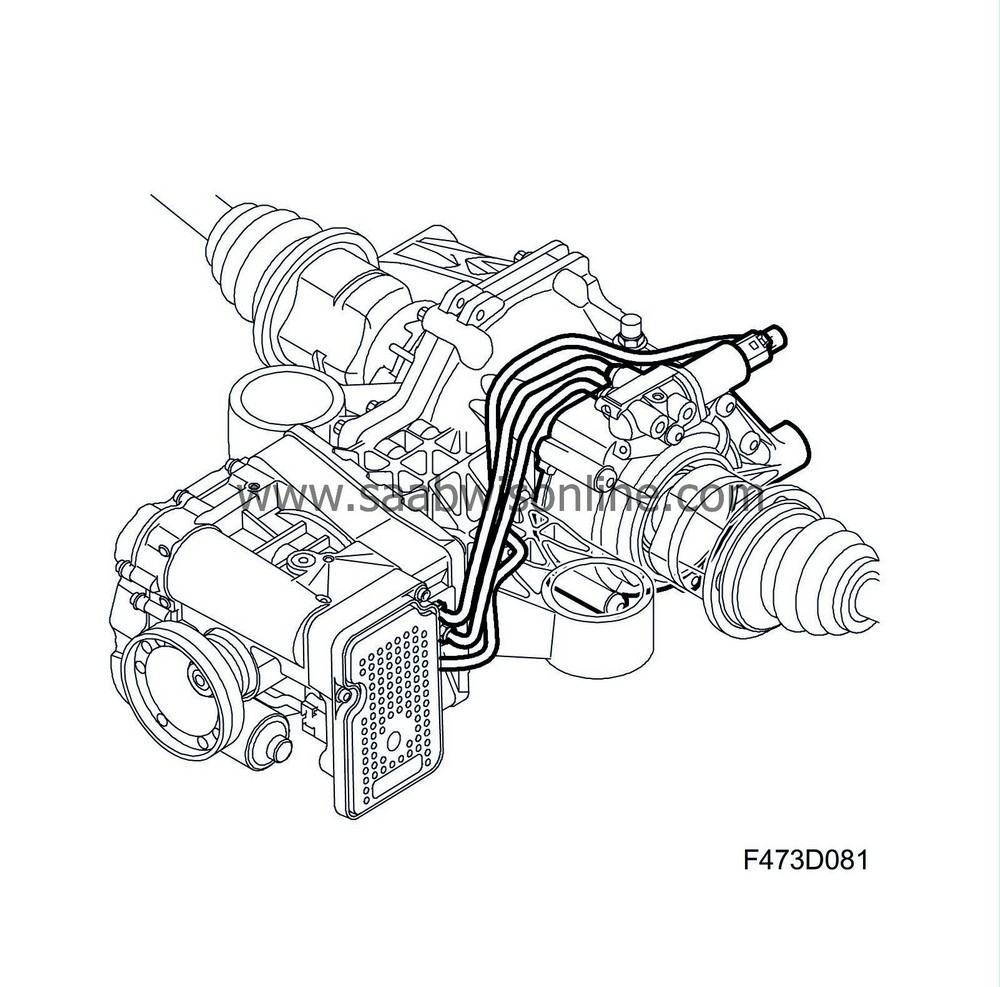

Limited slip differential clutch (eLSD)

| Limited slip differential clutch (eLSD) |

Its function is to fully or partly lock the left-hand drive shaft to the differential housing. When this takes place wheel torque can be distributed between the rear wheels.

