Turbocharger, 4WD

| Turbocharger, 4WD |

| To remove |

|

|||||||

|

|||||||||||||

| 1. |

Remove the battery cover and the engine cover.

|

|

| 2. |

Take the cap (A) off the expansion tank to release any pressure.

|

|

| 3. |

Remove the battery cable.

|

|

| 4. |

Raise the car.

|

|

| 5. |

Undo the right-hand side of the spoiler shield.

|

|

| 6. |

Place a suitable receptacle under the radiator. Connect a hose (A) to the radiator (B) and drain the coolant. Close the cock and refit the spoiler shield.

|

|

| 7. |

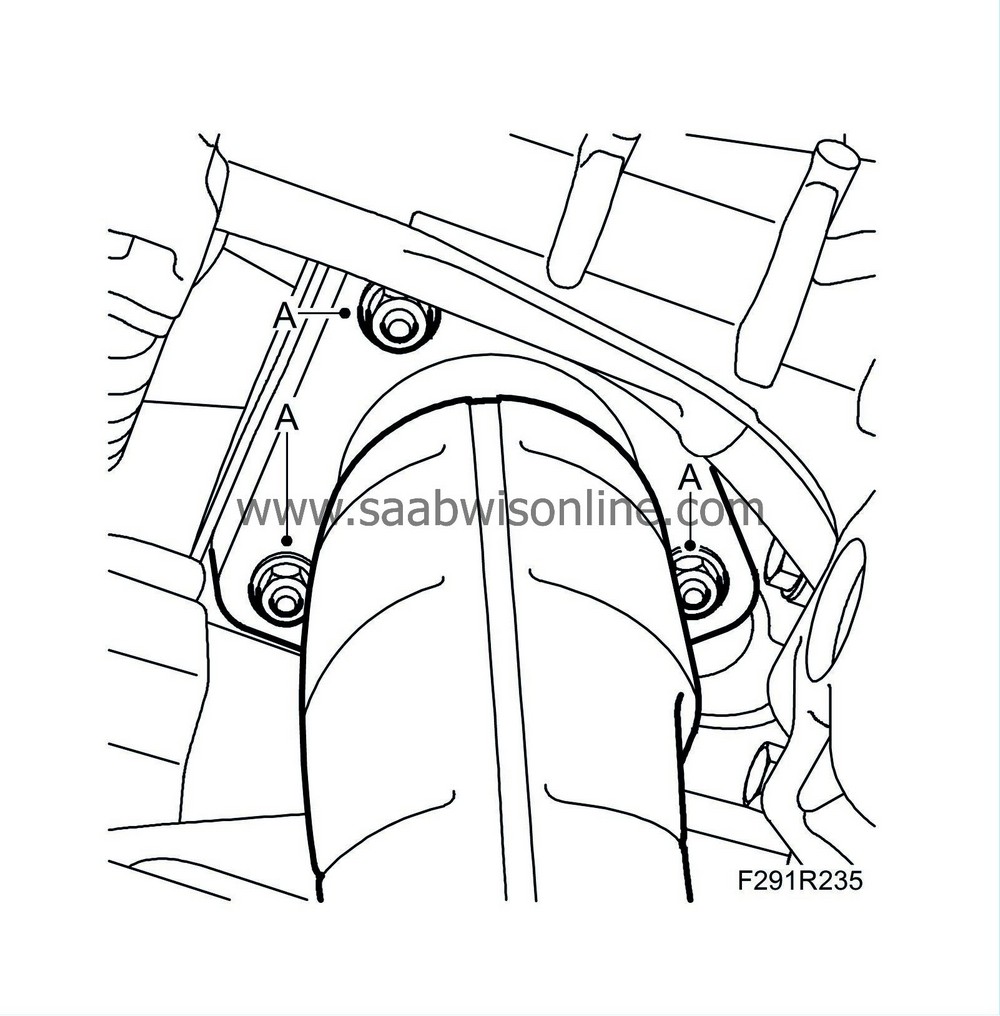

Remove the front nuts (A) of the rear catalytic converter and move aside. Fix in position with

83 95 212 Strap

.

|

|

| 8. |

RHD:

Remove

Alternator, B284, 4WD, (RHD)

.

|

|

| 9. |

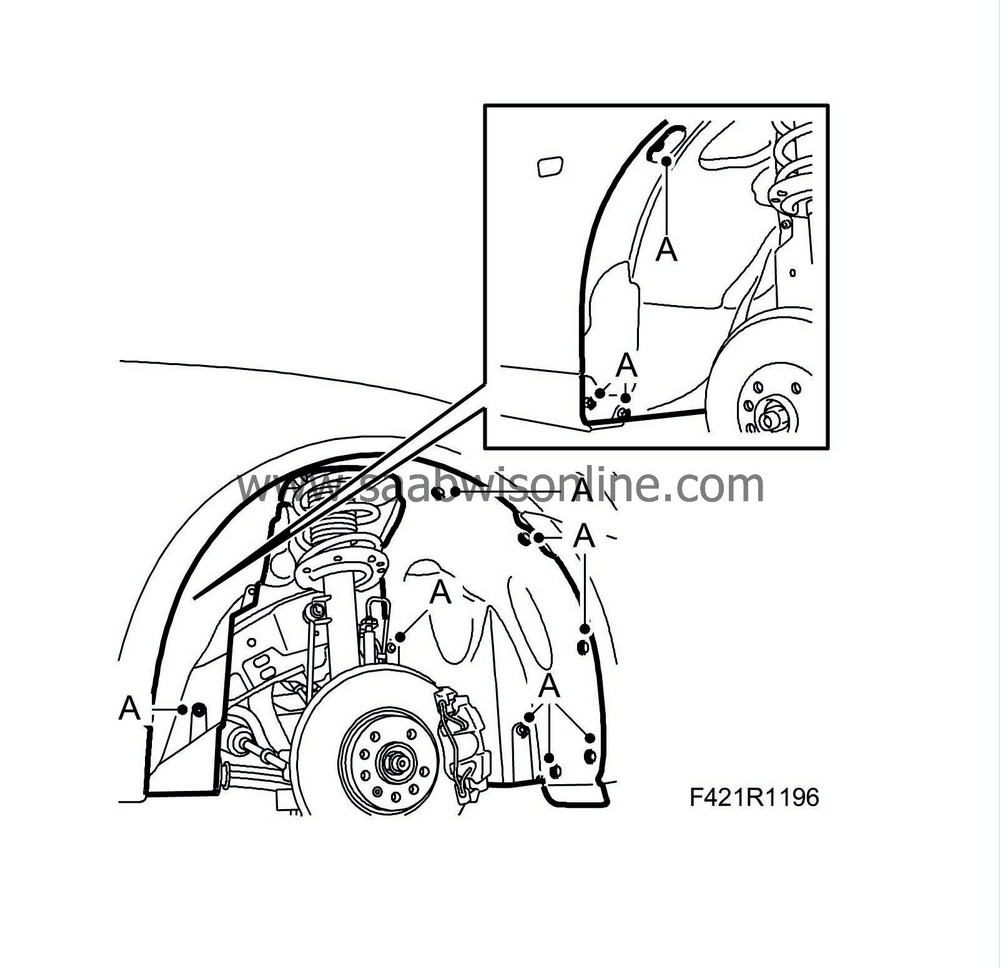

LHD:

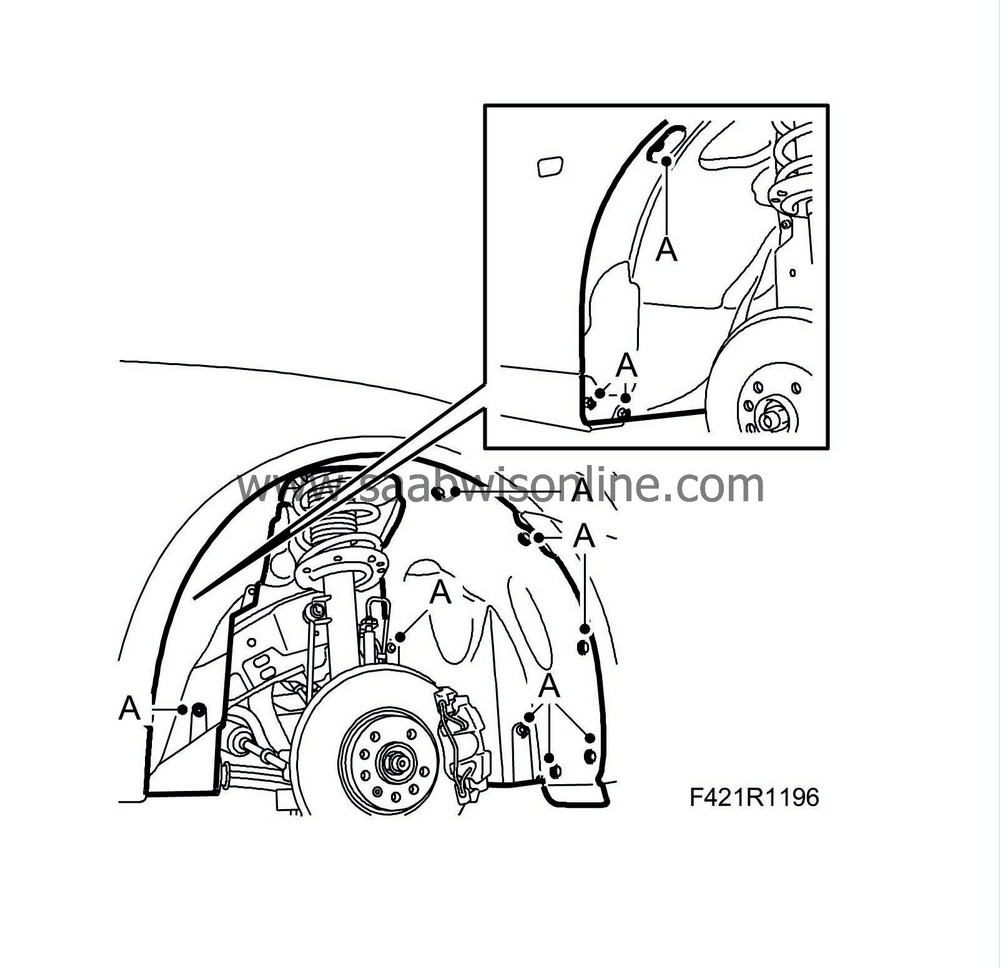

Remove the right wing liner (A).

