Piston with connecting rod, removing and fitting

|

|

Piston with connecting rod, removing and fitting

|

|

2.

|

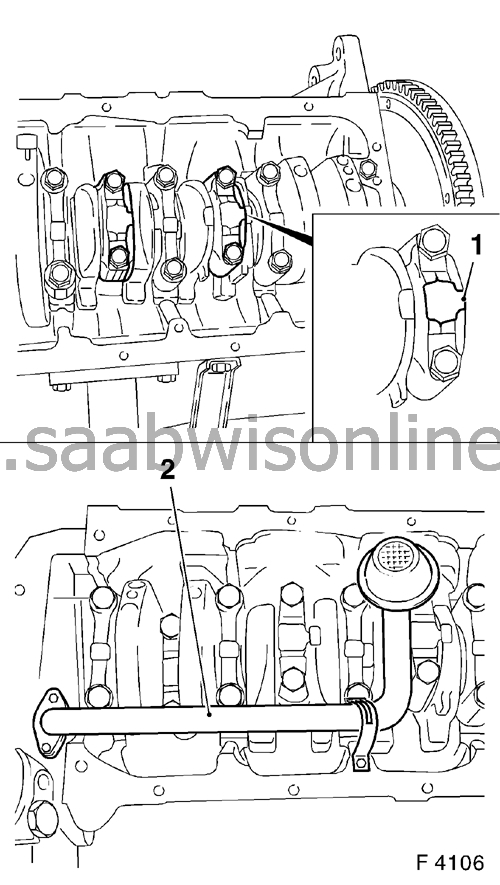

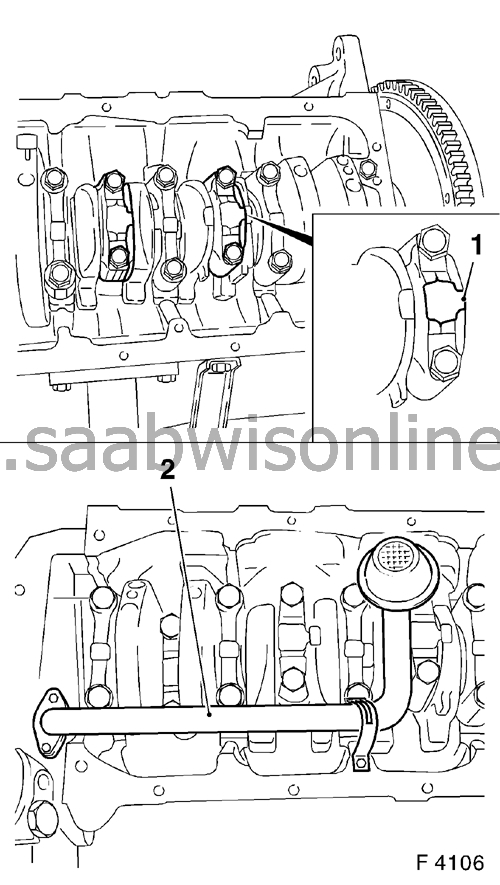

Remove the oil intake pipe (1) from the oil pump and the engine block.

|

|

4.

|

Remove the big-end bearing cap from the connecting rod.

The fracture surfaces of the connecting rods and the big-end bearing caps form an individual fit and must not be interchanged or damaged. Do not rest the connecting rods or big-end bearing caps on their fracture surfaces to avoid damage.

|

|

5.

|

Remove combustion residue from the top part of the cylinder bore.

|

|

1.

|

Press out the piston together with the connecting rod upward from the cylinder bore.

|

|

2.

|

Check and clean all parts, change them if necessary. Change the piston - see

Piston, change

.

|

|

3.

|

Put the crankshaft big-end journal in "ND position" and moisten it with engine oil.