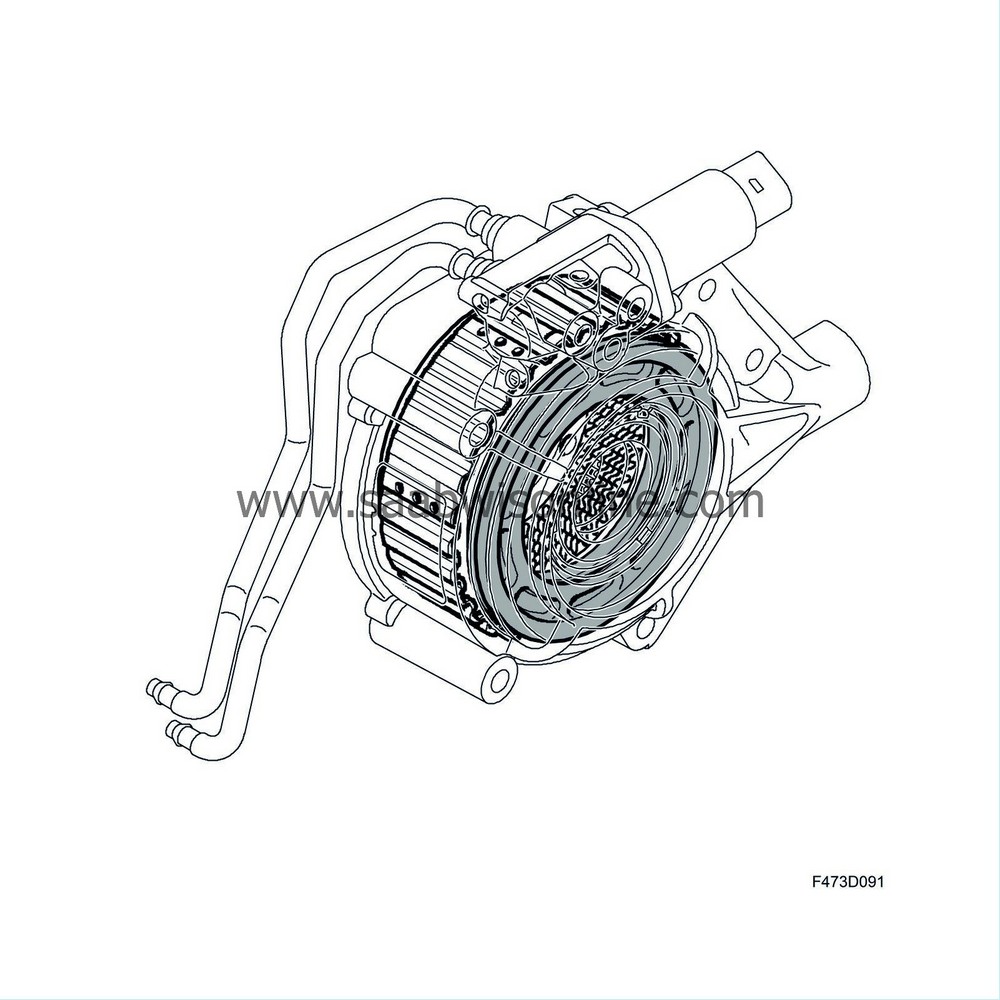

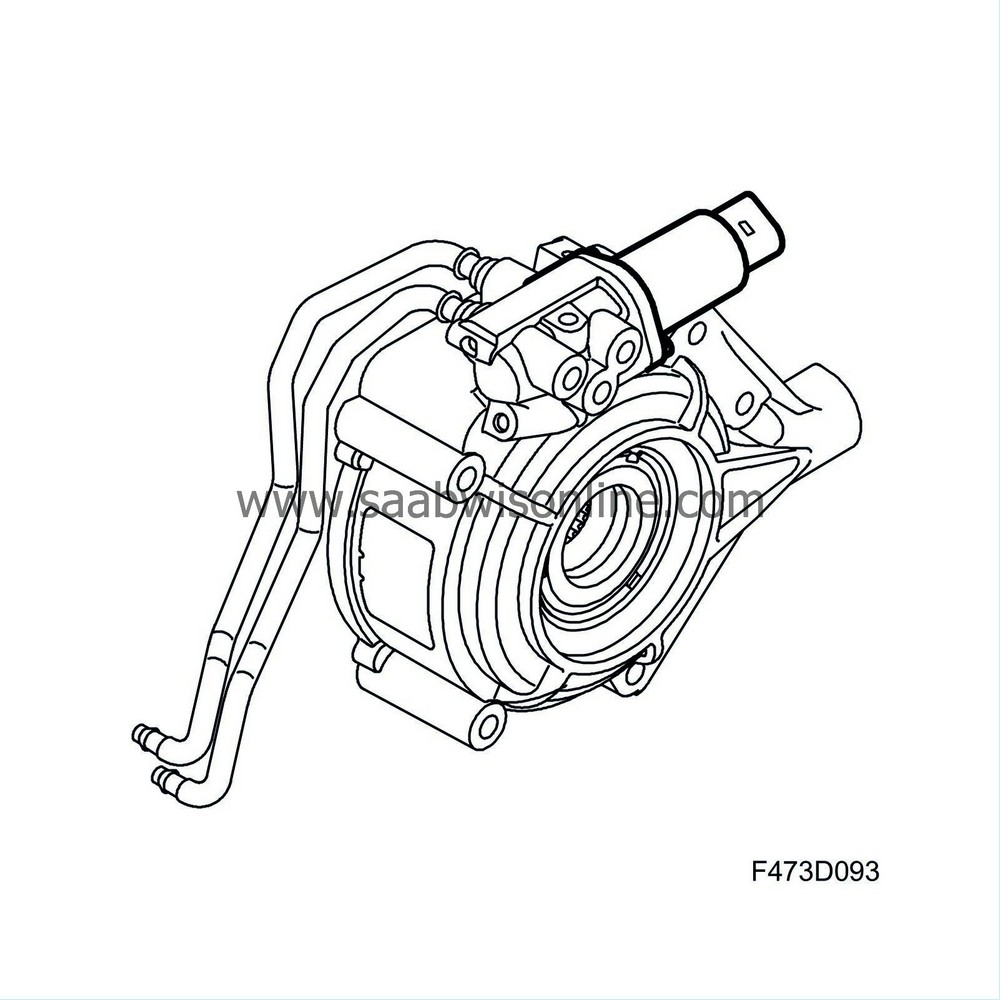

The limited slip differential clutch is a disc type, and it is electro-hydraulically controlled by the XWD control module via a pressure control valve which is fitted on the limited slip differential clutch's housing.

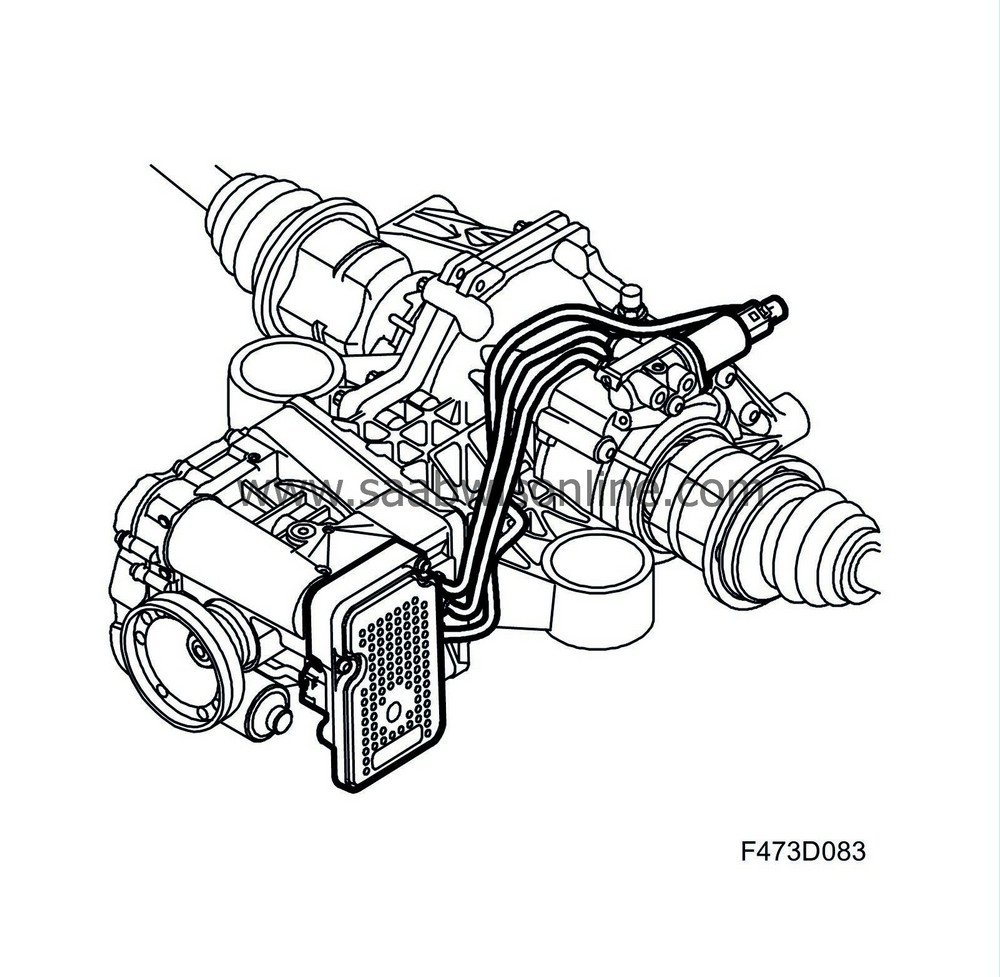

| Housing |

The limited slip differential clutch housing is produced from a high-pressure cast aluminium alloy. It is bolted with 7 bolts to the left-hand side of the limited slip differential. The control valve is fitted on the outside of the housing. Fitted inside are operating piston, clutch cage with disc pack and hub.

