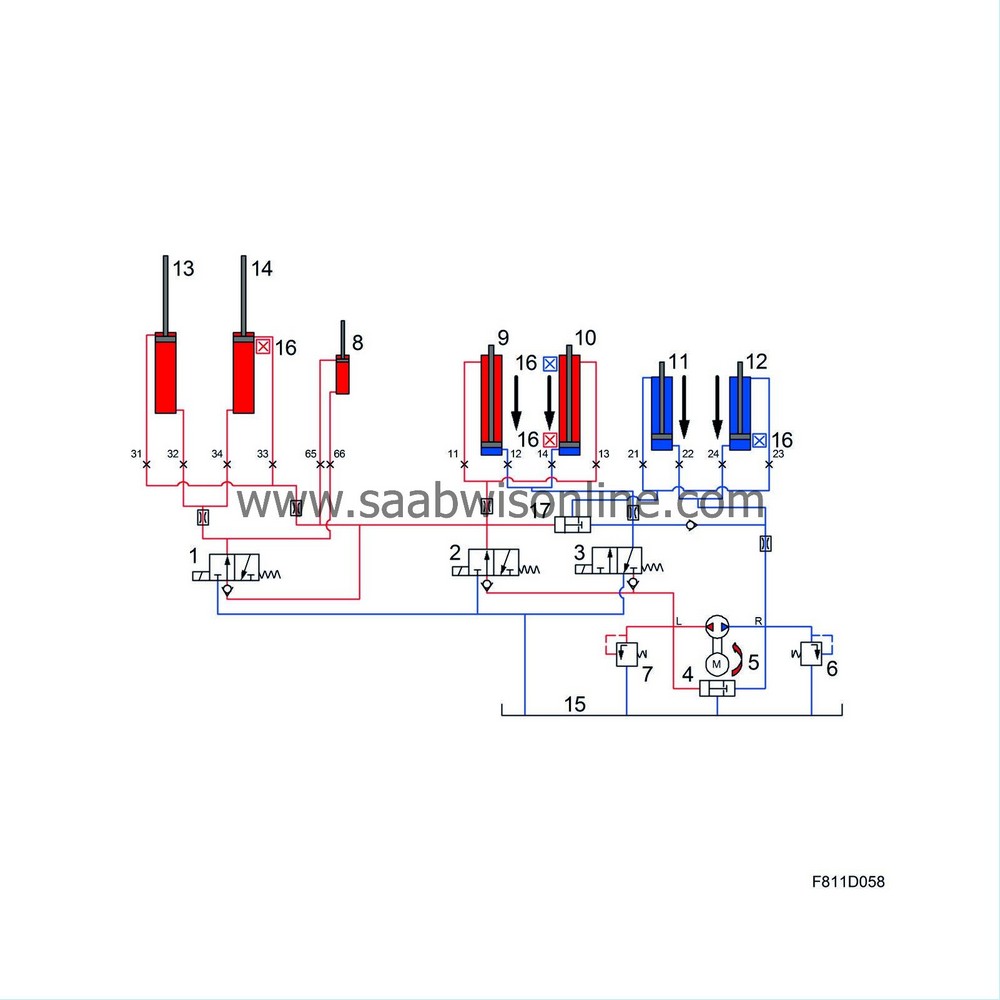

Soft top operation, detailed description

| Soft top operation, detailed description |

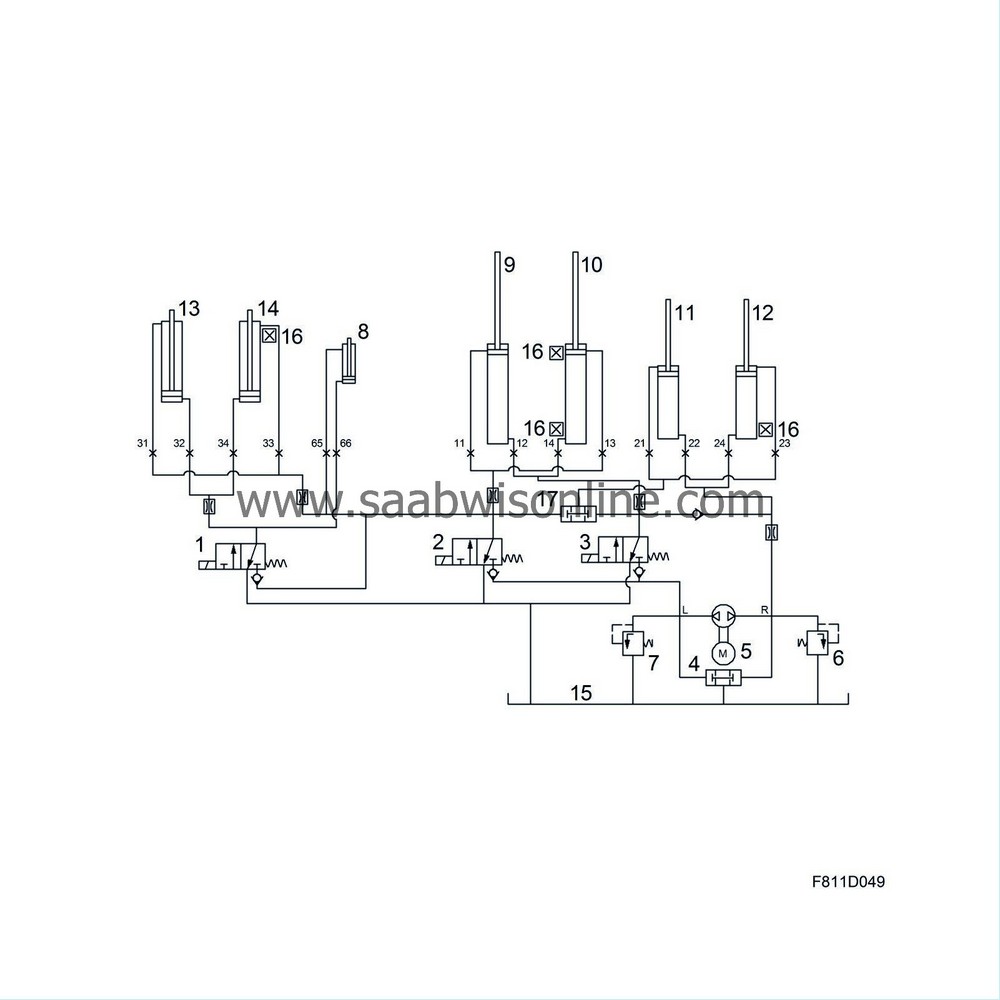

| 1. |

Solenoid valve 1 (green)

|

|

| 2. |

Solenoid valve 2 (blue)

|

|

| 3. |

Solenoid valve 3 (orange)