|

|

| 10. |

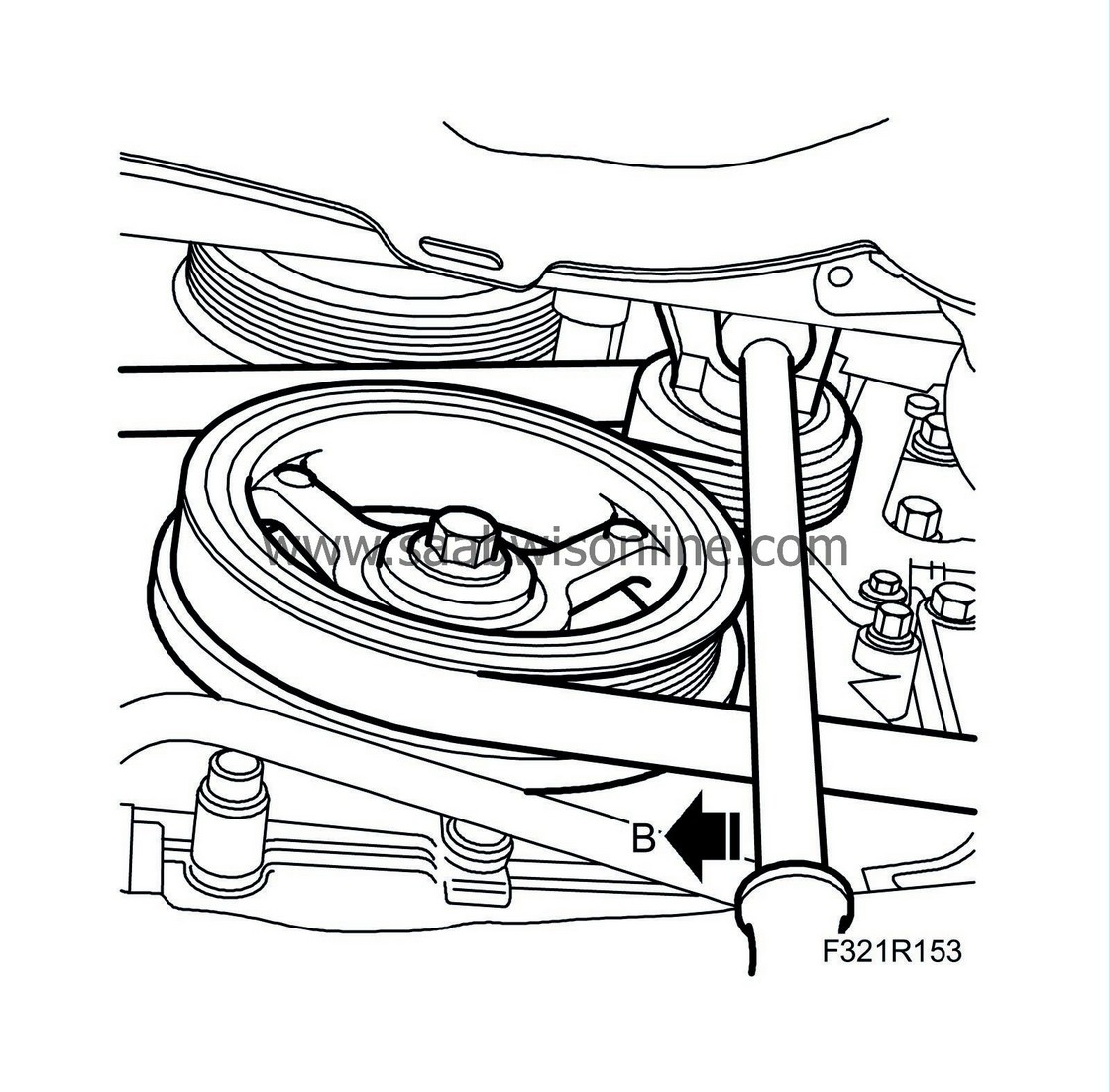

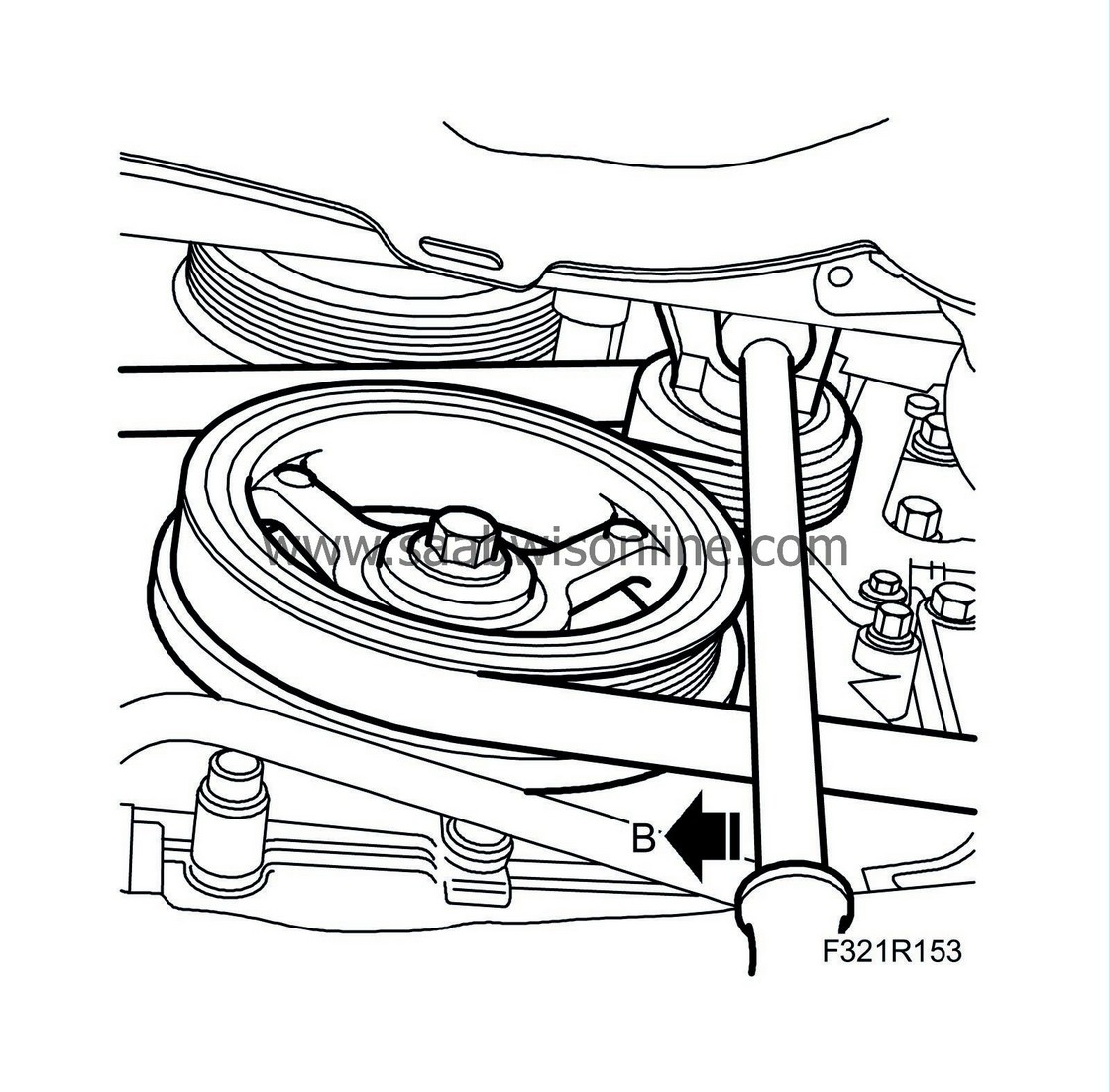

LHD:

Relieve the load on the belt tensioner and unhook the belt. Use a ½" puller (B).

|

|

| 11. |

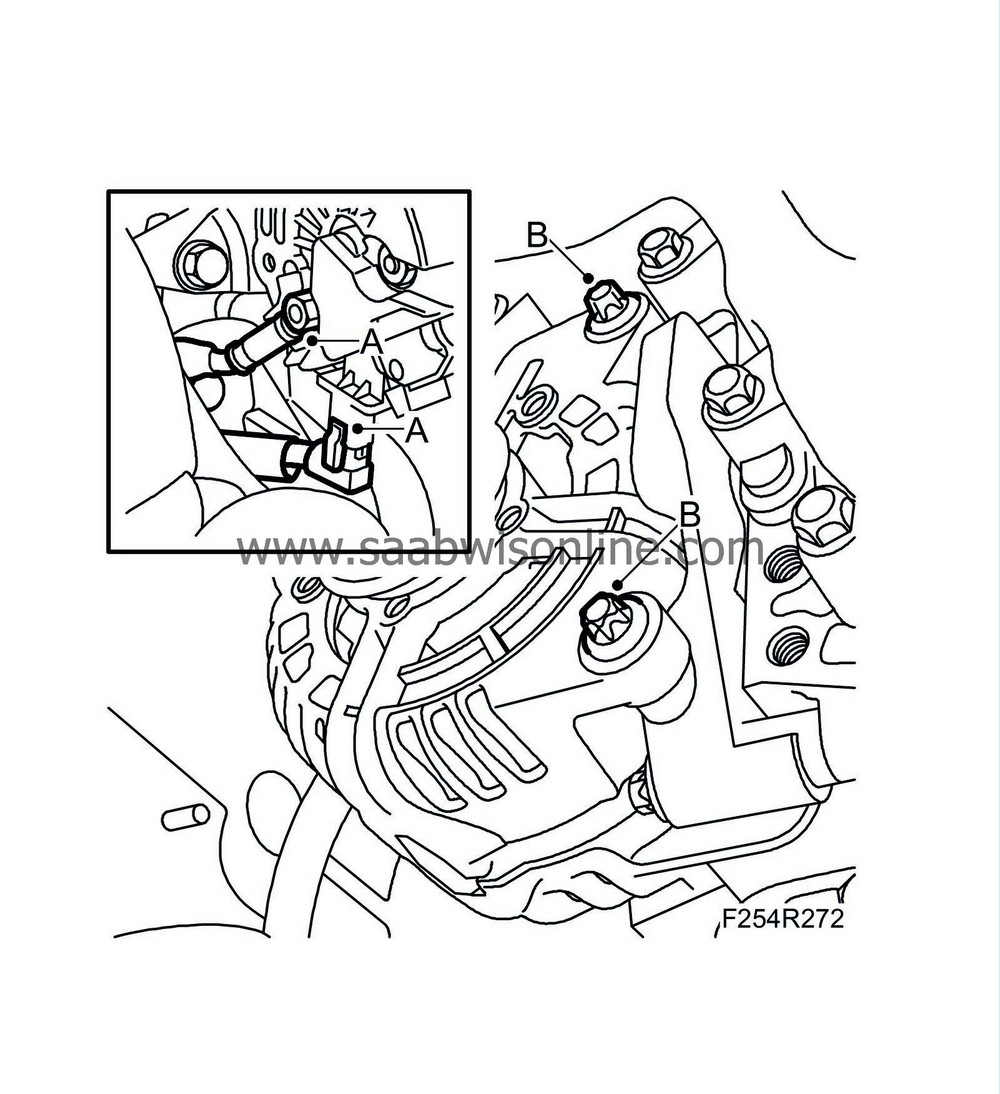

LHD:

