A-pillar outer panel, CV

| A-pillar outer panel, CV |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam may be recognized from the gold colour of the joint. A MIG brazing must always be replaced by a new MIG brazing.

|

|||||||

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

| 2. |

Remove the

Front wing

,

Bonnet

and

Door

.

|

|

| 3. |

Drill out the spot welds as illustrated. Drill out the upper welds only so that the nut piece follows.

|

|

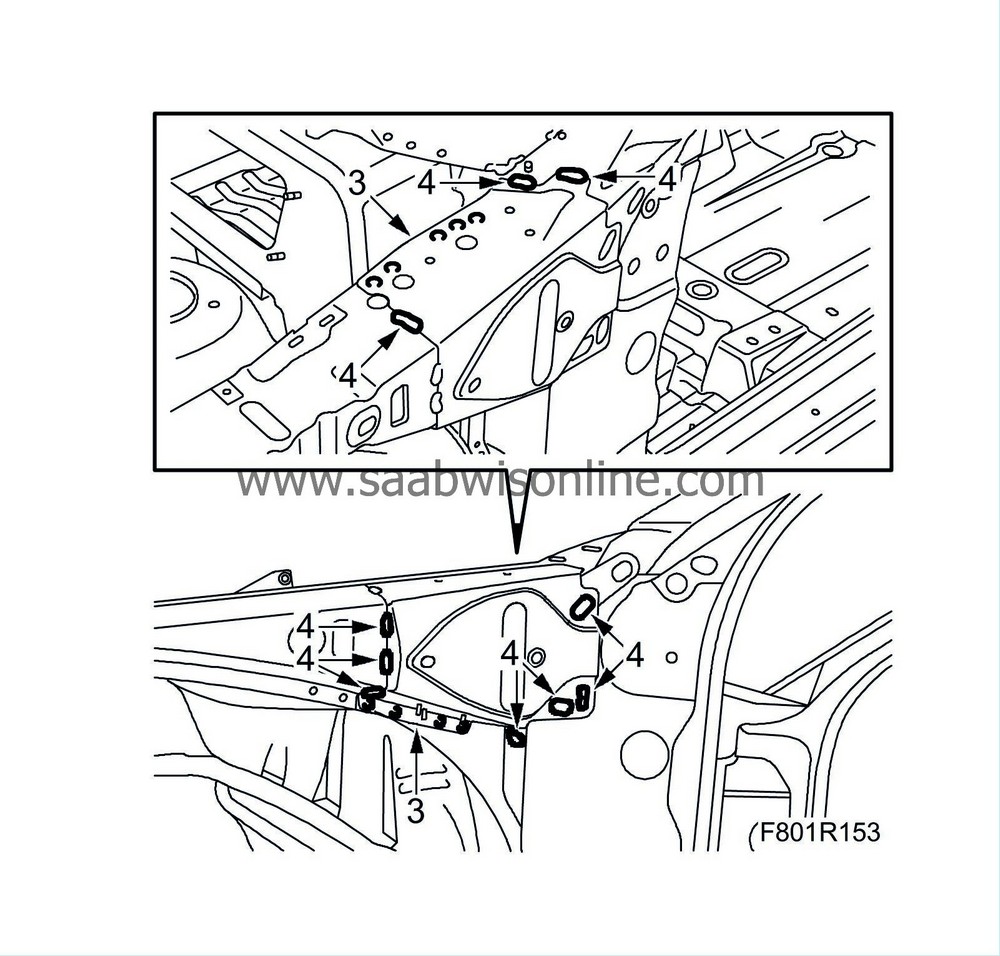

| 4. |

Grind away the welds, according to the illustration. Note that the seam welds are MIG brazed.

|

|

| 5. |

Knock loose the reinforcement.