|

|

| 4. |

Valve block with relief valves and shunt valves

|

|

| 5. |

Hydraulic pump

|

|

| 6. |

Oil reservoir

|

|

| 7. |

Electric motor

|

|

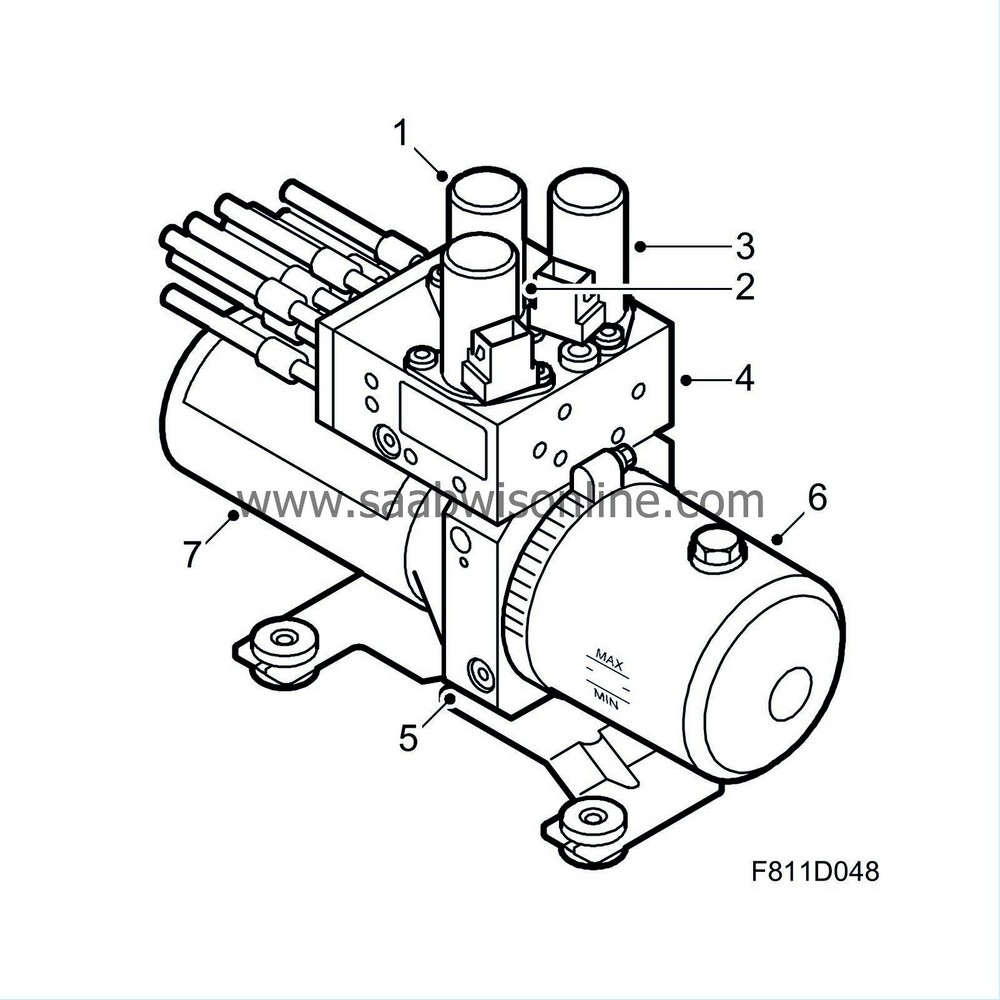

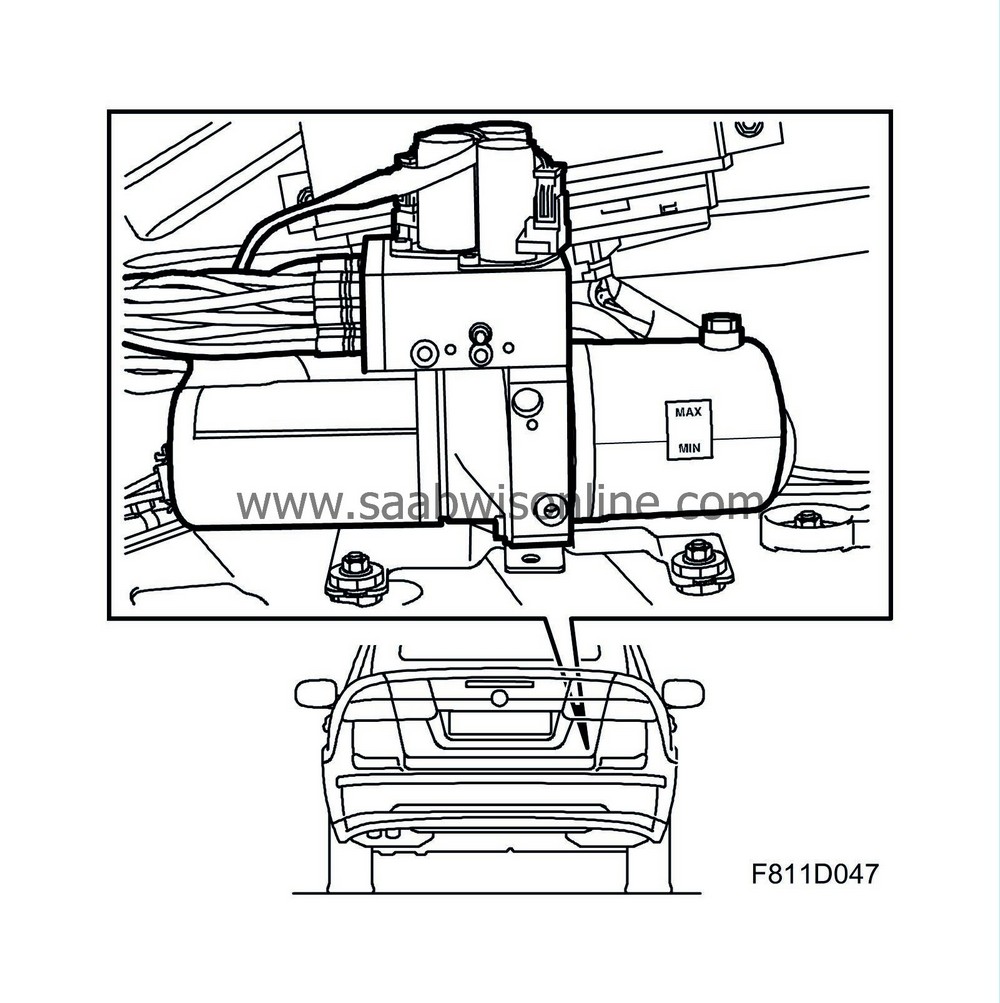

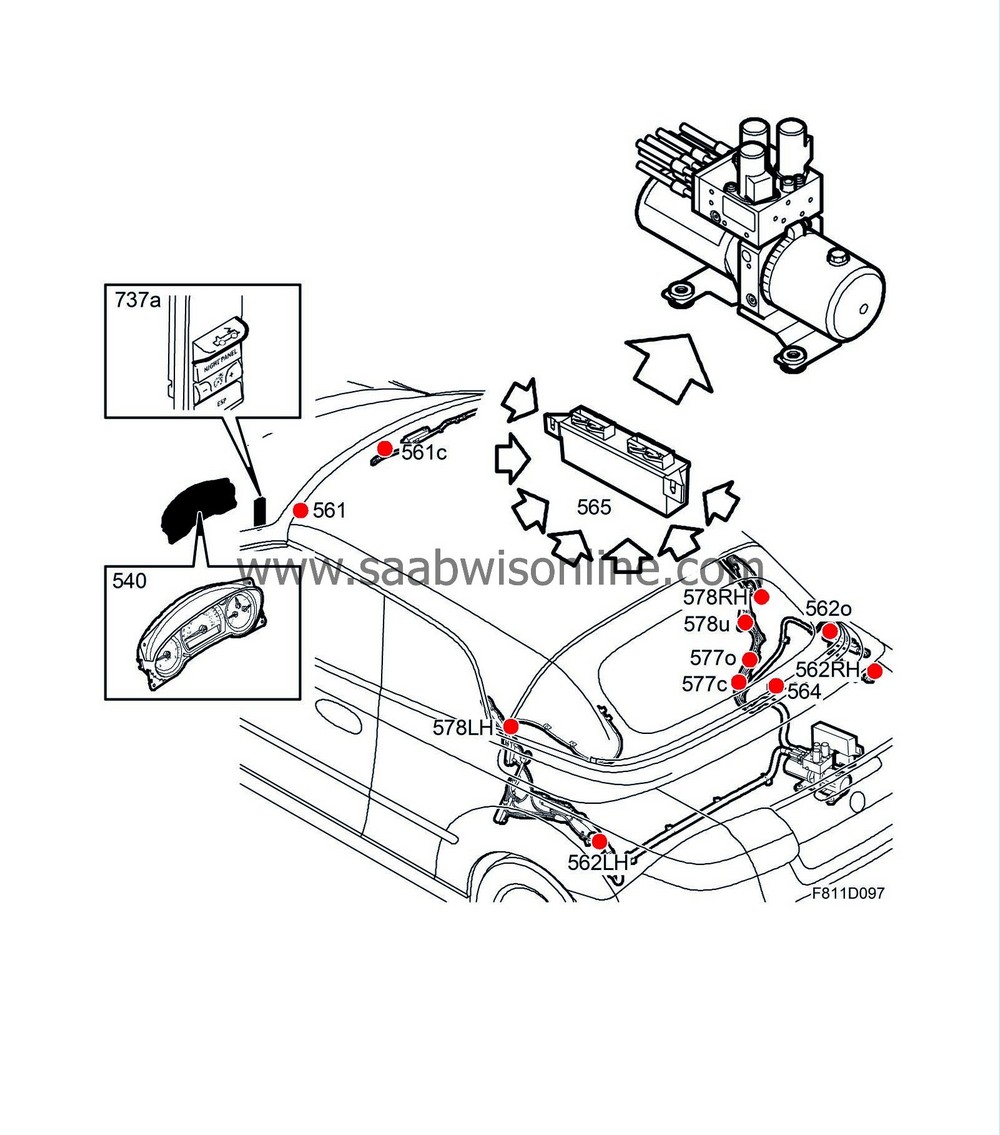

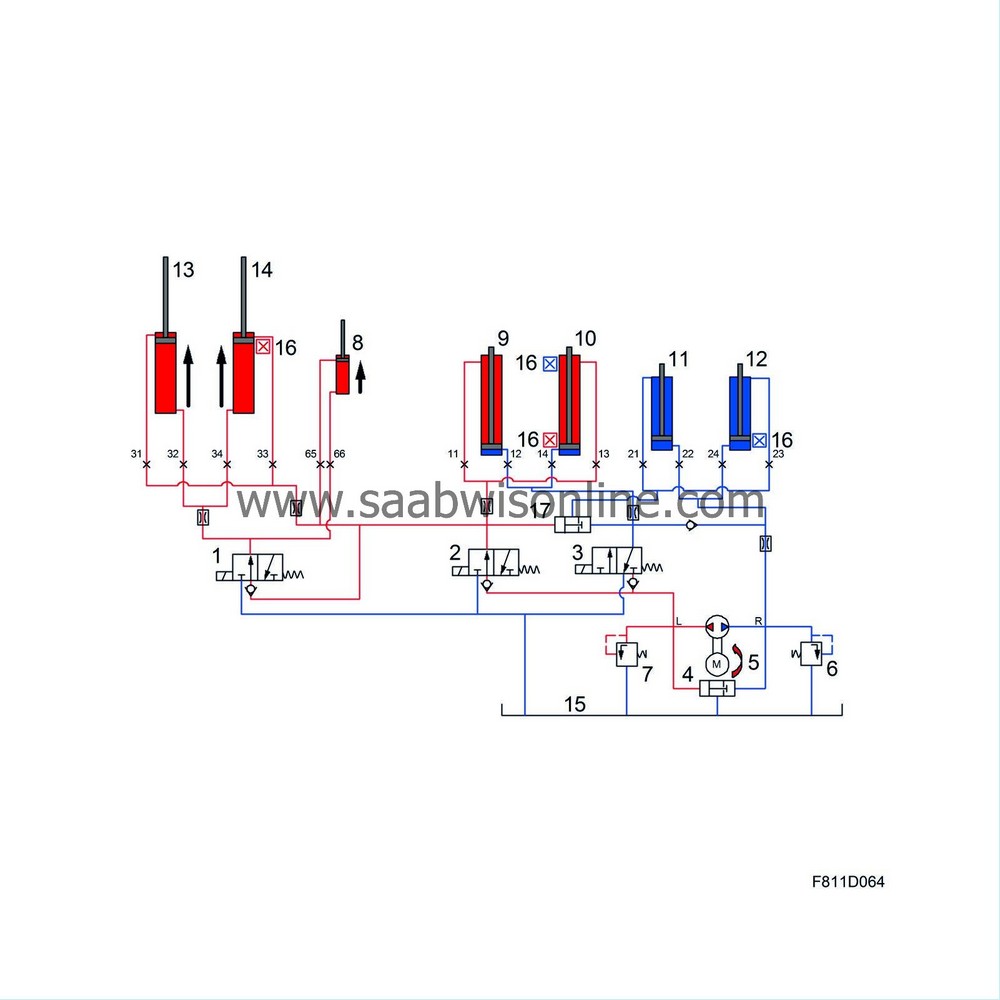

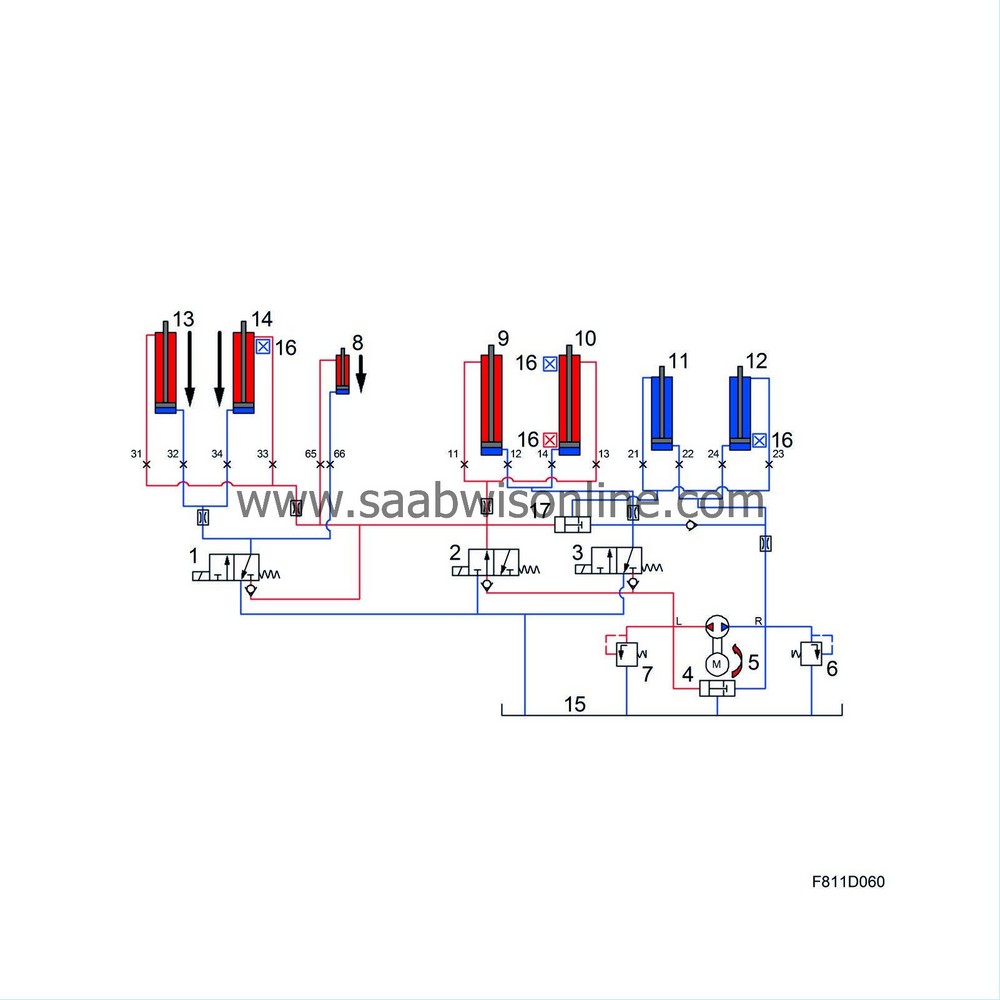

The hydraulic unit is located in the right-hand side of the luggage compartment. The system comprises also of two main hydraulic cylinders, which operate the soft top, two hydraulic cylinders to operate the sixth bow, two hydraulic cylinders for the soft top cover and one hydraulic cylinder to lock the soft top to the windscreen frame.

The hydraulic unit comprises a pump block with two pressure reduction valves (for clockwise or anticlockwise), two logic shunt valves (XOR valves) and three solenoid valves, 1, 2 and 3. Component locations .

The three electro-hydraulic valves are functionally identical and they are used to control the flow of oil to the hydraulic cylinders.