Disconnect the electrical connections (A) of the alternator.

|

|

| 12. |

LHD:

Remove the alternator retaining bolts (B). Move the engine to the left slightly if necessary. Move the alternator rearward.

|

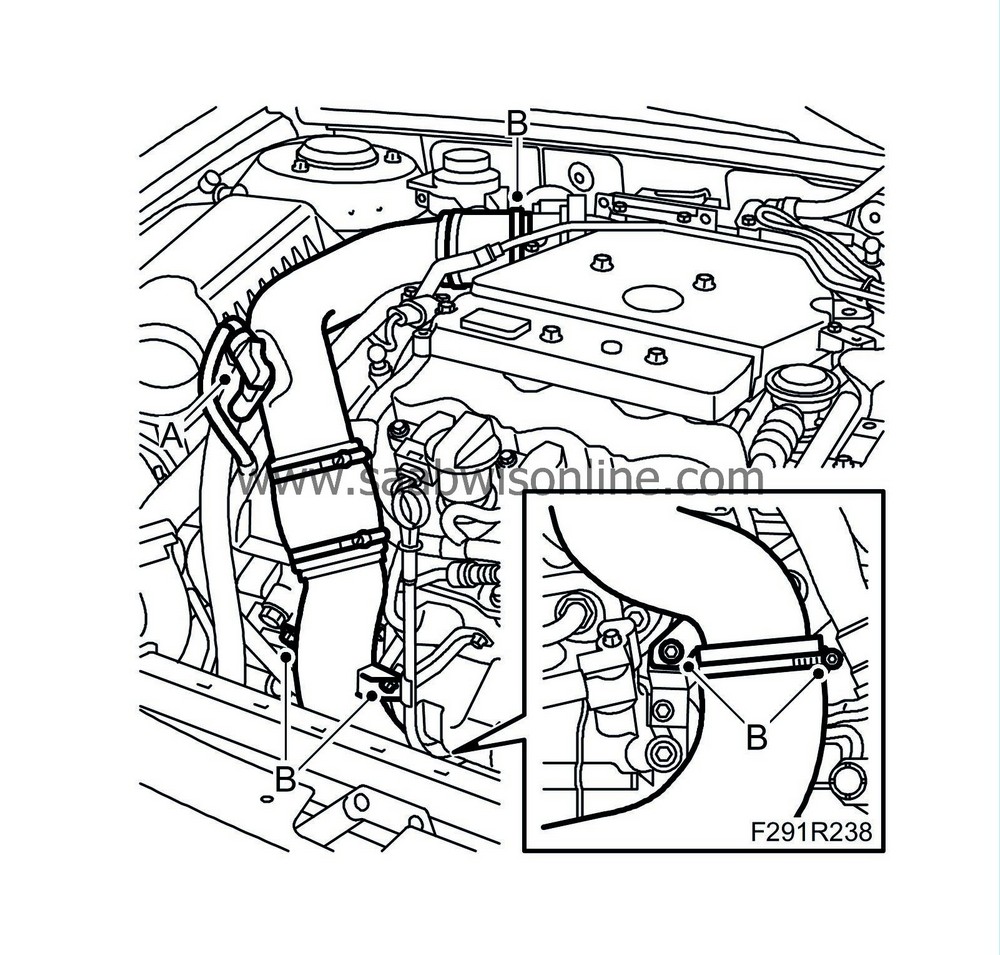

|

| 13. |

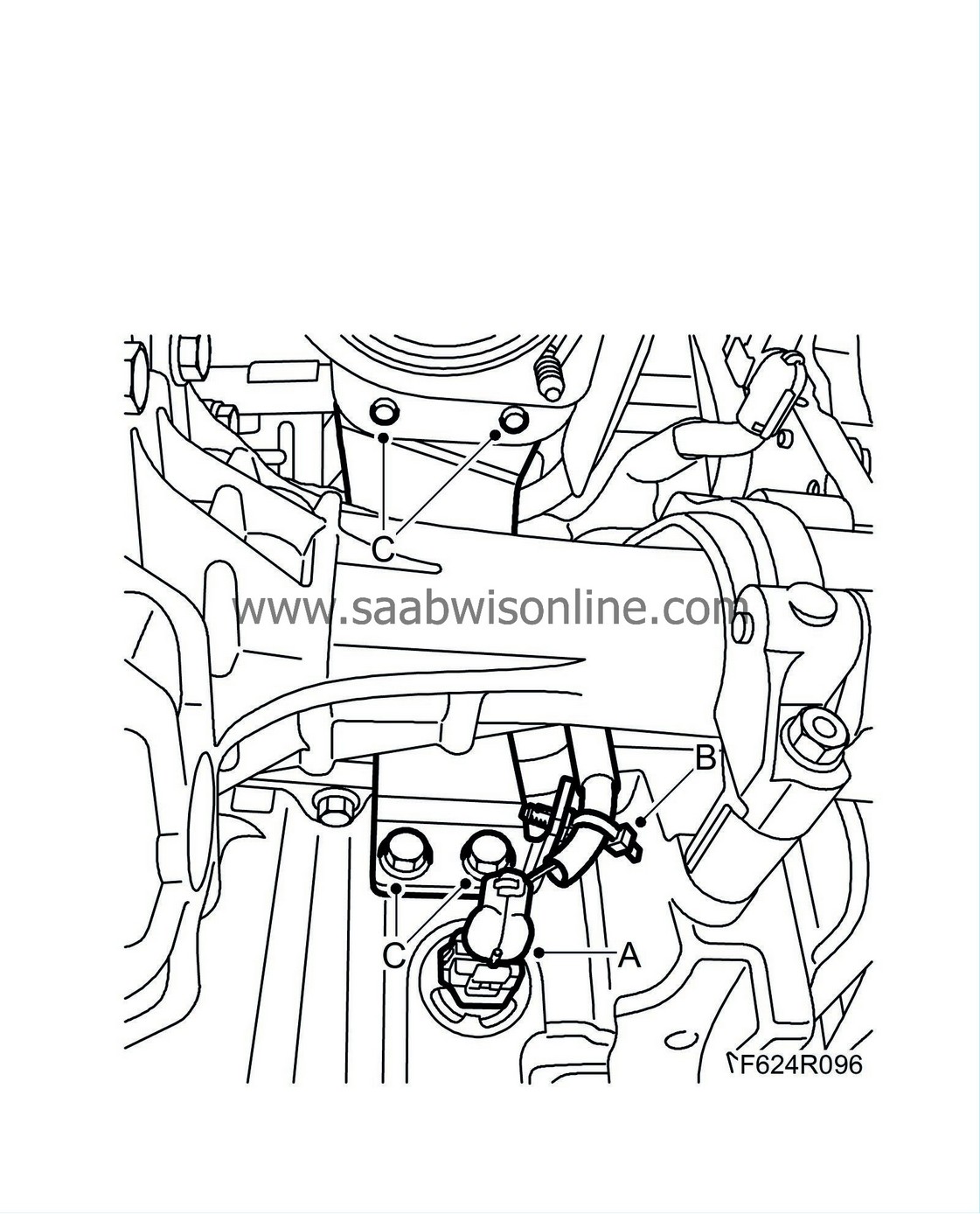

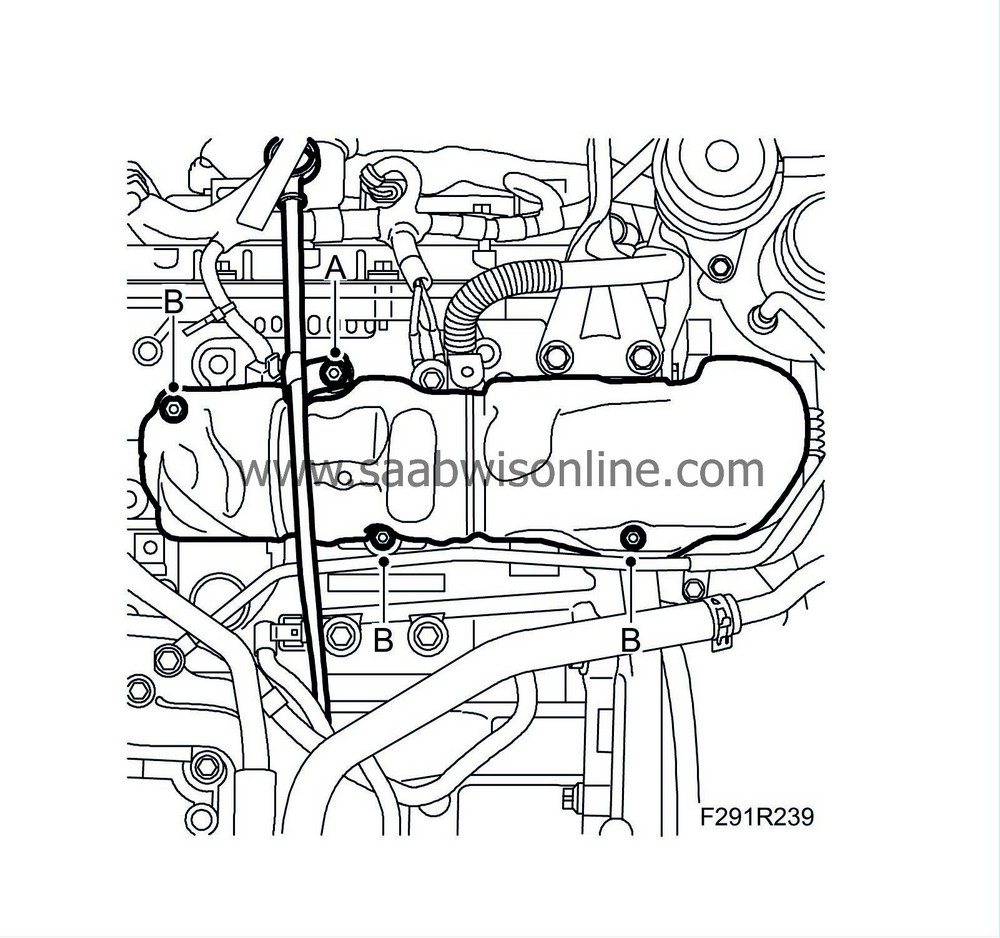

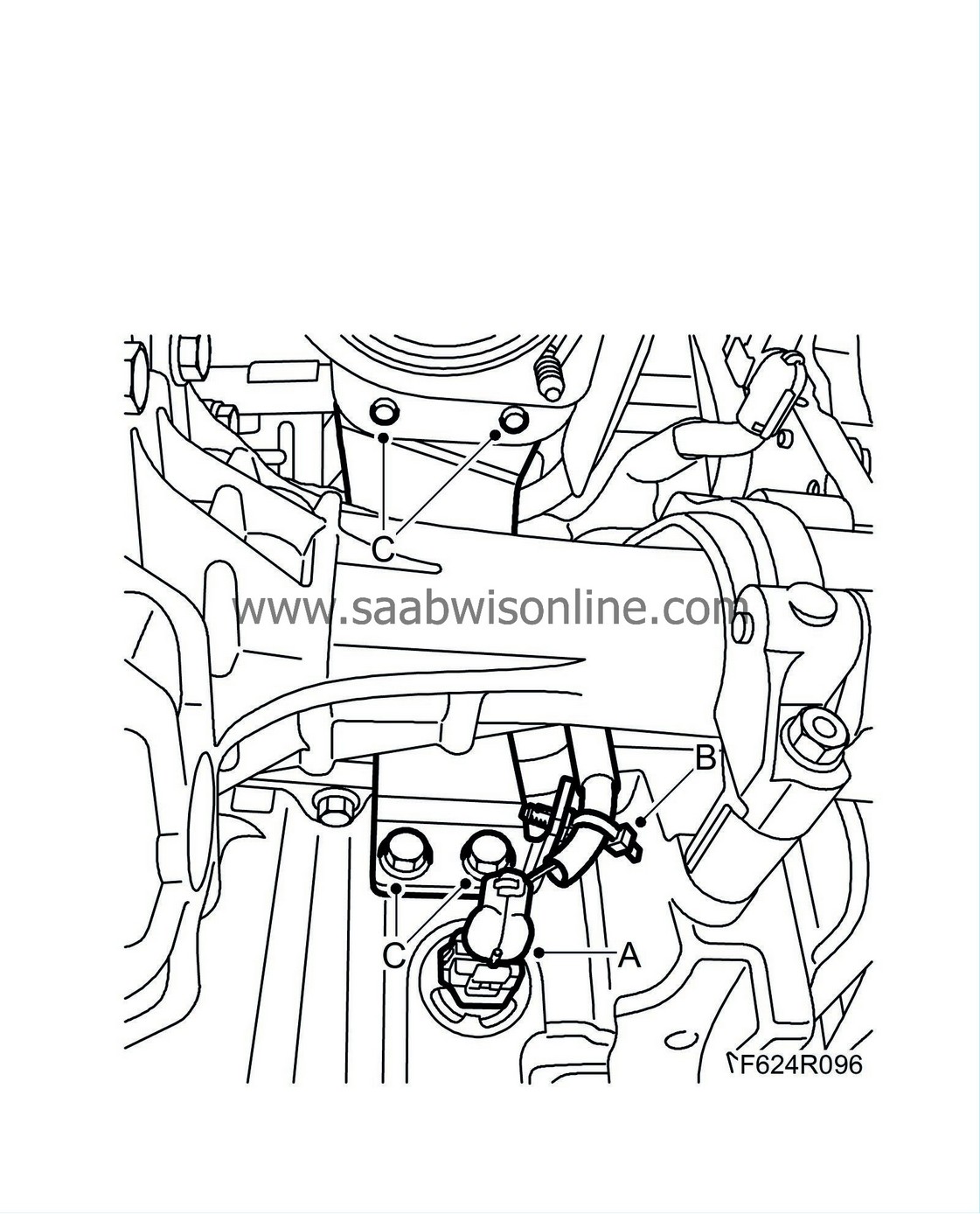

Unplug the oil level sensor connector (A) and remove the cable fixing (B).

|

|

| 14. |

