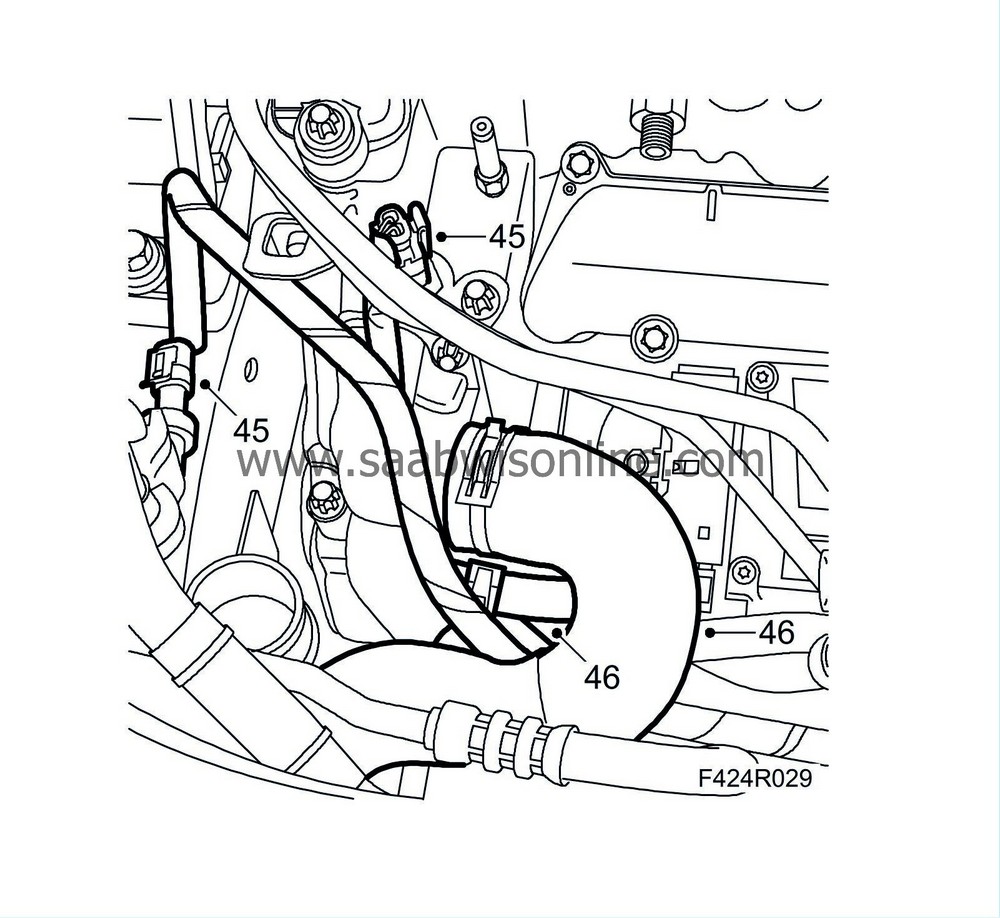

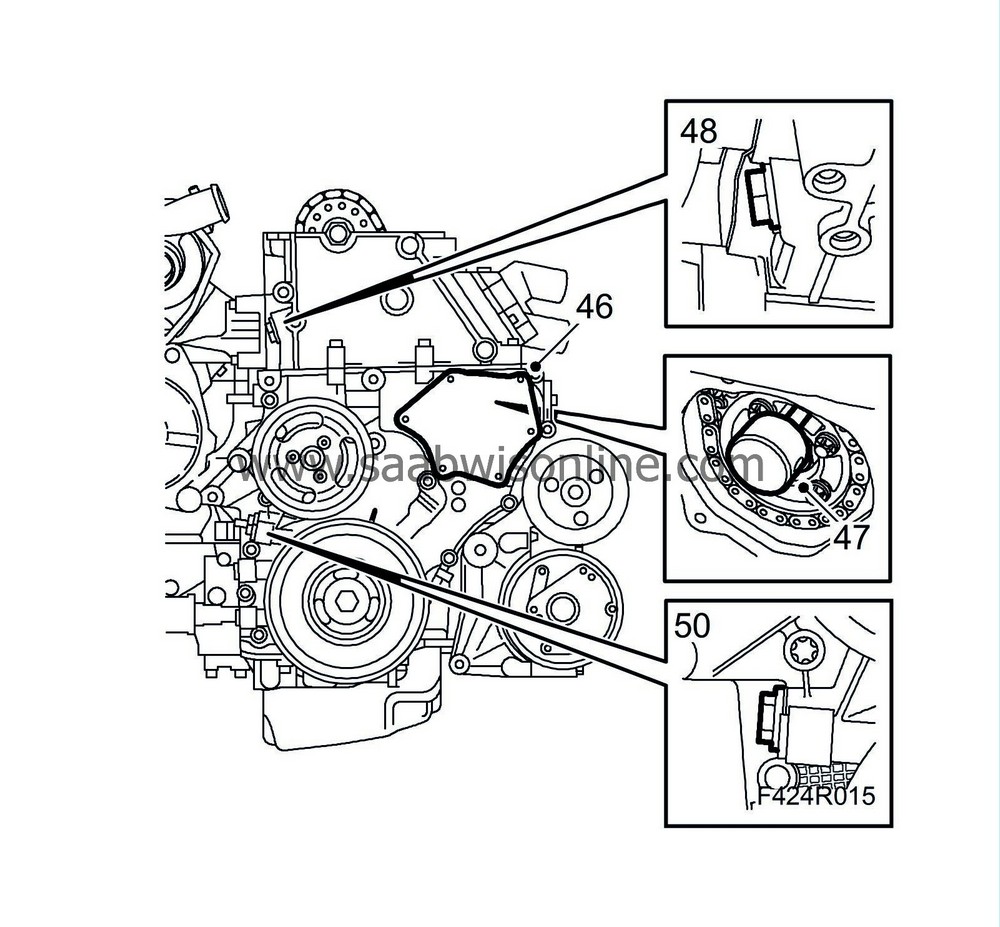

46.

|

Remove the bolts from the cover on the timing cover. Carefully insert a pallet knife behind the cover and prise it off.

|

Important

|

|

Take care, otherwise the cover can be distorted and cause leaks.

|

|

|

|

|

48.

|

Remove the upper timing chain tensioner.

|

|

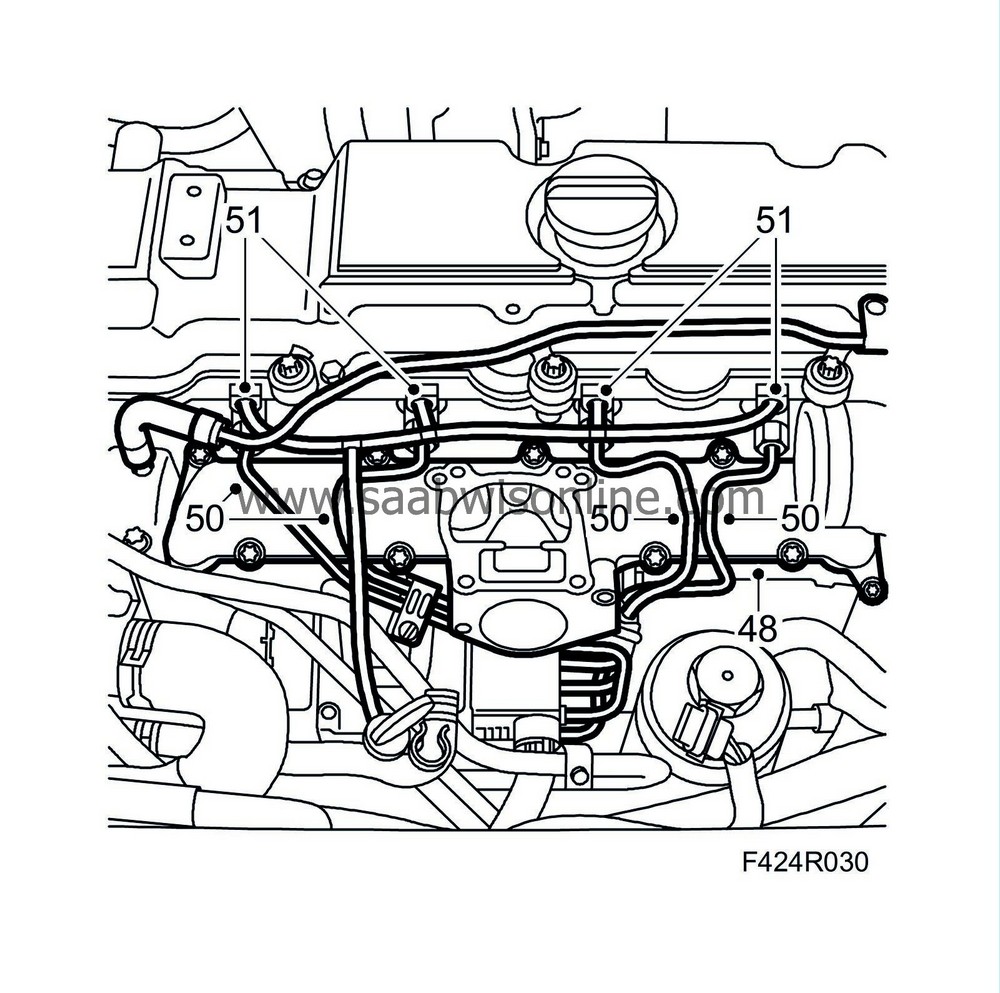

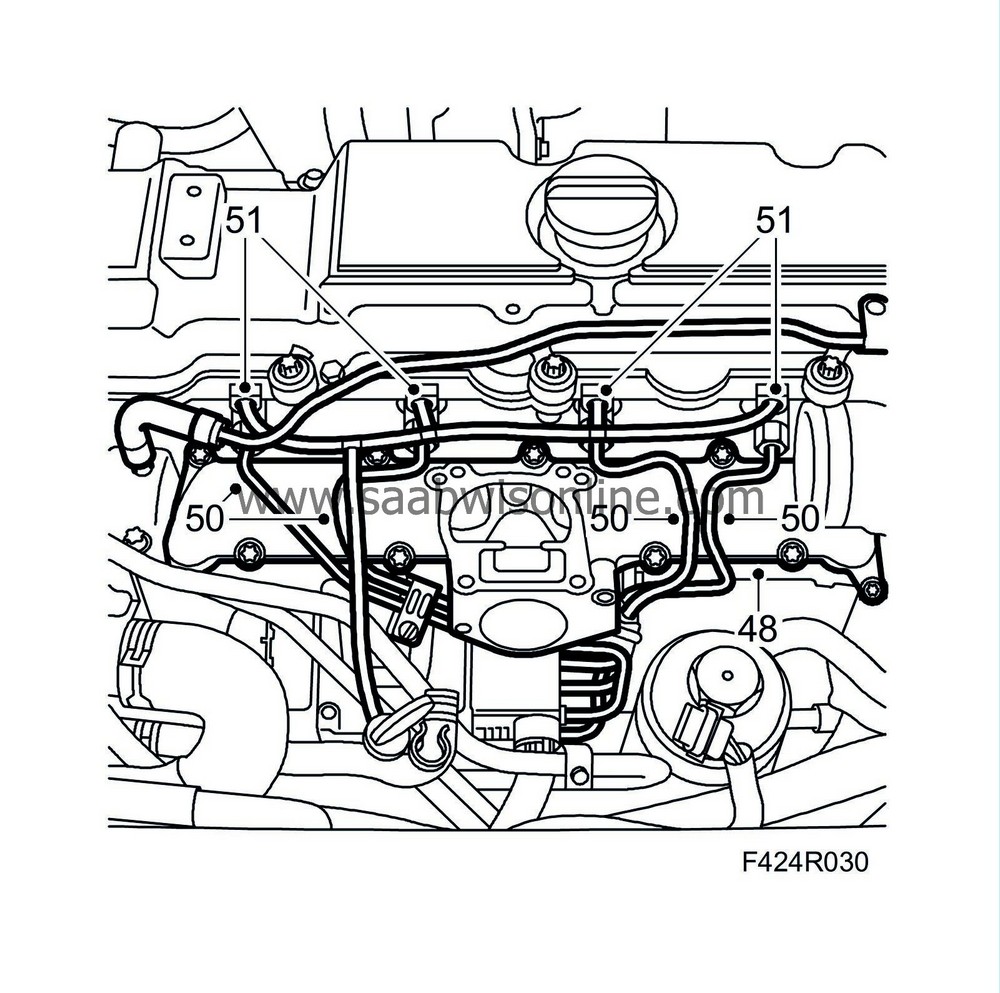

50.

