Power unit removal, A20NFT/LHU

|

|

Power unit removal, A20NFT/LHU

|

Warning

Warning

|

|

There is a large number of cables, hoses, wires, etc., that are secured with hard plastic cable ties. After tightening, the loose ends of these cable ties are cut off and may leave more or less sharp edges at fixing points.

|

|

Pay attention to the risk of cuts caused by these sharp ends!

|

|

|

|

|

|

|

1.

|

Place the car on a lift and apply wing covers.

|

|

2.

|

Open the cap on the expansion tank.

|

|

3.

|

Raise the car slightly and remove the front wheels.

|

|

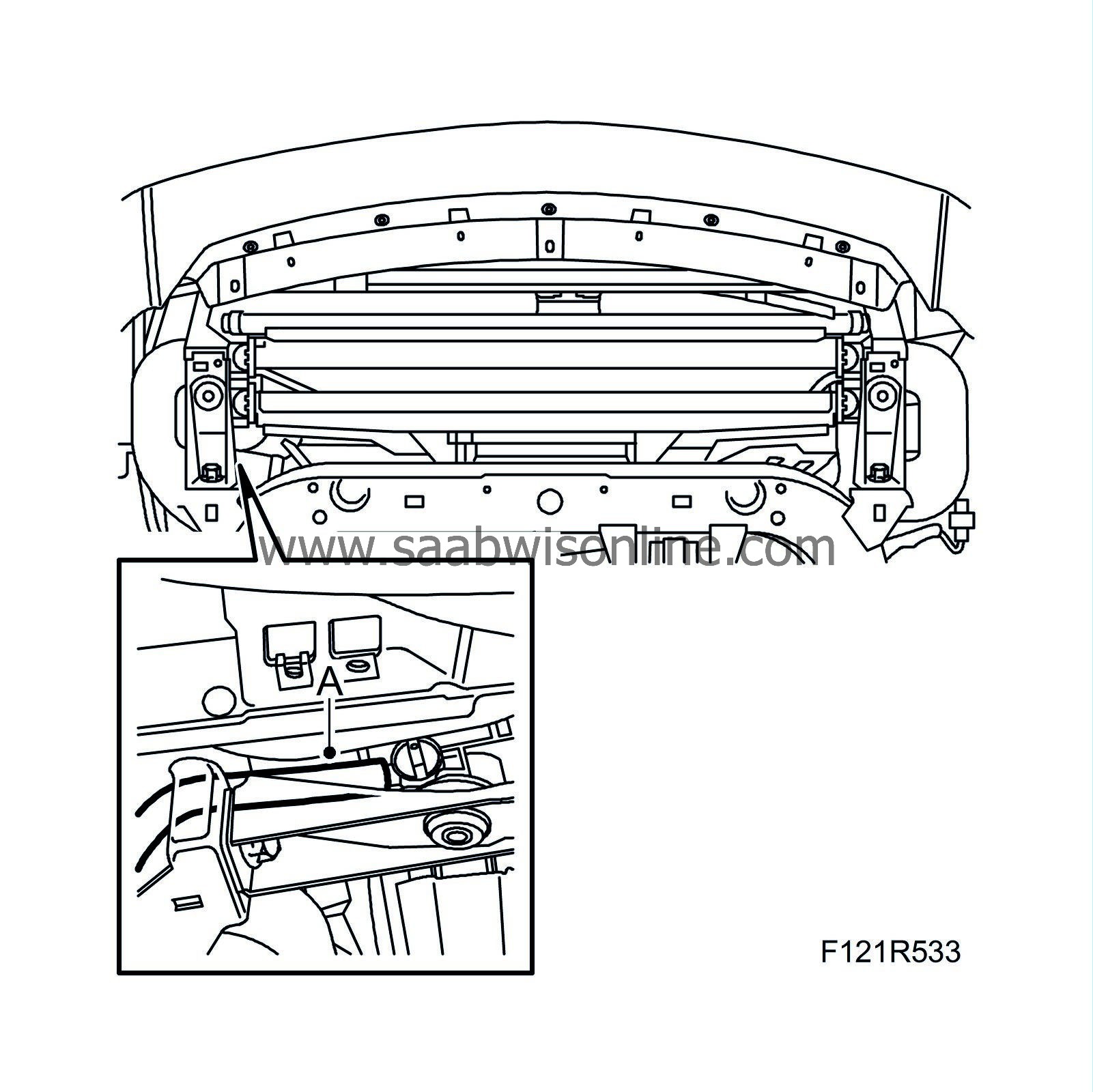

5.

