Valve mechanism, front cylinder head, B284 (old version)

| Valve mechanism, front cylinder head, B284 (old version) |

| To remove |

| Important | ||

|

Store all removed valve parts in the valve stand 83 93 787. |

||

| 1. |

Remove the

Camshaft cover, front

|

|

| 2. |

Remove the spark plugs.

|

|

| 3. |

Remove the coolant port.

|

|

| 4. |

Remove the camshaft solenoid valve (695F).

|

|

| 5. |

Remove the camshaft position sensor (555F).

|

|

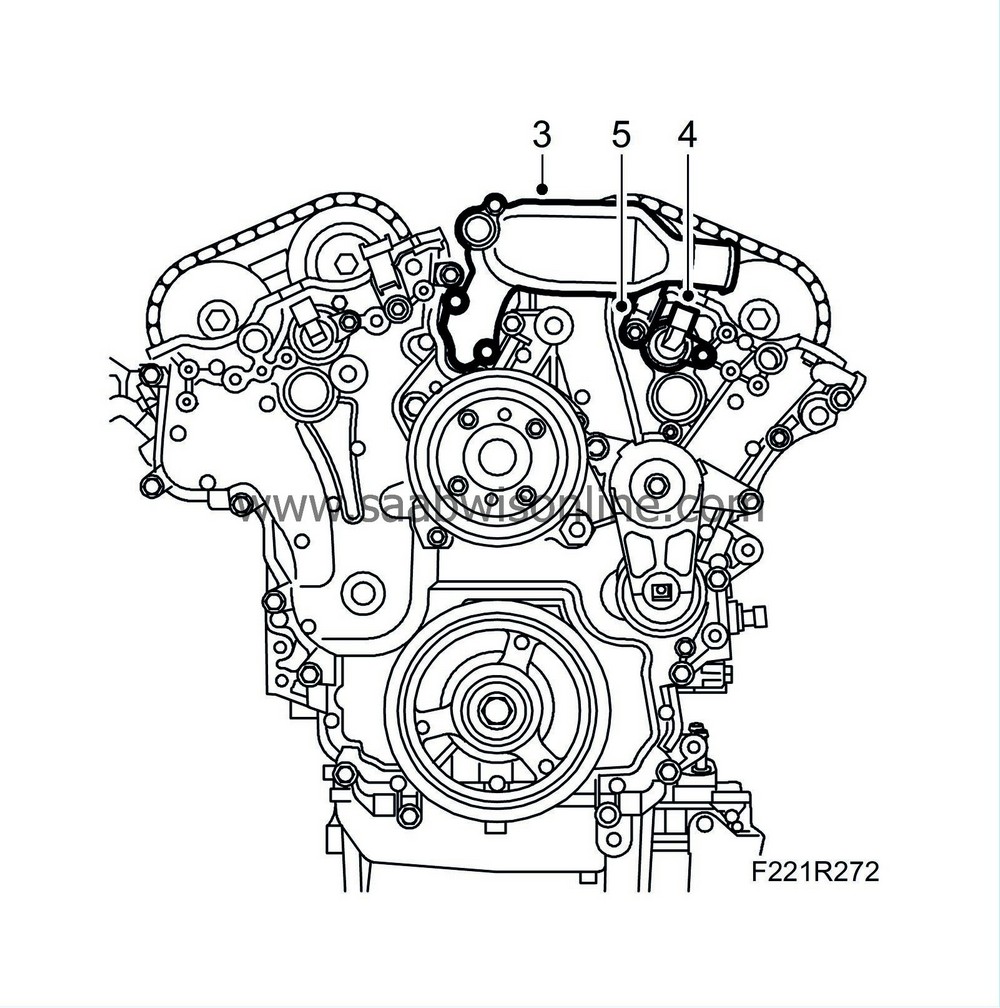

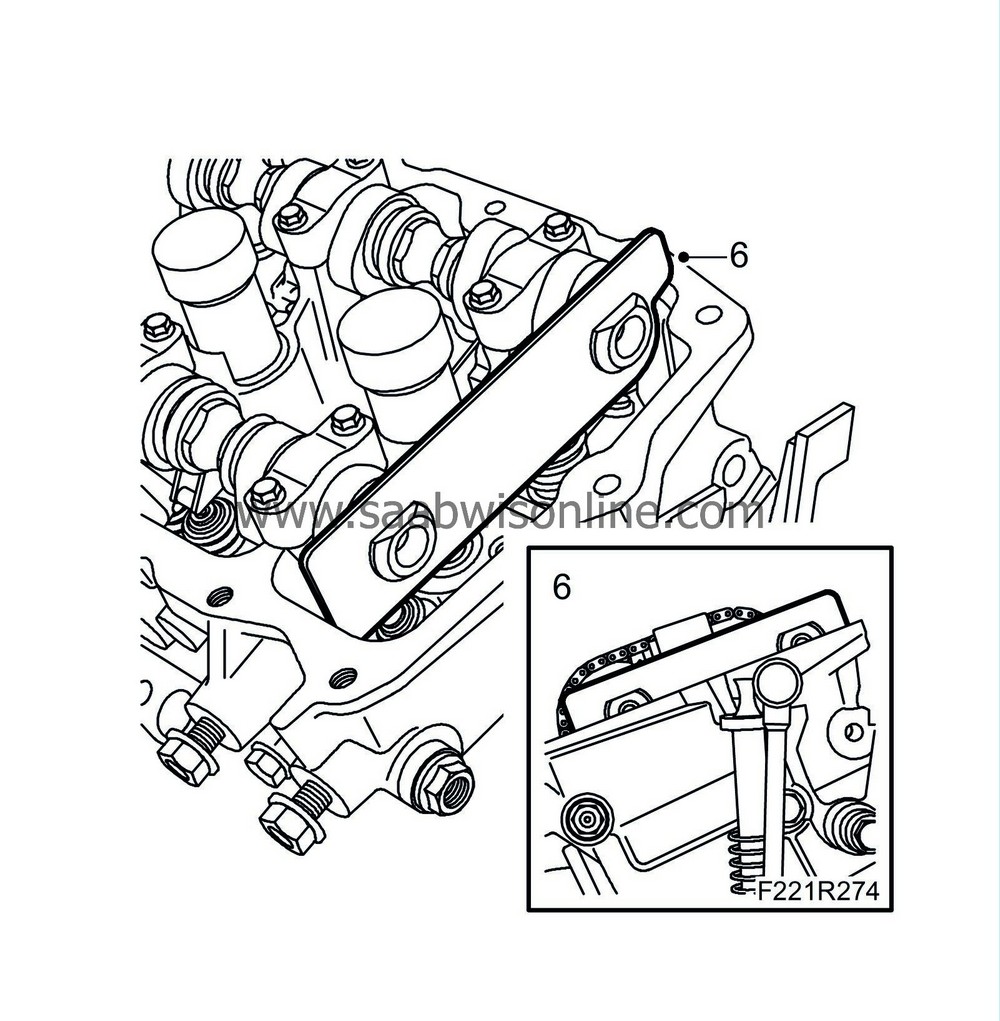

| 6. |

Rotate the crankshaft so that the markings on the camshaft sprockets are visible and the indentations align with the cylinder head. Use

EN-46105-1 Adjustment tool

as a gauge (the camshafts are now in their neutral position).