The fluid reservoir with level indications on the side is attached to the pump block with a hose clip. Observe that only fluid with part no. (16) 89 96 860 Power steering fluid Pentosin CHF-11S may be used.

| Pump unit |

The pump unit comprises a 4-cylinder piston pump which is driven by an electric motor. The motor rotation direction is controlled by STC. The hydraulic cylinders work with differential pressure in certain cases, i.e. the same pressure operates in the system but due to the piston rod taking up part of the area the pressure has a smaller area to operate in at the piston rod side. The result of this is that the piston is pushed out faster but with less force.

The soft top hydraulic cylinders for the sixth bow and soft top cover are operated anticlockwise.

| Valves |

The pressure is reduced by two pressure reducing valves (for rotation anticlockwise and clockwise) to 140 ± 10 bar. These reducing valves are situated after the respective delivery sides and lead fluid back to the suction side. Meanwhile, the connection between the delivery side and the fluid reservoir is closed.

The valve block, containing three solenoid valves and two shunt valves, is connected to the pump block.

Each of the three solenoid valves has three fluid connections:

| - |

Fluid pressure from pump

|

|

| - |

Fluid pressure to main cylinder

|

|

| - |

Oil return to reservoir

|

|

The valves have two positions: "Active" and "Rest". When a valve is active, the pressure from the pump is connected to the pressure for the cylinder in question. When a valve is at rest, the pressure for the cylinder is connected to the fluid return line to the reservoir. The valves may be activated by STC.