Remove the bracket (C) from the front catalytic converter and oil sump.

|

|

| 15. |

Lower the car.

|

|

| 16. |

Remove the

Fan cowling

.

|

|

| 17. |

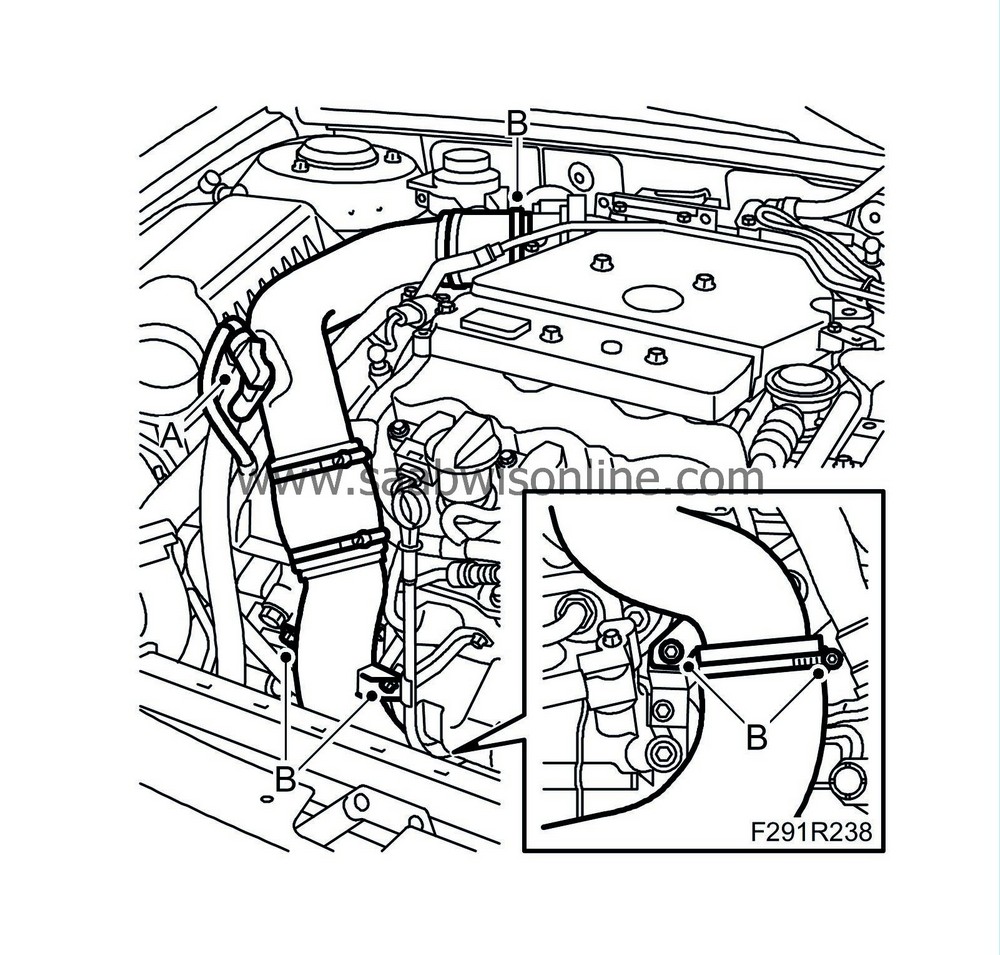

Detach the hoses (A) from the expansion tank.

|

|

| 18. |

Move up the tank, unplug the level sensor connector (B) and remove the quick coupling of the coolant hose (C). Lift away the coolant reservoir.

|

|

| 19. |

Remove the upper heat shield from the turbocharger (A) and catalytic converter (B).