|

Remove the lower timing chain tensioner.

|

|

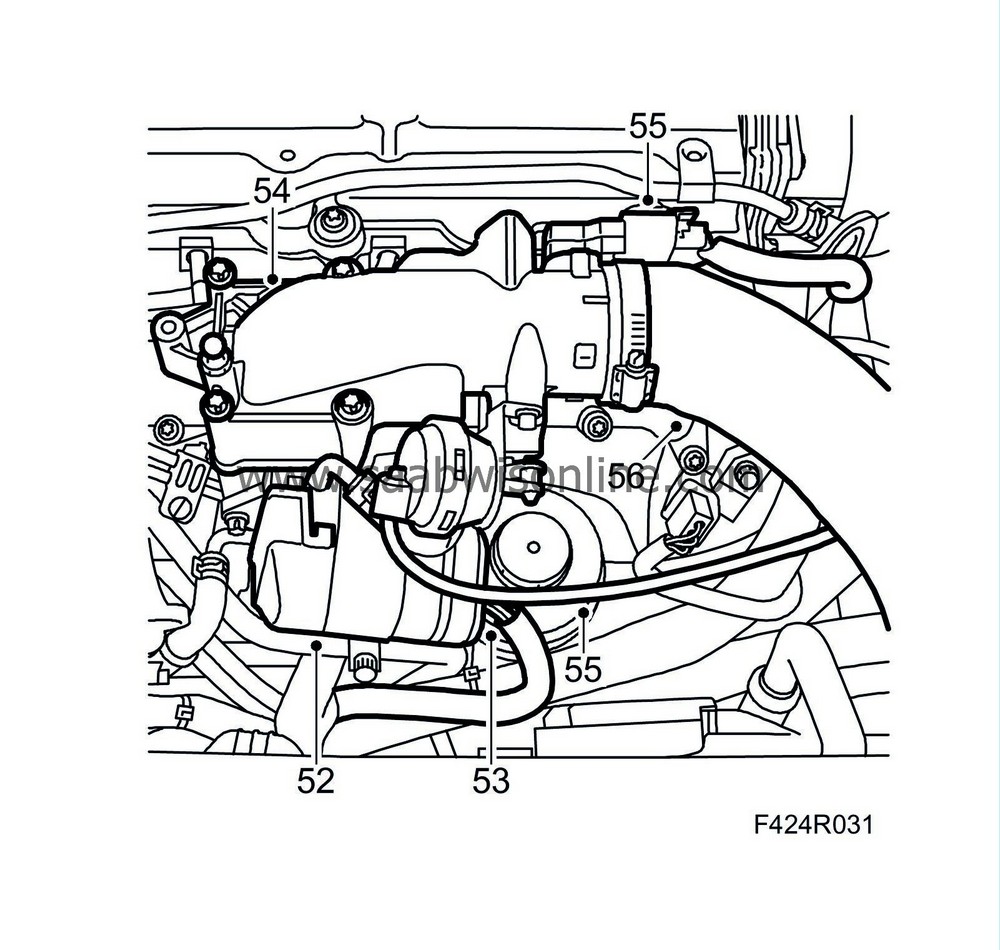

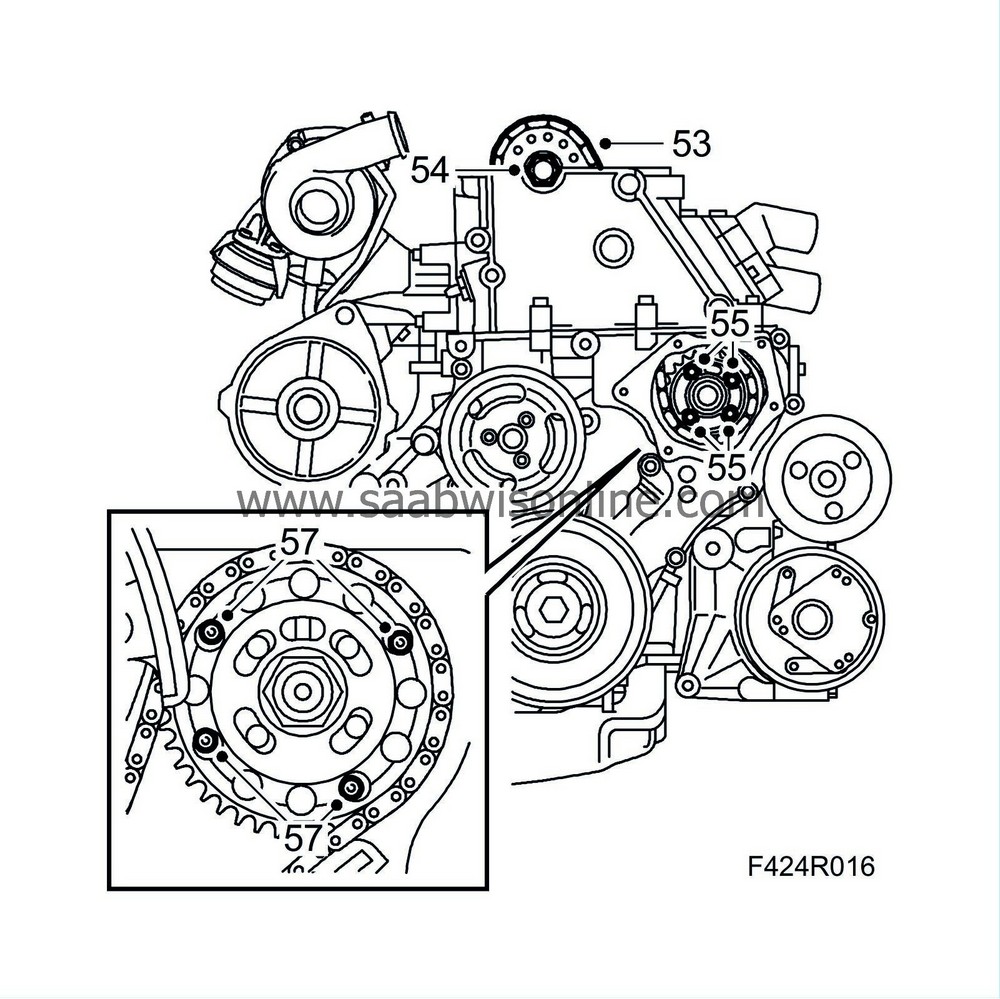

53.

|

Secure the upper timing chain to the camshaft sprocket with a cable tie.

|

|

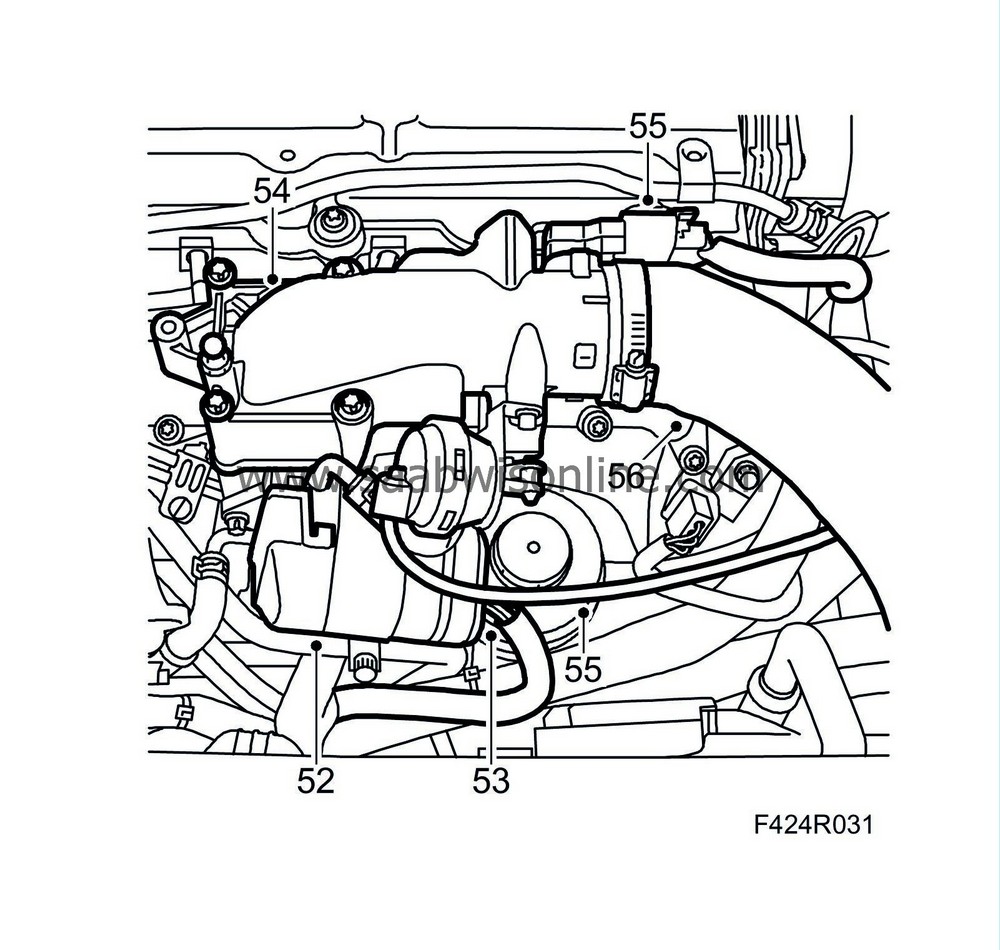

54.

|

Remove the camshaft sprocket using an open-ended wrench on the hexagonal key to hold the camshaft still.

|

|

55.

|

Undo the bolts from the sprocket on the fuel distribution pump and remove the sprocket.

|

Important

|

|

The centre nut must

absolutely not

be undone.

|

|

|

|

|

56.

|

Pull up the chain and remove it.

