Wiring harness repair

| Wiring harness repair |

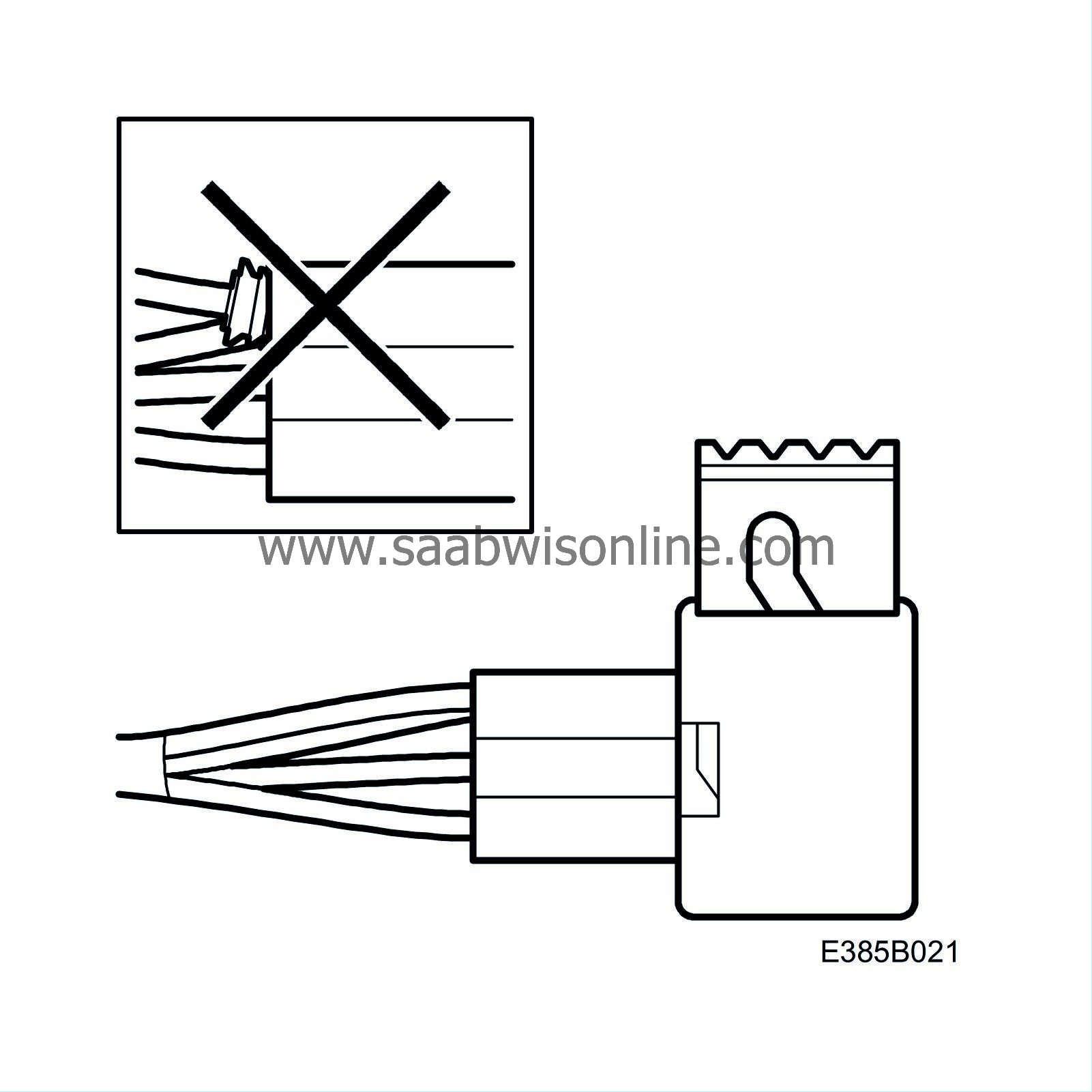

Always use wiring harness toolbox 86 12 939 for wiring harness repair. In order to prise the cable terminals out from the connector housings, use extraction tool 85 80 151. Extraction tool 85 80 151 is included in the kits numbered 86 12 483 and 86 12 939.

|

|||||||

A. If cable insulation only is damaged

If the cable is located inside the cabin or luggage compartment: Wind two layers of tape around the cable to cover about two centimetres on each side of the damaged spot.If the cable is located in the engine bay or underneath the car: Proceed with point 1 below.