|

|

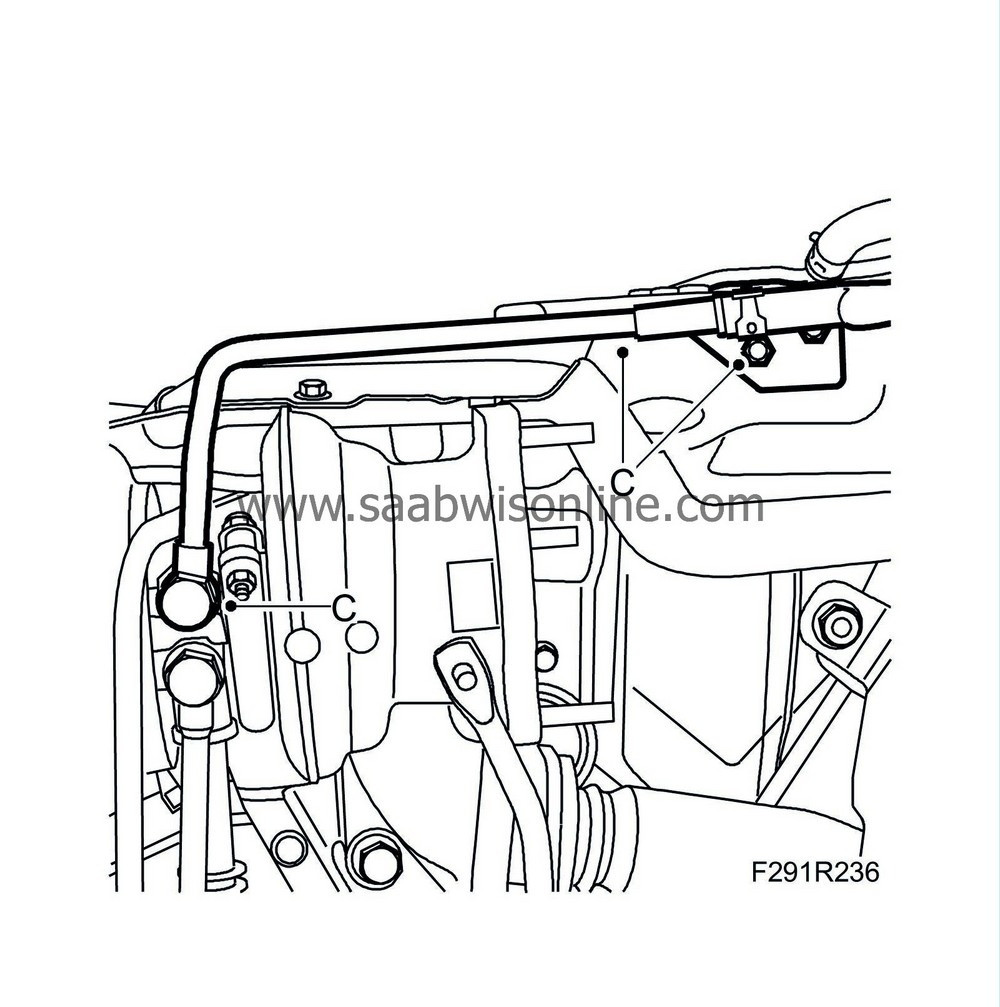

| 20. |

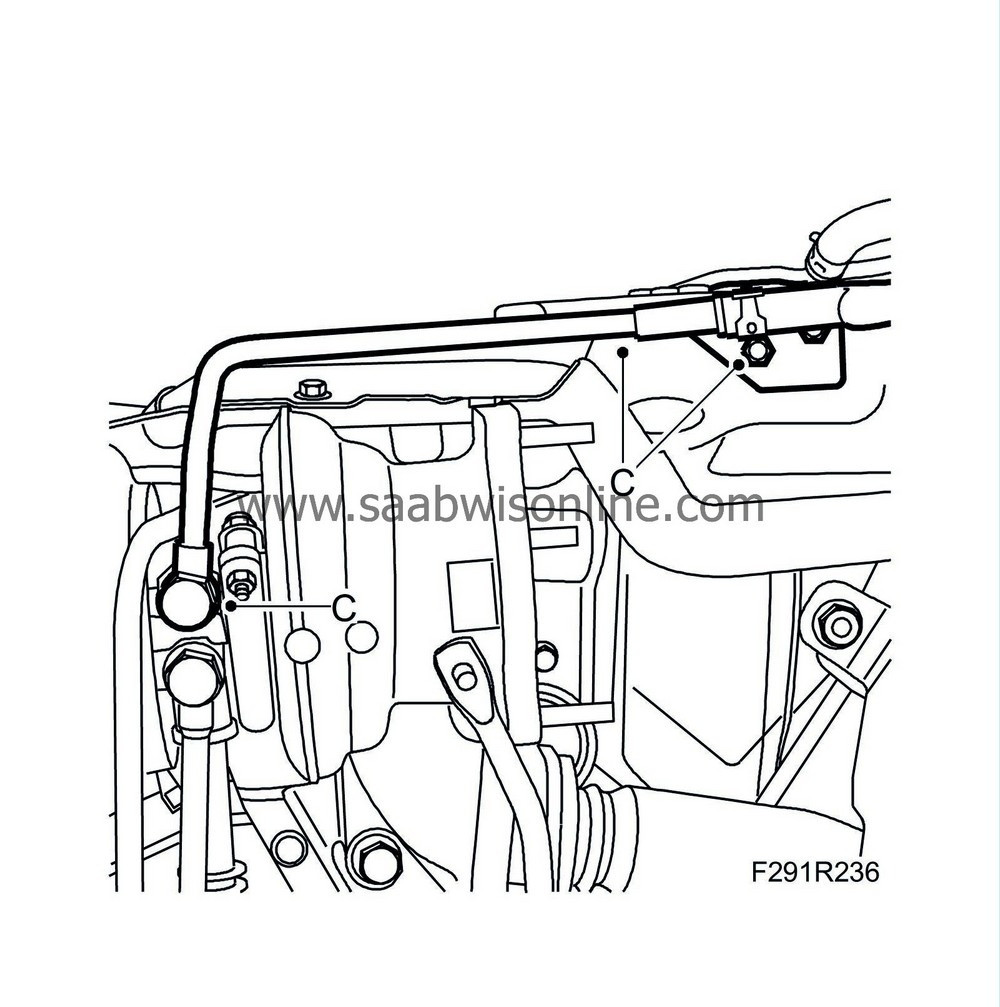

Remove the turbocharger coolant return pipe (C).

|

|

| 21. |

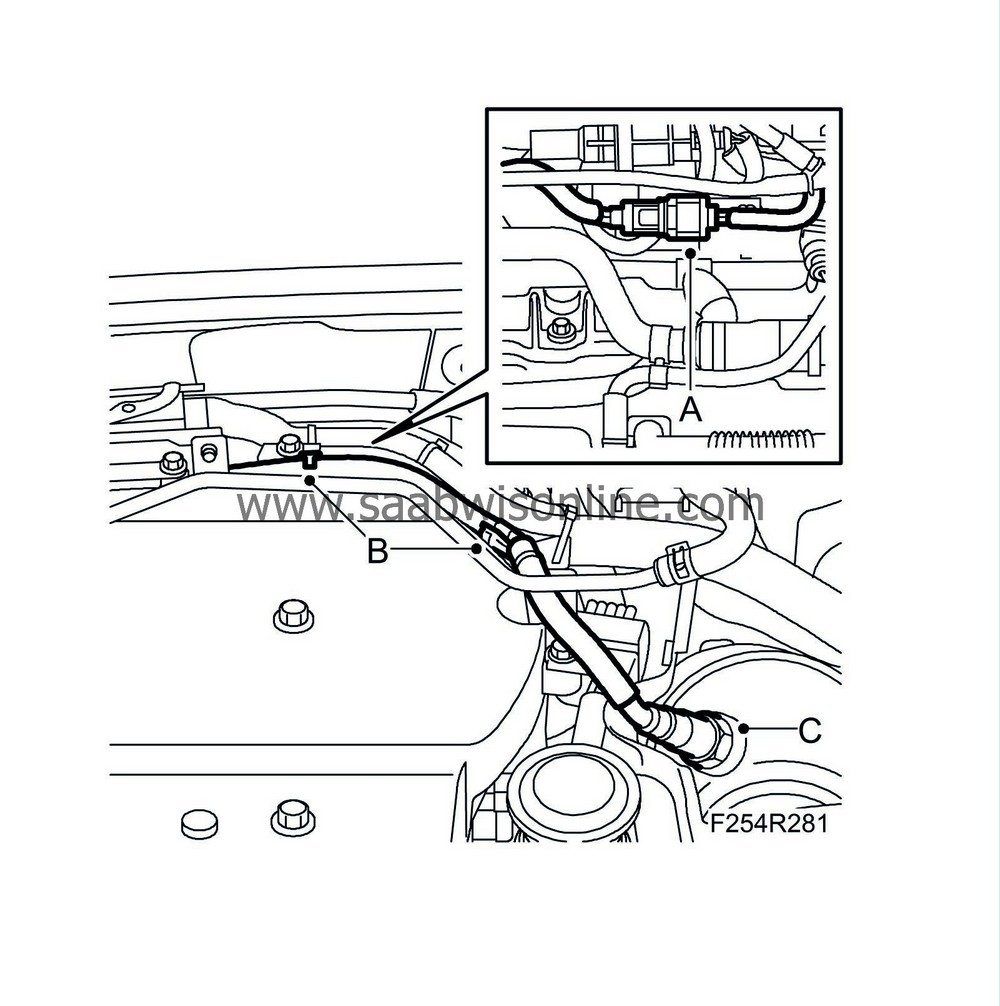

Unplug the connector of the upper oxygen sensor (A) and move up the cable (B).

|

|

| 22. |

Carefully raise the heat shield slightly. Use

83 96 350 Removal socket, oxygen sensor

when removing the oxygen sensor (C).

|

|

| 23. |

Remove the nuts (A). Lubricate the studs and nuts with rust removal oil.

|

|

| 24. |

Remove the catalytic converter from the bracket (B) and move it aside.