|

|

| 7. |

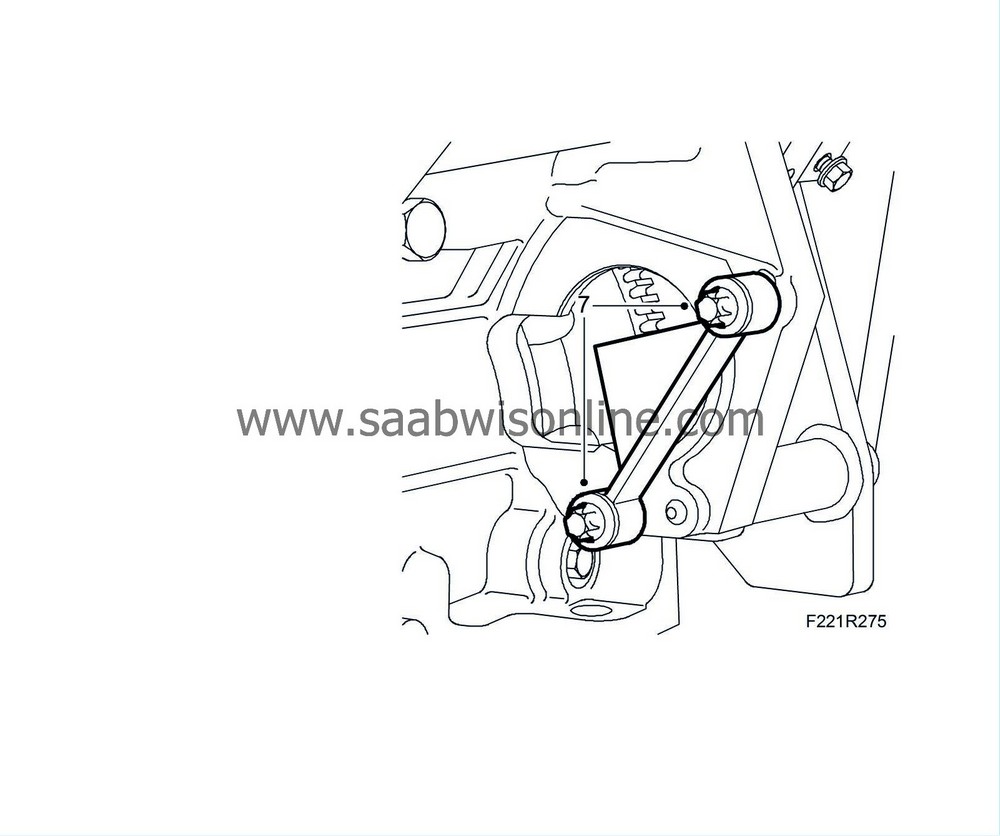

Fit

EN-46106 Flywheel locking attachment

.

|

|

| 8. |

Mark the chain and camshaft sprocket so they can be refitted in the same position.

|

|

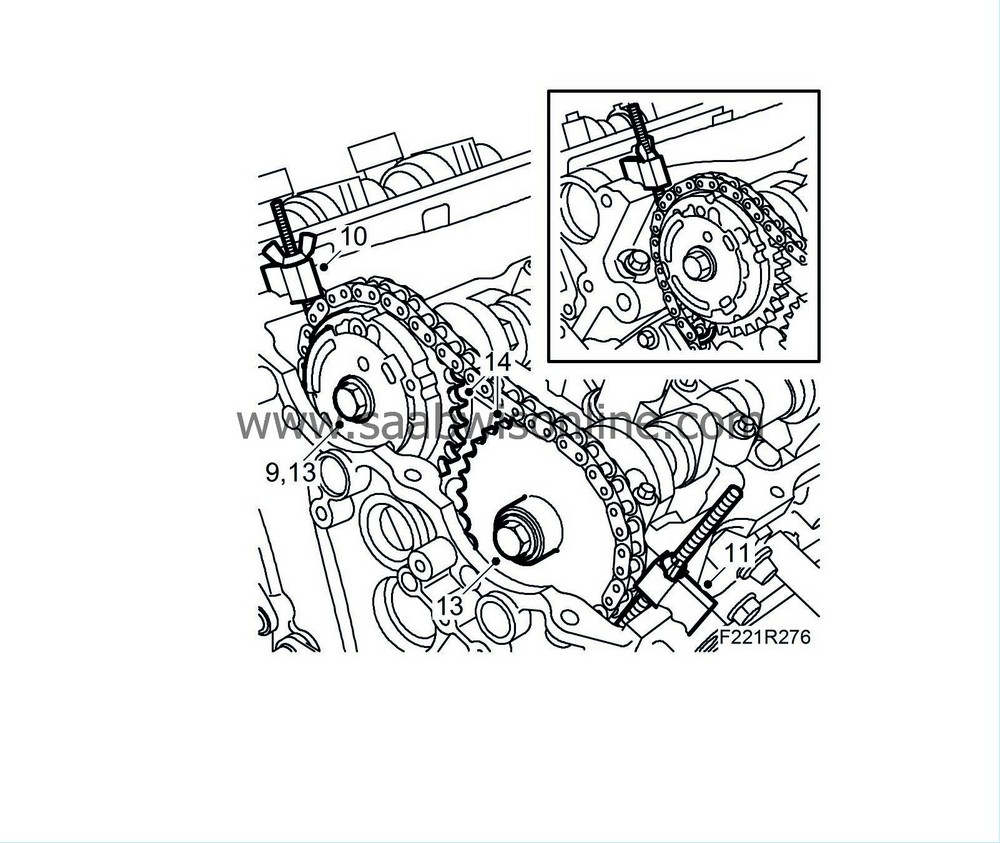

| 9. |

Reduce the tightening torque of the bolts holding the camshaft sprockets. Counterhold using an open spanner on the camshaft flats (do not remove the bolts).

|

|

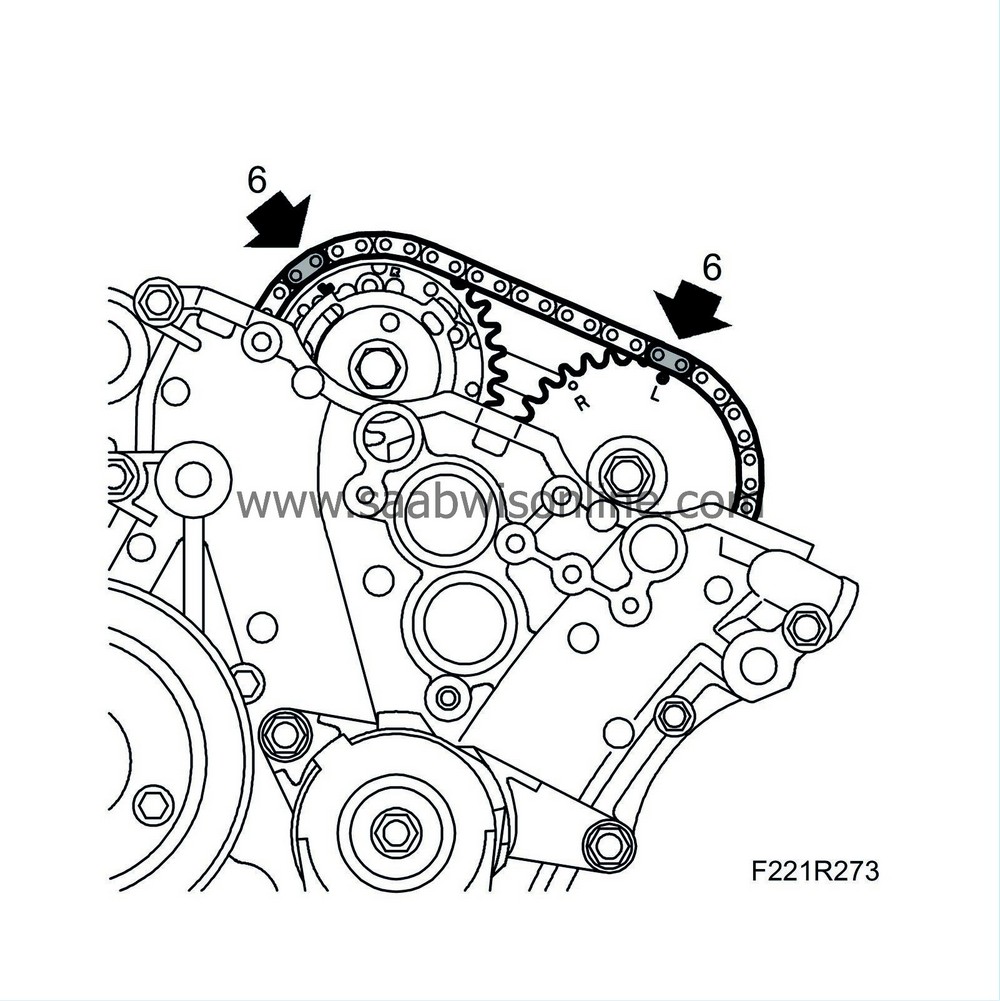

| 10. |

Fit

EN-46108-1 Fixing tool

to the camshaft chain on the intake side. Check that the tool grips the chain firmly.