B. If a strand of cable has broken or if the cable terminal has come loose:

| 1. |

Cut off the cable and strip the end/ends with the cable stripper set on 6 mm. Make sure that none of the strands of cable are damaged while stripping the cable. If any strands have been cut or damaged, the cable must be cut off completely and restripped.

|

|

| 2. |

Locate the relevant connector, cable terminal, seals or sleeves in the spare parts catalogue/EPC in order to obtain the part number.

|

|

| 3. |

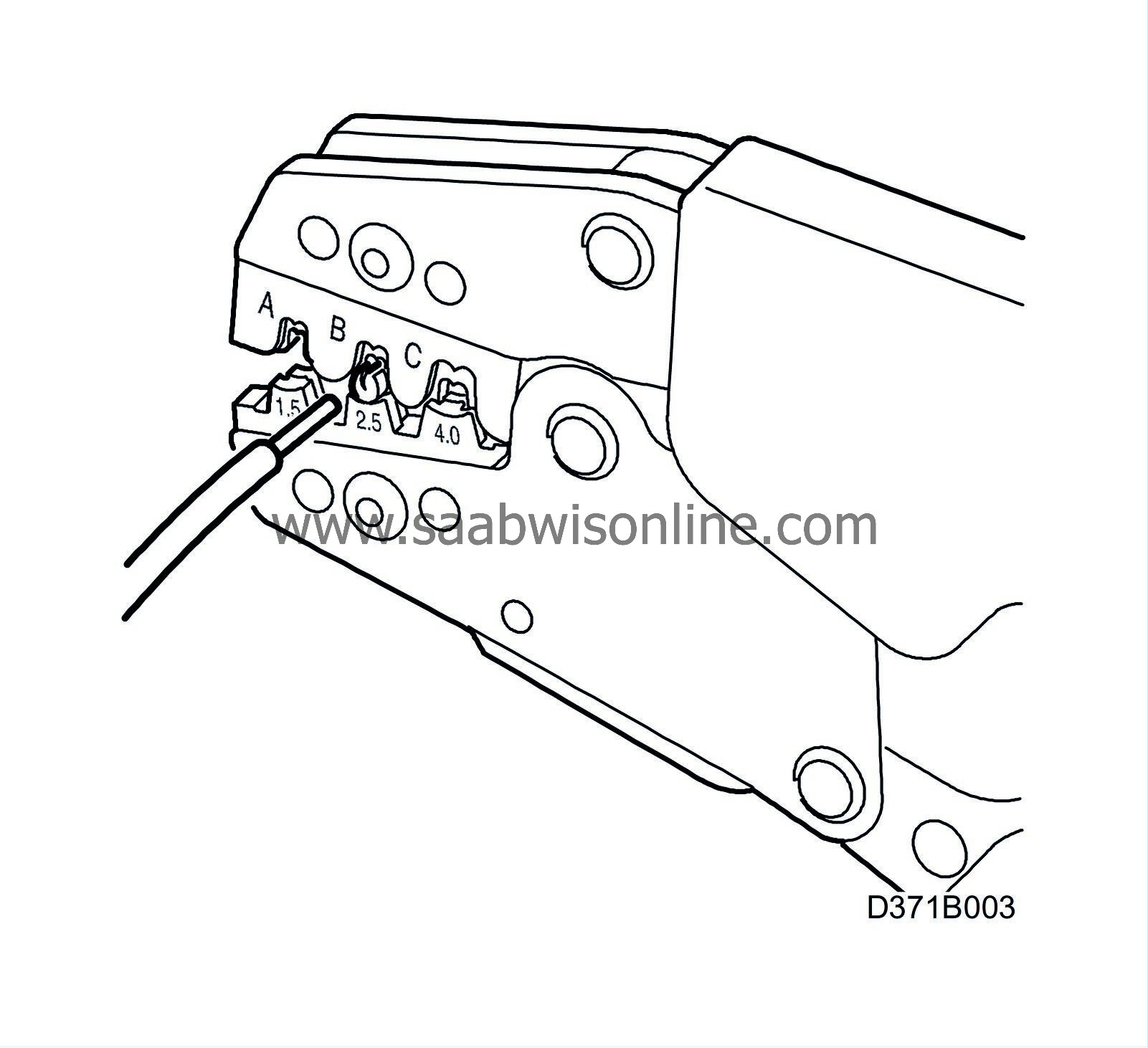

Locate the correct cable terminal, any seal or sleeve, see

List of cable terminals/sleeves and in which boxes they are kept

. Select the pliers with the same colour as the box.