|

|

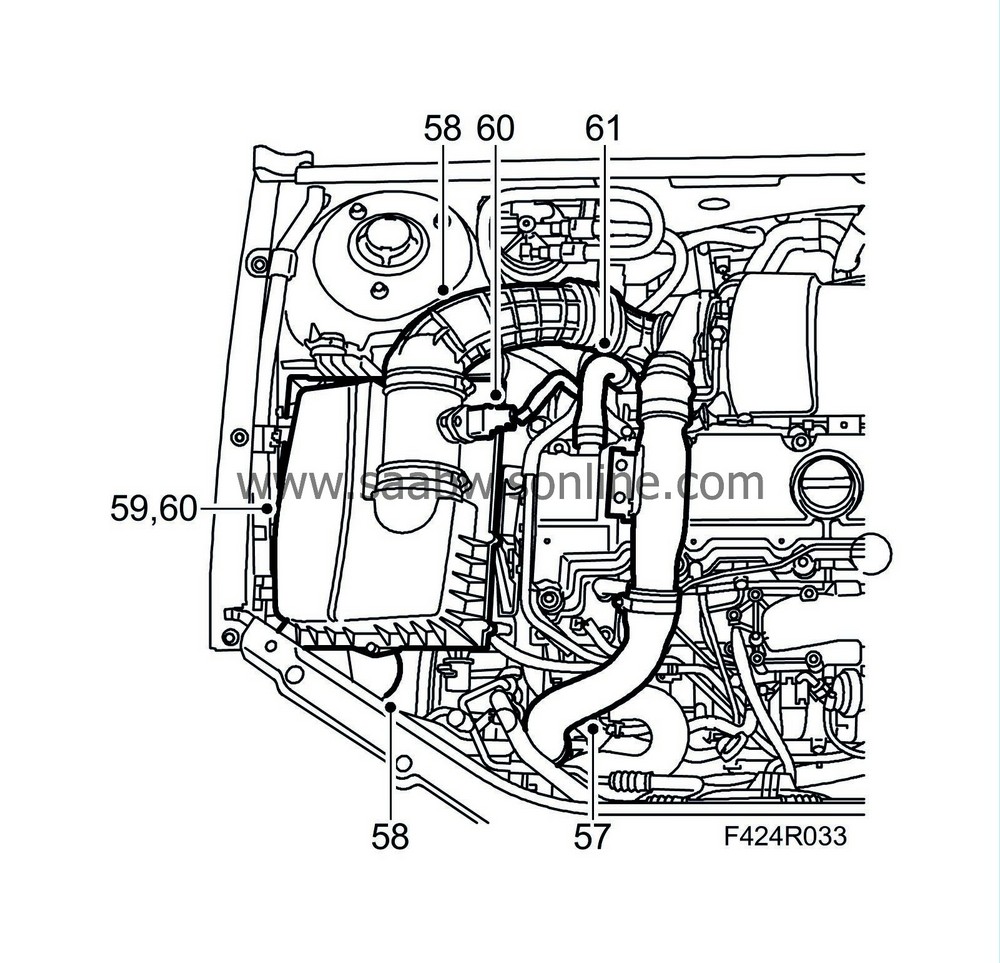

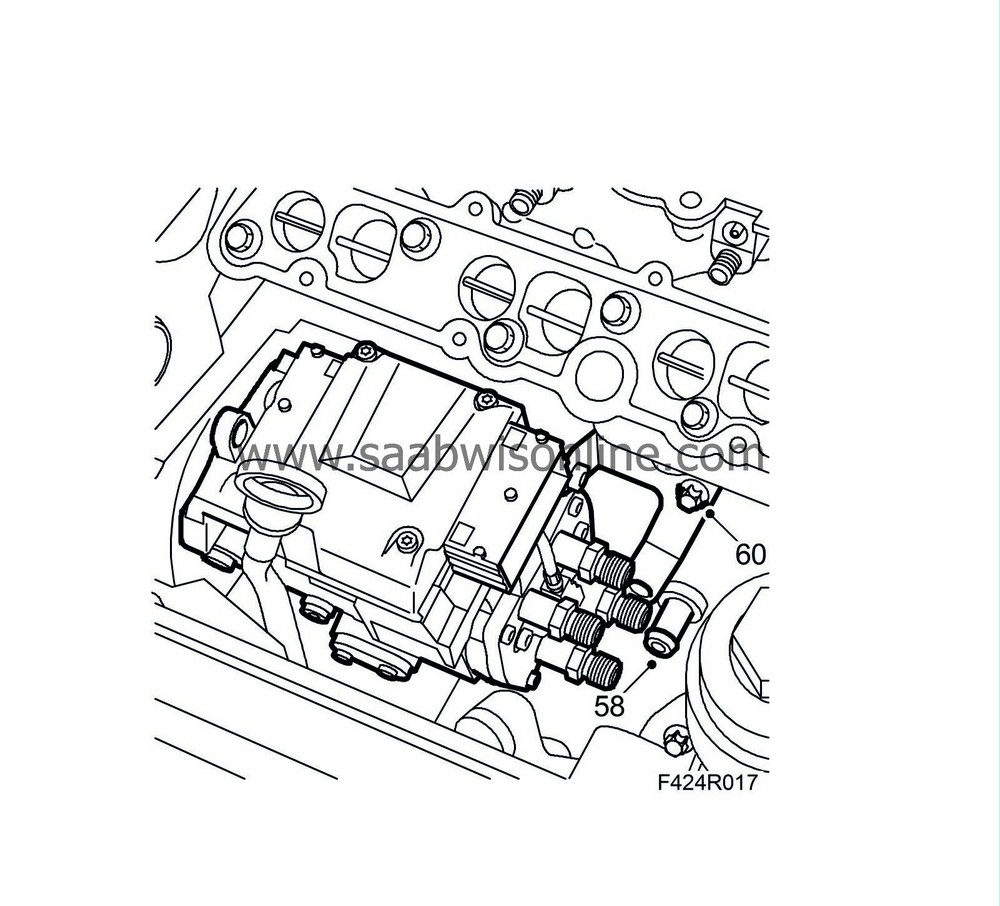

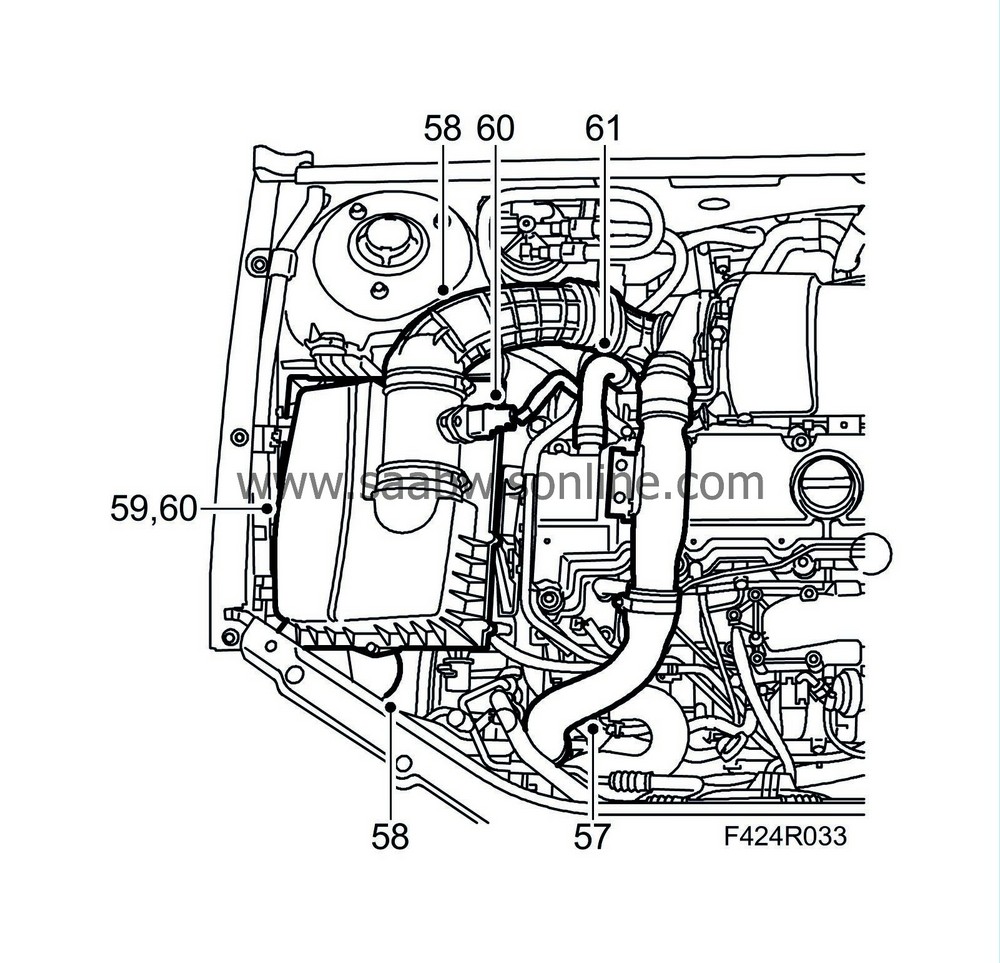

58.

|

Place a receptacle under the car. Undo the drain nipple using an 8-mm hex key. Connect a hose to the drain nipple on the engine block. Drain the coolant.

|

|

59.

|

Remove the drain nipple.

|

|

60.

|

Undo the bolt from the bracket on the cylinder block and remove the fuel pump.

|

Important

|

|

ESD-SENSITIVE COMPONENT

|

|

Earth yourself by touching the car body before plugging in / unplugging components.

Do not touch the component pins

. Read

Before removing a control module

before changing a control module.

|

|

|

|

|

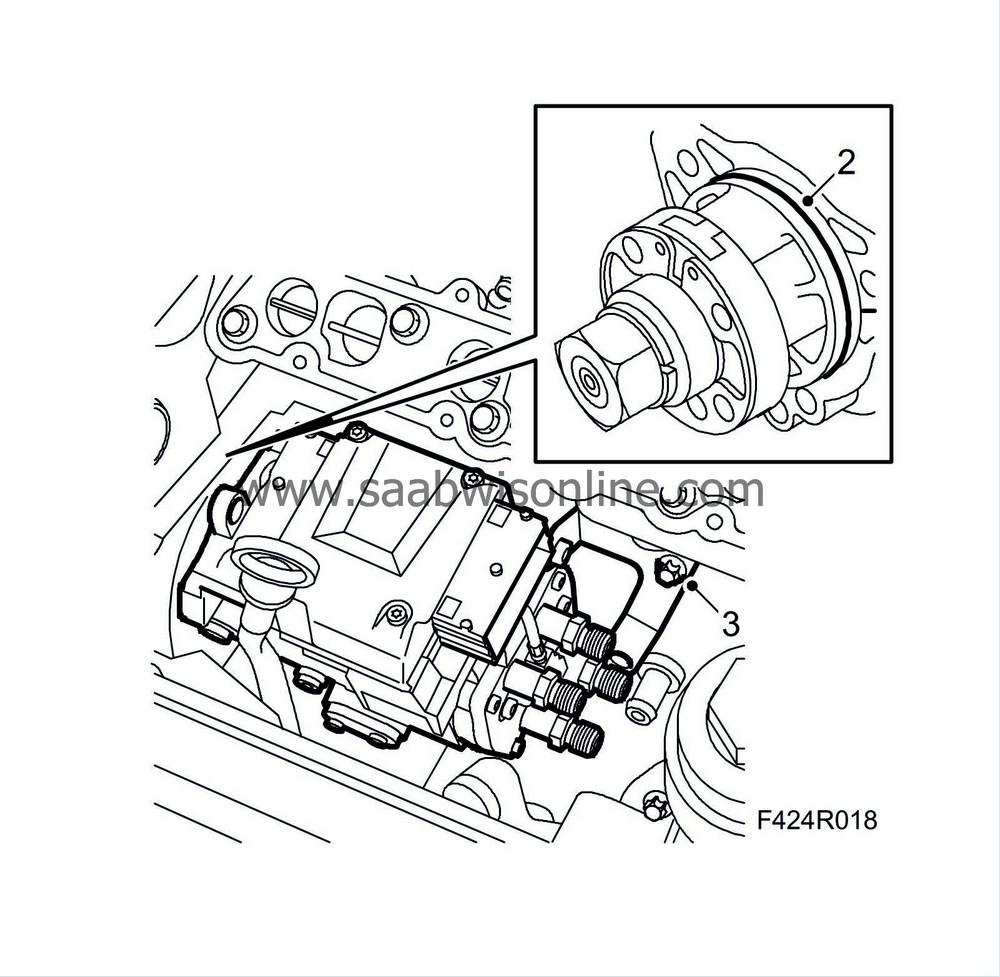

1.

|

Clean the sealing surfaces.

|

|

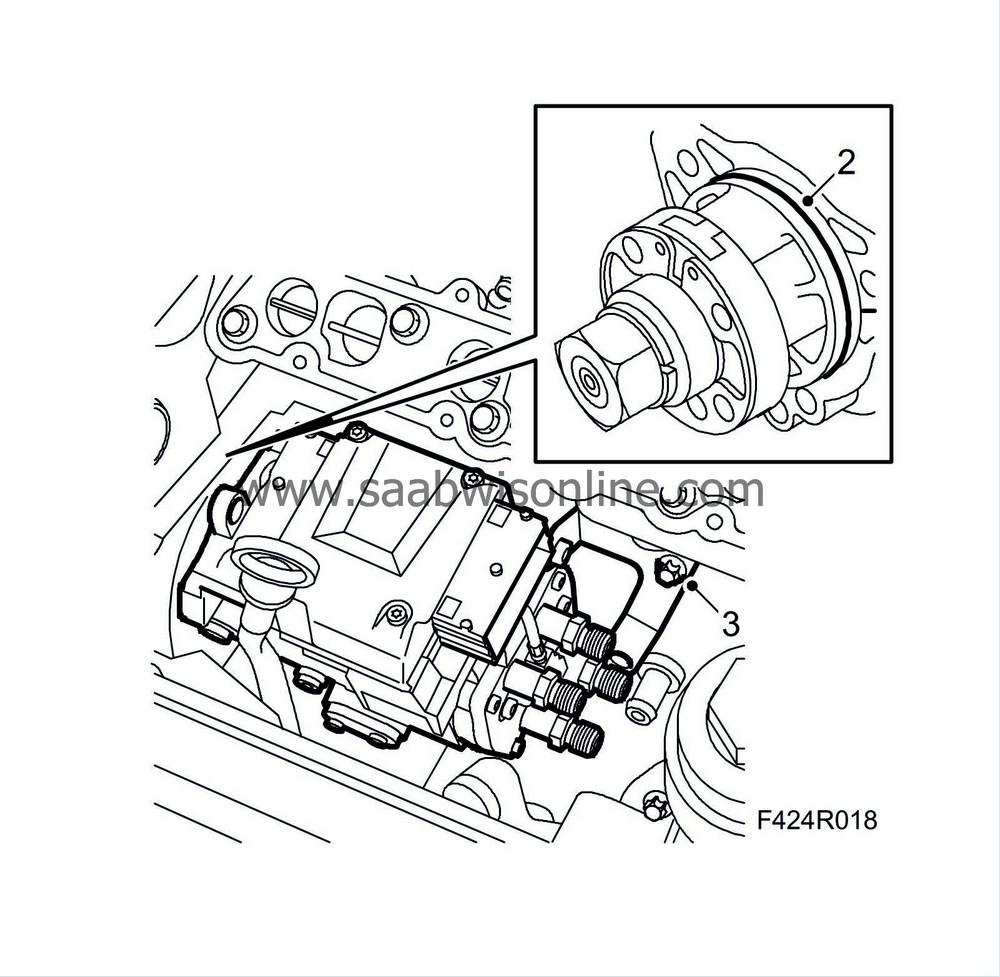

2.

|

Fit a new O-ring to the fuel distribution pump. Grease the O-ring with acid-free vaseline and fit the pump to the cylinder block. Transfer the bracket to the new pump if the pump has been changed.