|

|

| 11. |

Fit

EN-46108-2 Fixing tool

to the camshaft chain on the exhaust side. Check that the tool grips the chain firmly.

|

|

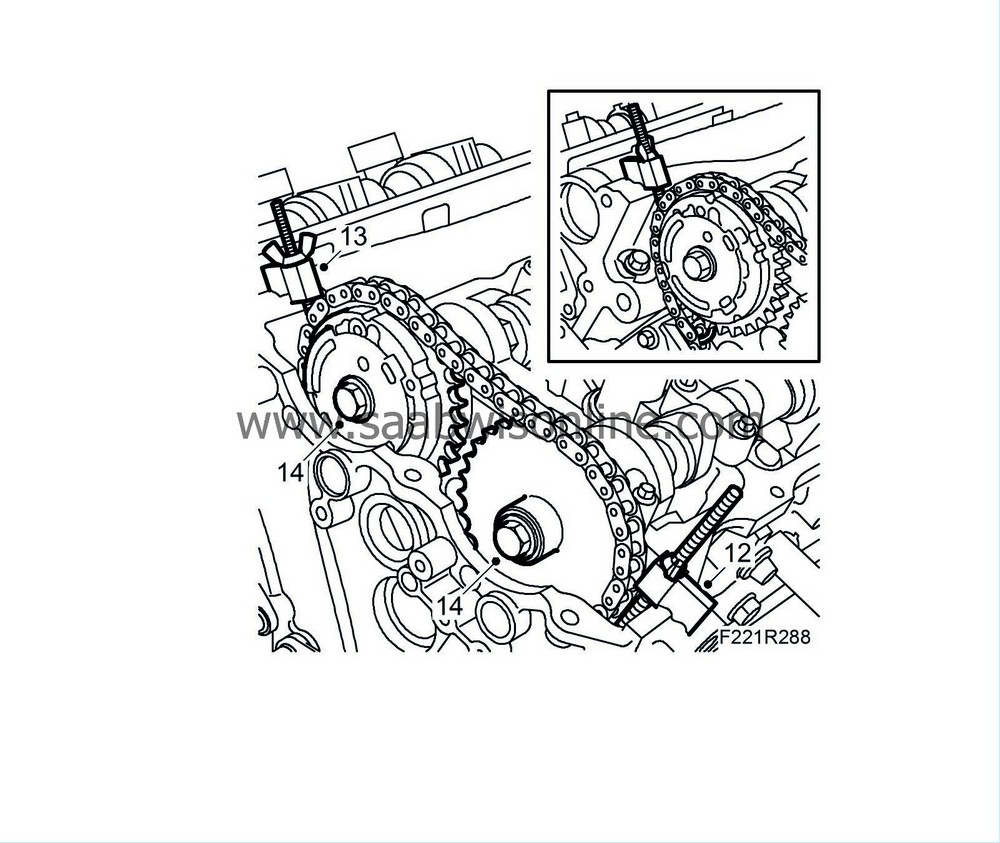

| 12. |

Tighten

EN-46108 Fixing tool

so that the chain is unloaded.

|

||||||||||

| 13. |

Remove the camshaft sprocket bolts.

|

|

| 14. |

Remove the sprockets from the camshafts.

|

|

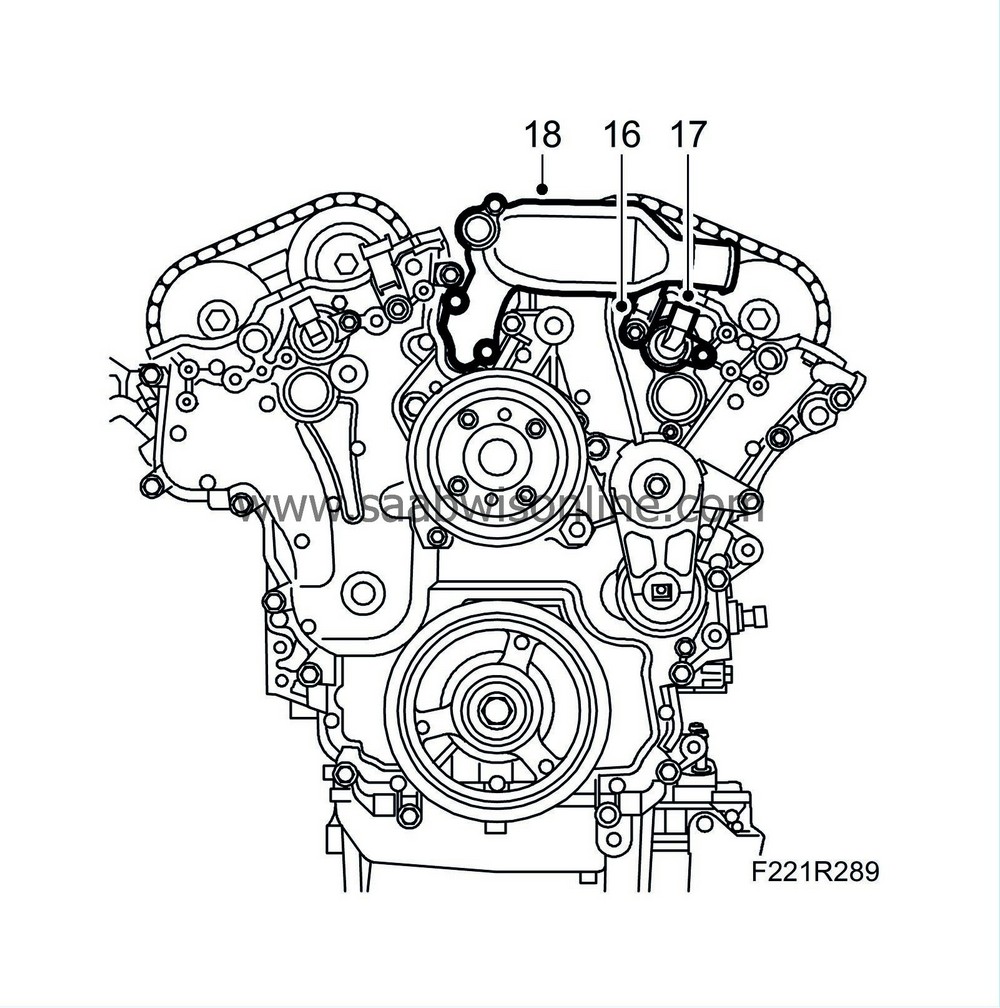

| 16. |

Lift out the camshafts and note the rear marking on the camshafts. The last letters in the marking: LI = intake camshaft, front cylinder bank. LE = exhaust camshaft, front cylinder bank.