|

|||||||||||||

| 5. |

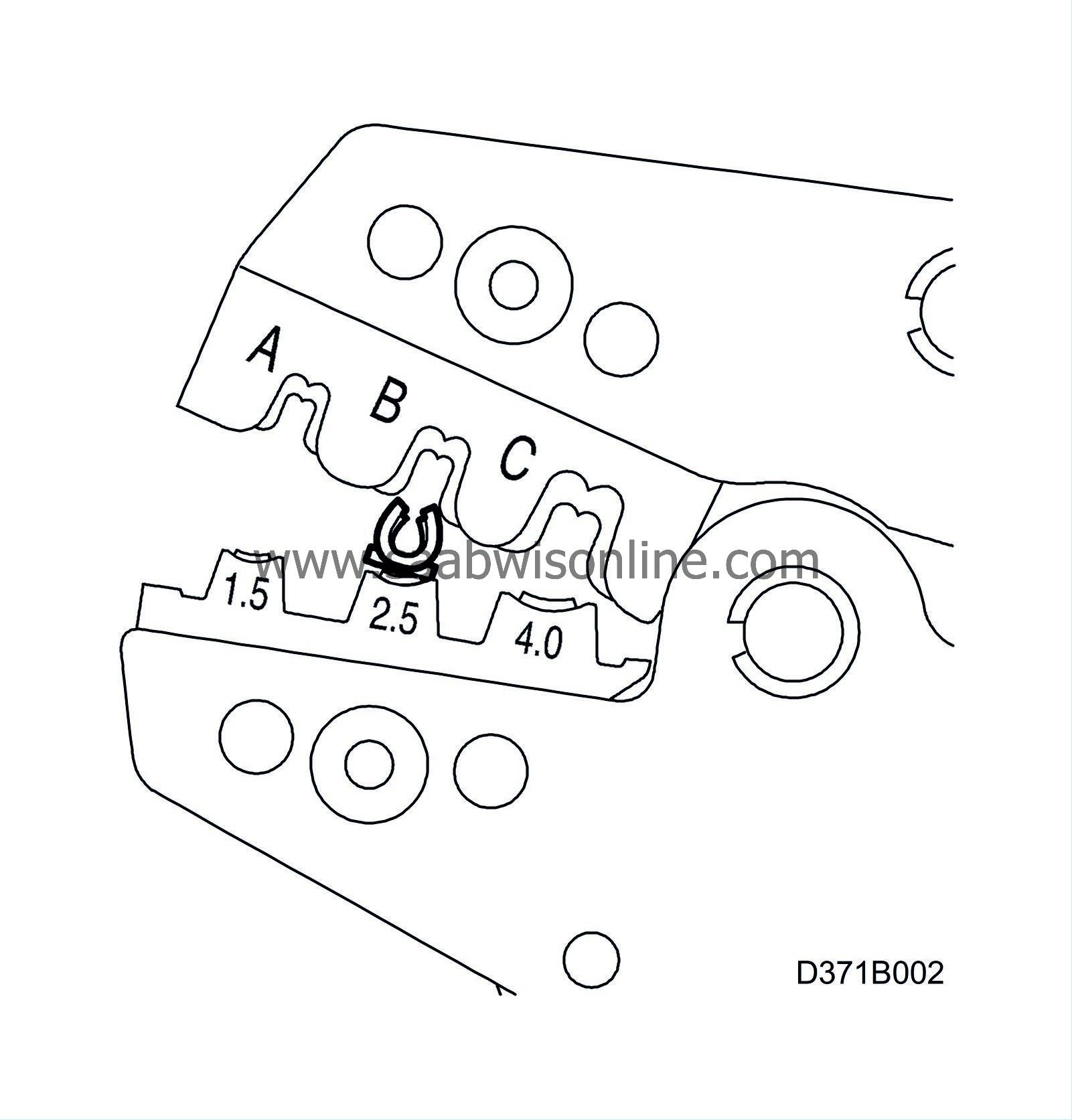

Place the cable terminal/sleeve into the pliers, see illustration, and clamp together the pliers to secure the cable terminal.

|

||||||||||

| 6. |

For fitting the cable terminal:

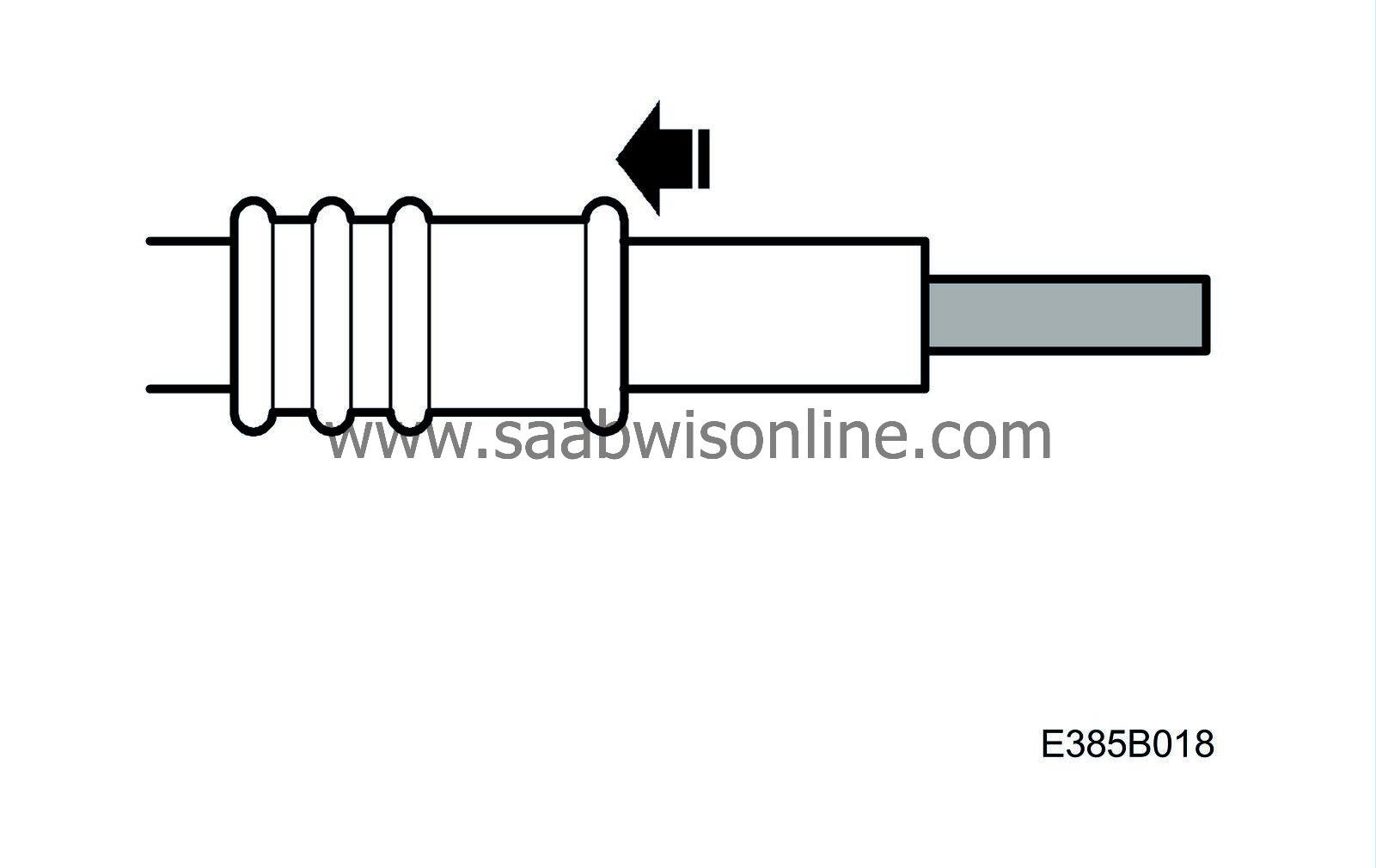

If the connection is equipped with a seal: Move the seal up with the thick section first, slightly above the cable insulation.