Tightening torque 20 Nm (15 lbf ft).

|

|

3.

|

Thread the bolt holding the bracket to the cylinder block and but do not tighten it.

|

|

6.

|

Tighten the bolt securing the bracket to the cylinder block.

Tightening torque 20 Nm (15 lbf ft).

|

|

7.

|

Fit the engine block drain plug with a new O-ring.

|

|

8.

|

Remove the adjustment tool from the fuel distribution pump.

|

|

9.

|

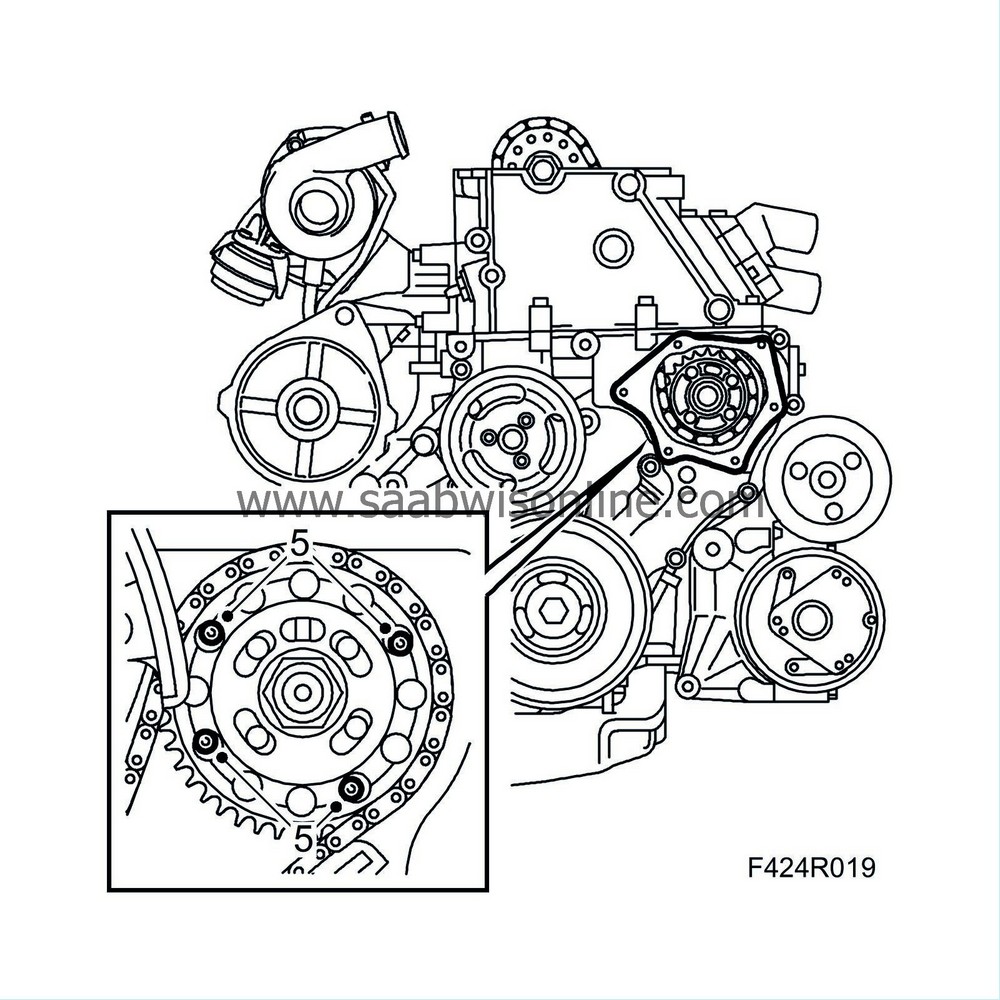

Lower the upper timing chain and position the fuel distribution pump sprocket. Fit the sprocket with a bolt. Fit the chain and tighten the sprocket bolt finger tight.

|

Important

|

|

The arrow on the sprocket must be aligned with the recess on the flange and the hole in the pump.

|

|

|

|

|

11.

|

Fit the camshaft sprocket to the camshaft.

|

|

13.

|

Fit the chain tensioner for the lower timing chain using a new gasket.

Tightening torque 60 Nm (44 lbf ft)

|

|

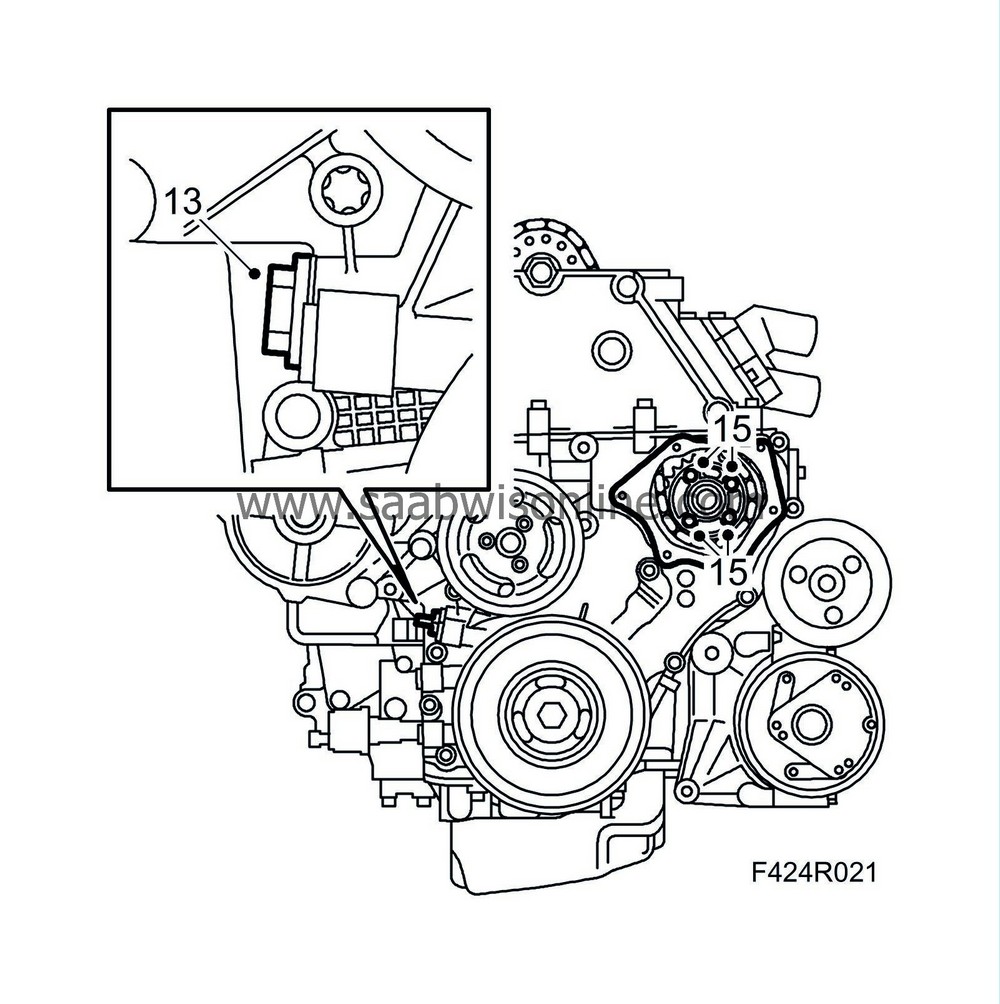

15.

|

Remove the check gauge from the fuel distribution pump and tighten the sprocket bolts.

Tightening torque 20 Nm (15 lbf ft).

|

|

16.

|

Re-insert the adjustment tool into the fuel distribution pump's recess.

|

|

17.

|

Check that the camshaft sprocket runs freely on the camshaft and fit a new bolt. Tighten the bolt finger tight.

|

|

19.

|

Fix the position for the adapter on the camshaft sprocket by lightly twisting it anticlockwise with a ratchet handle. Tighten the adjustment screw on the tool.

|

Important

|

|

Adjustment tool, fuel pump 83 95 337 must be easy to remove and fit at all times. If not, slacken the adjusting screw on the tool slightly

|

|

|

|

|

20.

|

Tighten the bolt securing the camshaft sprocket. Use an open-ended wrench in the hexagonal key to hold the camshaft still.

Tightening torque 90 Nm (67 lbf ft) + 60°

|

|

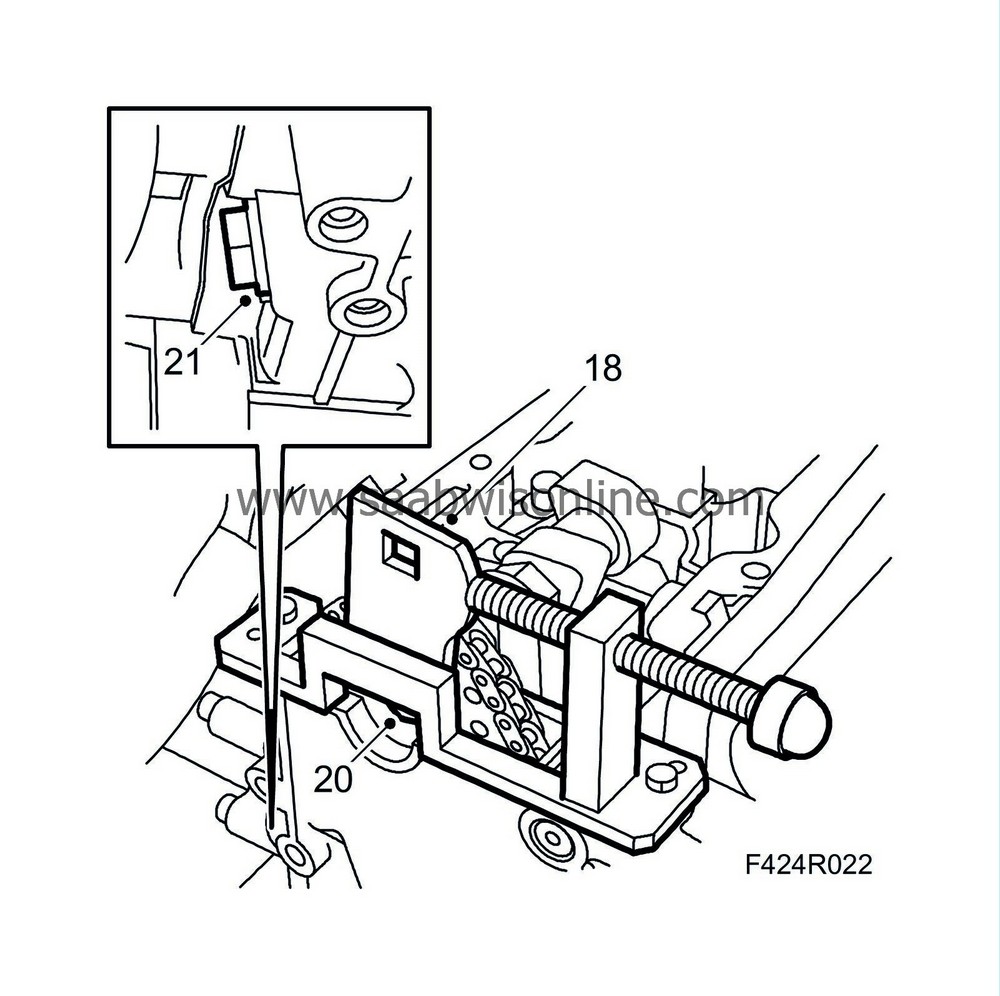

21.

|

Fit the chain tensioner for the upper timing chain using a new gasket.