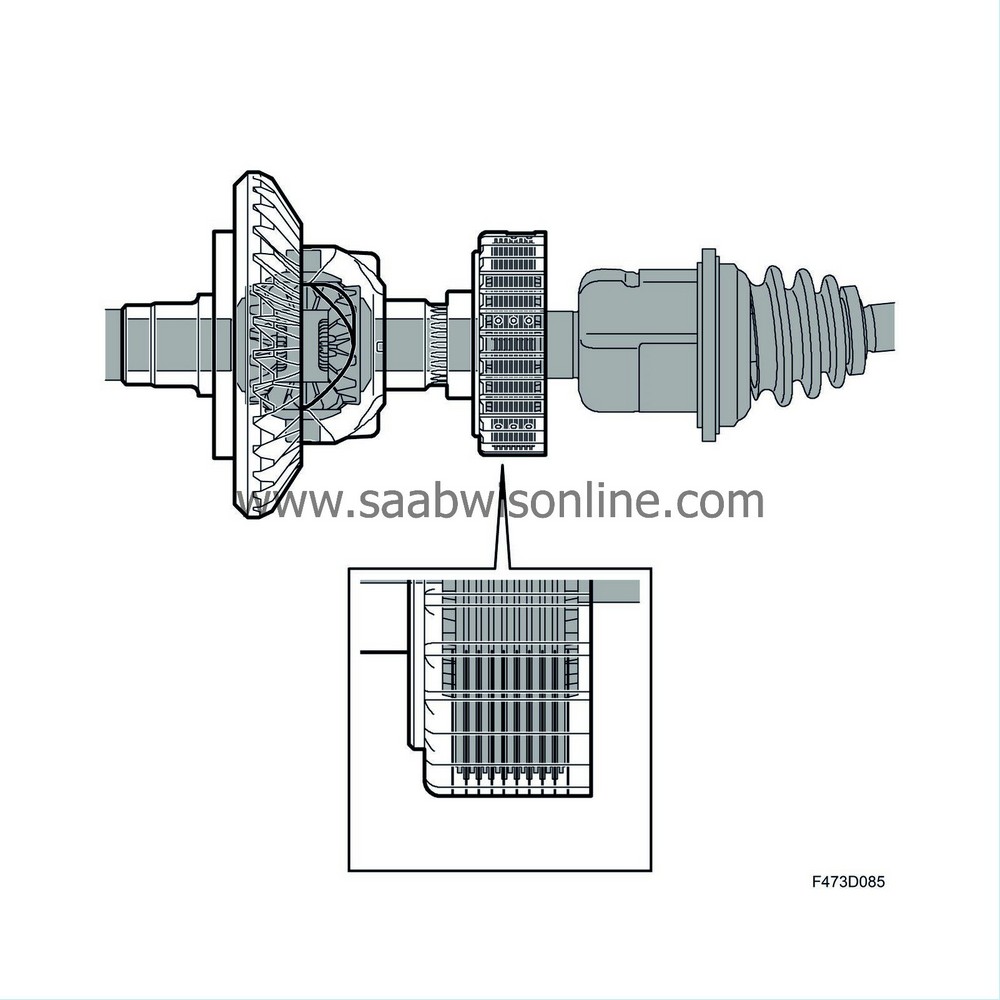

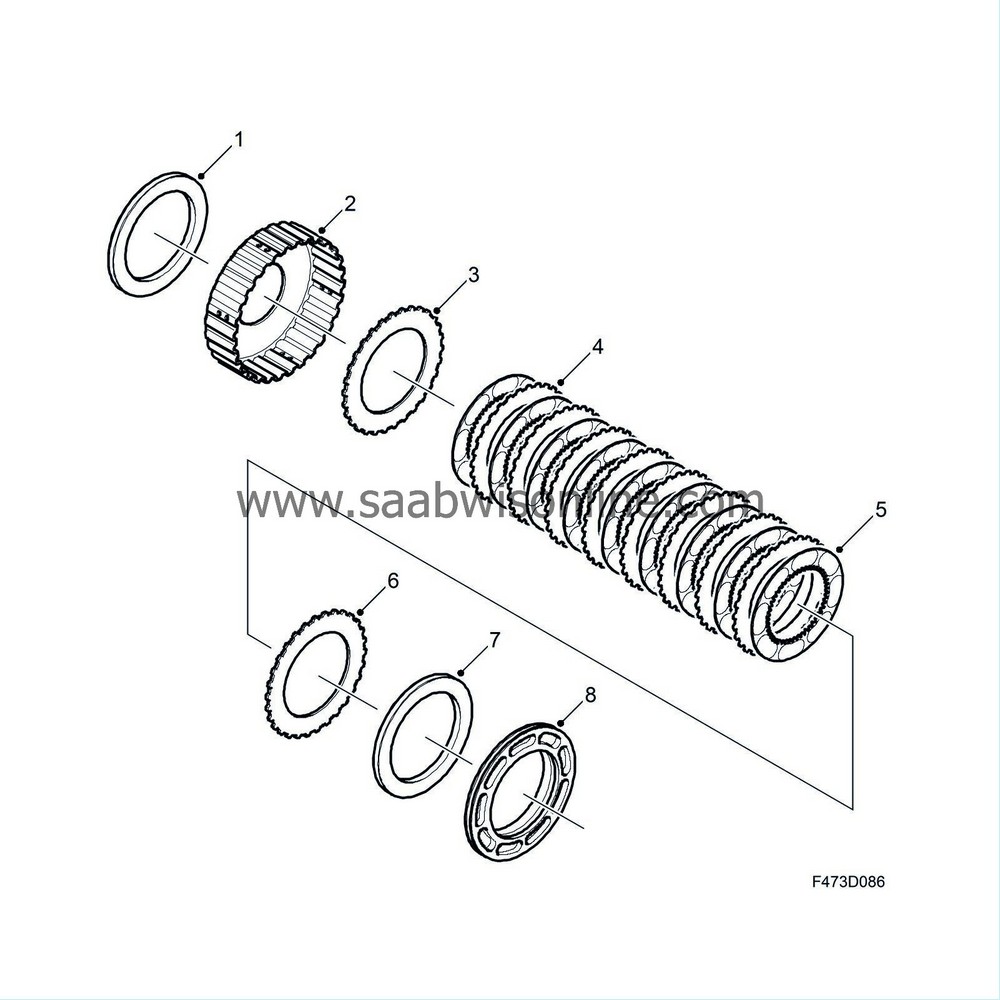

| Disc pack, assembly |

The disc pack assembly consists of a hub, smooth steel driven plates with friction material, clutch cage, thrust bearing and journal bearing.

The disc pack serves to steplessly distribute the torque between the rear wheels It consists of 9 driven plates (5) connected to the hub. They are made of steel and are equipped with friction material, which consists of carbon fibre applied to the discs in fields. Between the steel driven plates are 8 smooth steel discs (4). The periphery of the discs is serrated and fits between the drum's (2) bars. Farthest out in the disc pack are steel discs (3,6) which are considerably thicker. Their function is to distribute the force to the disc pack so that the pressure is evenly distributed. These are also serrated in the periphery which fits in the drum's bars.

The disc pack is compressed by means of an operating piston (8). Between the operating piston and the disc pack's first steel disc is a thrust bearing 879 which is an integrated part of the operating piston. The thrust bearing is a radial needle bearing. Between the rear of the drum and the limited slip differential housing is a journal bearing (1) which is an integrated part of the drum. The journal bearing is a radial needle bearing.