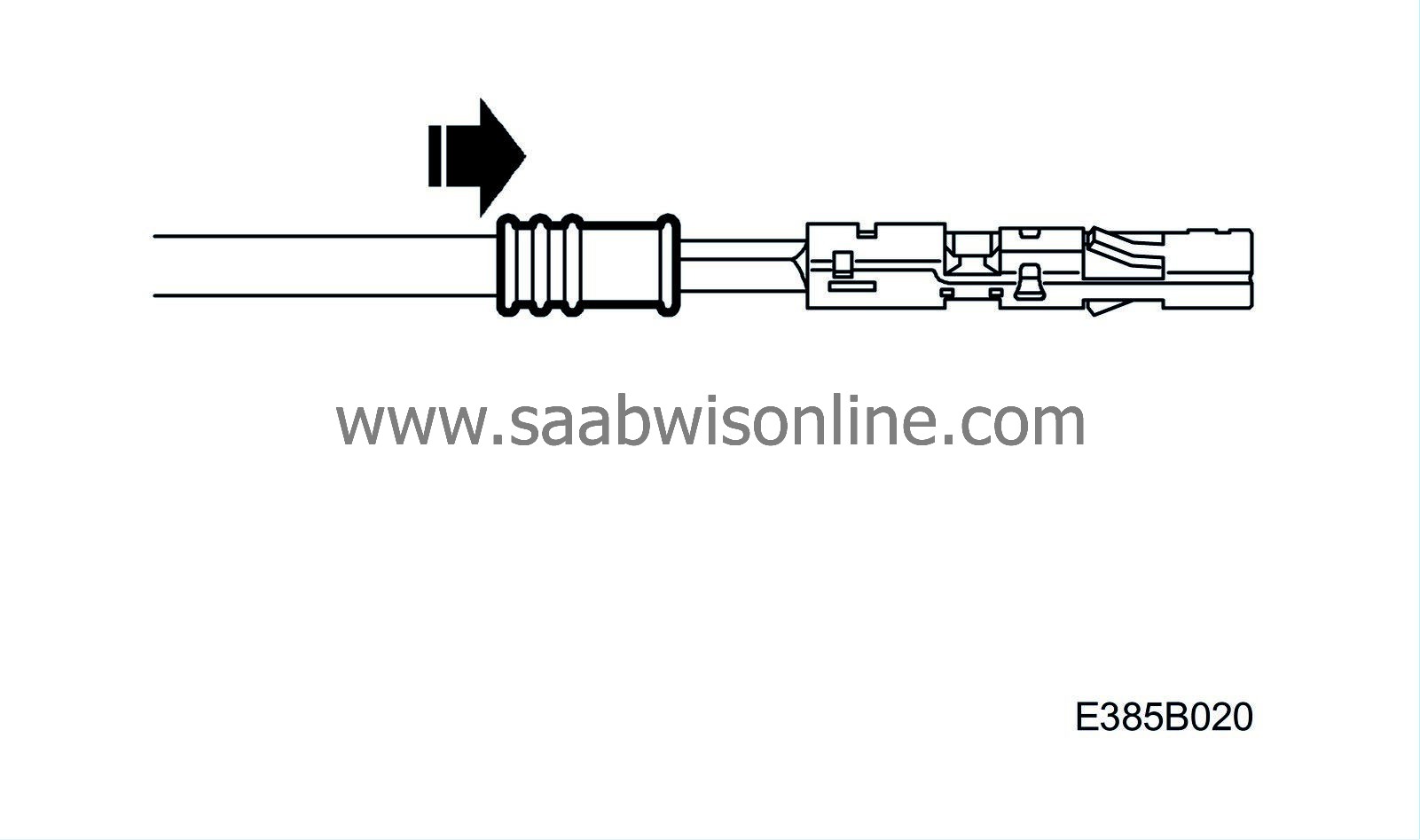

Insert the cable from the left (text side of pliers), see illustration. The strands must be visible on both sides of the cable terminal's contact area. Compress the cable terminal. Note that the pliers must be pressed together fully before the cable terminal can be released.

If the connection is equipped with a seal: Guide the thin section of the seal down over the cable terminal and the wire strands. The thick section of the seal must be fitted over the upper section of the cable terminal and the cable insulation.

If the connection is equipped with a seal: When connecting the cable terminal in the connector it is important to check that the cable terminals lock firmly and that the whole seal rests against the connector.