|

|

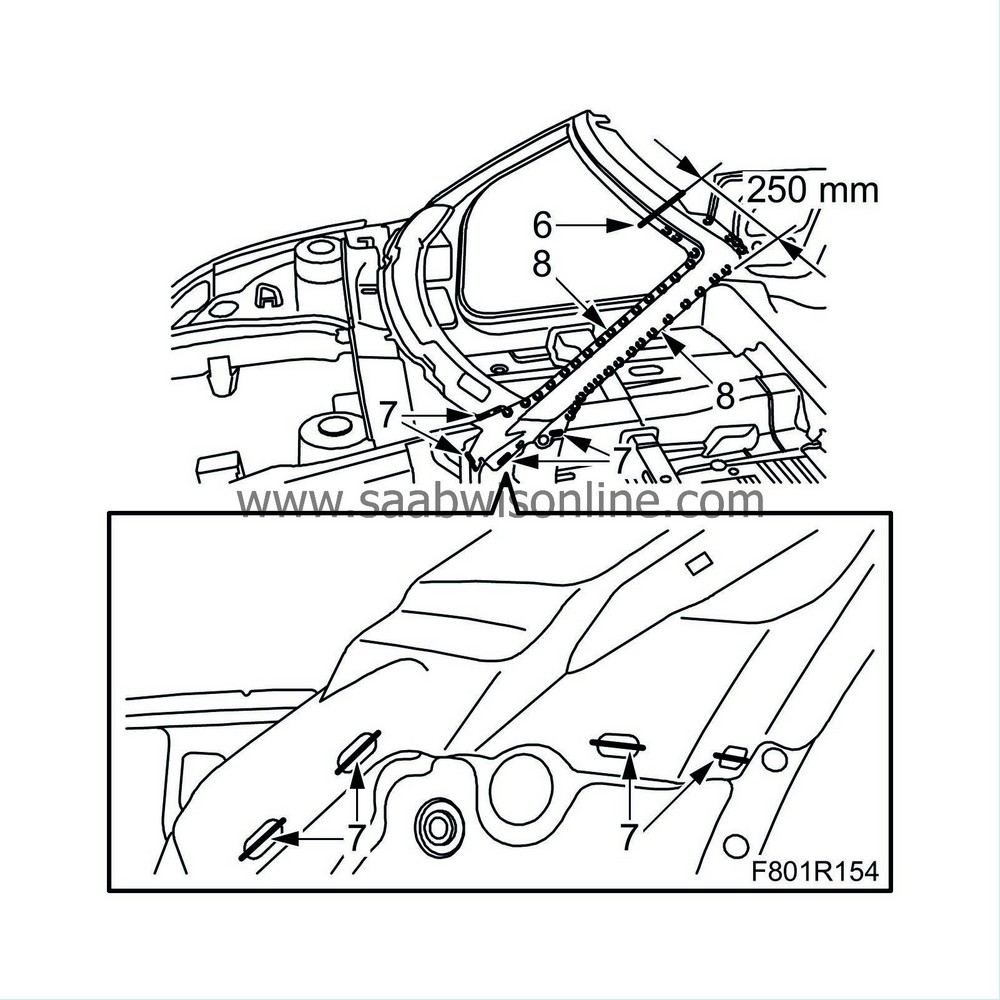

| 6. |

Cut the windscreen frame outer panel 250 mm from the outer edge of the A-pillar. Do not cut the underlying panel.

|

|

| 7. |

Grind the seam welds as illustrated.

|

|

| 8. |

Drill out the spot welds holding the A-pillar outer panel.

|

|

| 9. |

Tap away the A-pillar outer panel and align any deformed sheet metal or panels.

|

|

| 10. |

Drill holes for plug welding in the new A-pillar outer panel.

|

|||||||||||||

| 11. |

Apply welding primer to the surfaces to be plug welded. Use Teroson Zink Spray

|

|

| 12. |

Place the A-pillar outer panel in fitting position and secure it with welding clamps.

|

|

| 13. |

Align the A-pillar outer panel exactly.