Adjust the piston ring positions:

|

|

4.

|

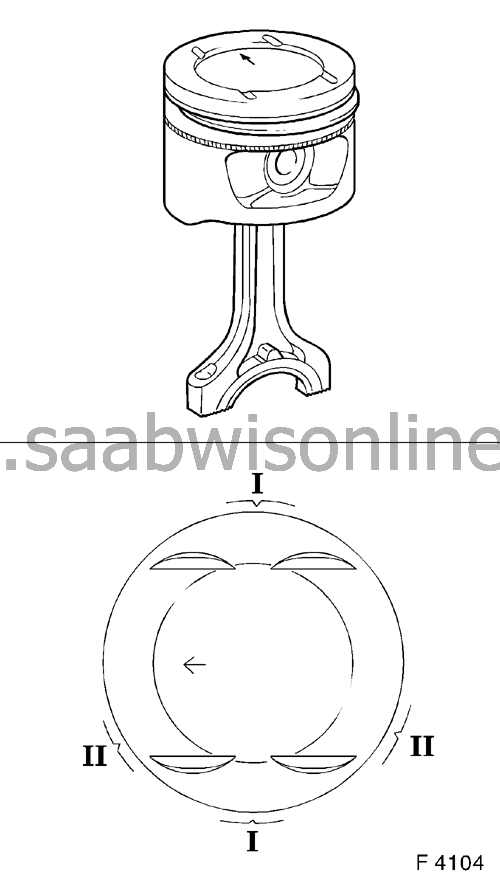

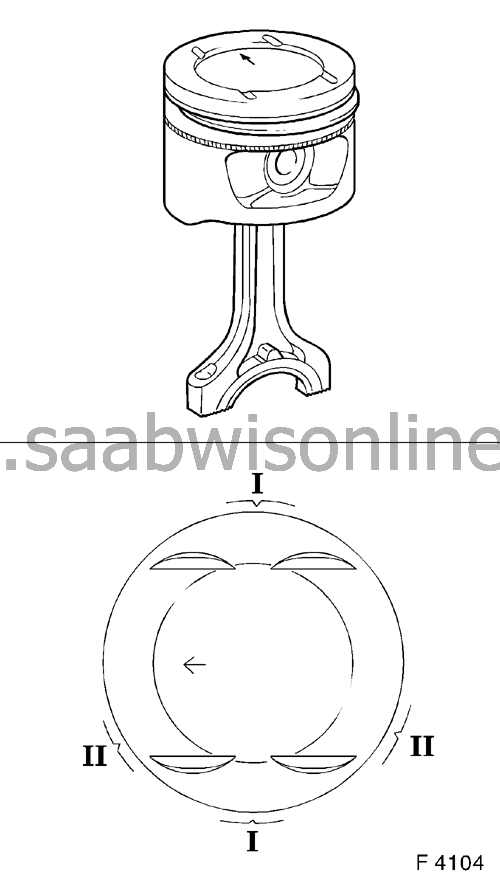

Oil scraper ring II: offset the steel ring gaps 25 to 50 mm to the left and right of the middle ring gap respectively. Piston ring I: offset the ring gap about 180°. Second piston ring with "TOP" face up.

|

|

5.

|

Moisten the piston rings with engine oil and compress them with a normal piston ring compressor.

|

|

6.

|

Push the piston into the cylinder bore with the handle of a hammer.

Caution

Note the fitting position of the piston and connecting rod.

|

|

7.

|

The arrow (1) on the bottom of the piston pointing towards the timing end of the engine, the boss (2) on the connecting rod towards the gearbox end.

|

|

1.

|

Note the order of the big-end bearing caps.

|

|

2.

|

Fit the big-end bearing caps - boss (1) on the big-end bearing cap pointing towards the gearbox end.

|

|

3.

|

Big-end bearing cap with new bolts on connecting rod - tightening torque 25 Nm + 30°.

|

|

4.

|

Fit the oil intake pipe (2) together with a new sealing ring on the oil pump - tightening torque 8 Nm

|

Note

|

|

Recut the threads before reuse and apply locking compound (red) when fitting the bolts. Mounting time including checking torque must not exceed 10 min.

|

|

|

5.

|

Fit the oil intake pipe onto the engine block - tightening torque 8 Nm.

|