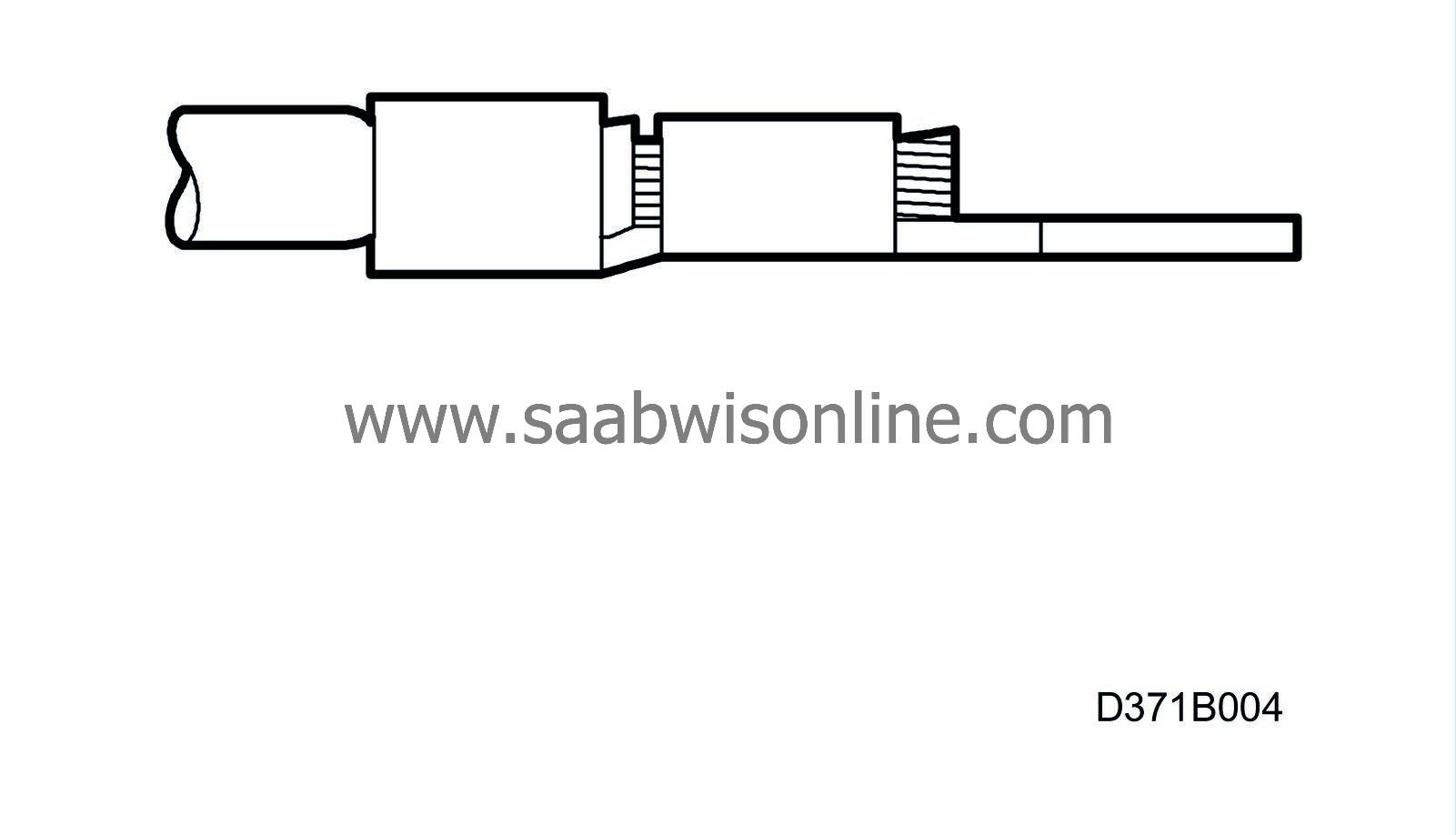

For fitting the sleeve: Insert the cable from the left (text side of pliers), see illustration. The strands must be visible on both sides of the cable terminal's contact area. Compress the sleeve. Note that the pliers must be pressed together fully before the sleeve can be released. Put a shrink tube with adhesive over the sleeve. Fit the cable into the other side of the sleeve in the same manner. Heat the shrink tube over the sleeve.

|

||||||||||

| List of cable terminals/sleeves and in which boxes they are kept |

RD = Red, GN = Green, YE = Yellow, BU = Blue, BK = Black, OGN = Olive green

| Part No. | RD | GN | YE | BU | BK | OGN |

| (16) 30 15 427 | X | |||||

| (16) 30 23 819 | X | |||||

| (16) 30 23 835 | X | |||||

| (16) 30 23 843 | X | |||||

| (16) 30 23 850 | X | |||||

| (16) 30 23 868 | X | |||||

| (16) 30 23 892 | X | |||||

| (16) 30 23 900 | X | |||||

| (16) 30 24 015 | X | |||||

| (16) 30 24 023 | X | |||||

| (16) 30 24 031 | X | |||||

| (16) 30 24 049 | X | |||||

| (16) 30 24 056 | X | |||||

| (16) 30 24 064 | X | |||||

| (16) 30 24 072 | X | |||||

| (16) 30 24 106 | X | |||||

| (16) 30 24 122 | X | |||||

| (16) 30 24 130 | X | |||||