|

|

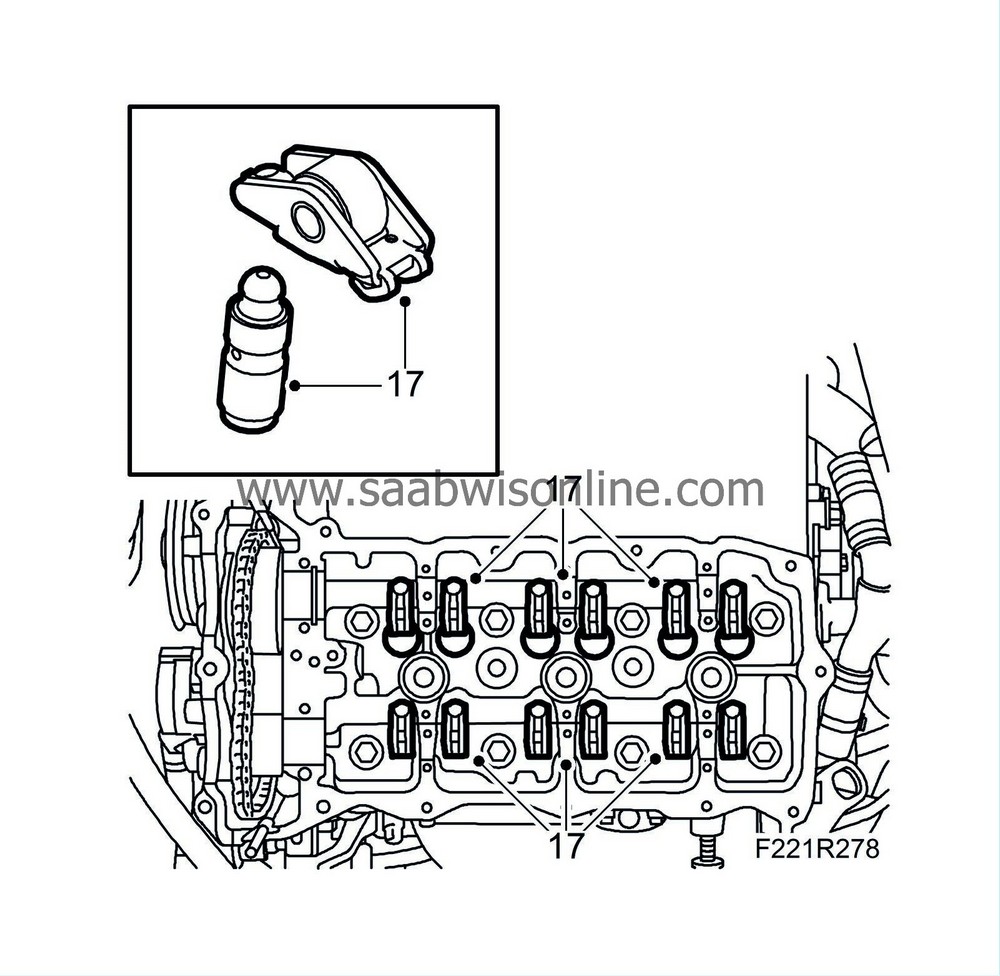

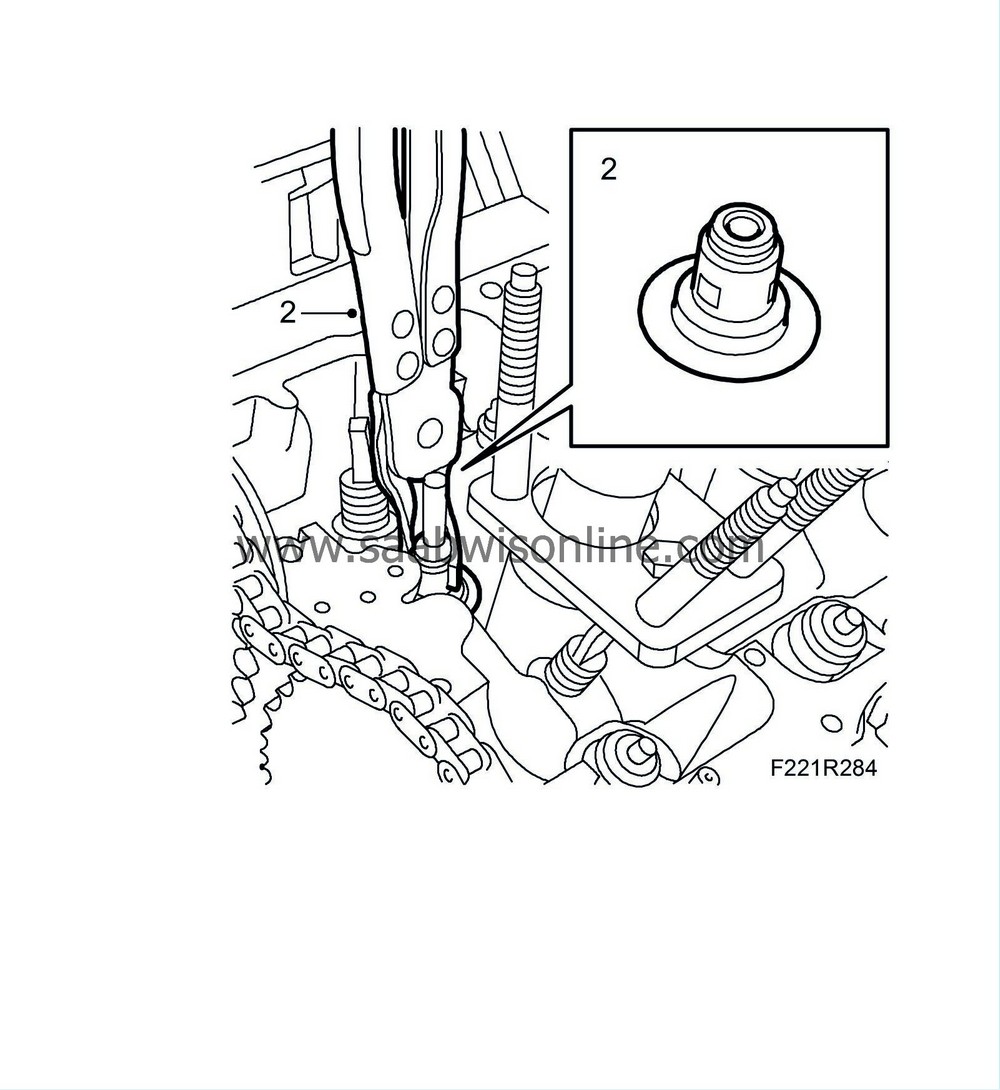

| 17. |

Remove the roller rockers and the hydraulic adjuster elements. Store them in

83 93 787 Valve stand

so they do not get mixed up.