|

|

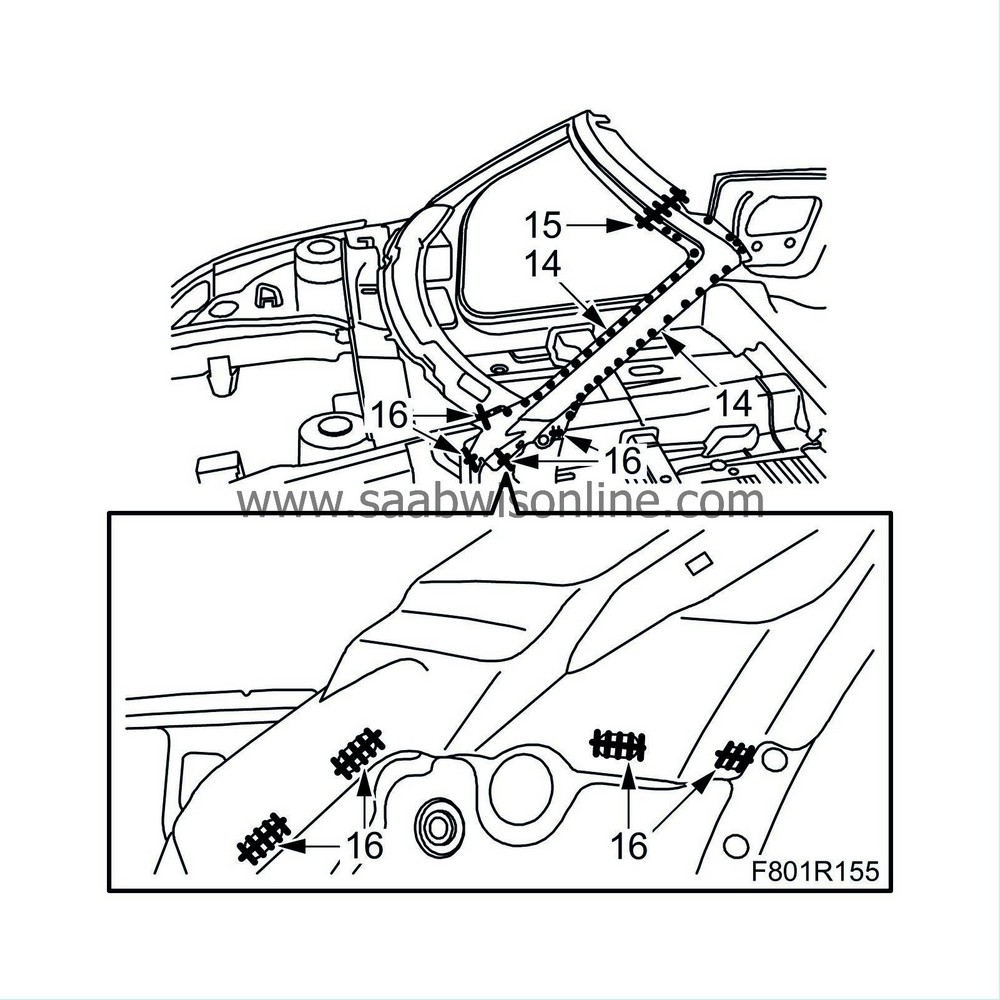

| 14. |

Plug weld the A-pillar outer panel.

|

||||||||||

| 15. |

All-weld the joint at the upper end of the upper A-pillar outer panel.

|

|

| 16. |

Seam weld the A-pillar outer panel as illustrated.

|

|

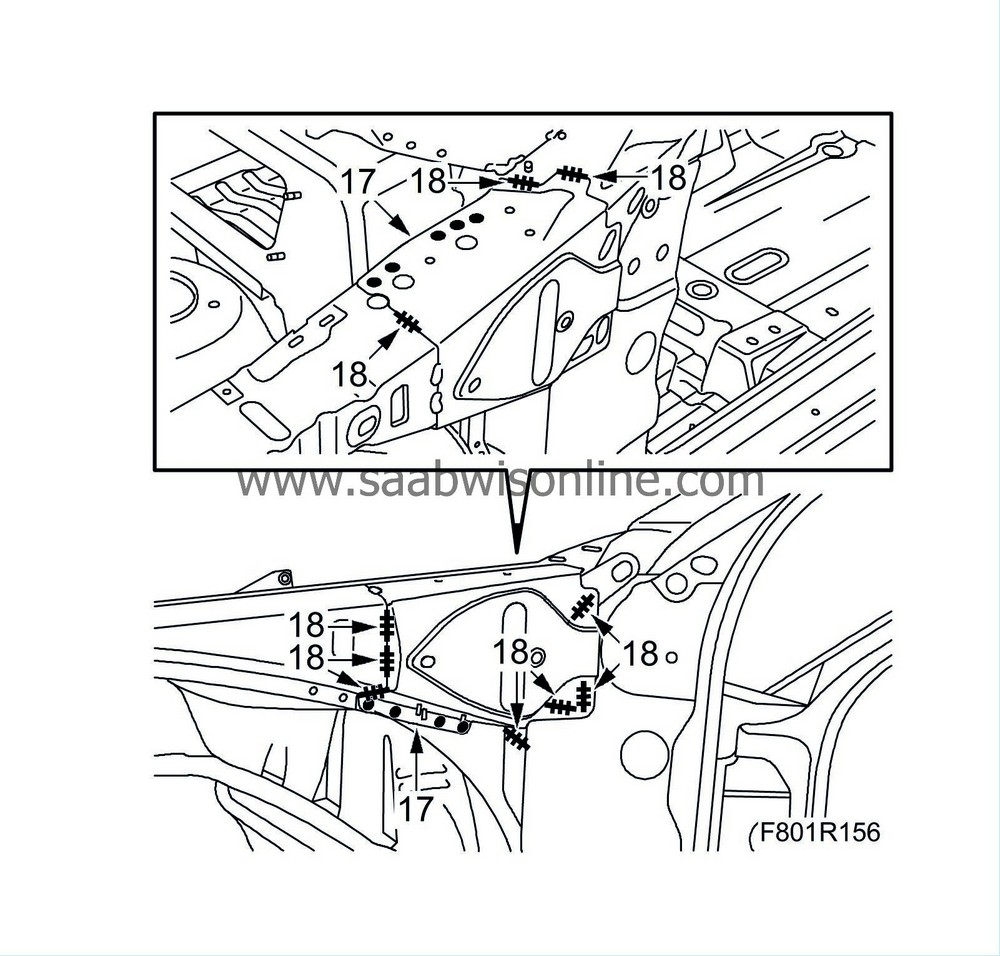

| 18. |

Seam weld and continuous weld on the outside of the front wheel housing. Note that the welds must be MIG brazed.

|

|

| 19. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 20. |

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

| 21. |

Use Terostat 1K-PUR to seal joints and metal folds.

|

|

| 22. |

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

|

| 23. |

Fit the

Front wing

,

Bonnet

and

Door

.

|

|

Warning

Warning