| (16) 30 24 148 | X | |||||

| (16) 30 24 155 | X | |||||

| (16) 30 24 189 | X | |||||

| (16) 30 24 197 | X | |||||

| (16) 30 24 668 | X | |||||

| (16) 30 24 676 | X | |||||

| (16) 30 25 624 | X | |||||

| (10) 40 63 012 | X | |||||

| (10) 40 63 970 | X | |||||

| (10) 41 15 085 | X | |||||

| (10) 41 15 275 | X | |||||

| (10) 41 15 481 | X | |||||

| (10) 44 66 728 | X | |||||

| (10) 44 66 801 | X | |||||

| (10) 45 16 043 | X | |||||

| (10) 45 38 005 | X | |||||

| (10) 45 38 062 | X | |||||

| (10) 45 38 856 | X | |||||

| (10) 45 38 872 | X | |||||

| (10) 46 92 257 | X | |||||

| (10) 46 92 612 | X | |||||

| (10) 51 08 238 | X | |||||

| (10) 51 08 246 | X | |||||

| (10) 51 08 253 | X | X | ||||

| (10) 53 51 739 | X | |||||

| (10) 53 51 747 | X | |||||

| (10) 53 51 788 | X | |||||

| (10) 53 51 796 | X | |||||

| (10) 79 69 256 | X | |||||

| (10) 85 82 413 | X | |||||

| (10) 85 82 603 | X | |||||

| (16) 86 12 145 | X | |||||

| (16) 86 12 152 | X | |||||

| (10) 91 22 508 | X | |||||

| (10) 91 20 775 | X | |||||

| (10) 12 789 934 | X | |||||

| (10) 12 790 414 | X | |||||

| (10) 12 790 465 | X | |||||

| (10) 12 790 612 | X | |||||

| (10) 30 520 560 | X | |||||

| (10) 30 545 461 | X |

Warning

Warning