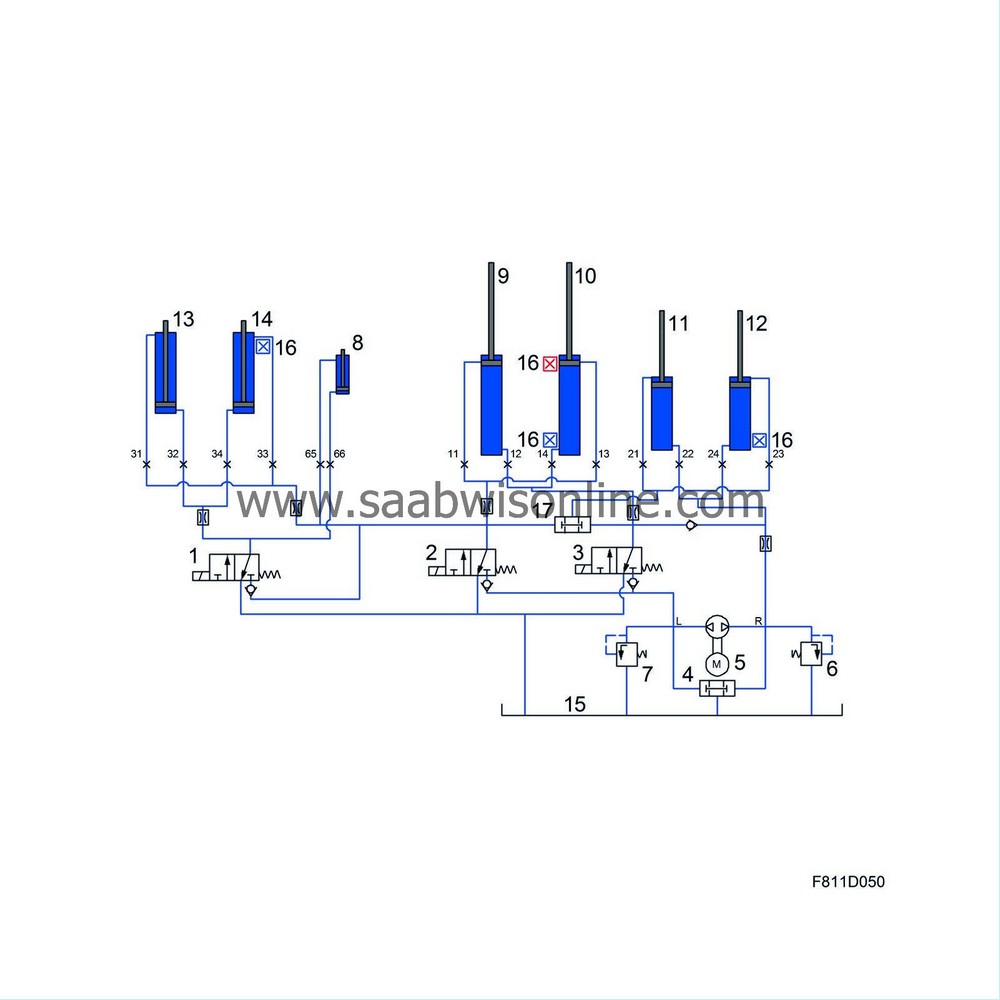

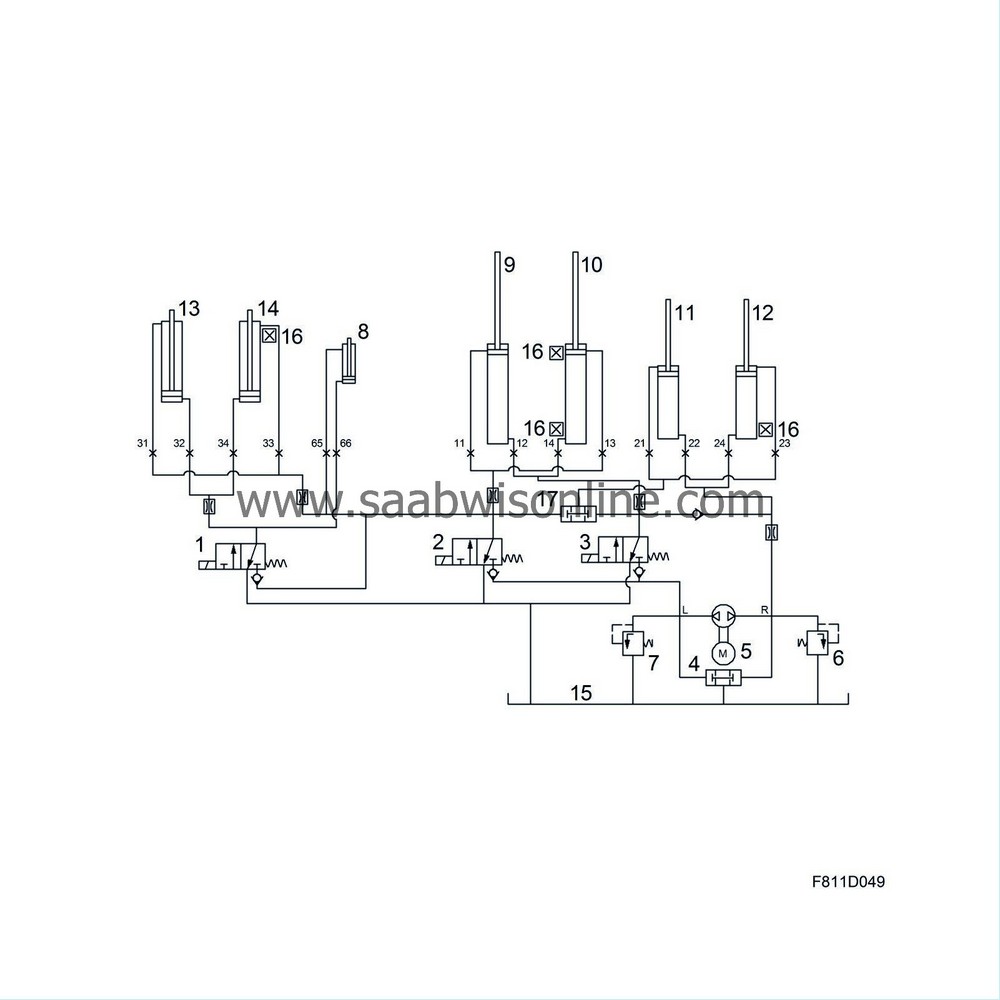

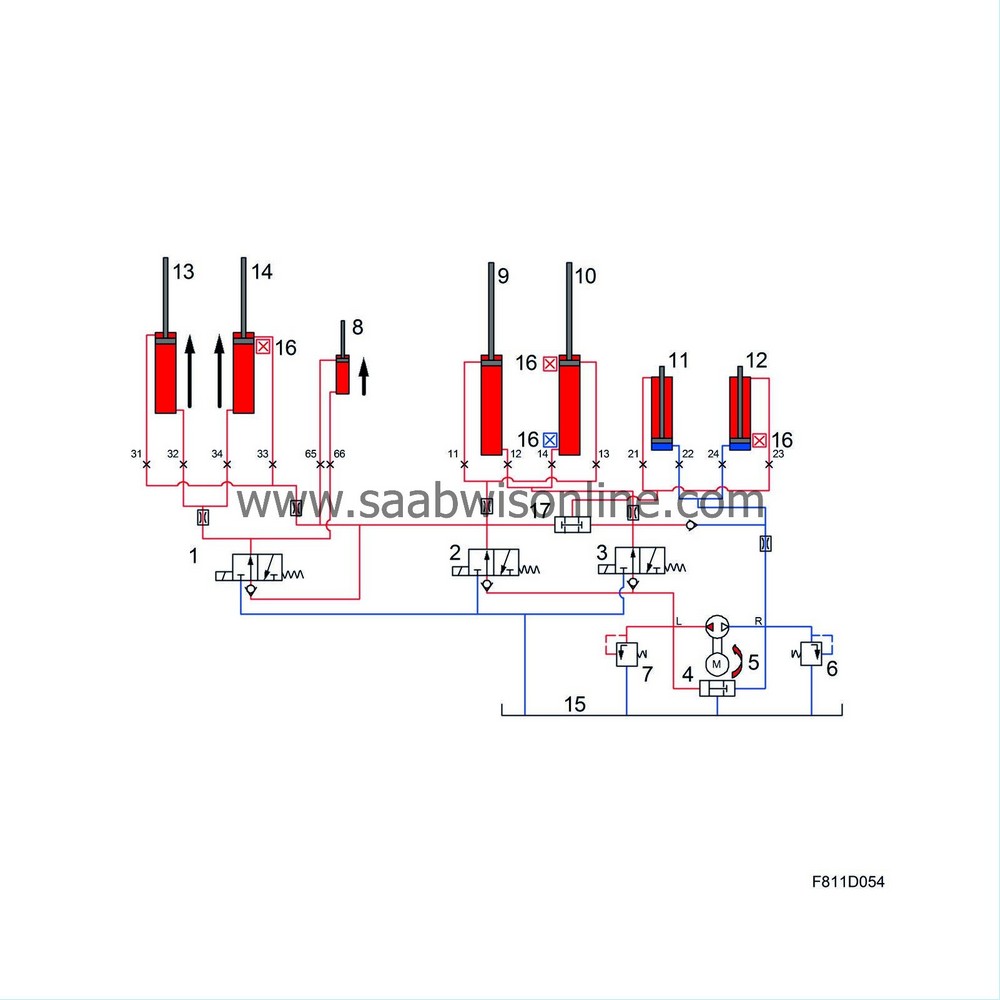

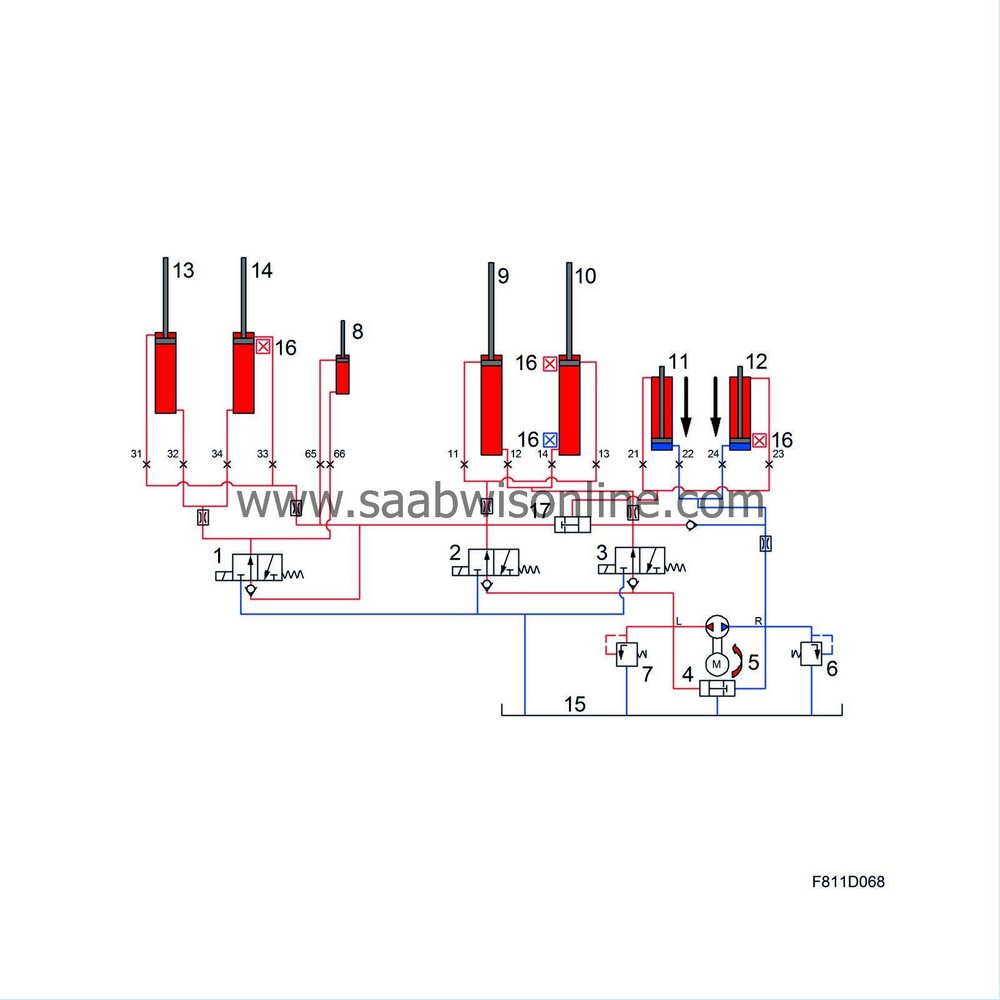

| Hydraulic functions for opening soft top |

Component locations

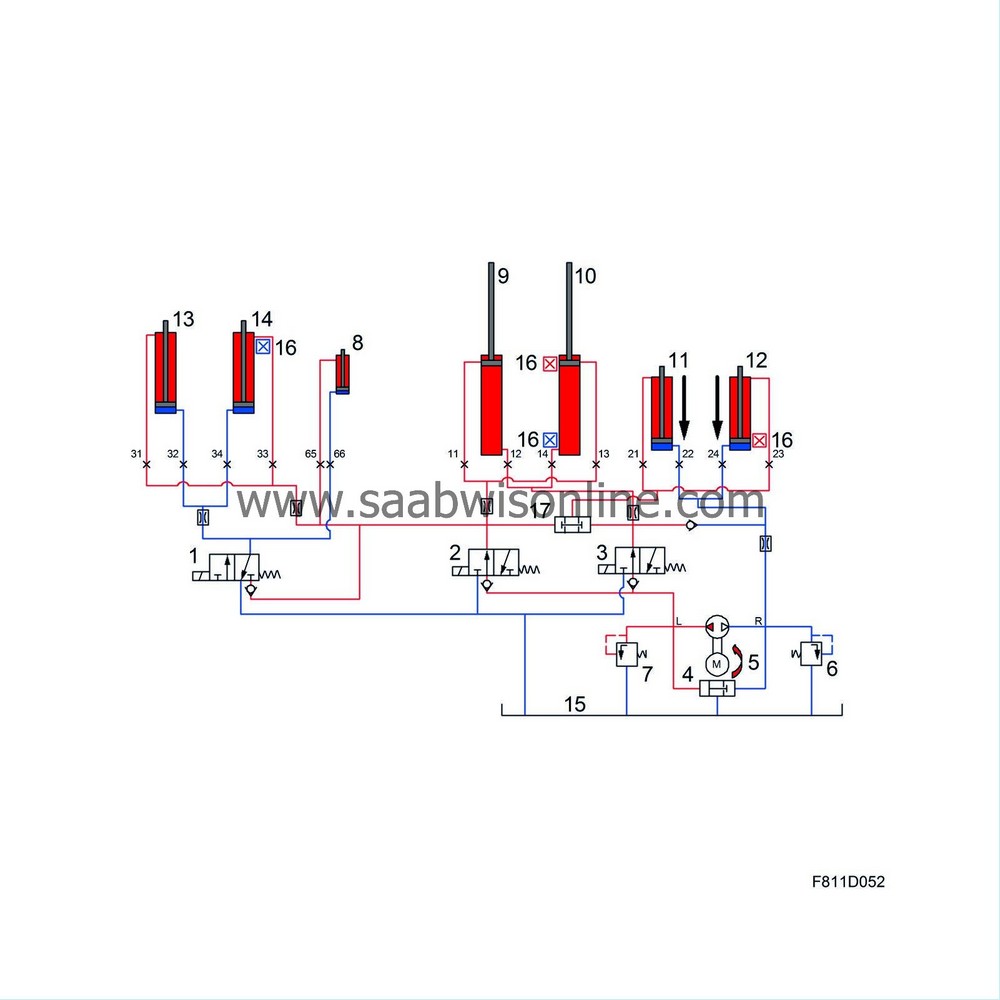

| 1. |

Solenoid valve 1 (green)

|

|

| 2. |

Solenoid valve 2 (blue)

|

|

| 3. |

Solenoid valve 3 (orange)

|

|

| 4. |

Shunt valve

|

|

| 5. |

Hydraulic pump with electric motor

|

|

| 6. |

Pressure reducing valve (clockwise)

|

|

| 7. |

Pressure reducing valve (anticlockwise)