|

|||||||

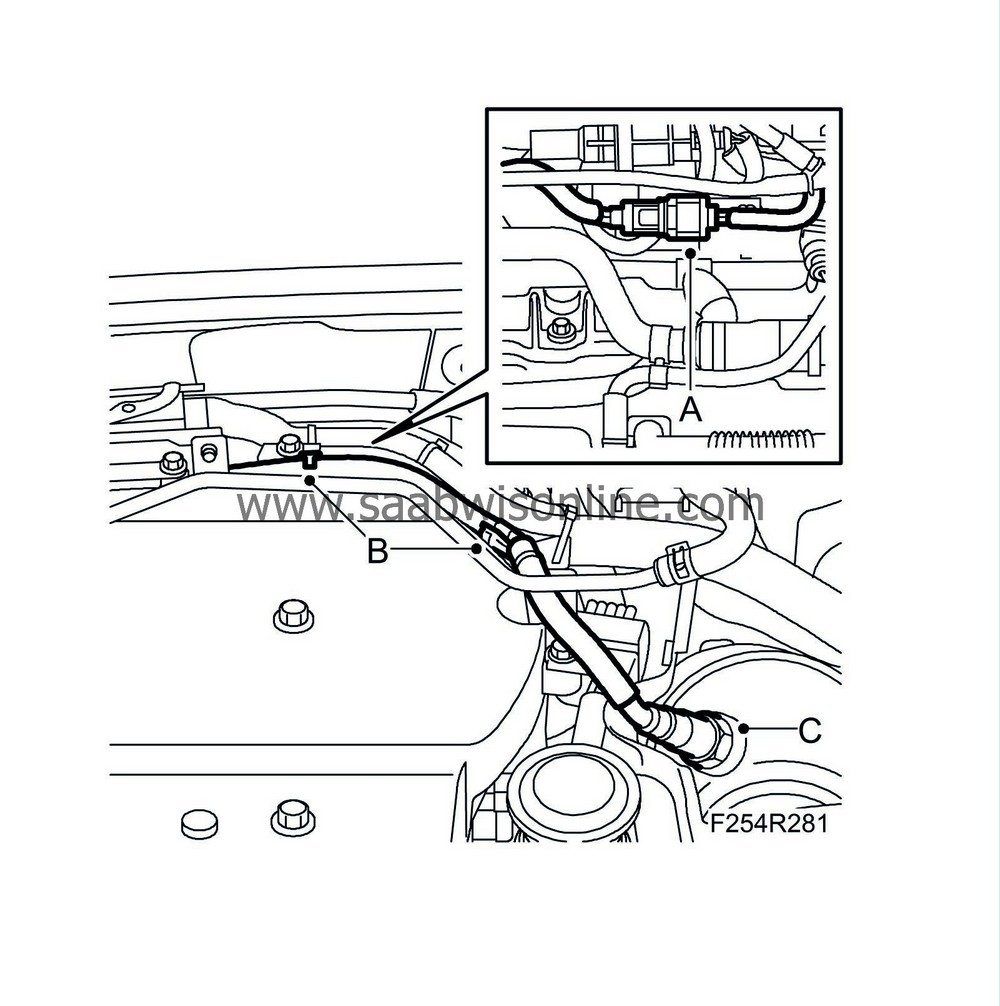

| 25. |

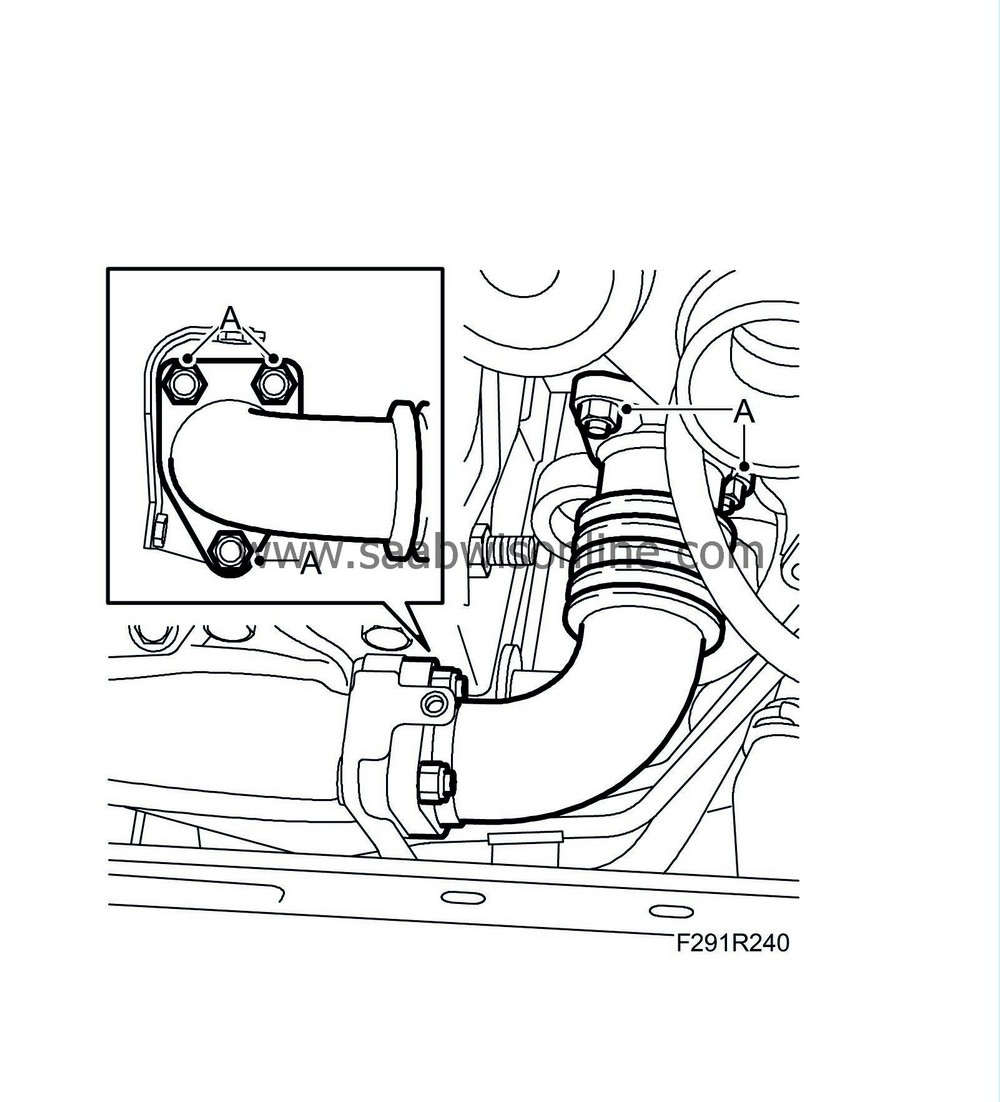

Detach the inlet pipe (A) of the secondary air injection pump from the pump.

|

|

| 26. |

Detach the outlet pipe (B) of the secondary air injection pump from the pump.

|

|

| 27. |

Unplug the connector (C) of the secondary air pressure sensor (760).

|

|

| 28. |

Remove the pipe (D).

|

|

| 29. |

Unplug the intake air sensor connector (688) (A).

|

|

| 30. |

Detach the upper turbocharger delivery pipe (B).

|

|

| 31. |

Remove the screw (A) holding the dipstick tube.

|

|

| 32. |

Remove the heat shield (B) of the front exhaust manifold.

|

|||||||

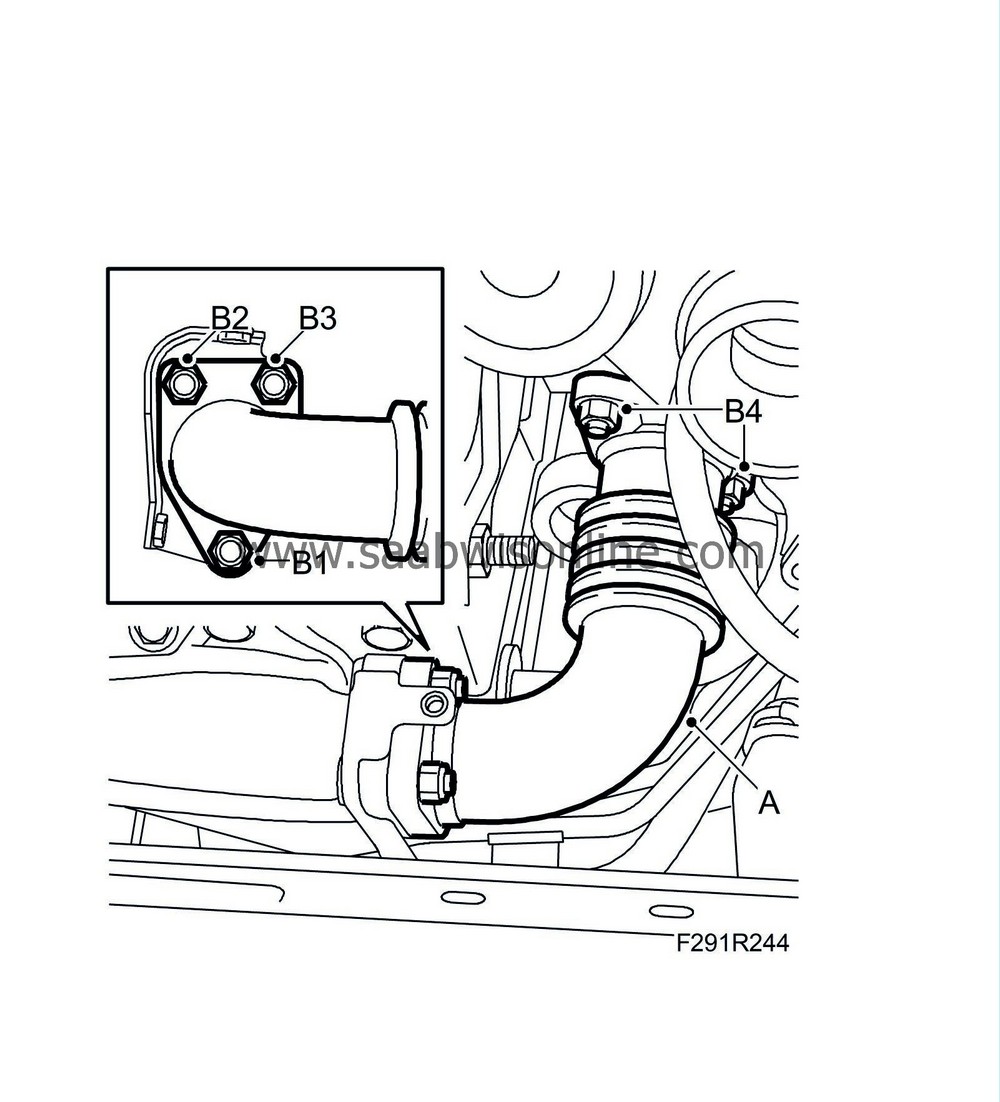

| 33. |

Detach the intermediate exhaust pipe (A) from the turbocharger and the front exhaust manifold.