Tightening torque 60 Nm (44 lbf ft)

|

|

23.

|

Turn the crankshaft two turns to just before the mark for TDC for cylinder 1. Check that both cams for cylinder 1 point obliquely upward.

|

|

25.

|

Insert

83 95 352 Adjustment tool, crankshaft

into the hole for the crankshaft position sensor. Press the tool in while turning the crankshaft to zero. The tool should enter a recess in the crankshaft and lock it.

|

|

27.

|

Check that the markings on the crankshaft pulley and timing cover are aligned. Also, the arrow on the single camshaft sprocket by the fuel distribution pump should be aligned with the recess on the pump.

|

|

31.

|

Fit the crankshaft position sensor with a new O-ring.

|

|

32.

|

Cover the opening in the timing cover with a lint-free cloth and clean any gasket remains from the sealing surface. Clean the sealing surface on the cover.

|

|

33.

|

Apply a 2 mm bead of

83 95 691 Flange sealant

to the cover. Remove the cloth from the timing cover and fit the cover.

Tightening torque 6 Nm (5 lbf ft)

|

|

34.

|

Clean away any gasket remains from the sealing surfaces on the cylinder head.

|

|

35.

|

Fit a new gasket to the timing cover. The bolts have sleeves where the gasket is to sit.

|

|

37.

|

Place the camshaft cover on the cylinder head and tighten the bolts.

Tightening torque 8 Nm (6 lbf ft)

|

|

38.

|

Fit the rear wiring harness mounting to the camshaft cover.

|

|

39.

|

Clean the sealing surfaces on the vacuum pump and cylinder head.

|

|

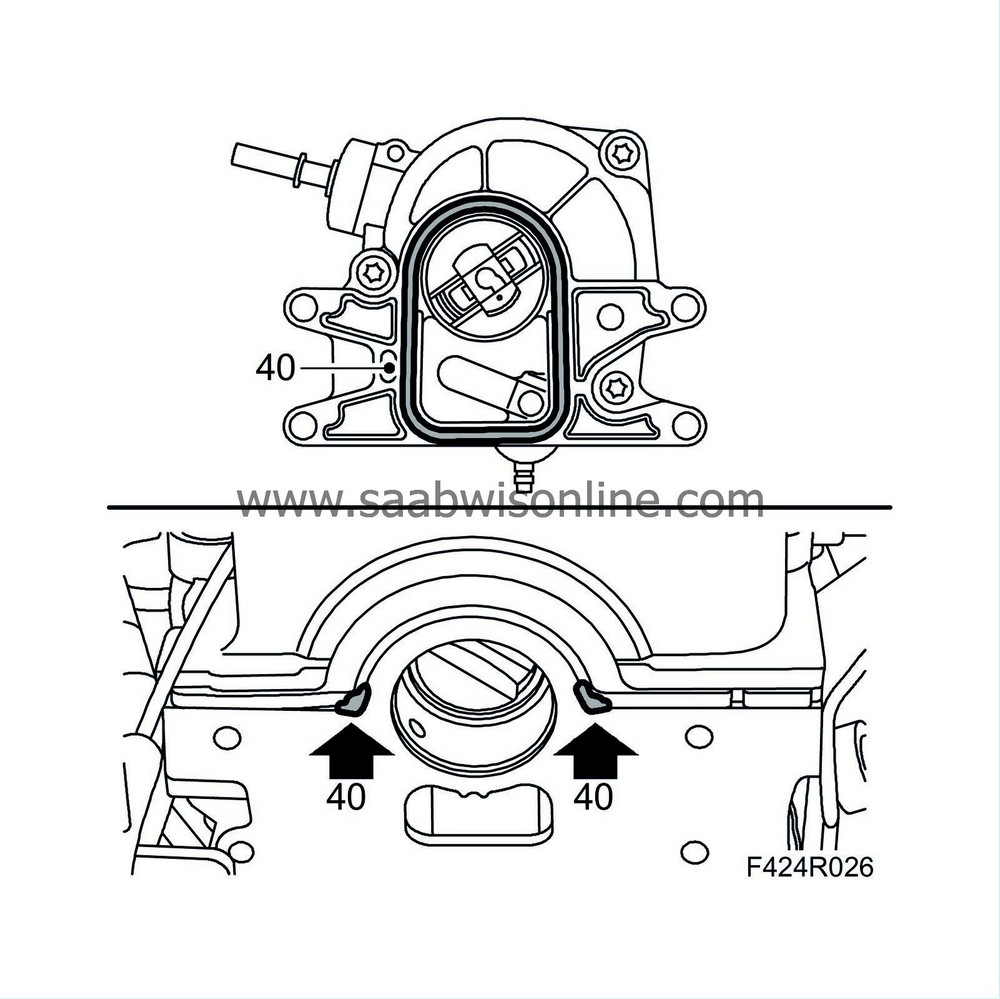

40.

|

Fit a new gasket to the vacuum pump and apply

83 95 691 Flange sealant

as illustrated. Fit the pump and adapter.

Tightening torque 8 Nm (6 lbf ft)

|

|

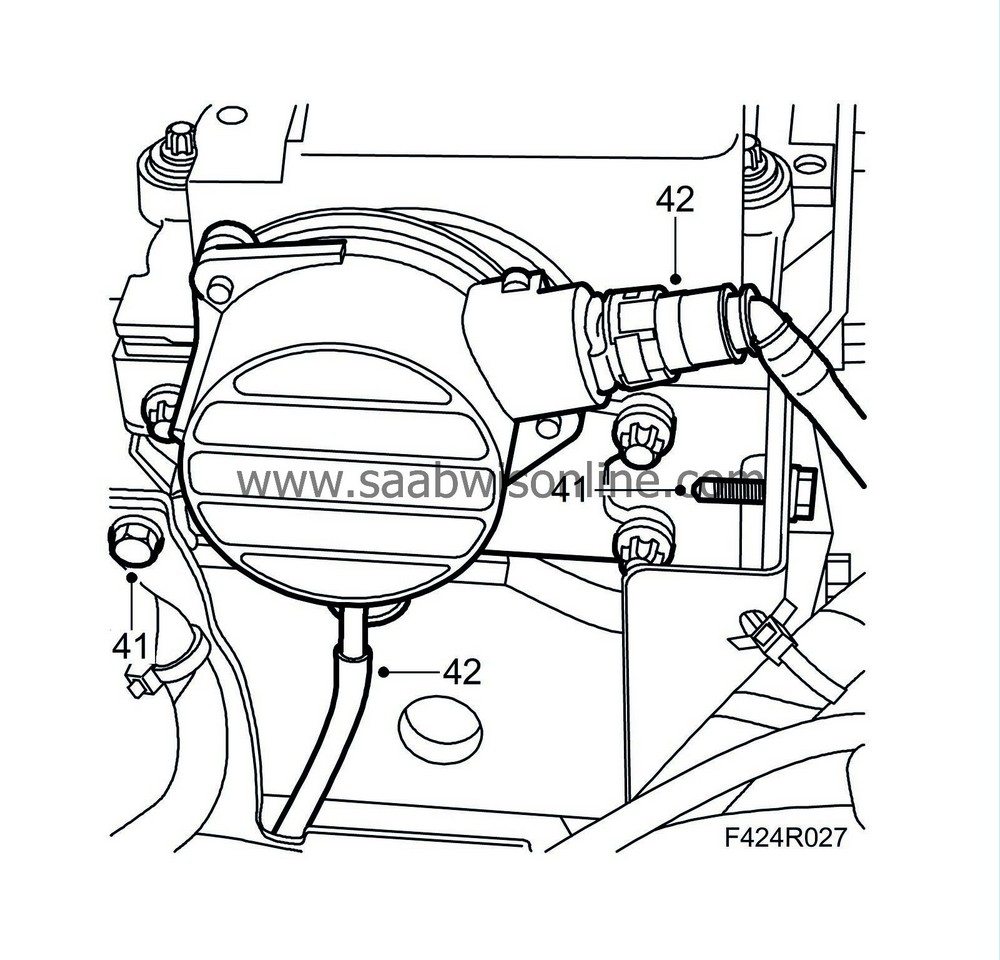

41.

|

Fit the cable duct.

|

|

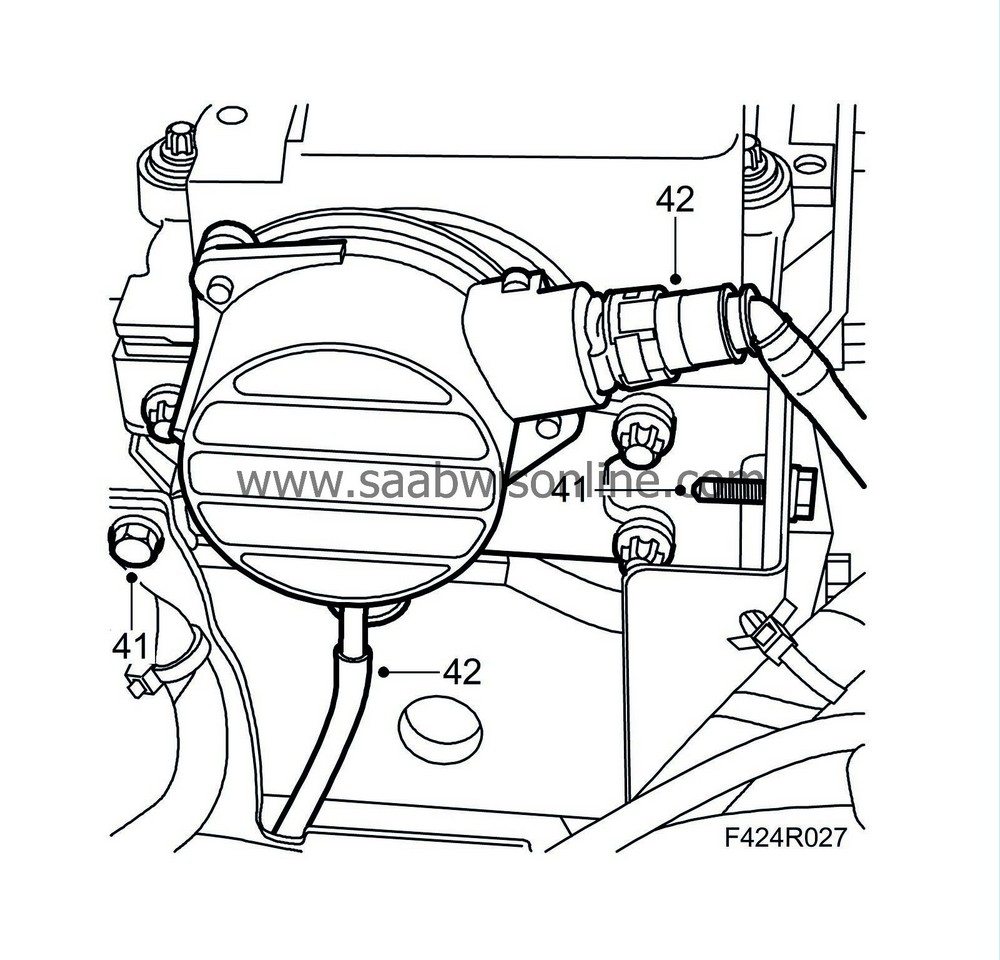

42.

|

Connect the vacuum hoses to the vacuum pump.