|

Place a receptacle under the car. Connect a hose (A) to the radiator and drain the coolant. Remove the hose and close the cock.

|

|

6.

|

Loosen the left and right-hand wing liner front section so that the subframe is free.

|

|

7.

|

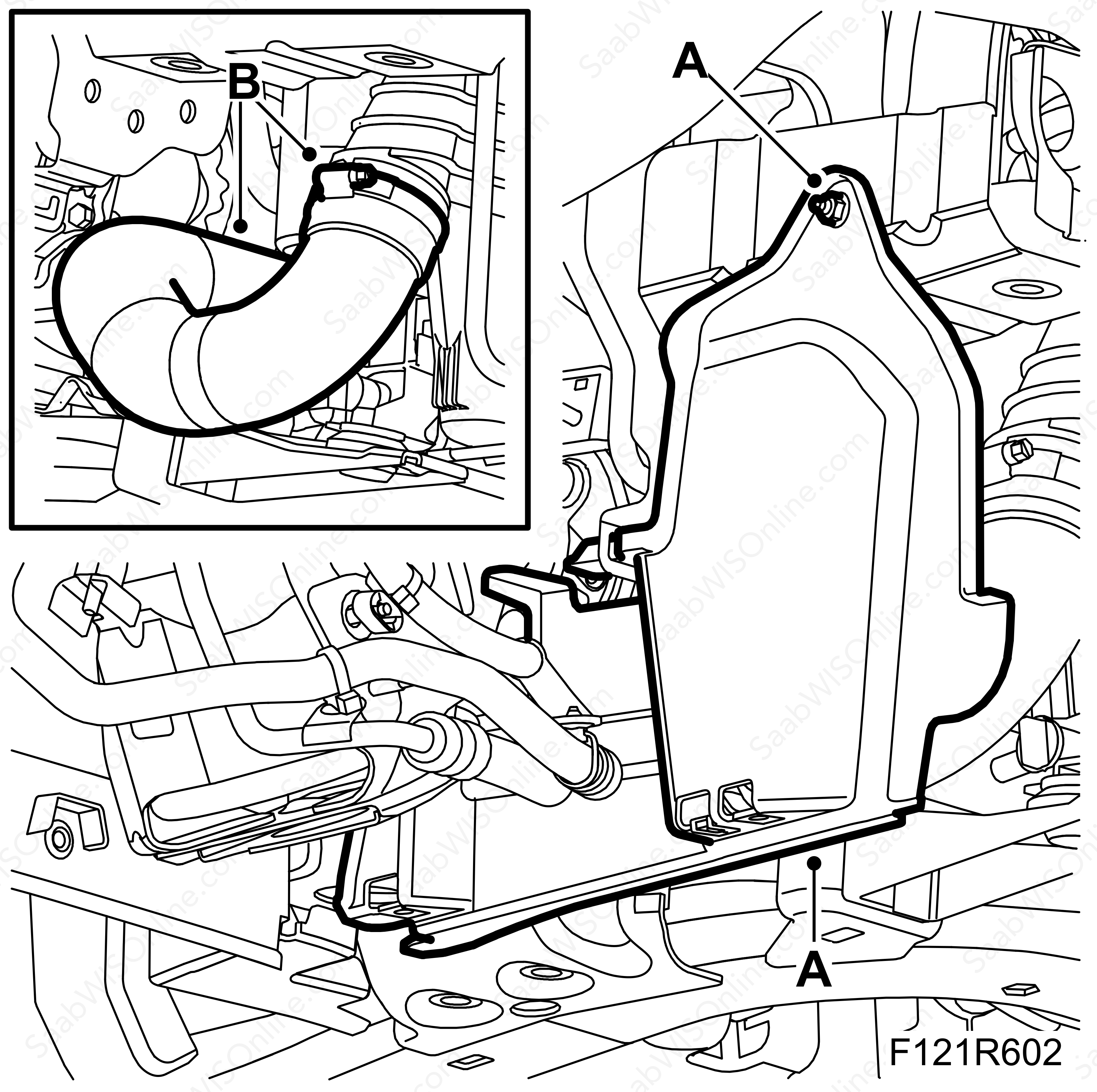

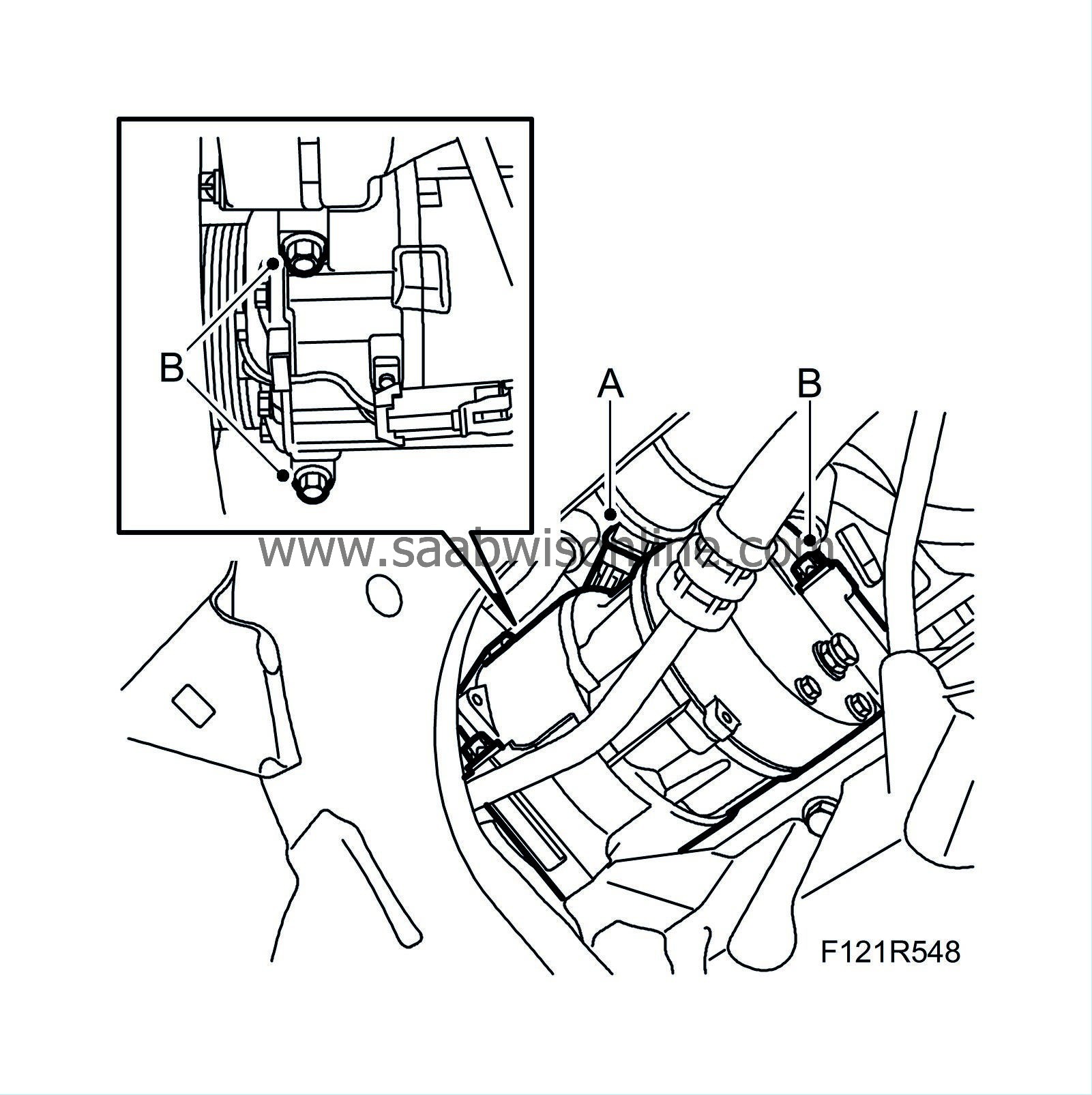

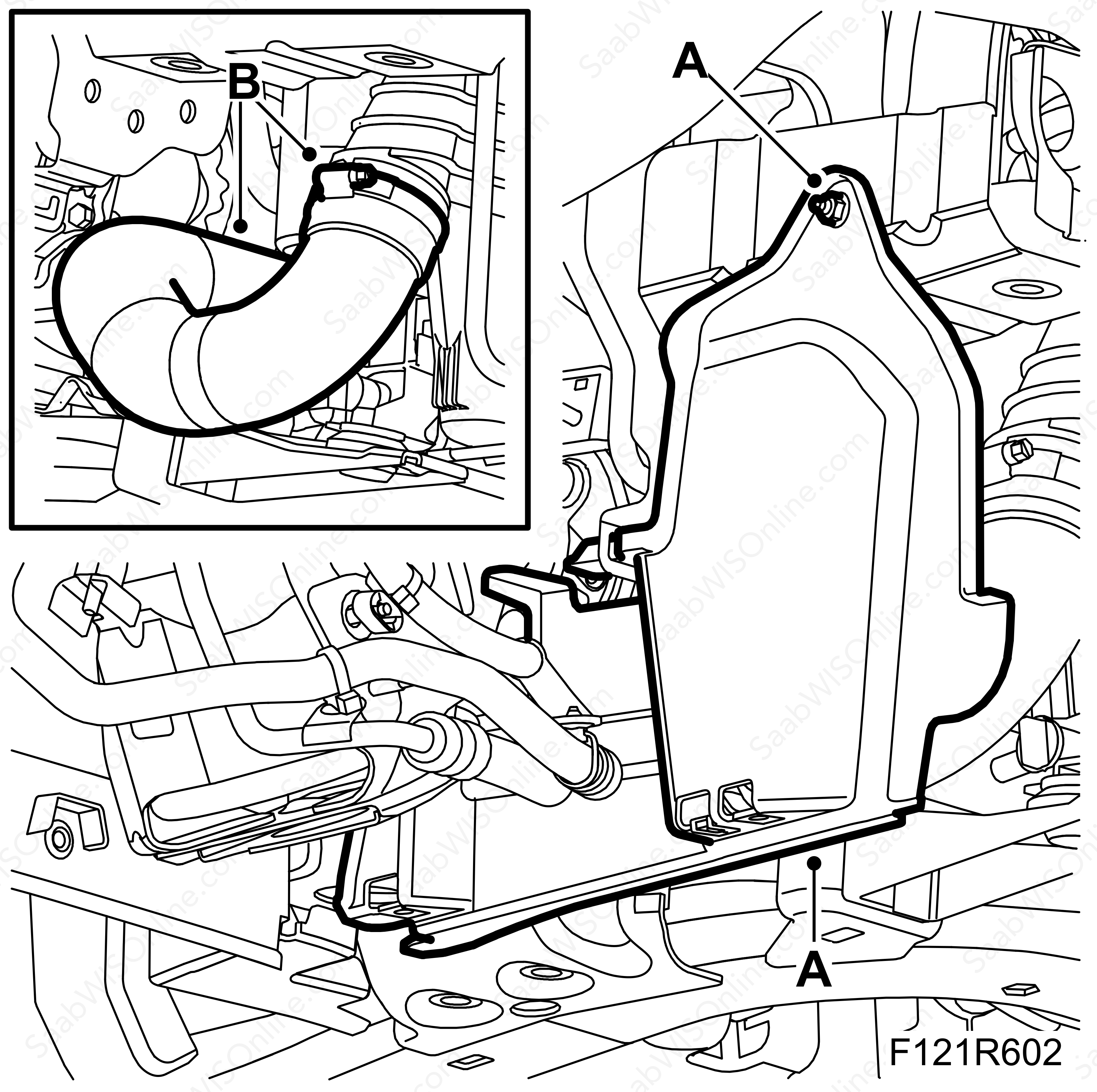

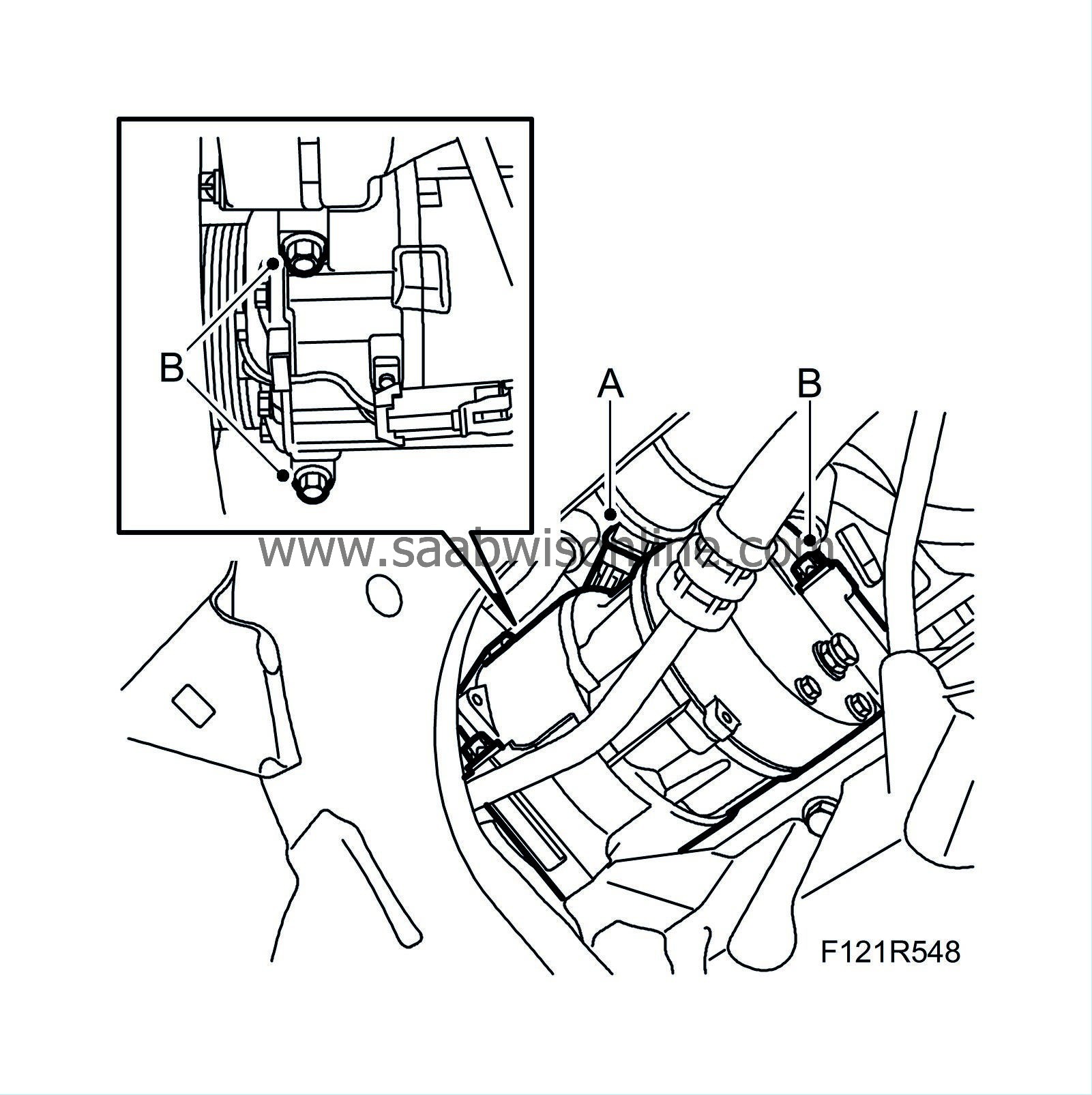

Remove the cover (A) on the right-hand side and the hose (B) between the charge air cooler and the charge air pipe.