|

|

| 34. |

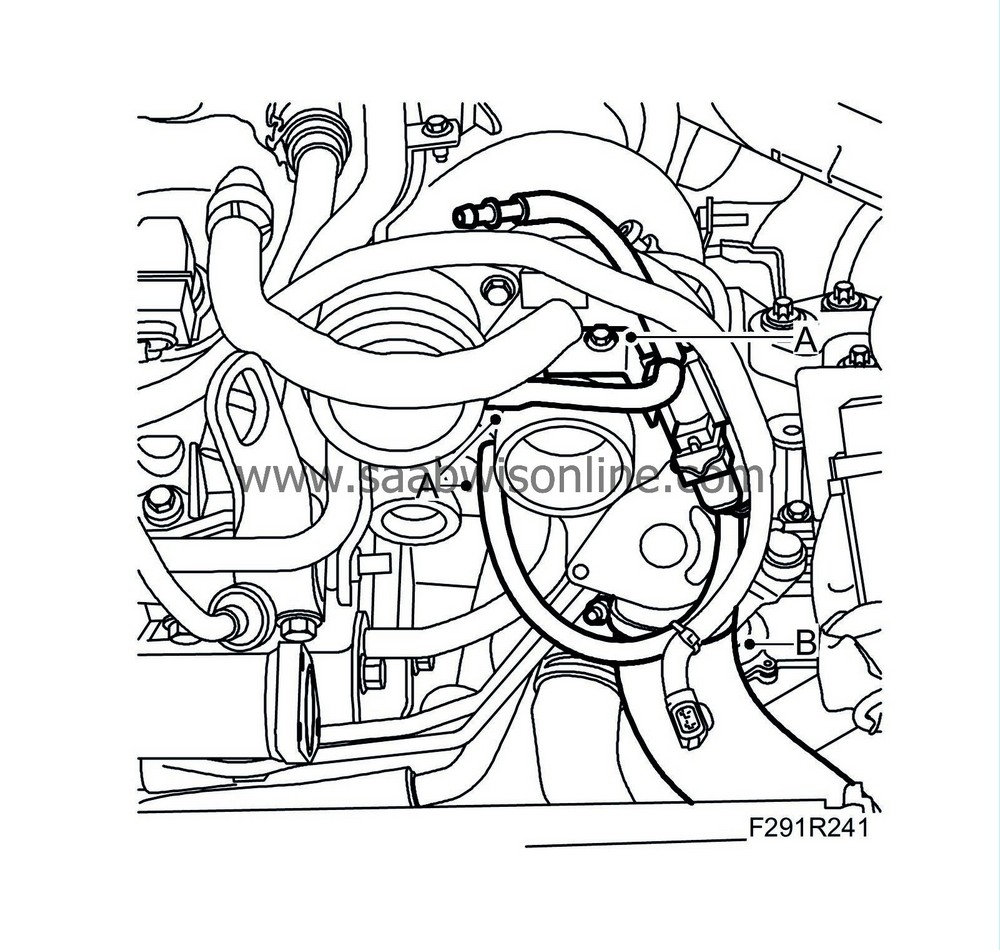

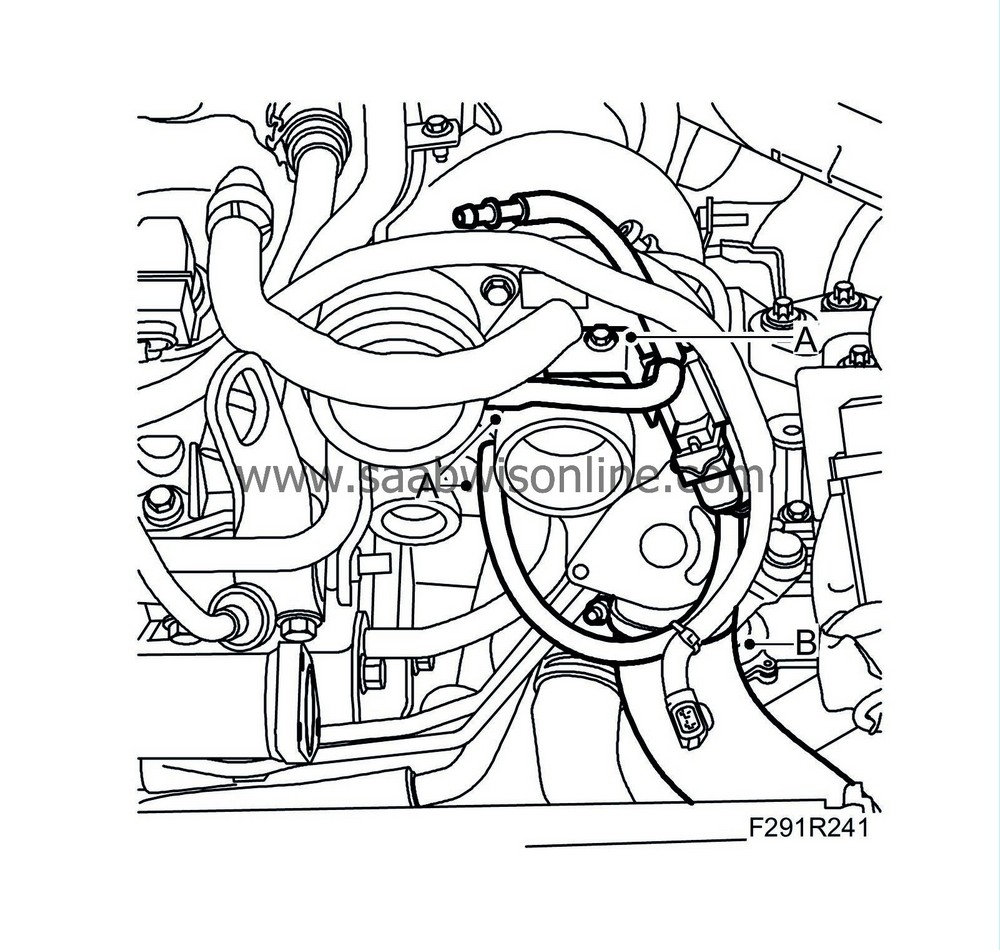

Detach the vacuum hoses and crankcase ventilation pipe from the turbocharger (A).

|

|

| 35. |

Detach the lower turbocharger delivery hose (B) from the turbocharger.

|

|

| 36. |

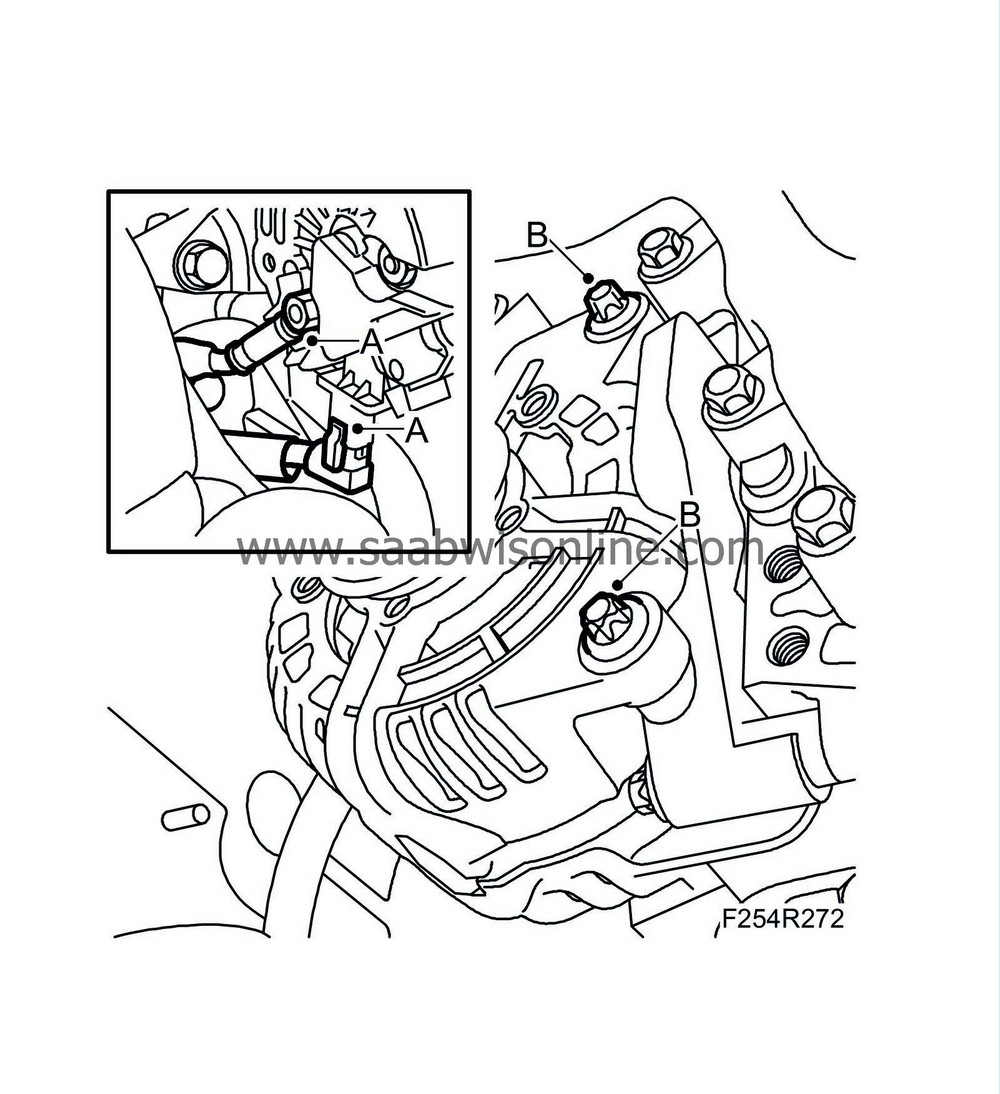

Detach the oil delivery pipe (A) from the engine.

|

|

| 37. |

Remove the oil return pipe (A) from the turbocharger.

|

|

| 38. |

Remove the oil delivery pipe's banjo screws (B) from the turbocharger.

|

|

| 39. |

Remove the coolant pipe's banjo screw (C) from the turbocharger.

|

|

| 40. |

Remove the nuts (D) of the rear intermediate exhaust pipe.

|

|

| 41. |

Remove the bolt (E) securing the turbocharger to the bracket using an impact socket and long puller. Remove the turbocharger.

|

|

| To fit |

| Important | ||

|

It is essential that there is oil in the turbocharger bearing housing when the engine is started, especially after a new turbocharger has been fitted. |

||

|

Fill the turbocharger's oil inlet with oil from an oilcan. Rotate the compressor wheel by hand a number times to ensure that oil enters the bearings. |

||

| 1. |

Position the turbocharger.