|

||||||||||

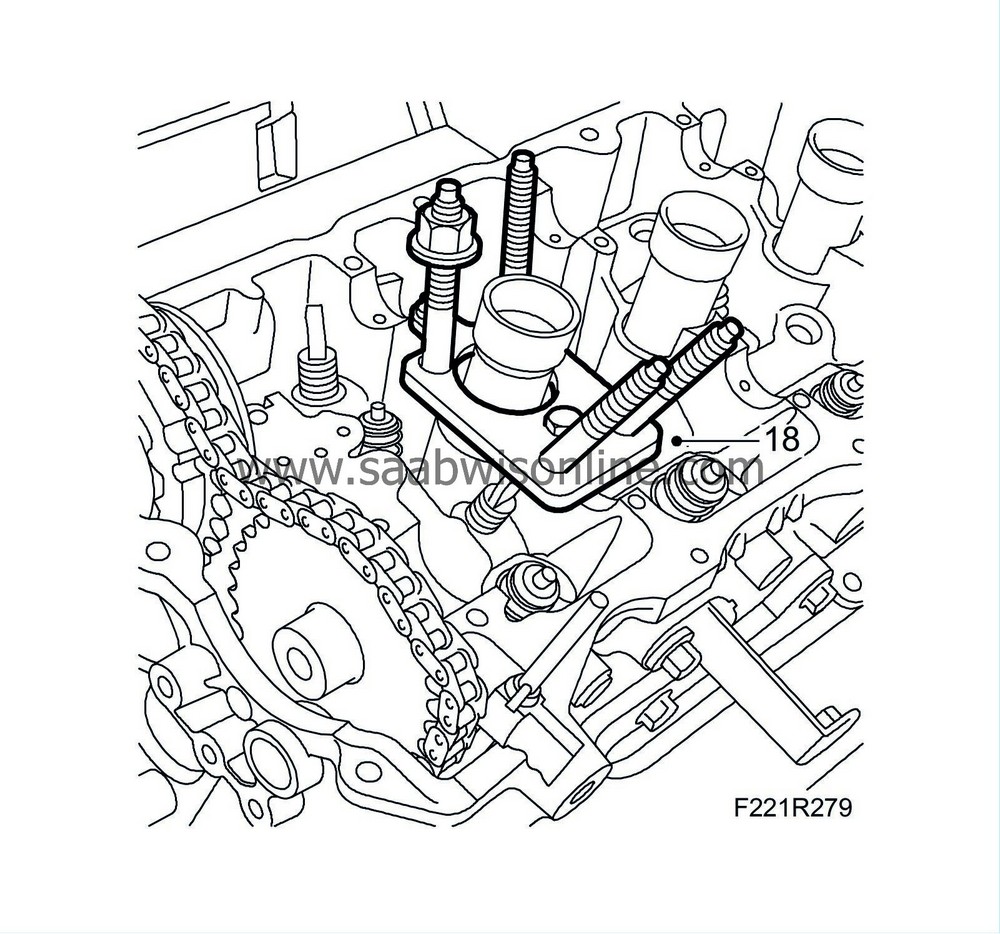

| 18. |

Fit

EN-46110-eu Valve spring tool

|

|

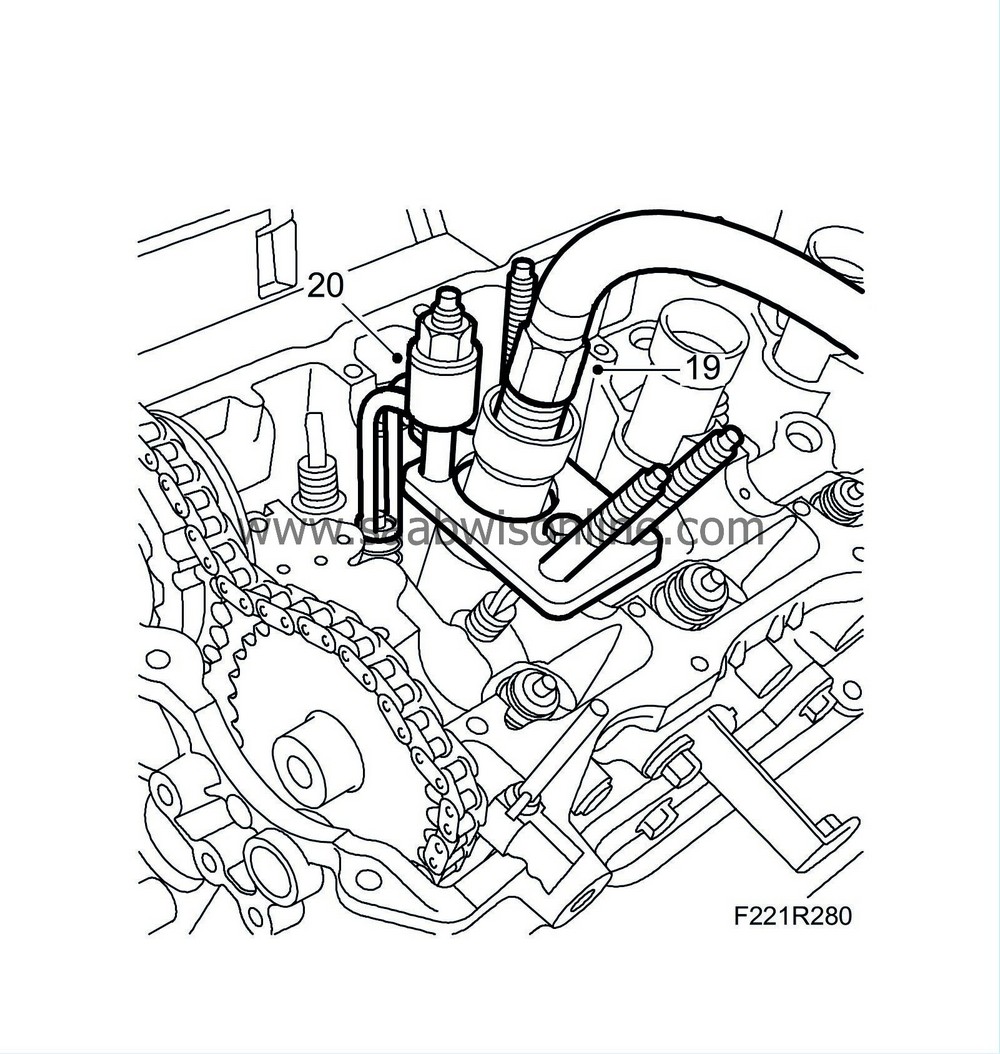

| 19. |

Fit

83 94 173 Air nipple for spark plug hole

. Connect compressed air and put the piston and valves under pressure.

|

|

| 20. |

Press down the valve plate with

EN-46110-eu Valve spring tool

.