|

|

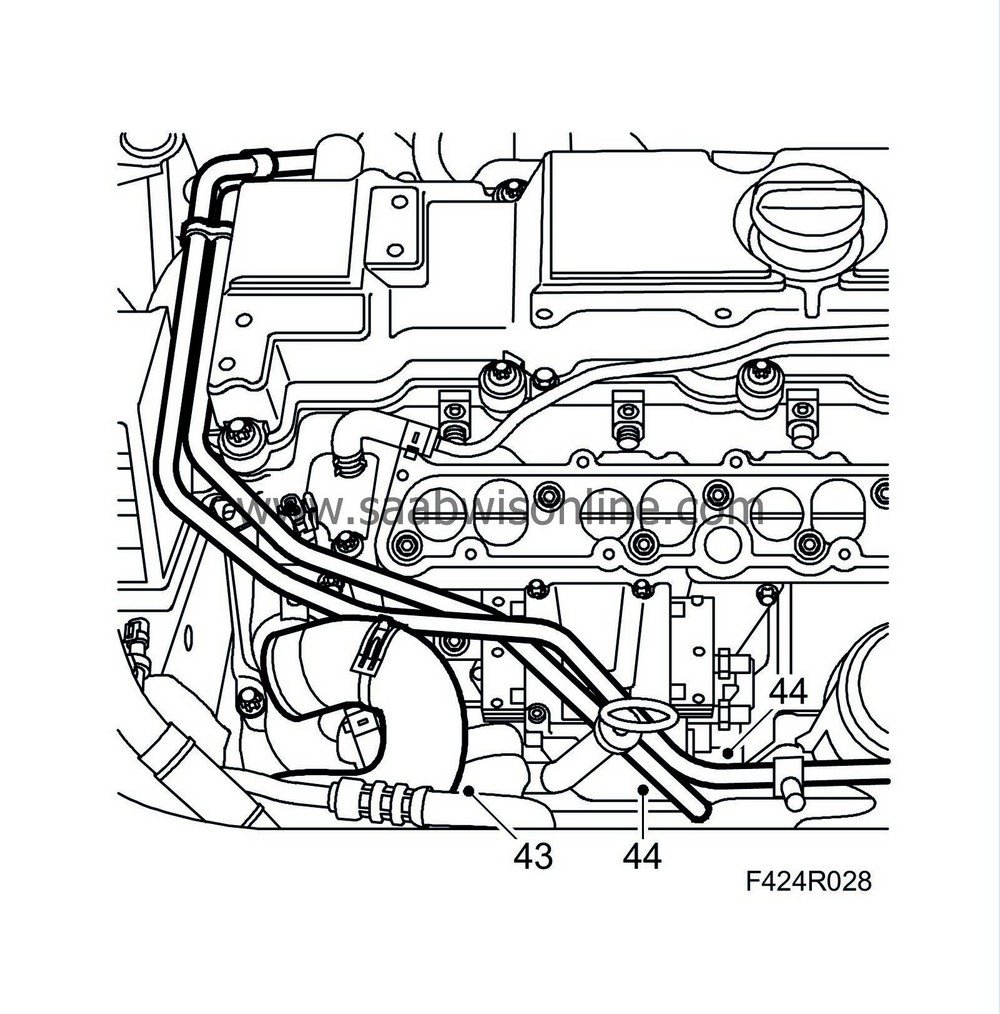

43.

|

Connect the coolant pipe and hose.

|

|

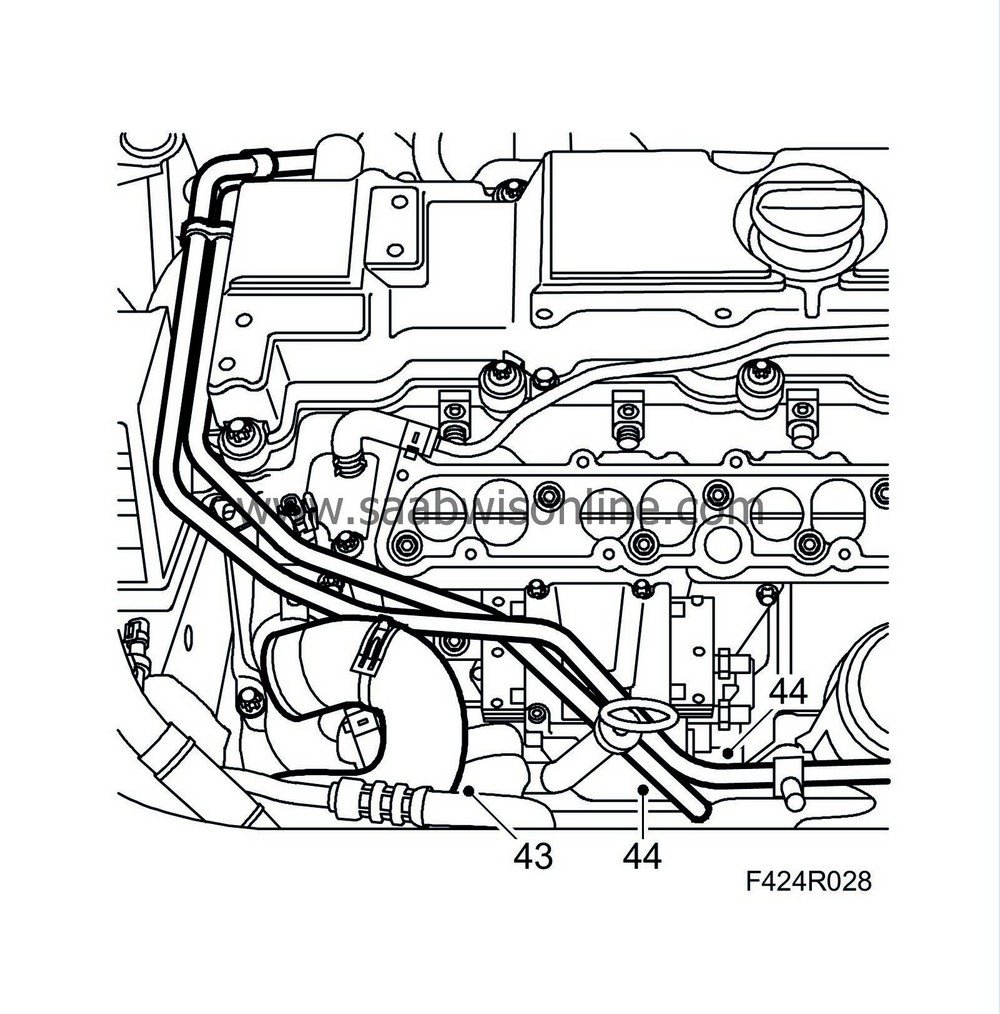

44.

|

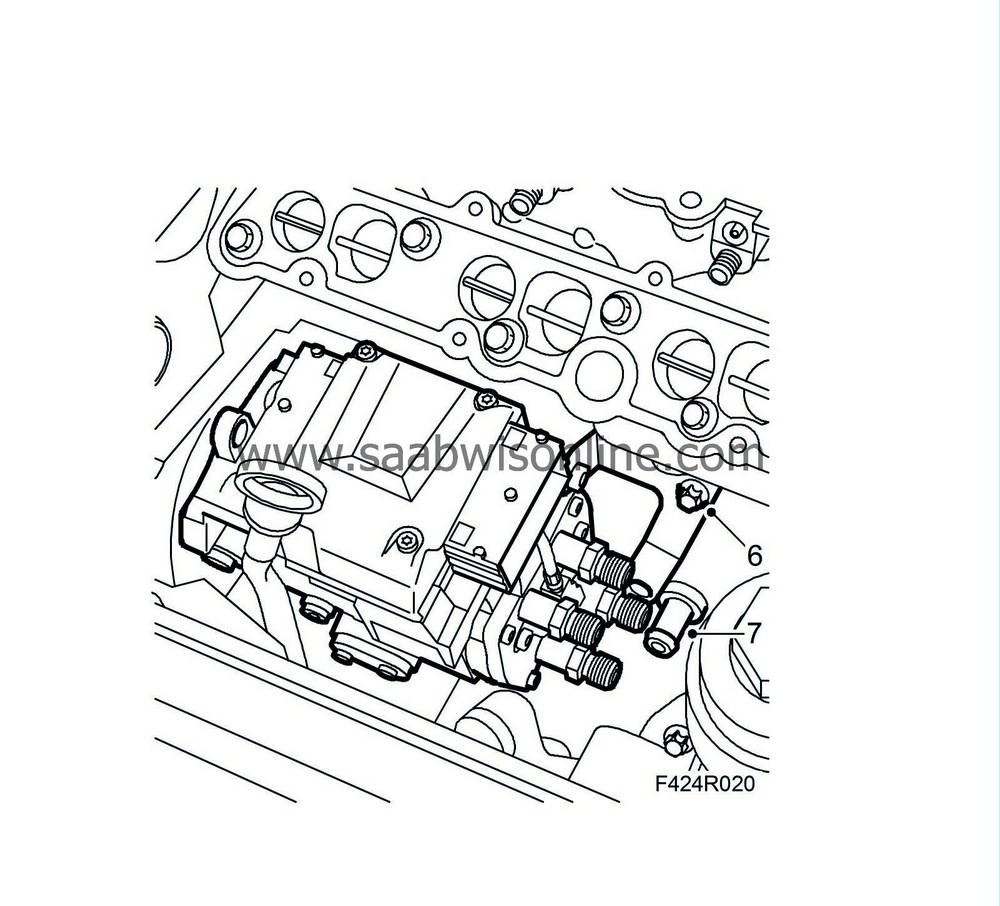

Fit a new fuel return hose to the deliver line. Fit the return and delivery fuel lines to the fuel pump using new seals. Do not fully tighten the connections.

Connect the fuel lines to the lines from the tank. Align the lines with the outlet in the camshaft cover and tighten the connections on the fuel pump.

Hold the fuel lines still to prevent them twisting when tightened.

Tightening torque 25 Nm (19 lbf ft)

|

Important

|

|

Take care when plugging in the connector so as not to damage or press out the pins/sleeves in the connector. For further information regarding connectors, refer to

Connectors, handling and inspection

.

|

|

|

|

|

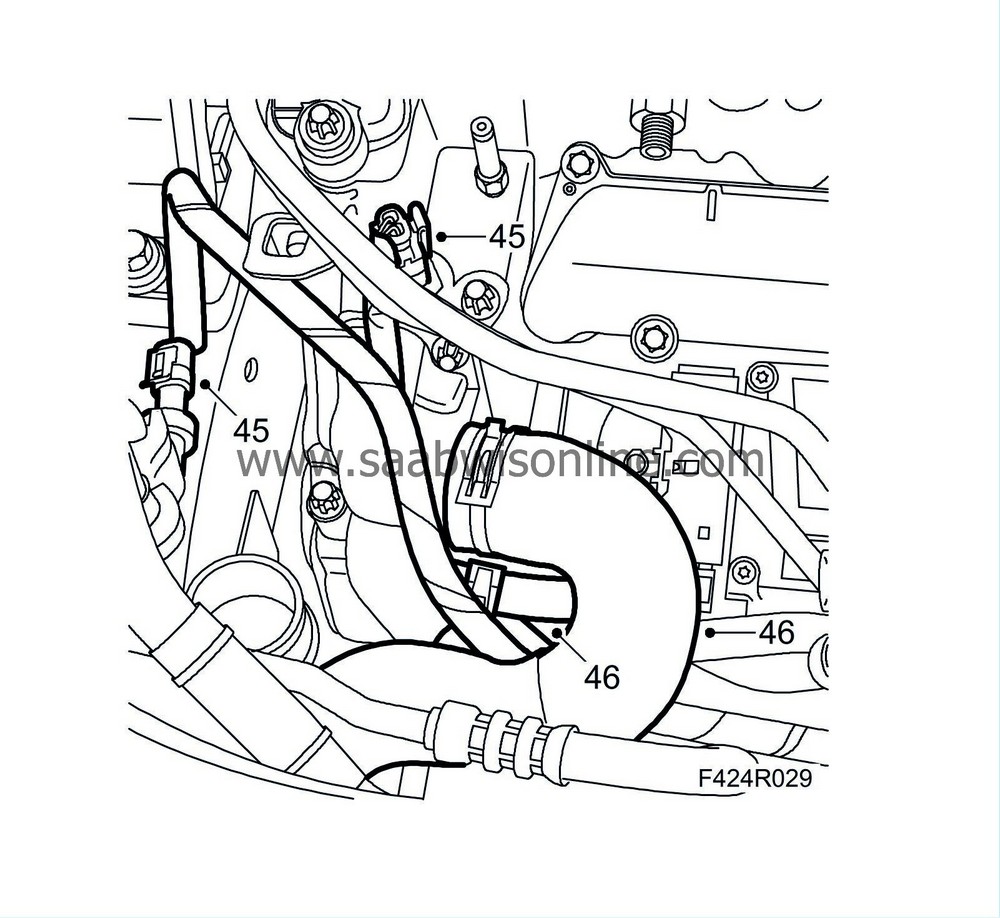

45.

|

Plug in connectors to the fuel pump control module, coolant temperature sensor and AC pressure sensor.

|

Important

|

|

ESD-SENSITIVE COMPONENT

|

|

Earth yourself by touching the car body before plugging in / unplugging components.

