Crankshaft, removing and fitting

|

|

Crankshaft, removing and fitting

|

|

4.

|

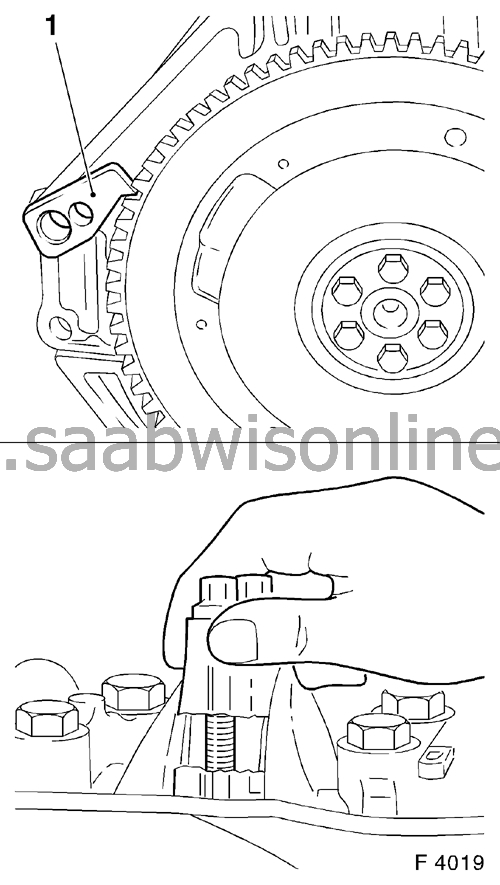

Block the flywheel and belt pulley respectively with KM-652 or

83 94 868 Flywheel locking attachment

(1) and remove the crankshaft.

Caution

Note the order of the big-end bearing caps. Remove the big-end bearing cap from the connecting rod.

The fracture surfaces of the connecting rods and the big-end bearing caps form an individual fit and must not be interchanged or damaged. Do not rest the connecting rods or big-end bearing caps on their fracture surfaces to avoid damage.

|

|

5.

|

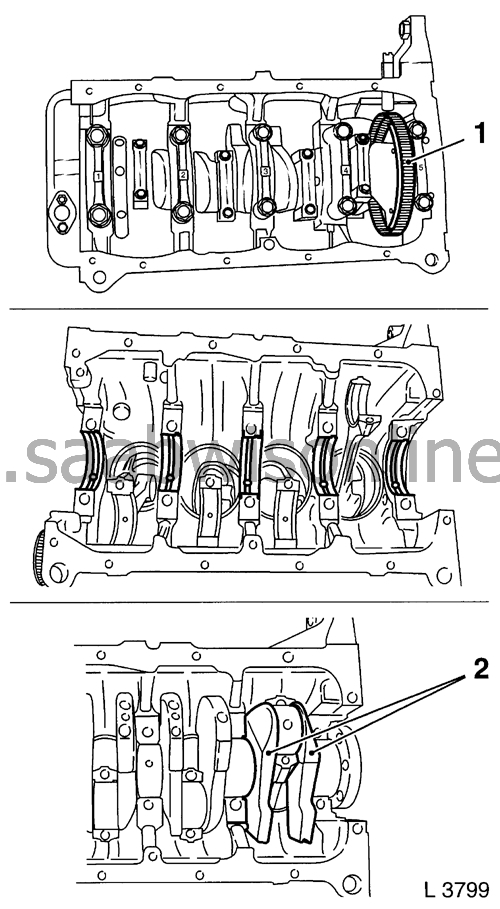

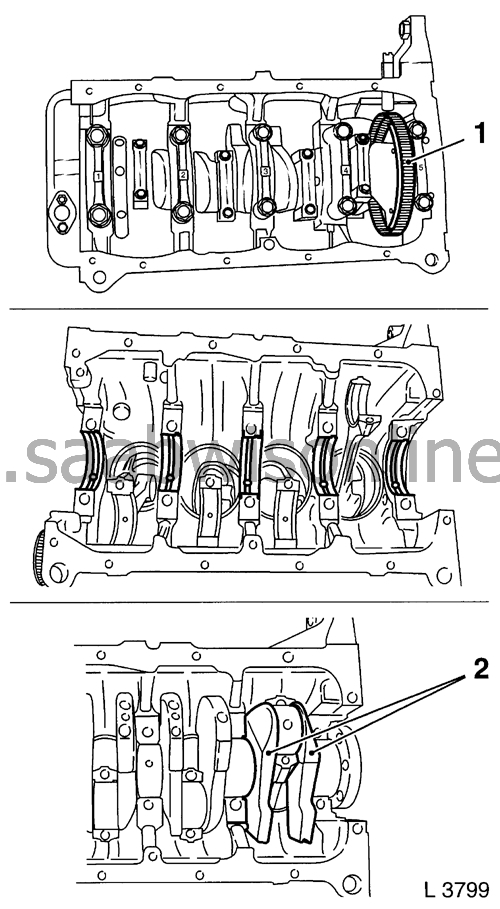

Note the order of the crankshaft bearing caps. Remove the crankshaft bearing cap from the engine block.

|

|

6.

|

Remove the crankshaft from the engine block.

|

|

9.

|

Moisten new bearing shells with engine oil and fit into the engine block and bearing cap. Fit the crankshaft carefully into the engine block. The crankshaft seat can be adjusted with light taps with a rubber hammer on the crank throws (2).

|

|

1.

|

Apply a bead of adhesive sealing compound (black) in the groove on the rear crankshaft bearing cap. Fit the crankshaft and big-end bearing caps.

Note the markings and fitting position.

Tightening torque/angle tightening

Crankshaft bearing cap on engine block - 50 Nm + 45° + 15°

|

Note

|

|

Use new bolts. Press in adhesive sealing compound (black) once more from above until it comes out of the joints after fitting the rear crankshaft bearing cap.

|

Big-end bearing cap on connecting rod - tightening torque 25 Nm + 30°.

|