|

|

| 8. |

Hydraulic cylinder, first bow/windscreen frame

|

|

| 9. |

Main hydraulic cylinder, LH

|

|

| 10. |

Main hydraulic cylinder, RH

|

|

| 11. |

Hydraulic cylinder, sixth bow left

|

|

| 12. |

Hydraulic cylinder, sixth bow right

|

|

| 13. |

Soft top cover hydraulic cylinder, right

|

|

| 14. |

Soft top cover hydraulic cylinder, left

|

|

| 15. |

Oil reservoir

|

|

| 16. |

Position sensor

|

|

| 17. |

Shunt valve

|

|

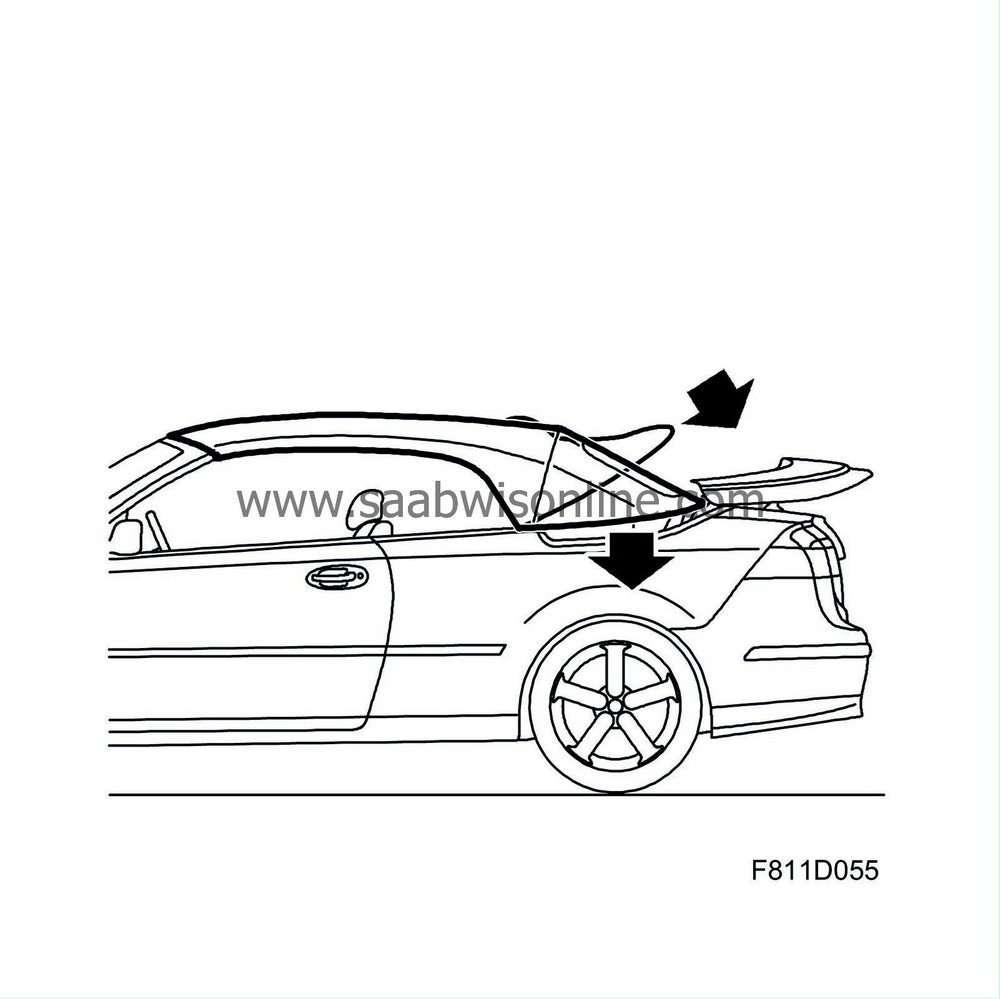

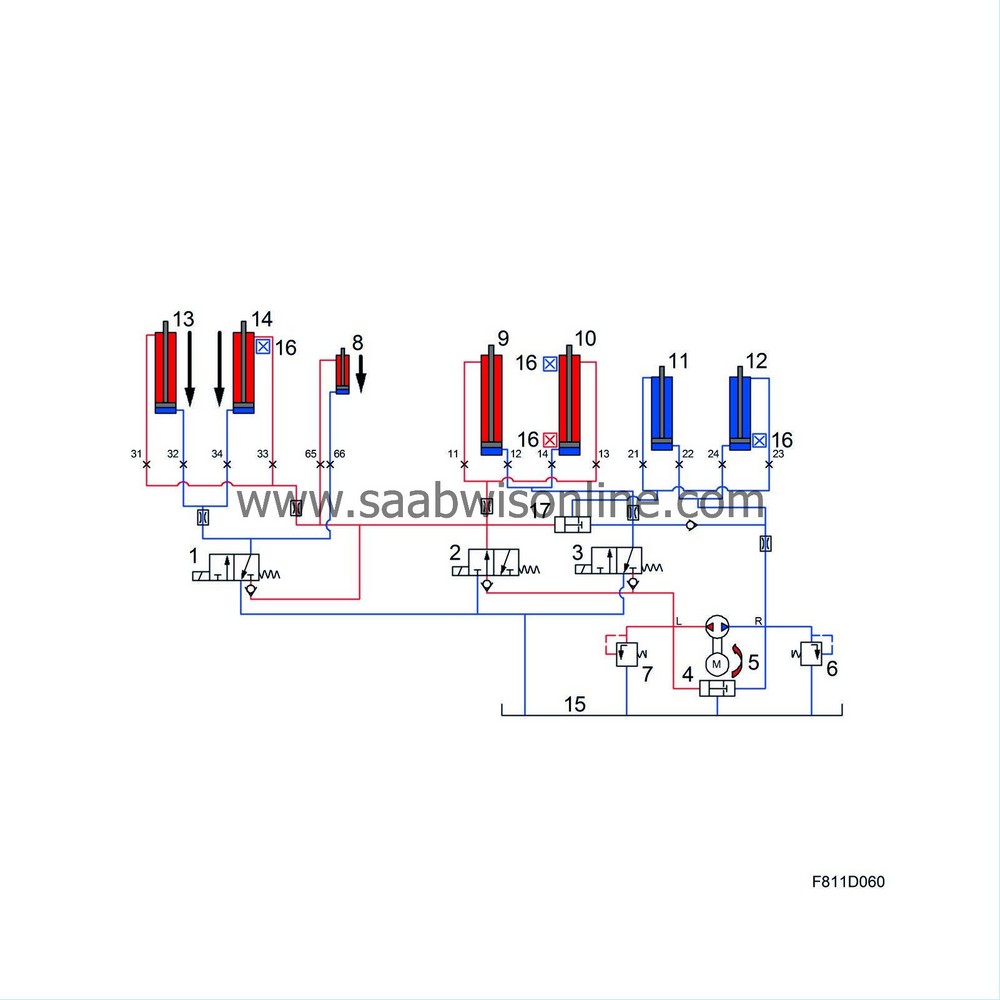

| Soft top sequences, opening the soft top, hydraulic functions |

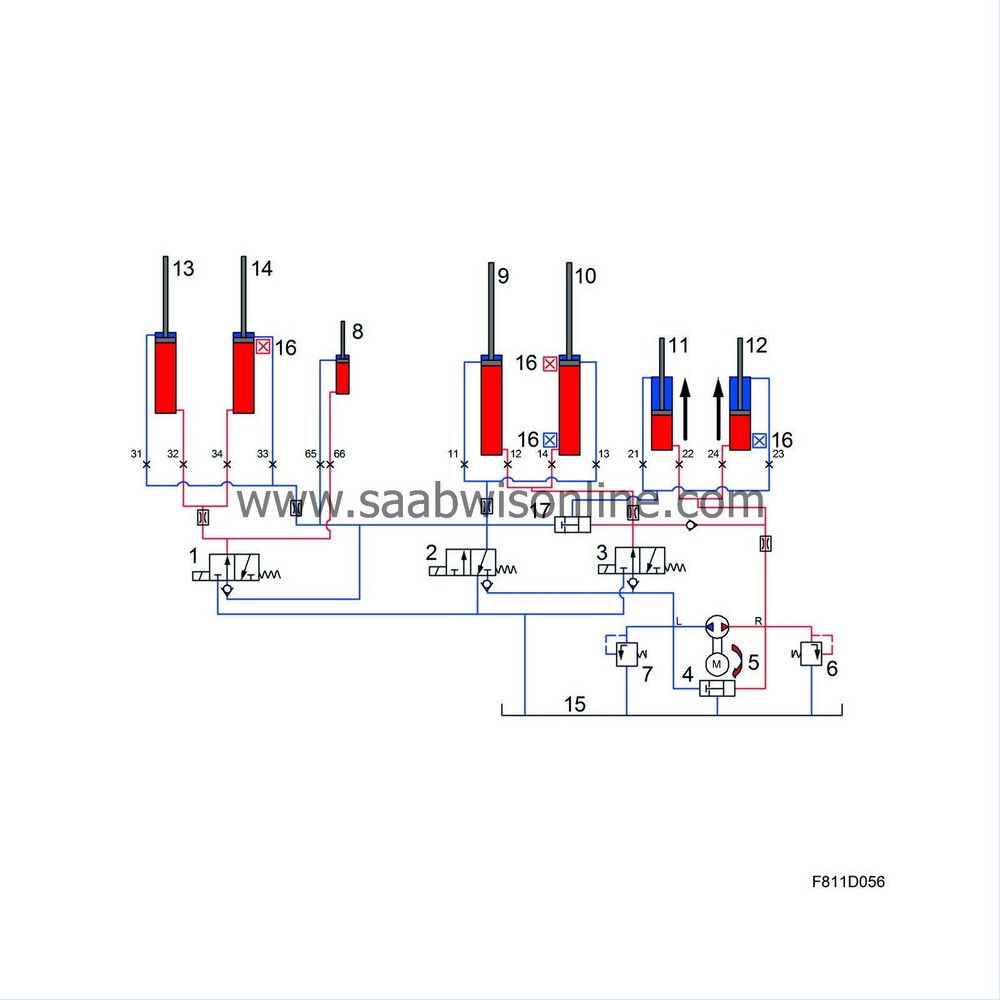

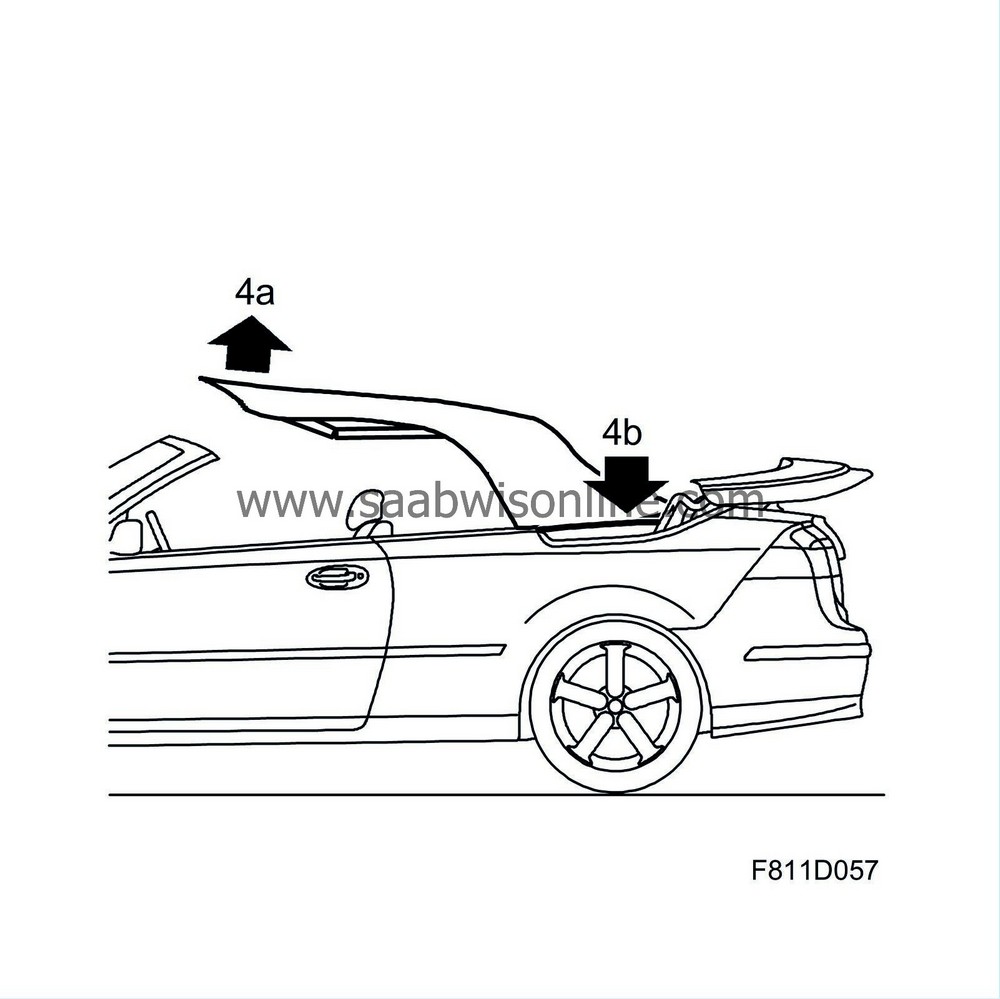

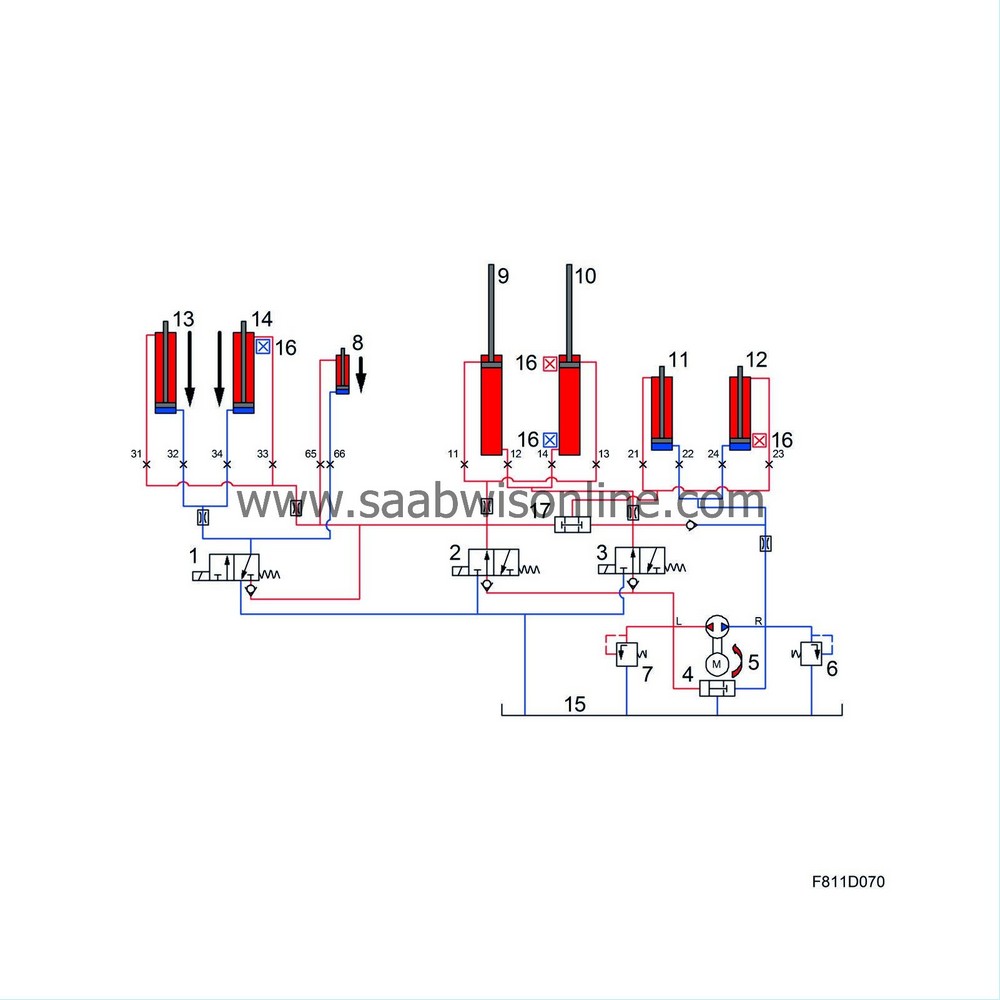

| Soft top sequences, closing the soft top, hydraulic functions |

The hydraulic system uses the following valve combinations to perform the soft top sequences:

| Opening sequence: | Pump rotation direction | solenoid valve 1 | solenoid valve 2 | solenoid valve 3 |

| Unlocking and opening the sixth bow | Pump left | 2 | 3 | |

| Unlocking the first bow and opening the soft top cover | Pump left | 1 | 2 | 3 |

| Sixth bow, intermediate position | Pump right | 1 | 3 | |

| Lowering the soft top | Pump left | 1 | 2 | |

| Locking the soft top cover | Pump left | 2 |

| Closing sequence: | Pump rotation direction | solenoid valve 1 | solenoid valve 2 | solenoid valve 3 |

| Opening the soft top cover | Pump left | 1 | 2 | |

| Raising the soft top | Pump left | 1 | 3 | |

| Opening the sixth bow | Pump left | 1 | 2 | 3 |

| Locking bow one and closing the soft top cover | Pump left | 2 | 3 | |

| Closing the sixth bow | Pump right | 3 |

| Electro-hydraulic system |

The position the soft top is in is detected by sensors integrated in the hydraulic system, soft top mechanism and windscreen frame. Information from each sensor is received by the STC. The soft top is controlled sequentially, which means that each soft top movement must be completed before the next one can start.