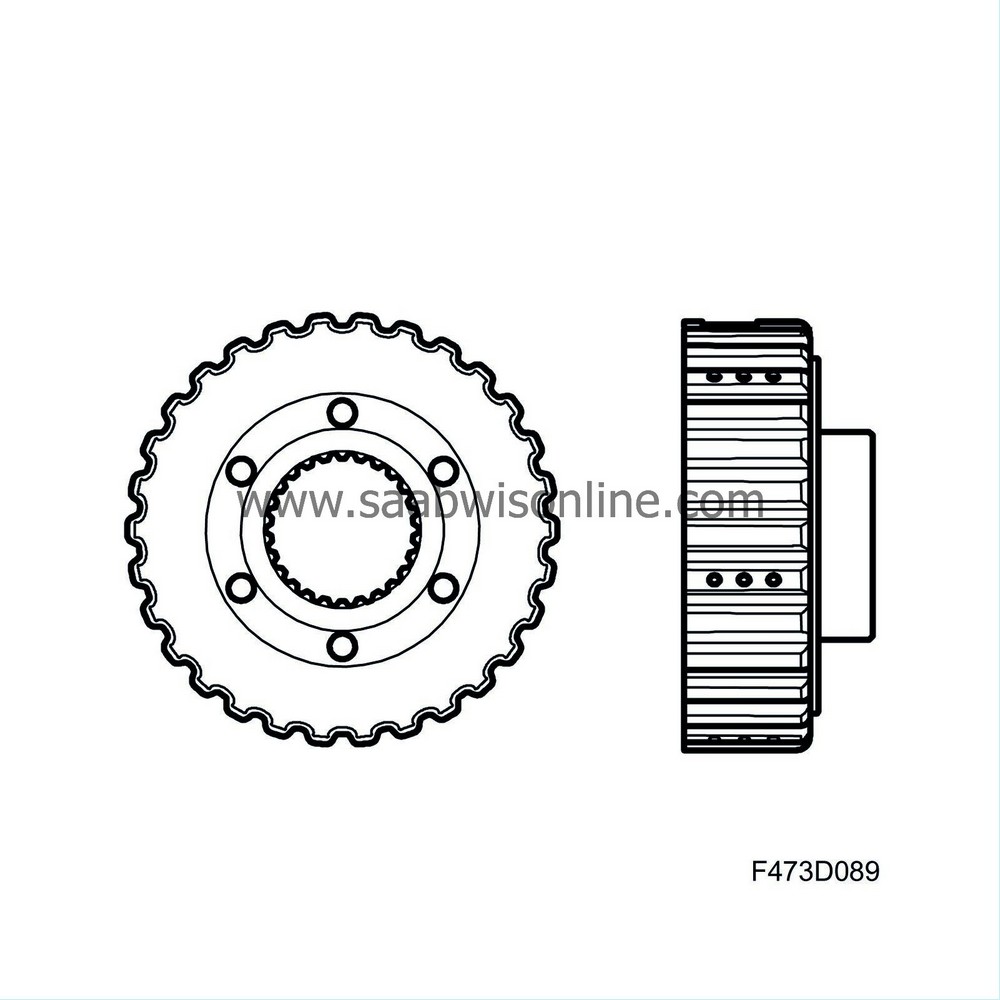

Hub is produced from steel and is internally equipped with splines which engage into the left-hand drive shaft. Externally it is equipped with bars in which the smooth steel driven plates engage. The axial position of the hub is governed by a thrust washer in bronze fitted in against the final drive gear. It is equipped with a number of holes so that oil from the final drive gear can flow into the hub.

For cooling and lubrication of the disc pack the hub is equipped with three longitudinal oil ducts. They are supplied with oil from a chamber in connection with the final drive gear. The oil is led through the ducts to the centre of the disc pack and is thrown out through the driven plates when they rotate.