|

|

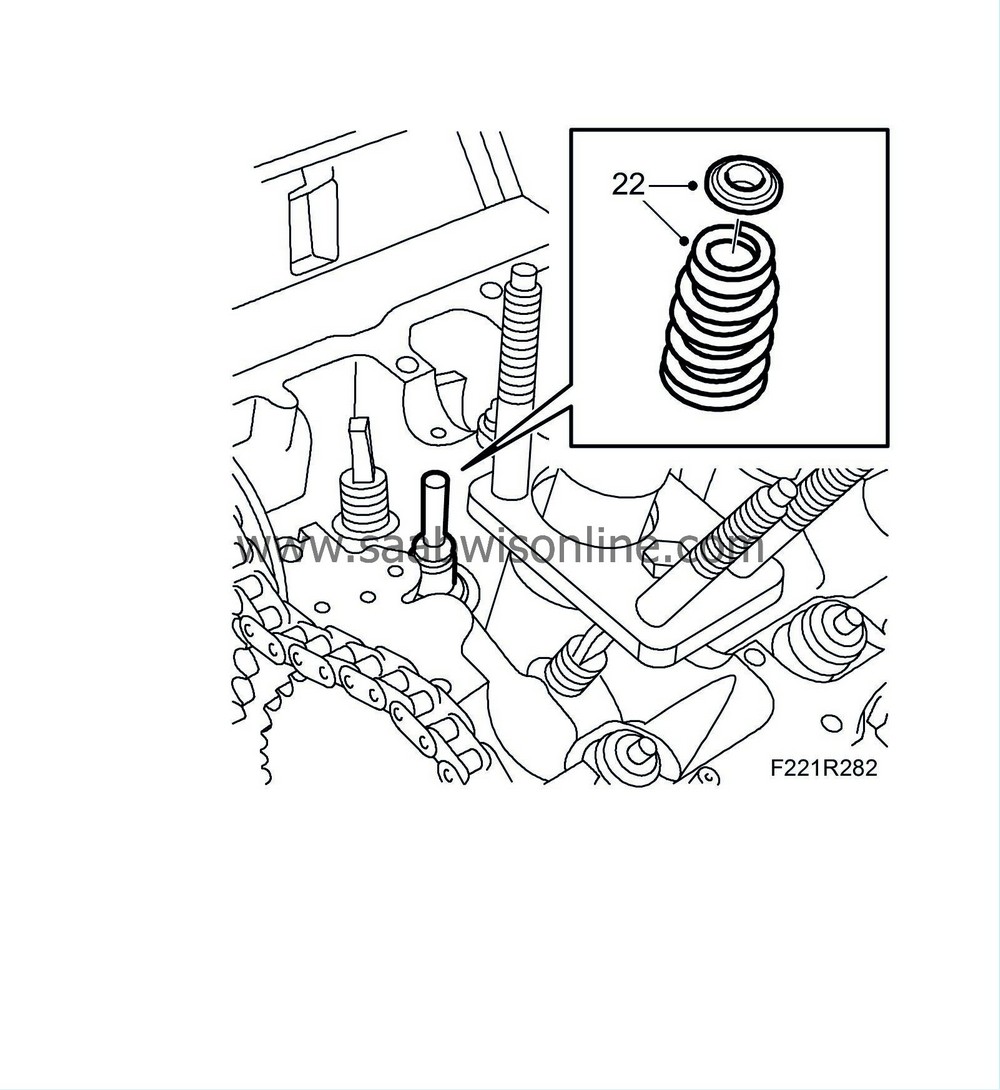

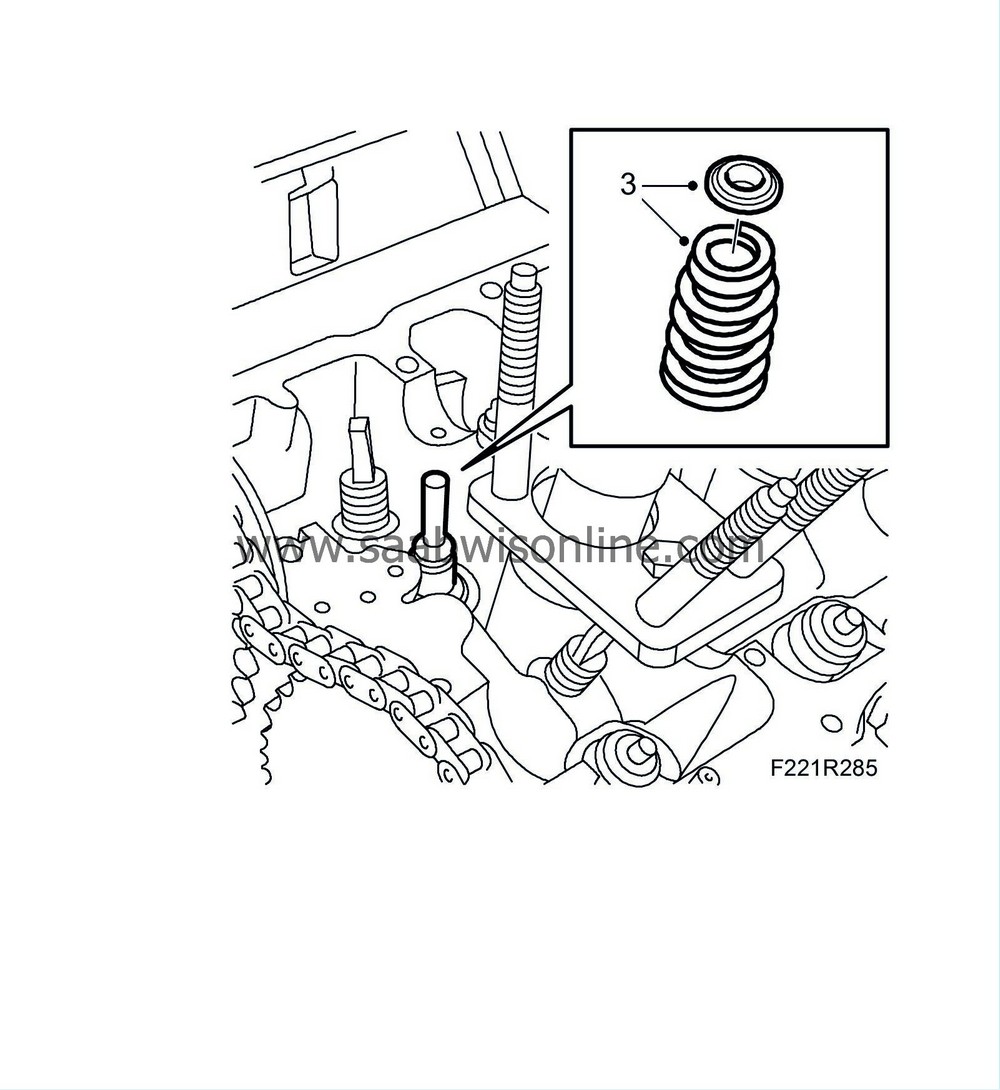

| 22. |

Lift out the spring plate and valve spring.