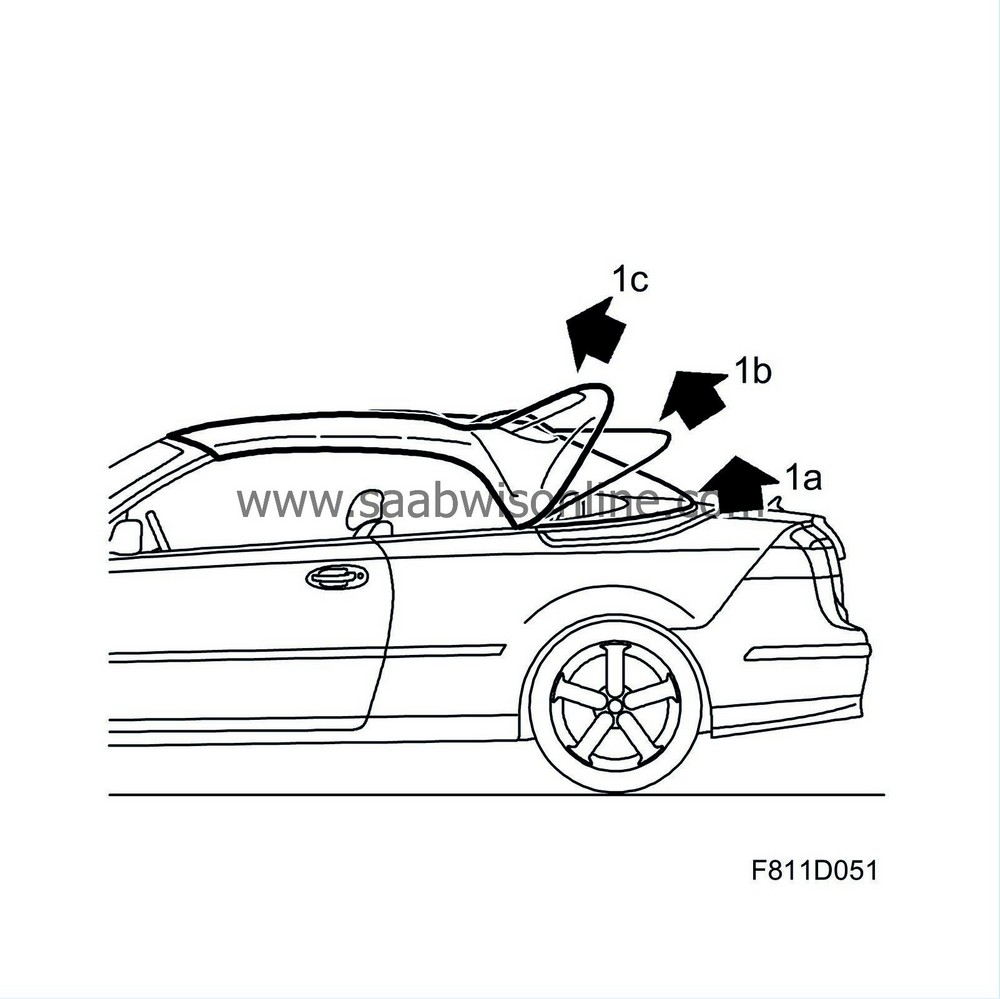

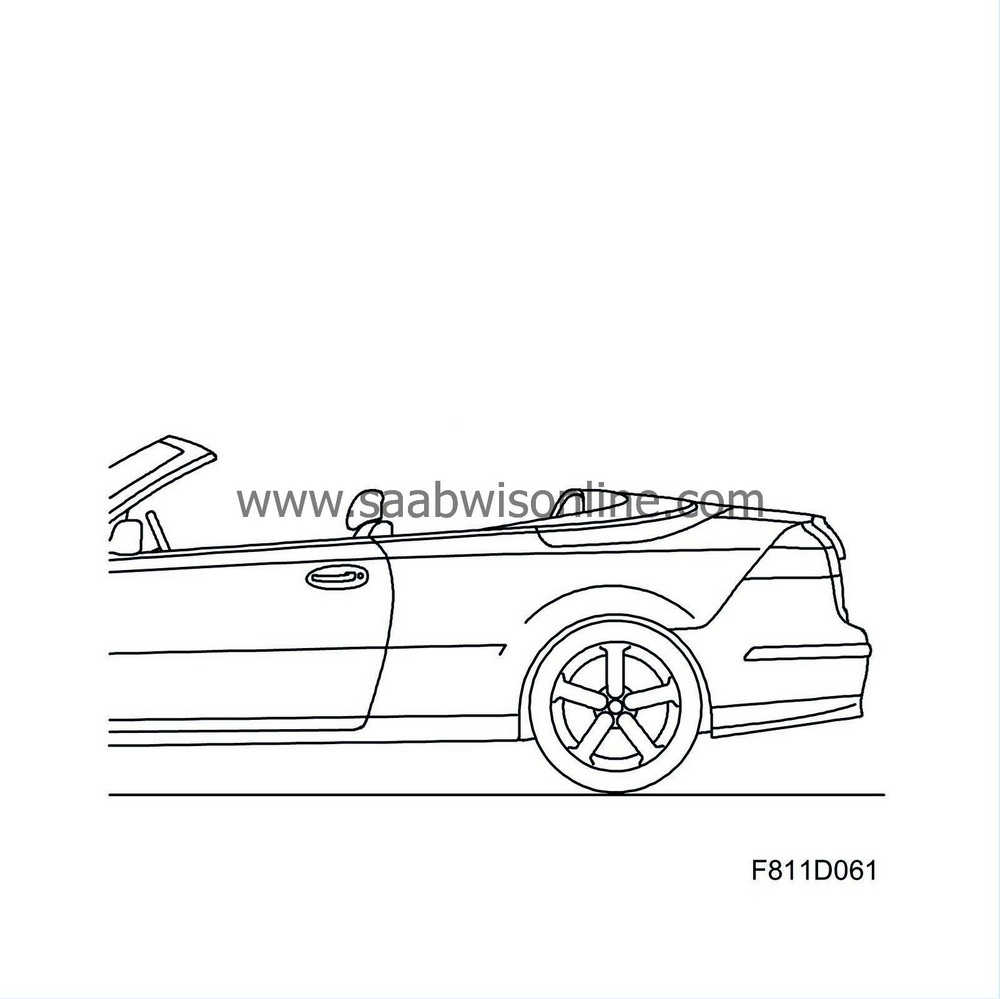

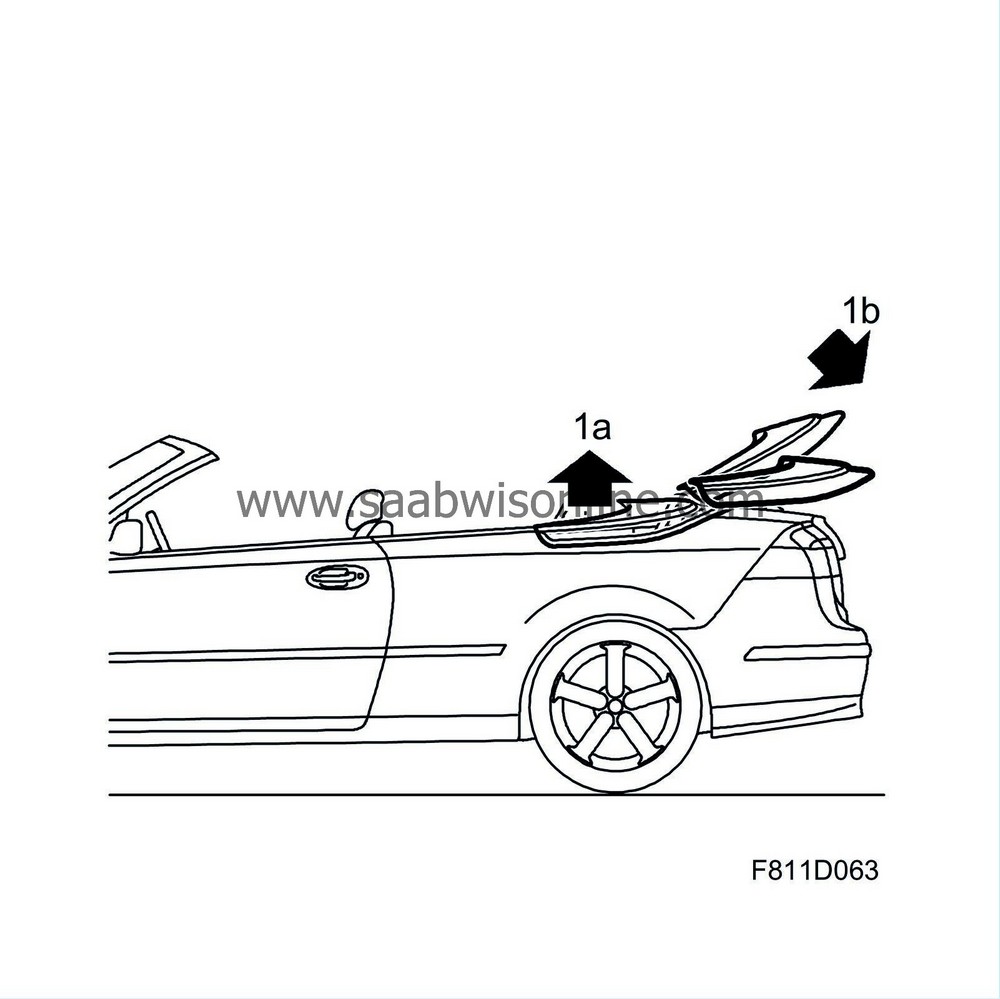

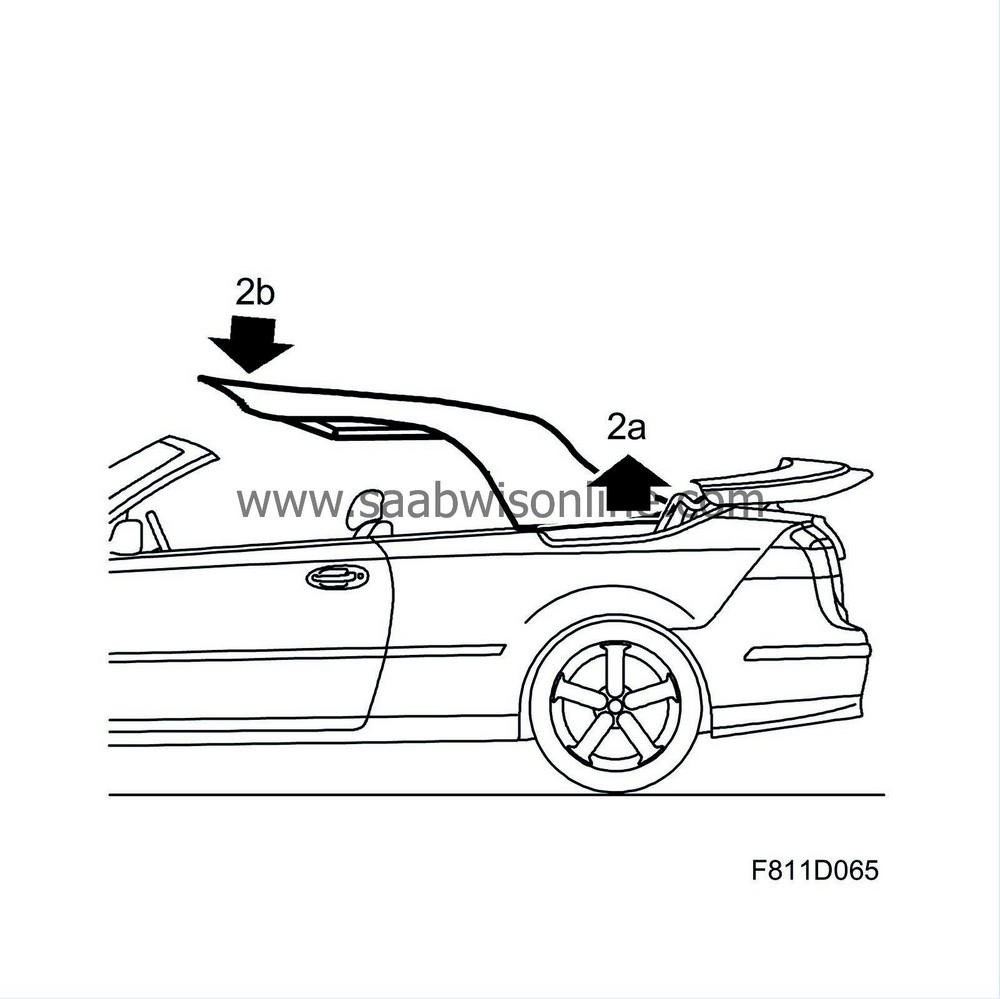

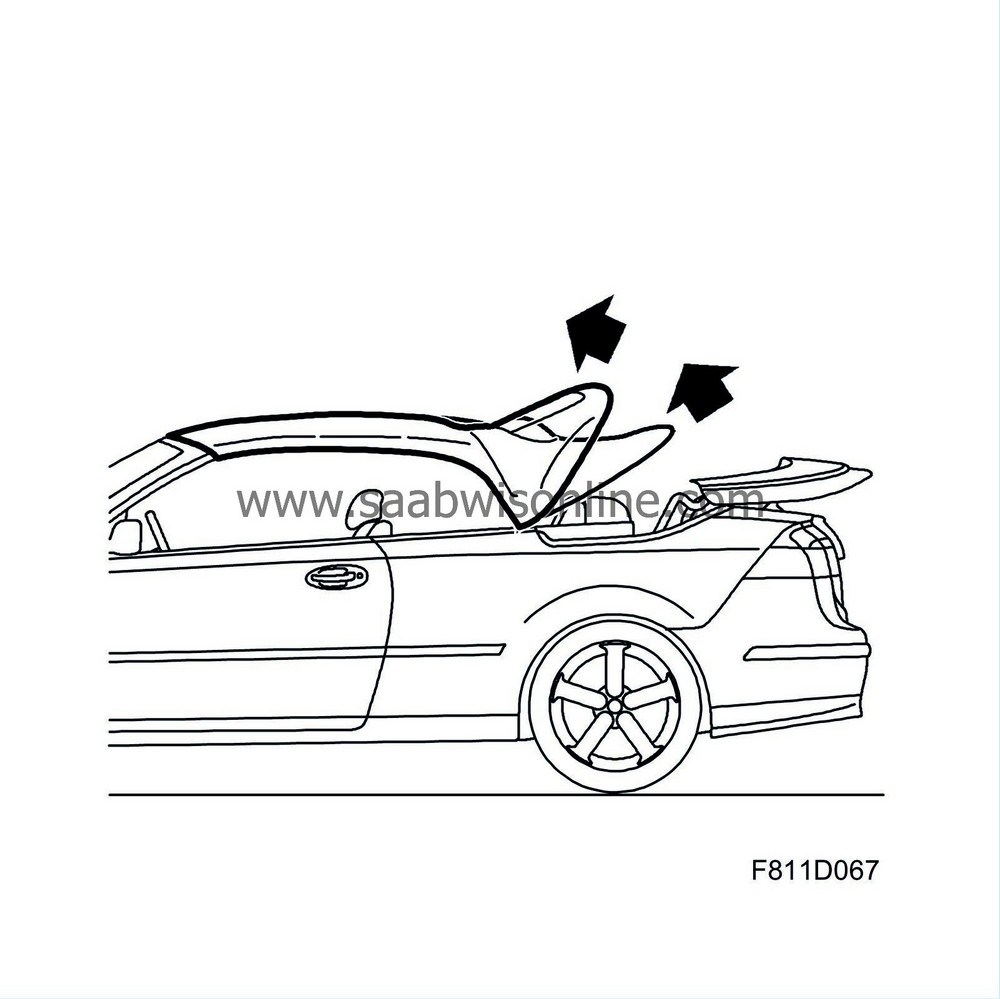

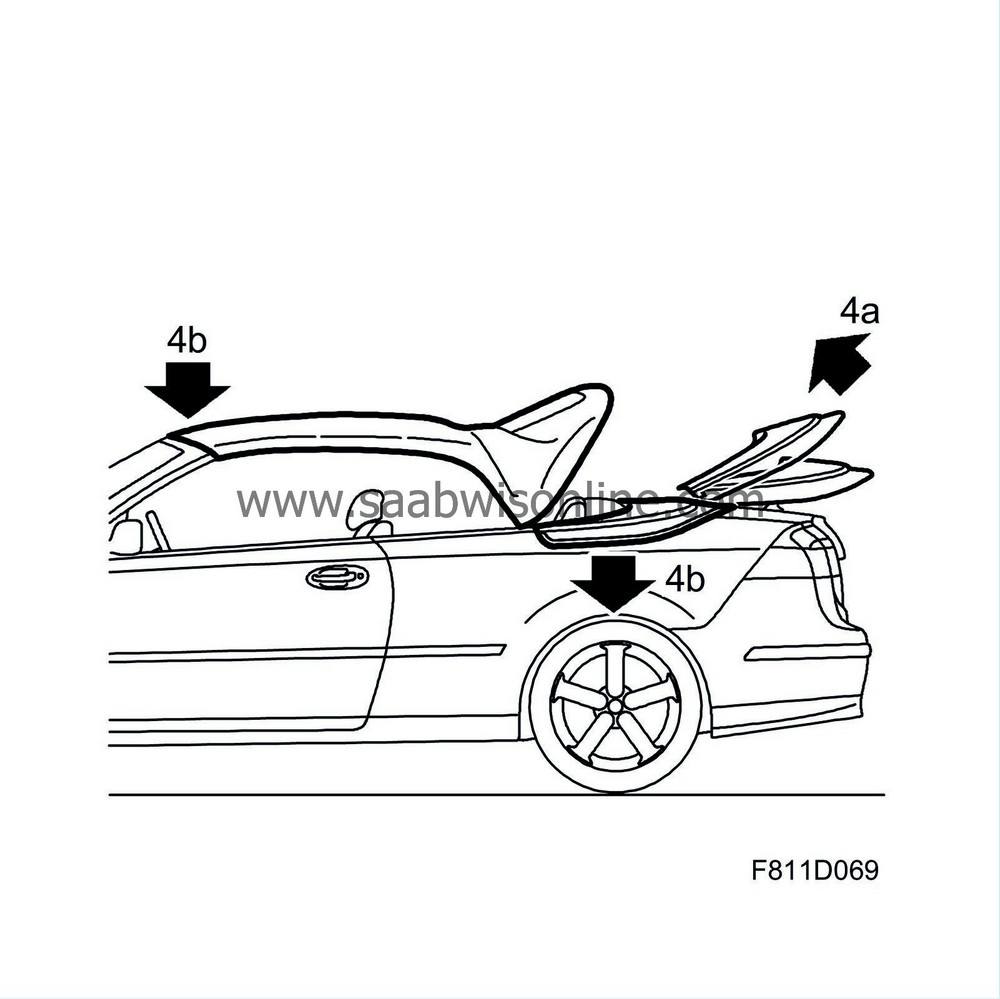

The soft top opens in the following steps:

| • |

Sixth bow opens

|

|

| • |

The first bow is unlocked and the soft top cover opens

|

|

| • |

Sixth bow lowered

|

|

| • |

Soft top lowered

|

|

| • |

Soft top cover latches

|

|

Soft top closes in reverse order.

STC, which controls the pump and the valves, must receive confirmation of the different movements from sensors and switches within a certain time period. When one such condition is not fulfilled, all movement will cease and STC will generate an error message sent via the bus and shown on SID (Saab Information Display), e.g. "CHECK SOFT TOP".

STC also used bus messages from other control modules. If the information does not correspond to default values, STC will no allow the soft top to be operated. STC then sends an error message on the bus that is shown on SID (Saab Information Display), e.g. "Battery voltage too low".

The automatic soft top operation is carried out sequentially and is described in the following tables. The movements will be carried out after pressing the soft top button. Soft top movement is controlled by the STC control module (Soft Top Controller).

| Conditions for soft top operation |

| • |

Ignition key ON

When the ignition is ON, the soft top can be operated using the switch. If the ignition switch is turned to ST while the soft top is being operated, the soft top movement will be stopped and must be reactivated. |

|

| • |

Vehicle speed below 30 km/h

The control module receives messages on the speed of the car via the I-bus. It is only possible to operate the soft top when the speed of the car is lower than 30 km/h. Otherwise the movement is stopped. The speed limiter is programmable with the diagnostic tool between 0 and 30 km/h. |