|

|

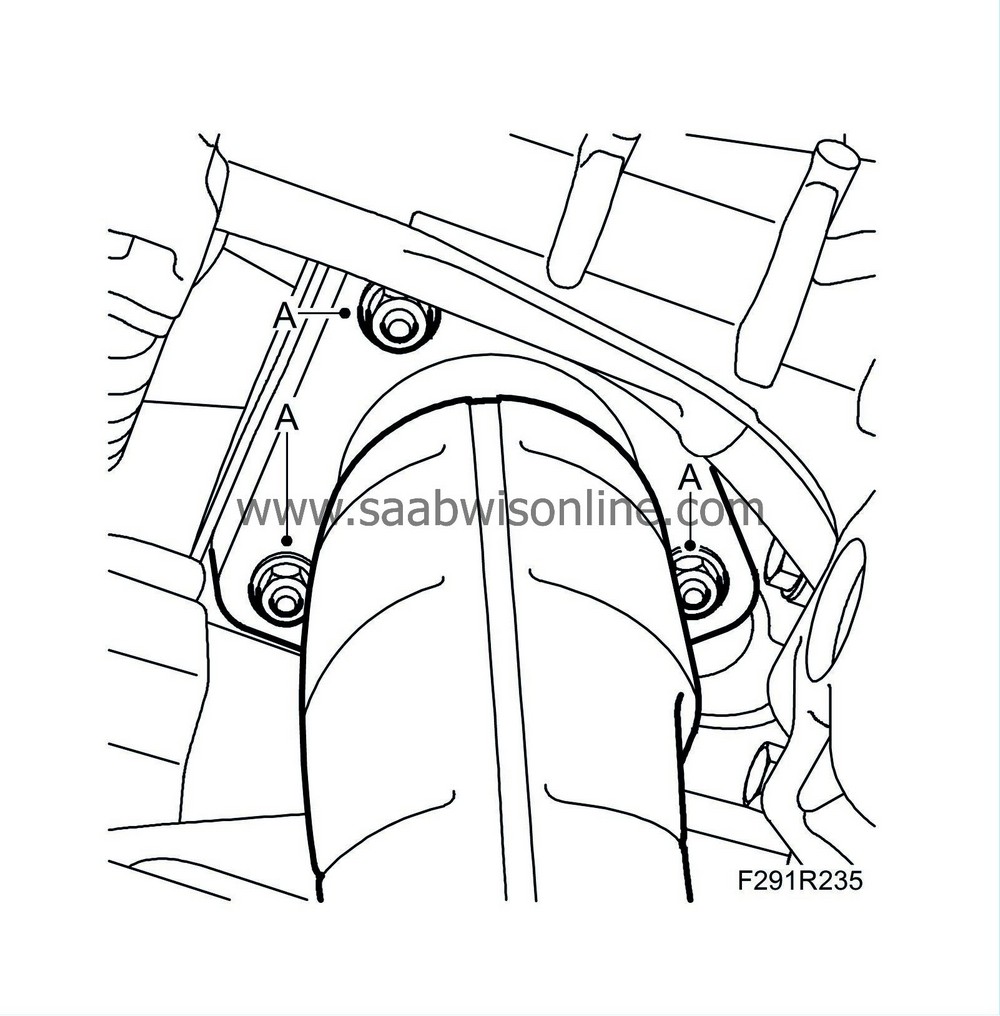

| 2. |

Fit the bolt (E) securing the turbocharger to the bracket.

Tightening torque: 65 Nm (48 lbf ft)

|

||||||||||

| 3. |

Fit the nuts (D) of the rear intermediate exhaust pipe. Tighten alternatingly.

Tightening torque 30 Nm (22 lbf ft) |

|

| 4. |

Fit the coolant pipe's banjo screw (C) to the turbocharger. Use new gaskets.

Tightening torque 30 Nm (22 lbf ft) |

|||||||

| 5. |

Fit the oil delivery pipe's banjo screws (B) to the turbocharger using new gaskets.

Tightening torque 30 Nm (22 lbf ft) |

|||||||

| 6. |

Fit the oil return pipe (A) to the turbocharger. Use new gaskets.

Tightening torque: 14 Nm (10 lbf ft) |

|

| 8. |

Attach the lower turbocharger delivery hose (B) to the turbocharger.

|

|

| 9. |

Attach the vacuum hoses and crankcase ventilation pipes to the turbocharger (A).

|

|

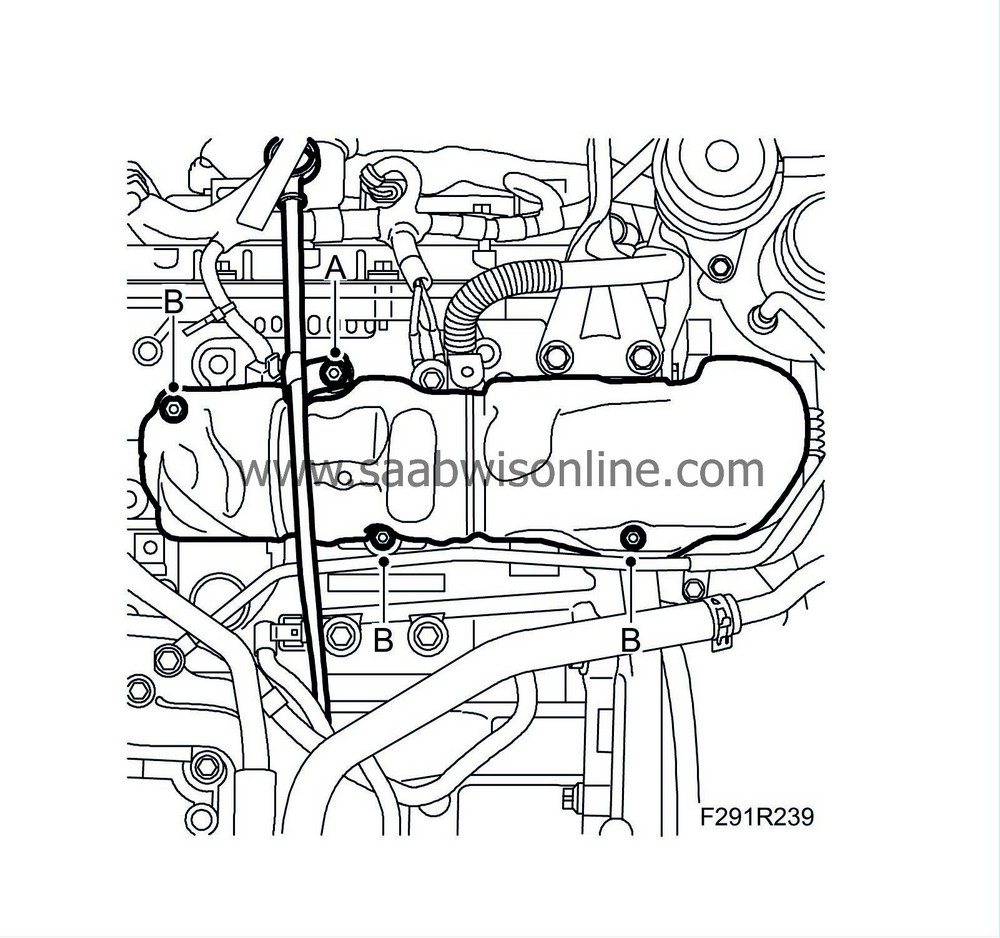

| 10. |

Attach the intermediate exhaust pipe (A) to the front exhaust manifold and the turbocharger. Use a new gasket and coat the studs with

90 513 210 Universal paste

.

|

||||||||||

| 11. |

Tighten the nuts as illustrated - first on the exhaust manifold and then on the turbocharger.

Tightening order (B1, B2, B3 and B4) alternatingly on the turbocharger. Tightening torque 30 Nm (22 lbf ft)

|

||||||||||

| 12. |

Fit the front exhaust manifold heat shield (B).

Tightening torque 10 Nm (7 lbf ft)

|

|

| 13. |

Fit the screw (A) holding the dipstick tube.

Tightening torque 10 Nm (7 lbf ft) |

|

| 14. |

Fit the upper turbocharger delivery pipe (B).

|

|

| 15. |

Plug in the intake air sensor connector (688) (A).

|

|

| 16. |

Fit the pipe (D).

|

|

| 17. |

Plug in the connector (C) of the secondary air pressure sensor (760).

|

|

| 18. |

Attach the secondary air injection pump's outlet pipe (B) to the pump.

|

|

| 19. |

Attach the secondary air injection pump's inlet pipe (A) to the pump.

|

||||||||||

| 20. |

Fit the catalytic converter nuts (A) to the turbocharger. Coat the studs with

90 513 210 Universal paste

.

Tightening torque 25 Nm (18 lbf ft)

|

|

| 21. |

Fit the catalytic converter to the bracket (B).

|

|

| 22. |

Fit the turbocharger's lower heat shield.

|

|

| 23. |

Lightly coat the threads of the front oxygen sensor with

90 513 210 Universal paste

and fit the oxygen sensor (C) using

83 96 350 Removal socket, oxygen sensor

.

Tightening torque 45 Nm (33 lbf ft).

|

|

| 24. |

Carefully press down the heat shield.

|

|

| 25. |

Secure the cable (B) and plug in the connector (A).

|

|

| 26. |

Fit the turbocharger coolant pipe (C).

Tightening torque, banjo screw: 30 Nm (22 lbf ft).

|

|||||||

| 27. |

Fit the upper heat shield to the catalytic converter (B) and turbocharger (A).

|

|

| 28. |

Attach the lower hose (C) of the coolant reservoir and plug in the level sensor connector (B).

|

|

| 29. |

Fit the coolant reservoir in the mounting.

|

|

| 30. |

Attach the breather hoses (A) to the coolant reservoir.

|

|

| 31. |

Fit

Fan cowling

.

|

|

| 32. |

Raise the car.

|

|

| 33. |

Fit the bracket (C) to the front catalytic converter and oil sump.

|

|

| 34. |

Plug in the oil level sensor connector (A) and attach the cable fixing (B).

|

|

| 35. |

RHD:

Remove

Alternator, B284, 4WD, (RHD)

.

|

|

| 36. |

LHD:

Fit the alternator retaining bolts (B).

|

|

| 37. |

LHD:

Connect the electrical connections (A) of the alternator.

|

|

| 38. |

LHD:

Relieve the load on the belt tensioner and position the belt. Use a ½" puller (B).

|

|

| 39. |

LHD:

Fit the right wing liner (A).

|

|

| 40. |

Fit the rear catalytic converter (A) using a new gasket.

Tightening torque 25 Nm (18 lbf ft)

|

|

| 41. |

Lower the car.

|

|

| 42. |

Carry out

Cooling system pressure testing

and

Bleeding and charging the cooling system

.

|

|

| 43. |

Check the oil level and top up as necessary.

|

|

| 44. |

Connect the battery cable.

|

|

| 45. |

Fit the battery cover and the engine cover.

|

|

| 46. |

Remove the wing covers and restore car electrical functions, see

After disconnecting the battery

.

|

|

| 47. |

Start the engine and check for any exhaust, oil and coolant leakage.

|

|

Warning

Warning