|

|

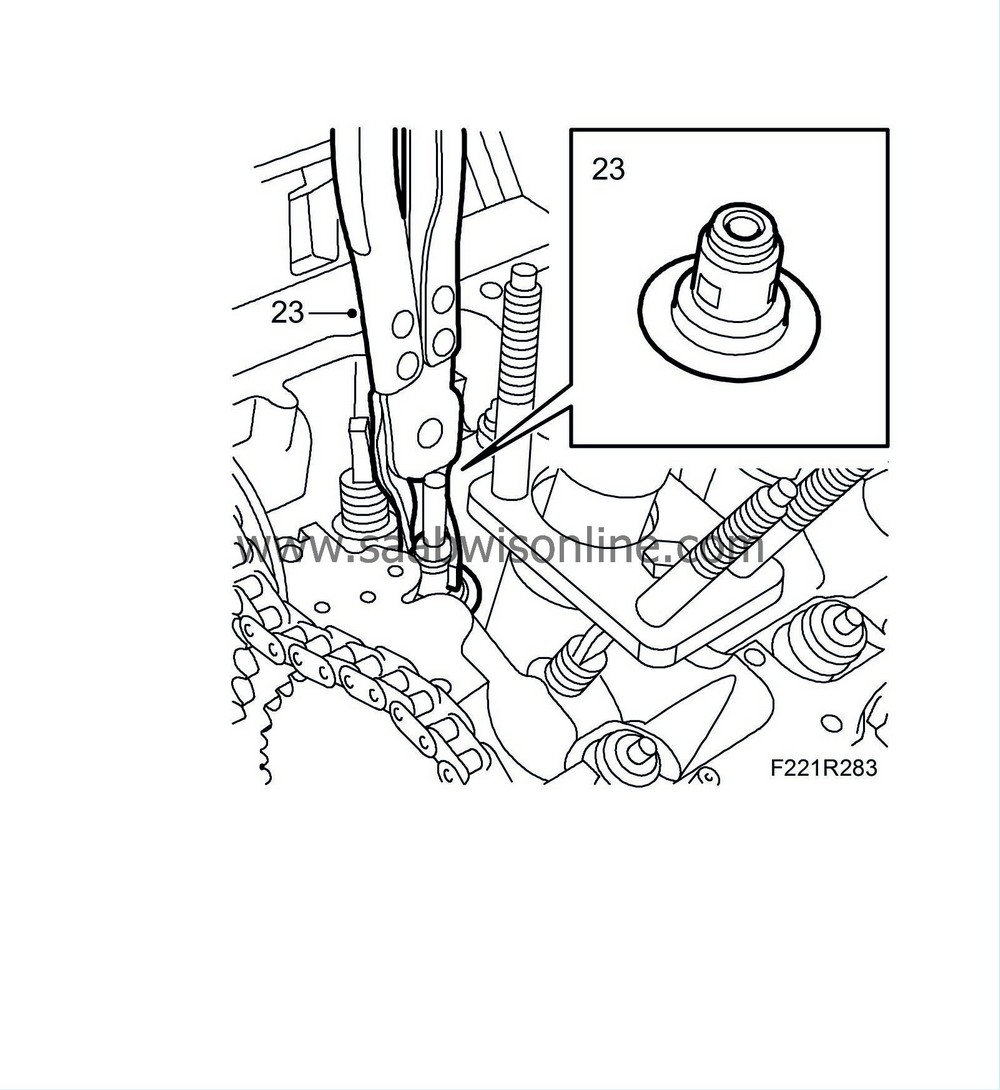

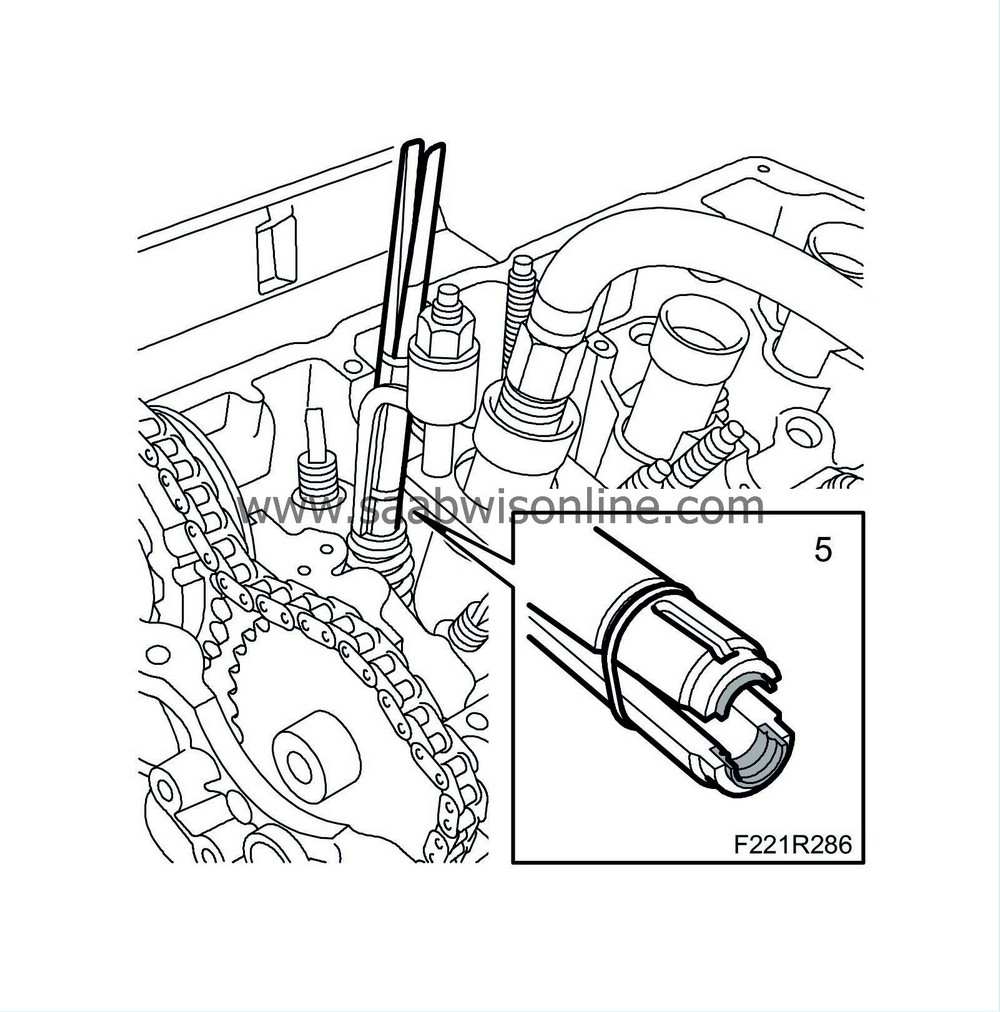

| 23. |

Lift out the valve guide seal using

83 94 157 Pliers, valve guide seal

.

|

|

| To fit |

| 1. |

Clean all parts and check contact surfaces and bearing surfaces for wear.

|

|

| 2. |

Fit the valve guide seal using

83 94 157 Pliers, valve guide seal

.

|

|

| 3. |

Fit the valve spring and spring plate.

|

|

| 4. |

Press down the valve plate with

EN-46110-eu Valve spring tool

.

|

|

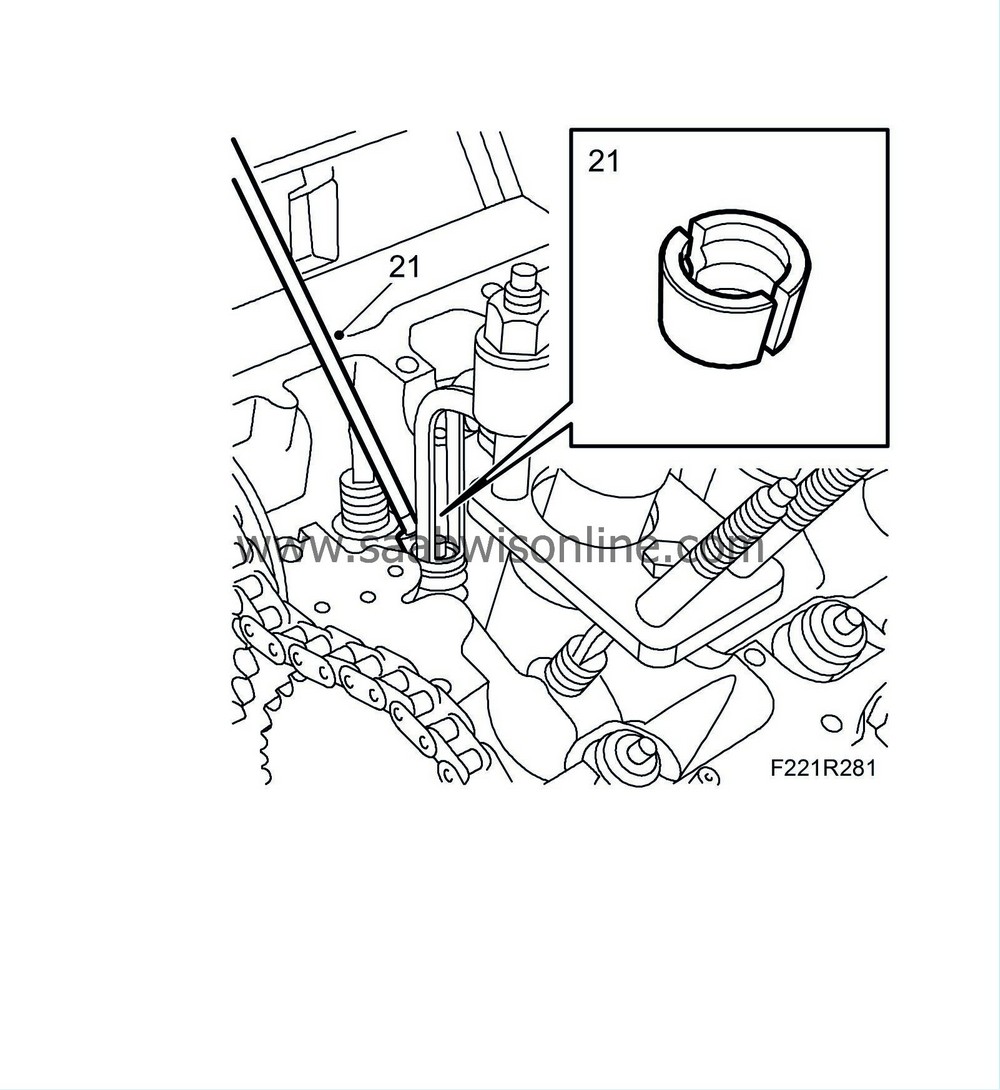

| 5. |

Fit the valve cone using

EN-46117 Fitting tool

.

|

|

| 6. |

Unload the valve and remove

EN-46110-eu Valve spring tool

.

|

|

| 7. |

Disconnect the compressed air and remove the air nipple.

|

|

| 8. |

Position the camshafts and use

EN-46105 Adjustment tool

to check that the camshafts are mounted at the correct angle. The last letters in the marking: LI = intake camshaft, front cylinder bank. LE = exhaust camshaft, front cylinder bank.