|

| • |

Soft top storage lowered (applies only to opening the soft top)

The control module receives information on the soft top storage position from the position sensor. If the soft top storage is folded when an attempt is made to open the soft top, the soft top operation will be stopped and the message "CHECK SOFT TOP STORAGE" shown on SID. |

|

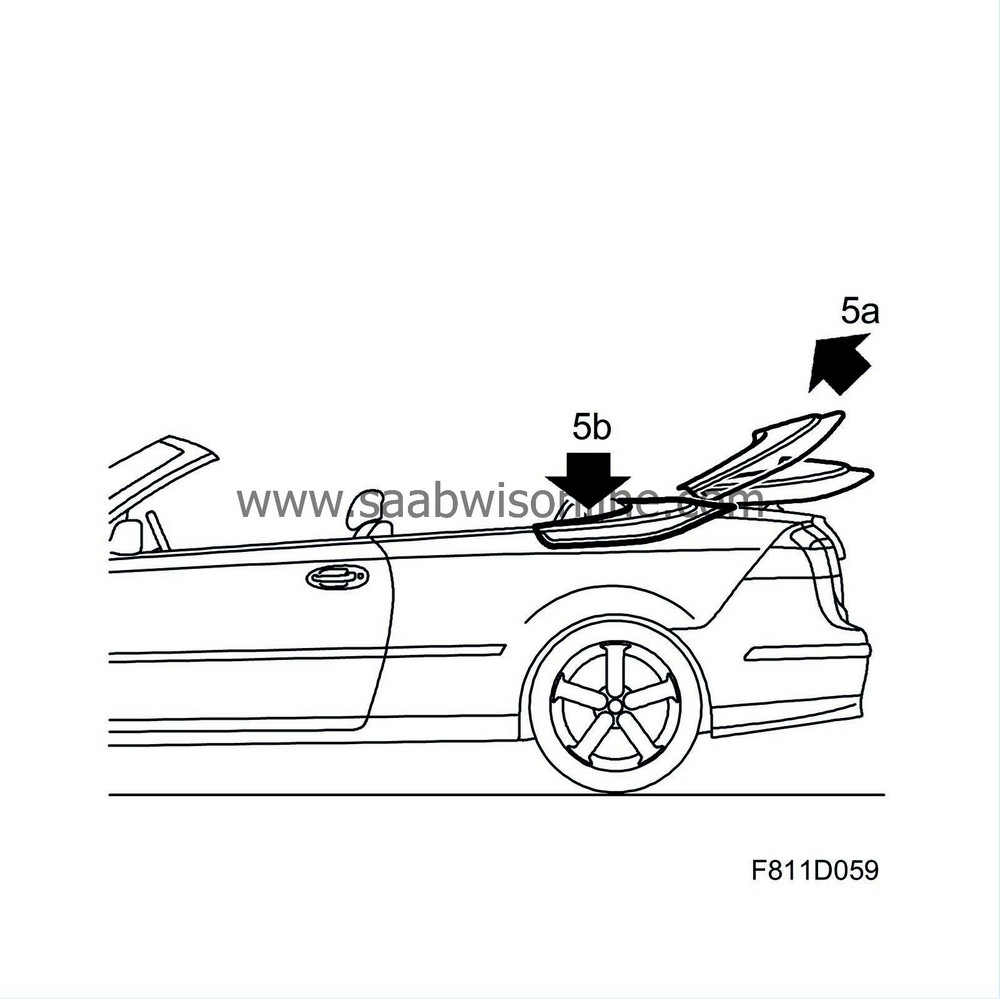

| • |

Boot lid closed

The control module receives information that the boot lid is closed via the I-bus. If the boot lid is open and an attempt is made to operate the soft top, its operation will be stopped and the message "CLOSE TRUNK LID" shown on SID. The boot lid must be closed or it will collide with the soft top cover when it is opened. |

|

| • |

Power supply to control module between 9-16V

The power supply to the control module must be between 9-16V for the control module to be able to operate the soft top or the windows. |

|

| • |

Temperature, pump motor

The soft top pump motor must not be overheated. The STC system is capable of operating the soft top in 3 minutes which is equivalent to six to seven opening and closing sequences respectively in succession. The cooling off period is twice as long as the total operating time. The soft top can always be closed irrespective of the pump motor temperature. |

|

| • |

Temperature above -5°C

The soft top can be damaged if it is operated in under -5°C. The soft top is locked with the first press of the button and the following SID message is displayed: "Soft top can be damaged when operated in temperatures below zero". If the button is pressed again within 50 seconds the soft top can be operated. The soft top can always be closed irrespective of the temperature. |

|

| • |

Roll bars must not be activated.