Do not touch the component pins

. Read

Before removing a control module

before changing a control module.

|

|

|

|

|

46.

|

Connect the coolant hoses to the thermostat housing.

|

|

47.

|

Secure the wiring to the coolant hose using a cable tie.

|

|

48.

|

Clean the sealing surfaces for the upper intake manifold. Fit the upper section with a new gasket.

Tightening torque 10 Nm (7 lbf ft)

|

|

49.

|

Check the connecting cones on the fuel distribution pipes and replace if necessary.

|

|

50.

|

Fit the fuel distribution pipes.

Tightening torque 25 Nm (19 lbf ft)

|

|

51.

|

Fit the new fuel return hoses to the fuel bridges and connect the previously fitted fuel return hose.

|

|

52.

|

Fit the EGR valve using a new O-ring.

Tightening torque 10 Nm (7 lbf ft)

|

|

53.

|

Plug in the EGR valve and connect the coolant hose.

|

|

54.

|

Fit the throttle body using a new gasket.

Tightening torque 10 Nm (7 lbf ft)

|

|

55.

|

Fit the connector and vacuum hose to the throttle body.

|

|

56.

|

Fit the turbo delivery hose to the throttle body.

|

|

57.

|

Remove the plugs and connect the charge air hose and pipe to the turbocharger and fit the charge air pipe to the fan cowling.

|

|

58.

|

Fit the filter housing intake hose. Fit the air filter housing.

|

|

60.

|

Fit the lid to the air filter housing.

|

|

61.

|

Fit the intake hose from the mass air flow sensor to the turbocharger and the hose for the crankcase ventilation.

|

|

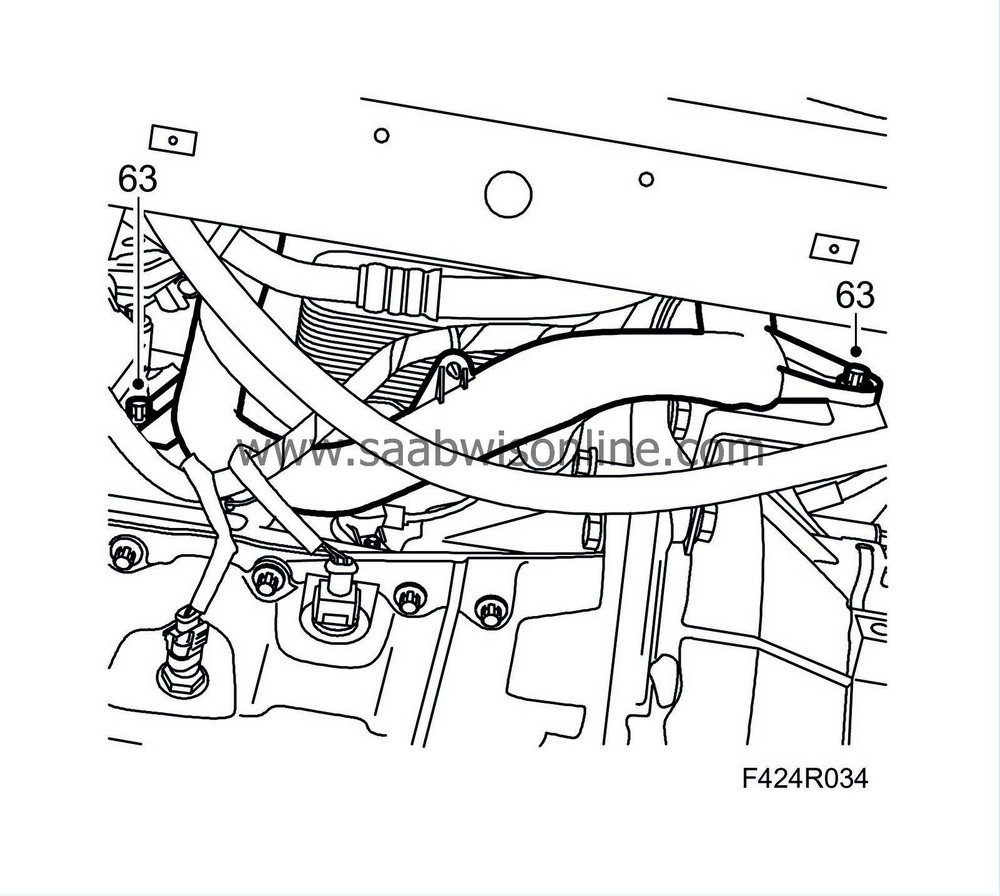

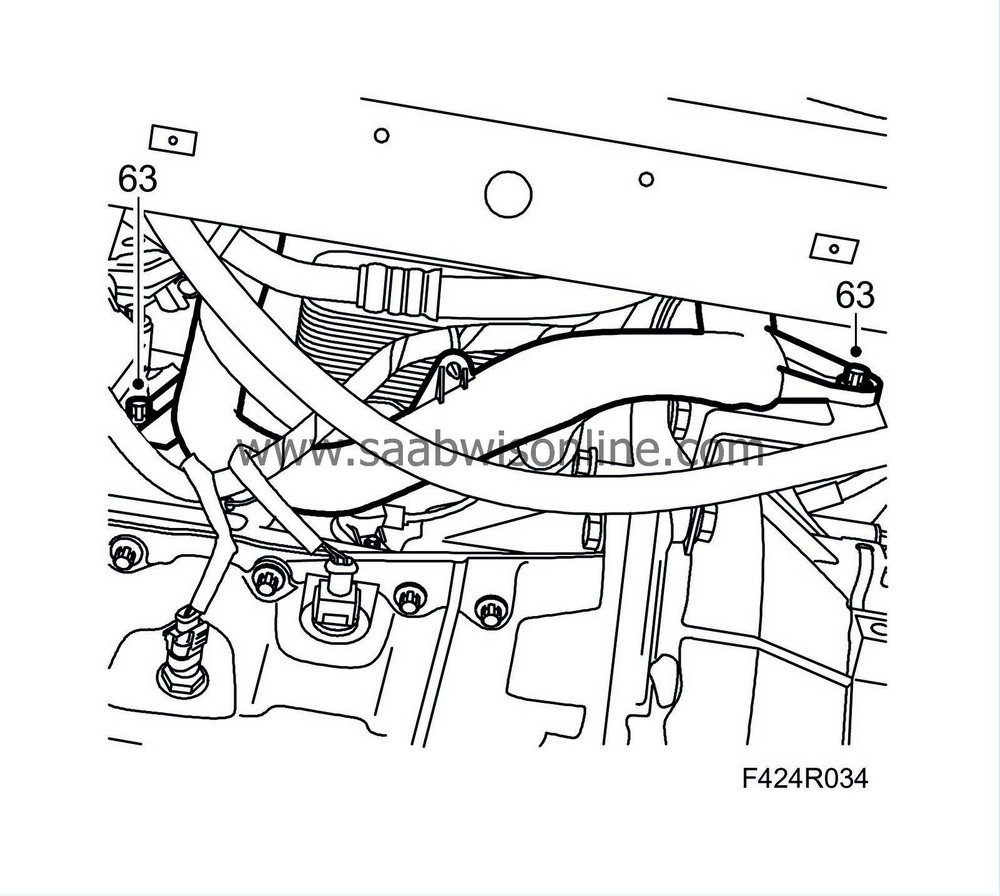

63.

|

Fit the bolts to the coolant pipe.

|

|

64.

|

Check that the coolant drain cock is closed.

|

|

65.

|

Fit the belt tensioner tightening the upper bolt first.

Tightening torque 42 Nm (31 lbf ft)

|

|

66.

|

Tighten the lower bolt.

Tightening torque 23 Nm (17 lbf ft)

|

|

67.

|

Check that the belt pulleys are clean and dry.

|

|

68.

|

Fit the poly-V-belt as marked and check that it is correctly seated in the pulleys.