|

|

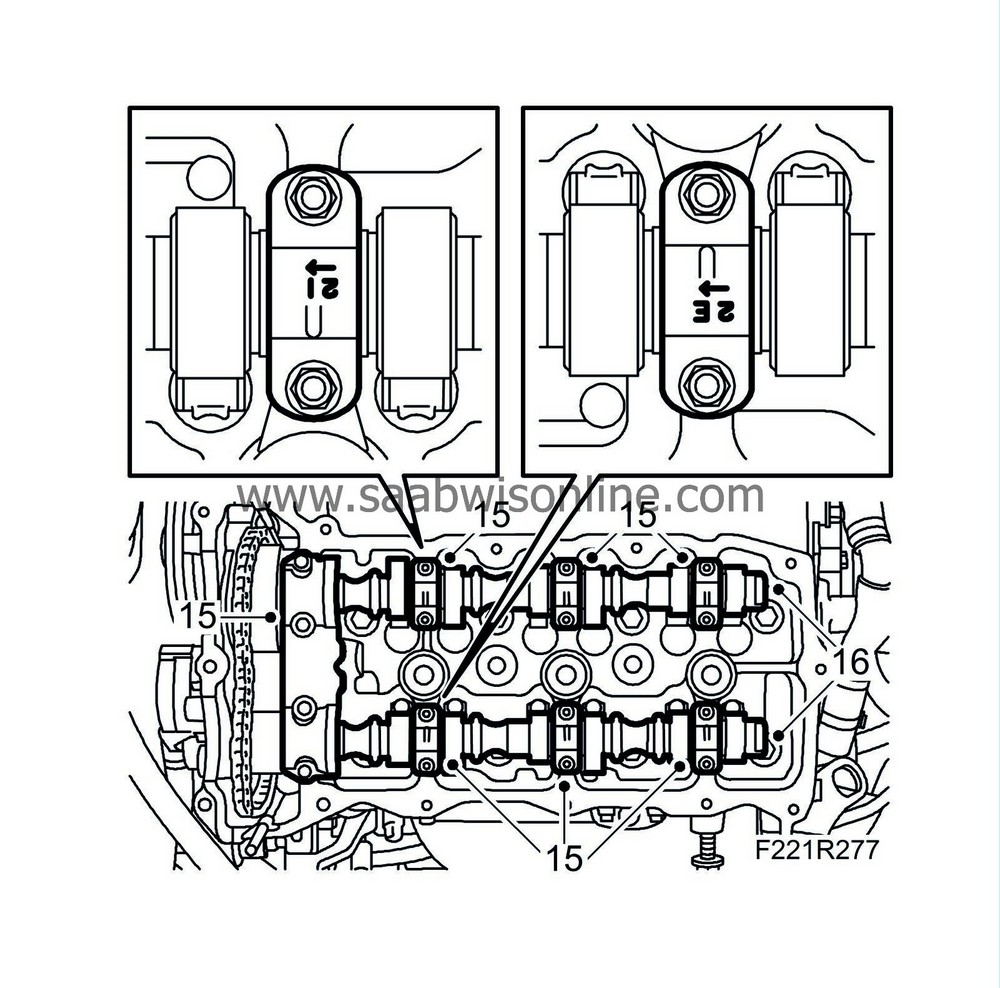

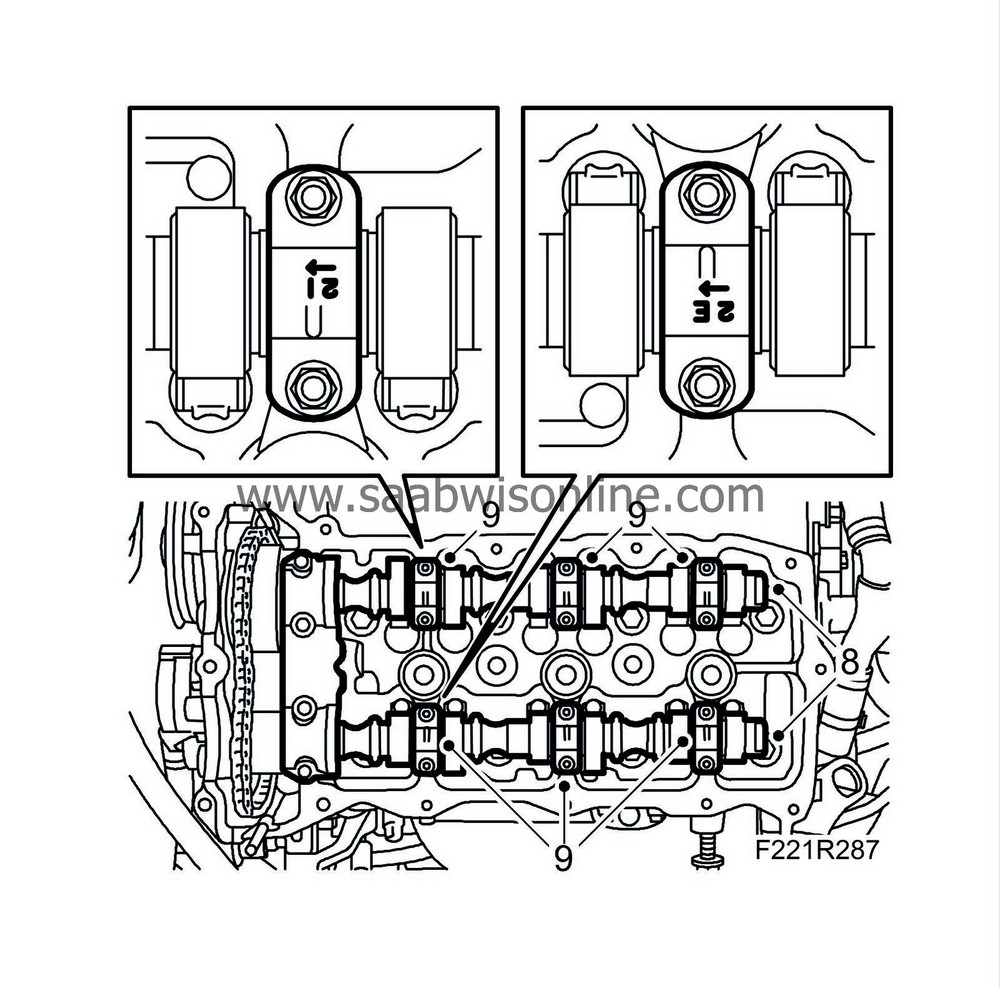

| 9. |

Fit the bearing caps as illustrated (markings on caps). Start where the cams point down and load the tappets. Note: Tighten the bolts in stages - 1/2 to 1 turn.

Tightening torque 10 Nm (7 lbf ft)

|

||||||||||

| 10. |

Fit the sprockets with chain on the camshafts. Tighten the bolts by hand.

|

|

| 11. |

Check that the marks on the chain match the markings on the sprockets.

|

|

| 12. |

Remove

EN-46108-2 Fixing tool

.

|

|

| 13. |

Remove

EN-46108-1 Fixing tool

.

|

|

| 14. |

Tighten the bolts of both camshaft sprockets, counterholding with an open spanner on the camshaft flats.

Tightening torque: 65 Nm (48 lbf ft) |

|

| 15. |

Remove

EN-46106 Flywheel locking attachment

.

|

|

| 16. |

Fit the camshaft position sensor (555F) using a new gasket.

Tightening torque 10 Nm (7 lbf ft) |

|

| 17. |

Fit the camshaft solenoid valve (695F) using a new seal.

Tightening torque 10 Nm (7 lbf ft)

|

|

| 18. |

Fit the coolant port using a new seal and gasket.

Tightening torque 10 Nm (7 lbf ft) |

|

| 19. |

Fit the spark plugs.

|

|

| 20. |

Fit the

Camshaft cover, front

|

|