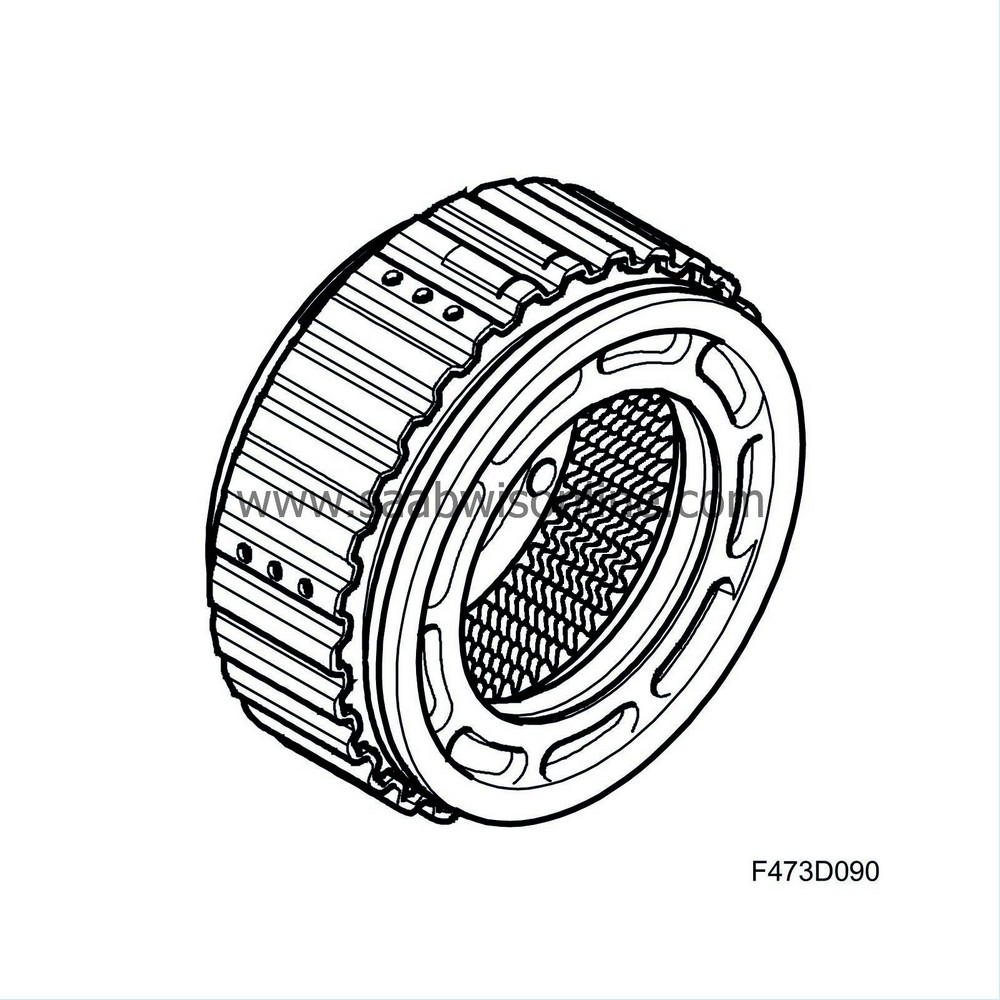

Drum is produced in pressed steel plate, its centre is produced in steel and is laser welded to the drum. Its walls have drainage holes for the oil that has passed through the disc pack. The oil is thrown out against the walls by the rotation of the drum and is led back to the final drive gear.

The disc pack is compressed by means of an operating piston. Between the operating piston and the disc pack's first steel disc is a thrust bearing which is an integrated part of the operating piston. The thrust bearing is a radial needle bearing. Between the rear of the drum and the limited slip differential housing is a journal bearing which is an integrated part of the drum. The journal bearing is a radial needle bearing.