|

|

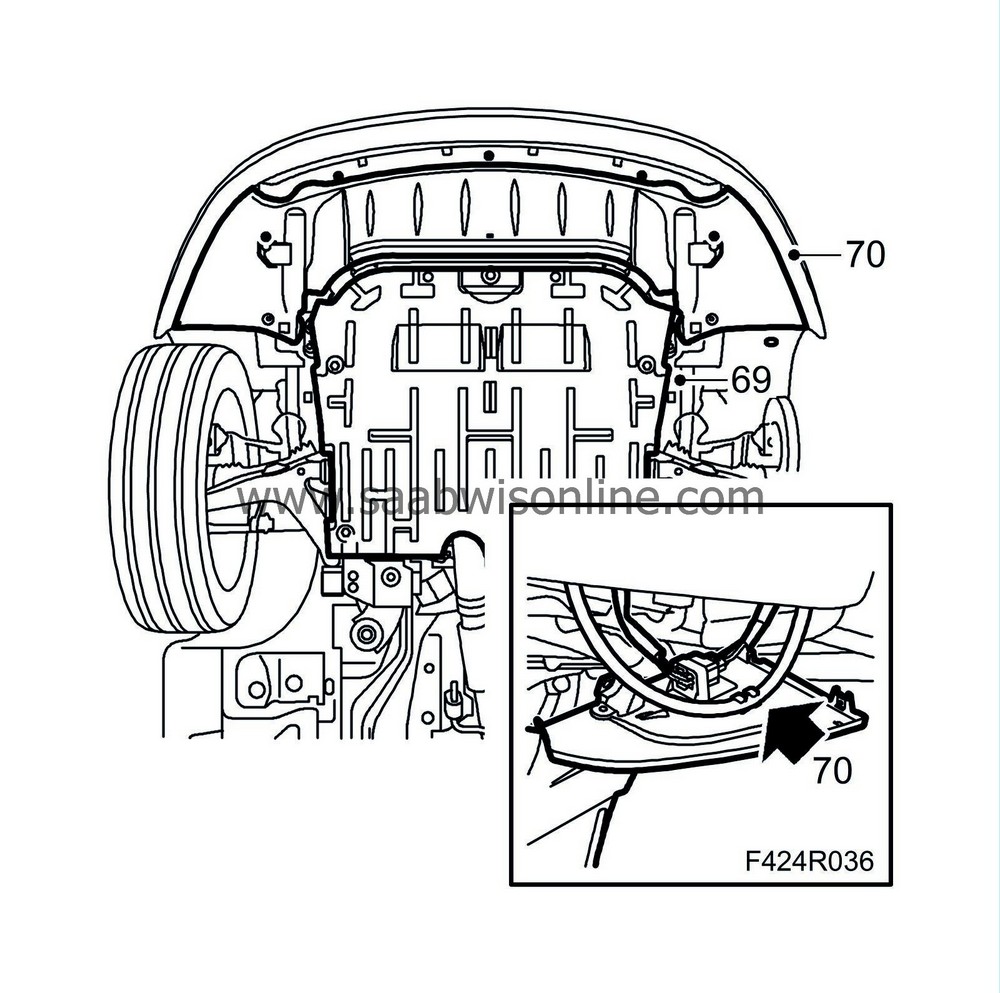

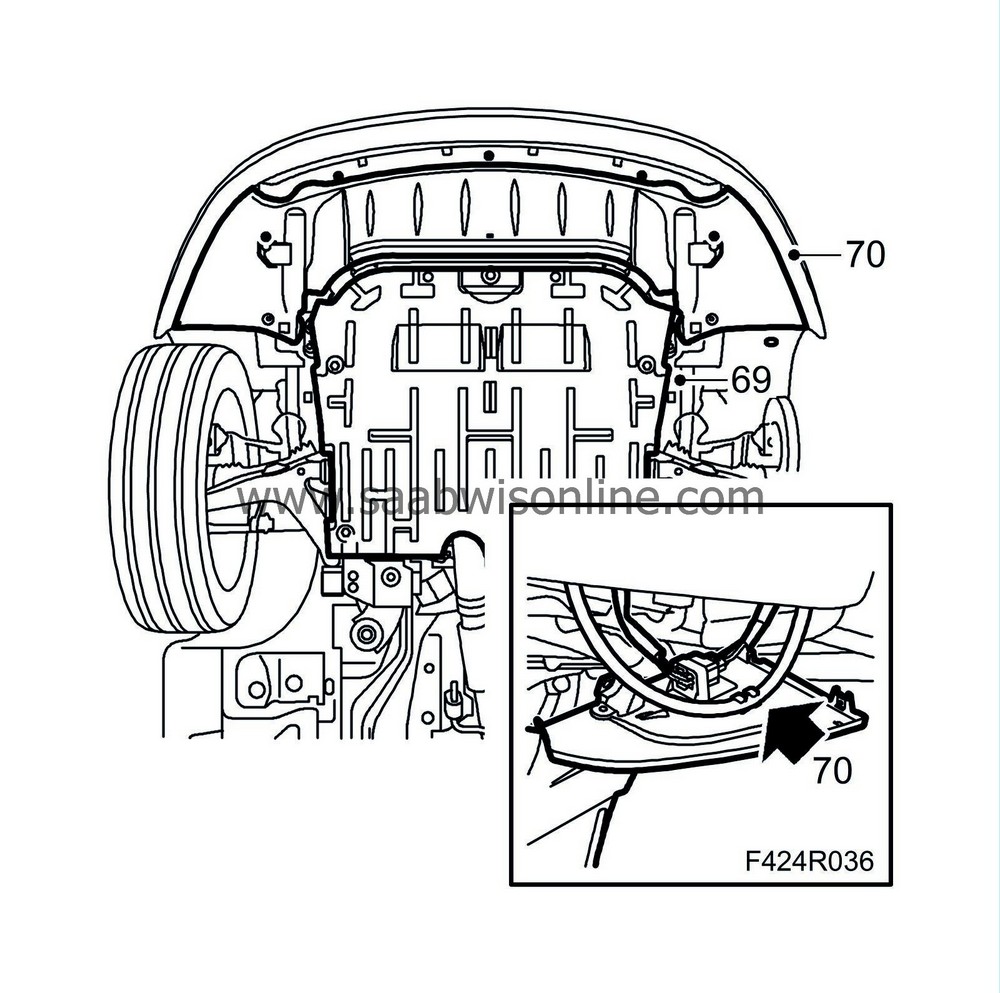

69.

|

Fit the lower engine cover.

|

|

70.

|

Fit the front spoiler shield. Plug in and fit the connector. Fit the headlight washer hose.

|

|

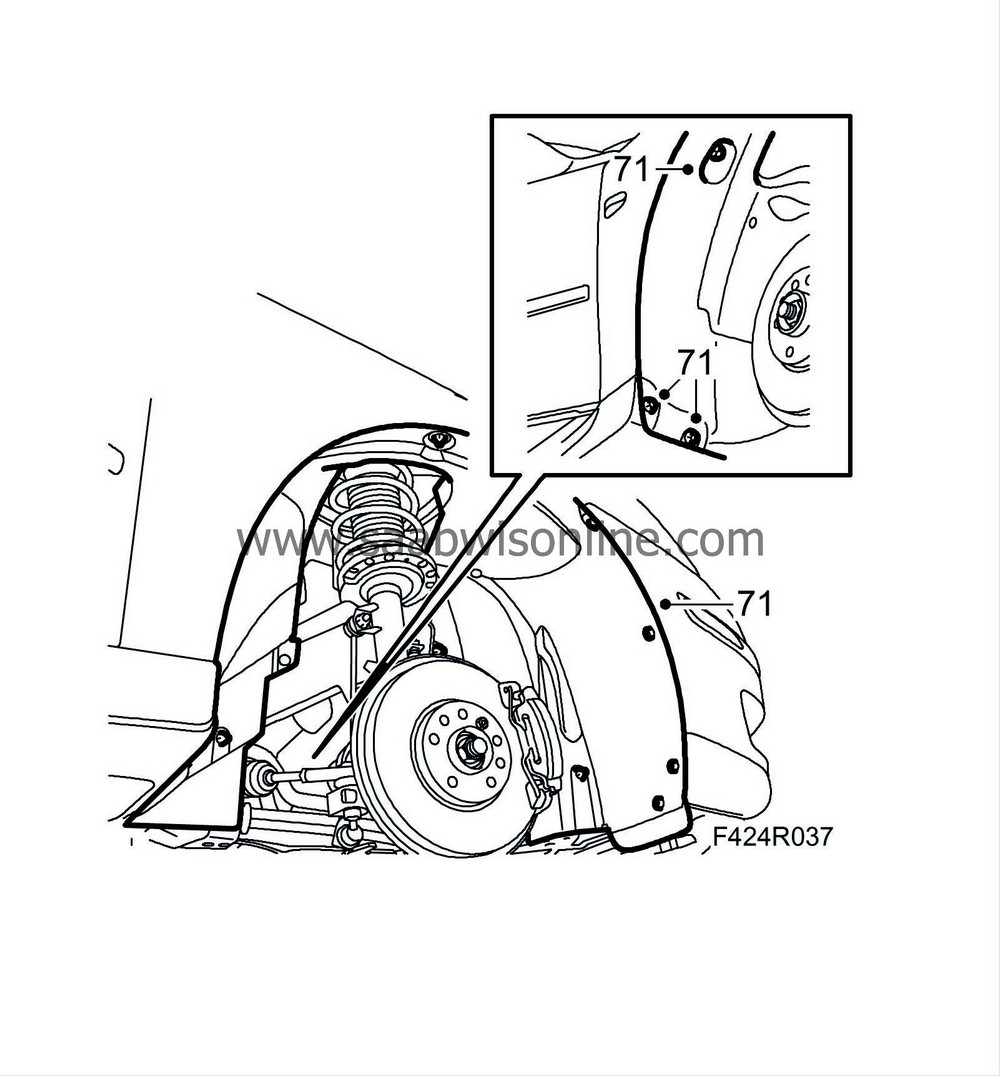

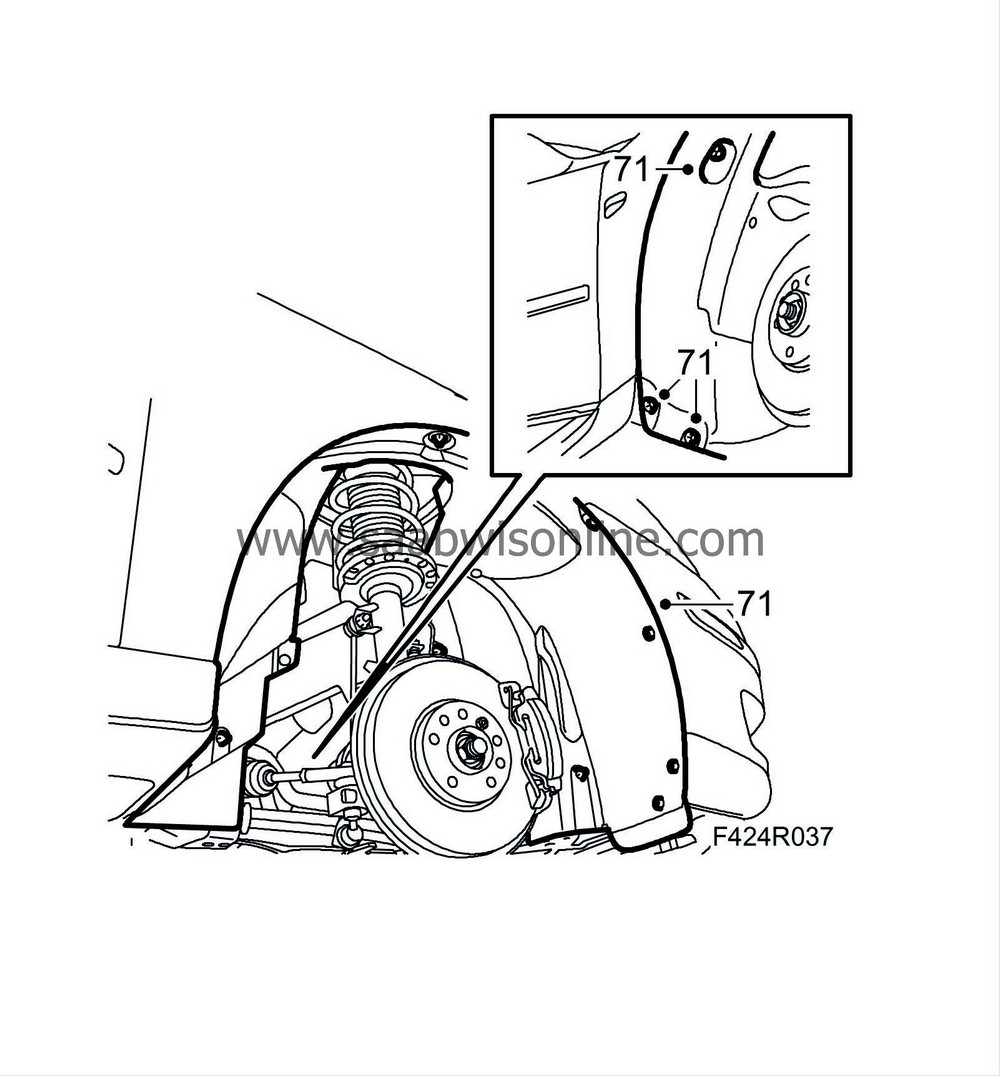

71.

|

Fit the right-hand wing liner.

|

|

72.

|

Fit the wheel. Refer to

Wheels

.

|

|

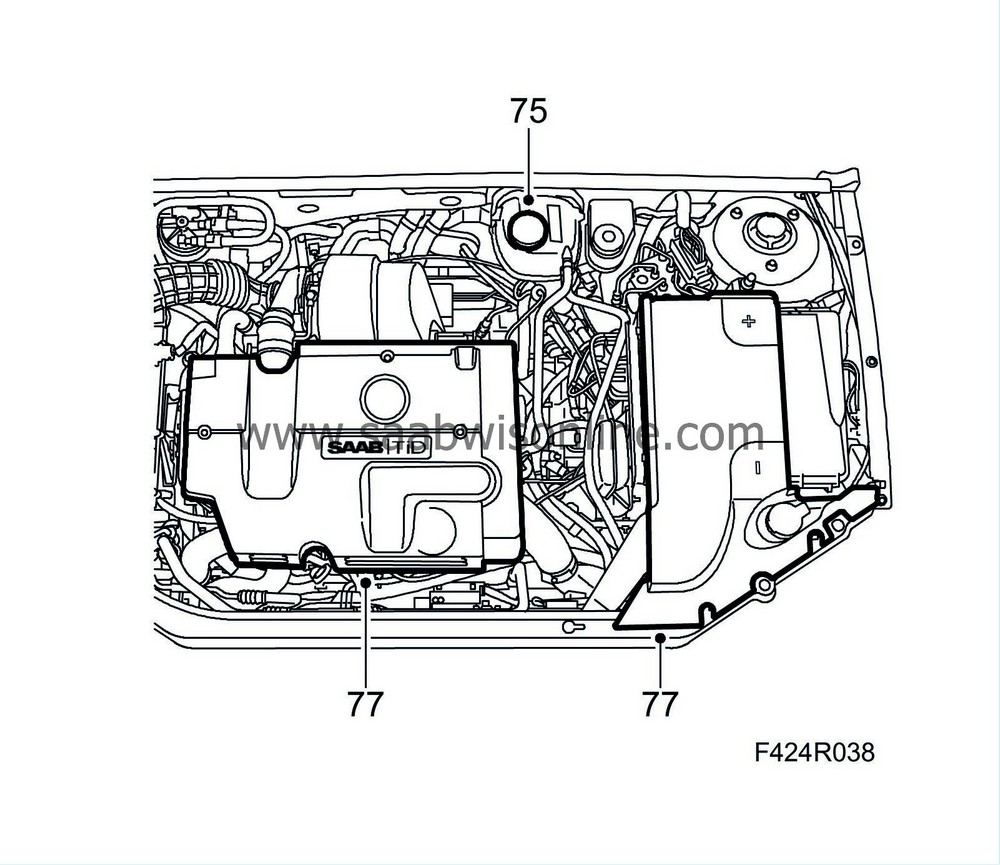

76.

|

Fit the upper engine cover.

|

Warning

Warning