Sensors in the mechanism for the roll-over bars detect the position. |

|

| • |

All the control module inputs/outputs are valid

The system performs a self-test every time the ignition switch is turned to ON. |

|

| Soft top sequences, opening the soft top, sensor inputs |

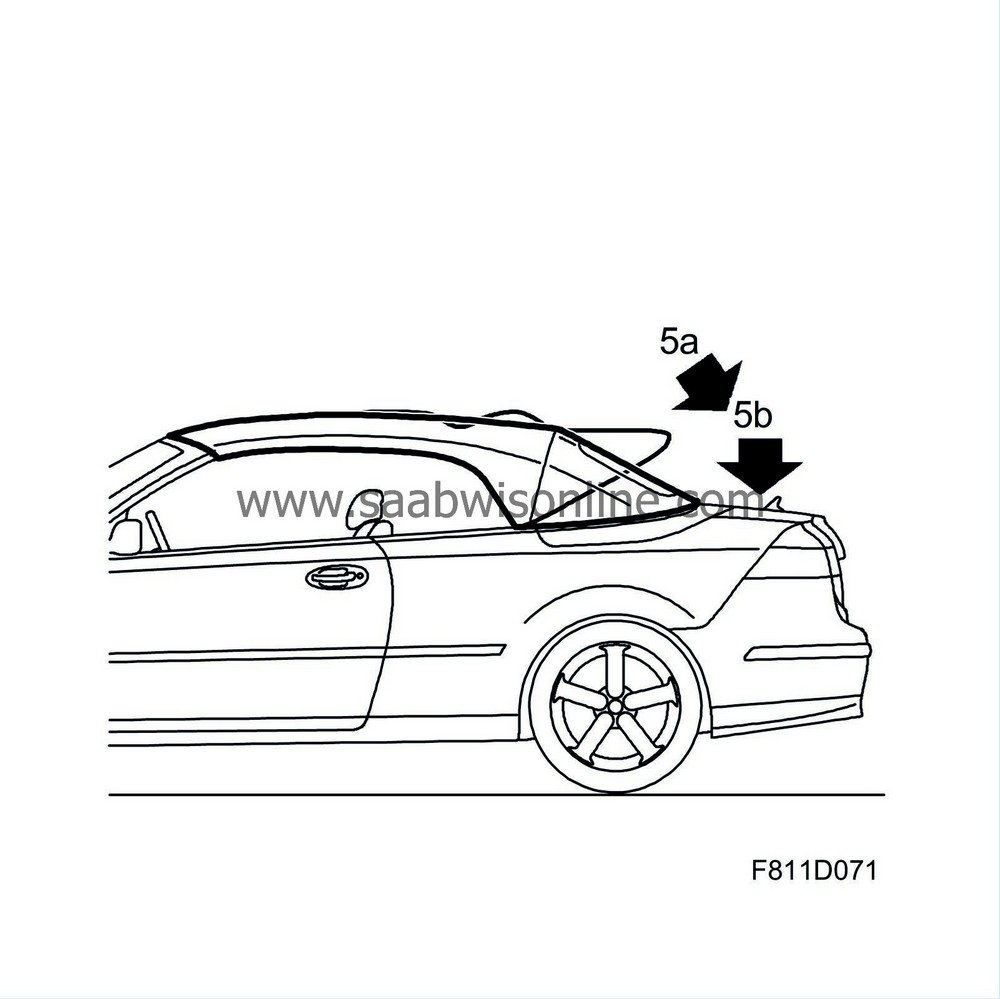

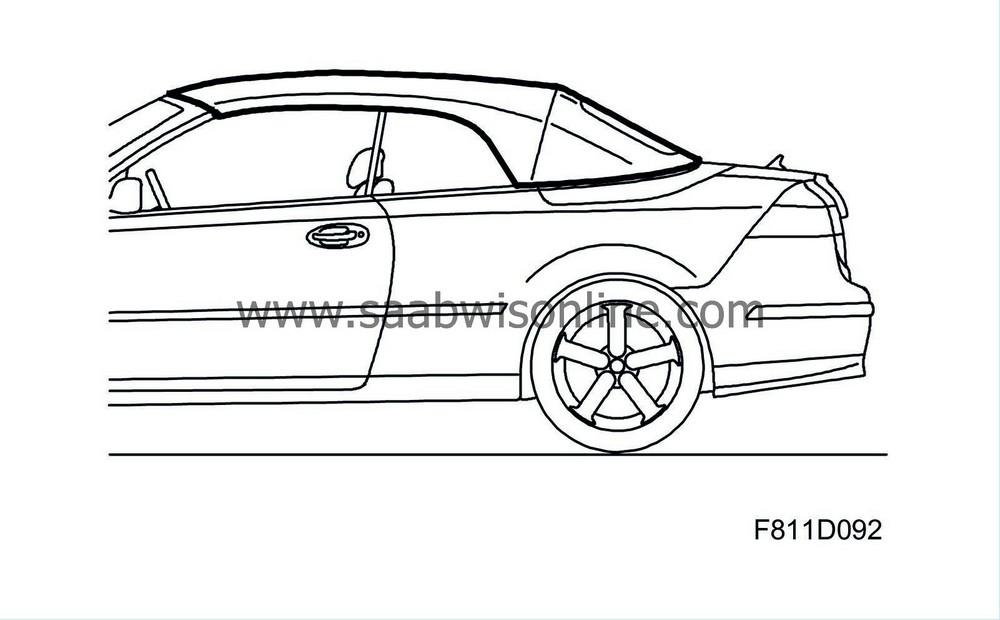

The illustrations and the hydraulic circuit diagram describe the movements of the soft top during raising and retracting. The tables describe the status of the position sensors with respect to each movement sequence. The outputs are marked in italics and the inputs are underlined in the table headings. For changes of status, the read values are marked in bold.

Supervision time. Each of the movements (soft top, bow and cover) has a maximum allowed time (supervision time). STC controls each of the movements so that none of them exceed their respective supervision times. If the time is exceeded, the hydraulic system will immediately switch to stop mode. Automatic operation can be restarted by releasing the button "Close soft top" or "Open soft top" and then pressing the relevant button again.

The diagnostic tool can be used to read the status of each position sensor.

Description of position sensor status:

| On | Active input |

| Off | Input inactive |

| On/Off | Input in transition mode |

| 2. |

Step 1, unlocking and opening of sixth bow.

When activating the soft top button, the control module performs the following:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| 3. |

Step 2, releasing first bow and opening soft top cover.

|

|||||||||||||||||||||||||||||||||||||

| 4. |

Step 3, sixth bow, intermediate position.

|

|||||||||||||||||||||||||

| 5. |

Step 4, lowering the soft top.

|

|||||||||||||||||||||||||

| 6. |

Step 5, locking the soft top cover.

|

|||||||||||||||||||||||||||||||||||||

| 7. |

Status of position sensors prior to activation when the soft top is open.

|

|||||||||||||||||||||||||

| Soft top sequences, closing the soft top, sensor inputs |

| 1. |

Status of position sensors prior to activation when the soft top is open.

|

|||||||||||||||||||||||||

| 2. |

Step 1, opening the soft top cover.

|

|||||||||||||||||||||||||||||||||||||

| 3. |

Step 2, raising the soft top.

|

|||||||||||||||||||||||||

| 4. |

Step 3, opening the sixth bow

|

|||||||||||||||||||||||||

| 5. |

Step 4, locking the first bow and closing the soft top cover.

|

|||||||||||||||||||||||||||||||||||||

| 6. |

Step 5, closing the sixth bow

|

|||||||||||||||||||||||||||||||||||||

| 7. |

Status of position sensors when soft top is closed.

|

|||||||||||||||||||||||||

| Window operation, opening the soft top. |

| 1. |

When the button for soft top operation is pressed, STC opens the soft top provided the conditions for soft top operation are approved.

|

|

| 2. |

When the soft top is down and the cover is closed. The bus message "soft top status" is changed from ”lower sequence” to "open". MIU indicates such with an audible signal.

|

|

| 3. |

If the button for soft top operation is held in STC will send the bus messages "Request to move front windows", "Automatic opening" and "Request to move rear windows", "Automatic opening". The windows are operated by each respective door module to their lowest positions.

There is no difference between cars with pinch protection and those without. |

|

| Window operation, closing the soft top, |

| 1. |

Pressing the soft top button will send a ”Soft top operation close” bus message from ICM.

|

|

| 2. |

STC closes the soft top if the conditions for operating the soft top are fulfilled.

|

|

| 3. |

When the soft top is fully closed, STC transmits the bus message "Closed". MIU will indicate such with an audible signal.

|

|

| 4. |

If the button for soft top operation is held in STC will send the bus messages "Request to move front windows", "closing" and "Request to move rear windows", "closing".

|

|

| SID, text messages |

The following messages are included in the soft top system and can be shown on SID together with an acoustic signal.

| SID, text message | Cause | Suitable action | ||||||

| The front of the soft top is unlocked. Try again. | The automatic locking of the soft top to the windscreen frame was unsuccessful. |

|

||||||

| Soft top motor overheated. Wait for it to cool down. | The soft top has been operated too intensively in a short period. | Wait for the soft top motor to cool down. | ||||||

| Remove the luggage carrier in order to operate the soft top. | Luggage carrier fitted | Remove the luggage carrier. | ||||||

| Open the boot lid. Move any luggage out of the way of the soft top. | The soft top storage is not in its lowest position. | Move whatever is obstructing the soft top storage. | ||||||

| The soft top can be damaged if operated in freezing conditions. | Sent if soft top is lowered when temperature is below -5°C | |||||||

| Only manual operation is possible. Get in touch with your garage. | Diagnosis has discovered a fault. | Read DTCs/carry out fault diagnosis. | ||||||

| Soft top cover is unlocked. Try again. | Soft top cover latch has not locked. | Try again and perform fault diagnosis if necessary. | ||||||

| Poorly charged battery. | The car battery voltage is too low to operate the soft top. | Charge the battery. | ||||||

| Release and lower the roll-over protection. Get in touch with your garage. | One or both roll-over bars is up. | Push down the roll-over bars and try again. | ||||||

| Probable soft top collision. Remove the obstruction and try again. | Something is obstructing the soft top. | Remove the obstruction. | ||||||

| Raise/lower the soft top completely in order to open the boot lid. | The boot lid is open. | Stop operating the soft top. | ||||||

| Raise/lower the soft top completely before driving off. | The car is driven off before the soft top is closed. | Slow down to < 10 km/h and stop operating the soft top. | ||||||

| Close the tailgate. | The boot lid is open. | Close the boot lid. | ||||||

| The driver's seat is not locked. | The seat backrest is not locked. | Fold back the backrest completely to locked position. | ||||||

| The front passenger seat is not locked. | The seat backrest is not locked. | Fold back the backrest completely to locked position. | ||||||