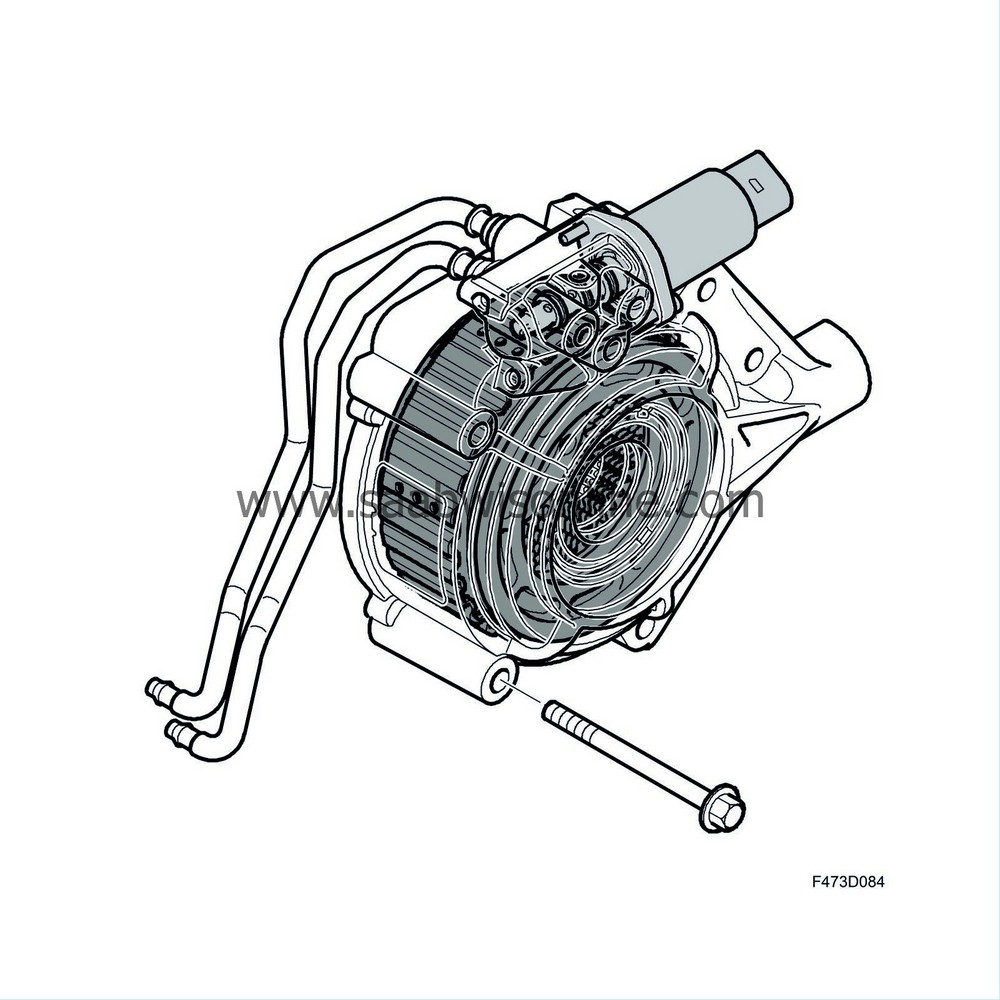

| Operating piston, (ring piston) |

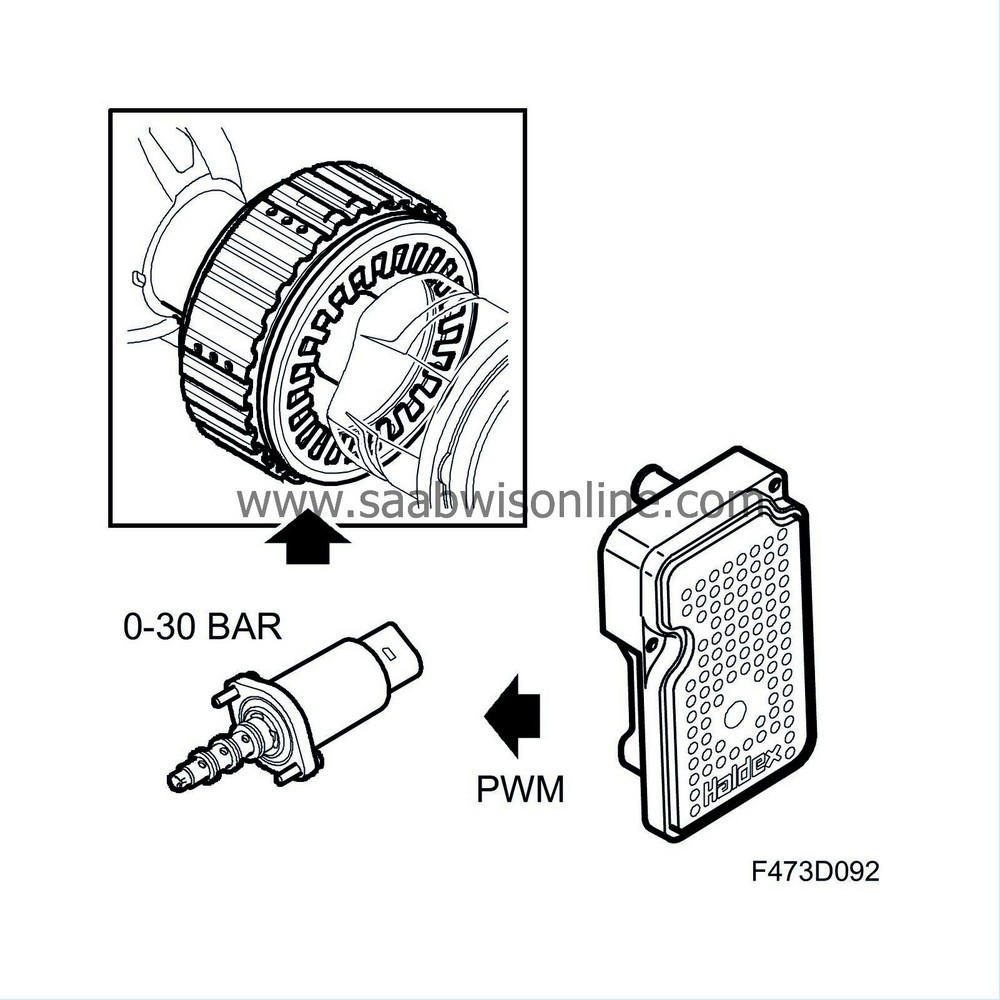

The function of the operating piston is to generate the force required to control the limited slip differential clutch's disc pack. It is located in the limited slip differential clutch's housing. The piston's cylinder is formed by the housing. On the rear of the piston a variable oil pressure (0-30 bar) acts via the pressure control valve which is controlled by the XWD control module.

The operating piston is ring shaped and produced from an aluminium alloy. The piston is equipped with grooves internally and externally, in each of which is a sealing ring. A disc spring is fitted on the rear of the piston to provide preload and to absorb excess play in the thrust bearing, disc pack and journal bearing. A thrust bearing is integrated with the piston on the side turned toward the disc pack. The bearing is the needle bearing type.

| Pressure control valve |

The pressure control valve is located above the limited slip differential clutch housing. It is the same type as the differential clutch .