|

|

8.

|

Lower the car and remove the upper engine cover and the dipstick.

|

|

9.

|

Remove the battery cover.

|

|

11.

|

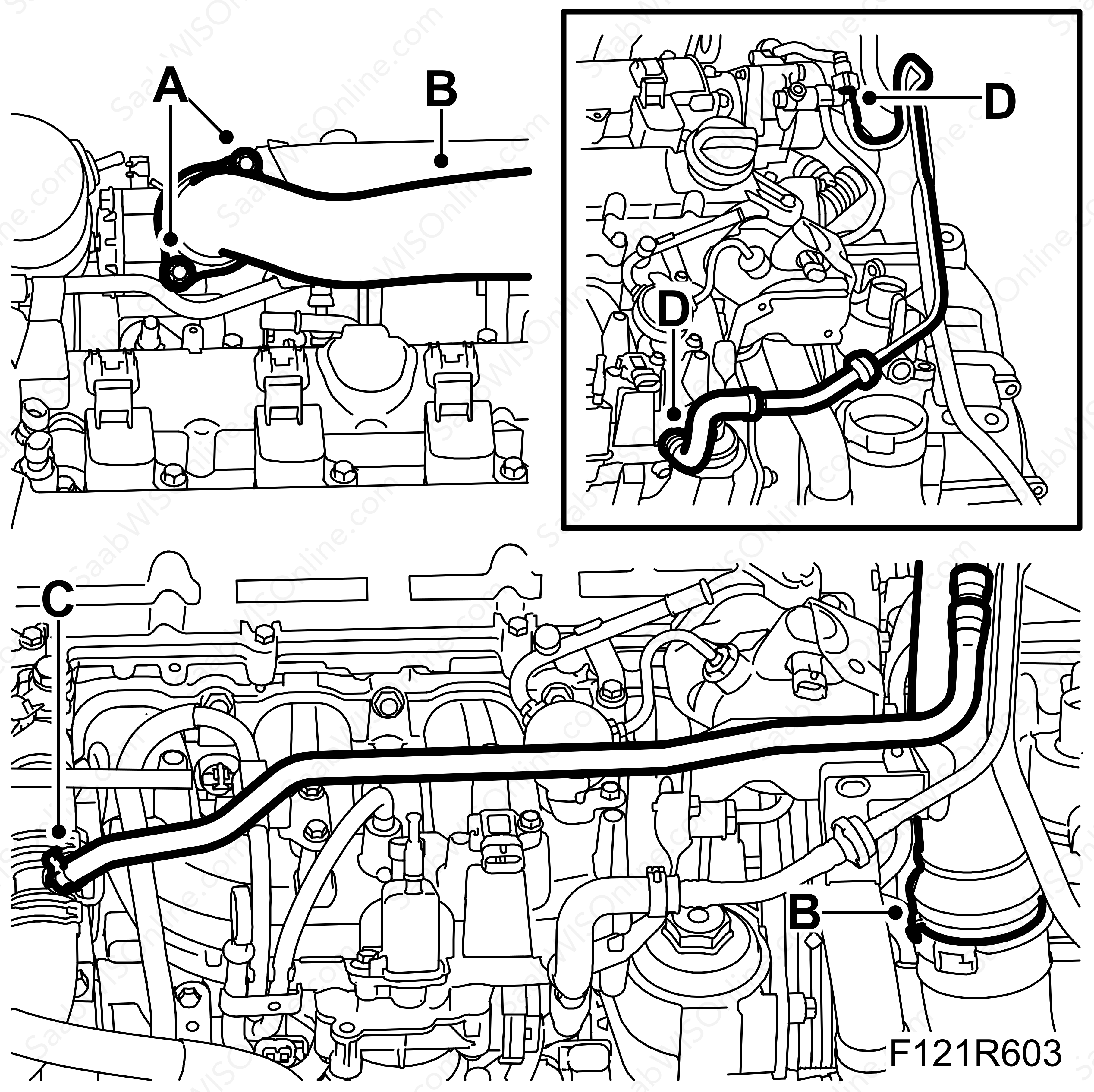

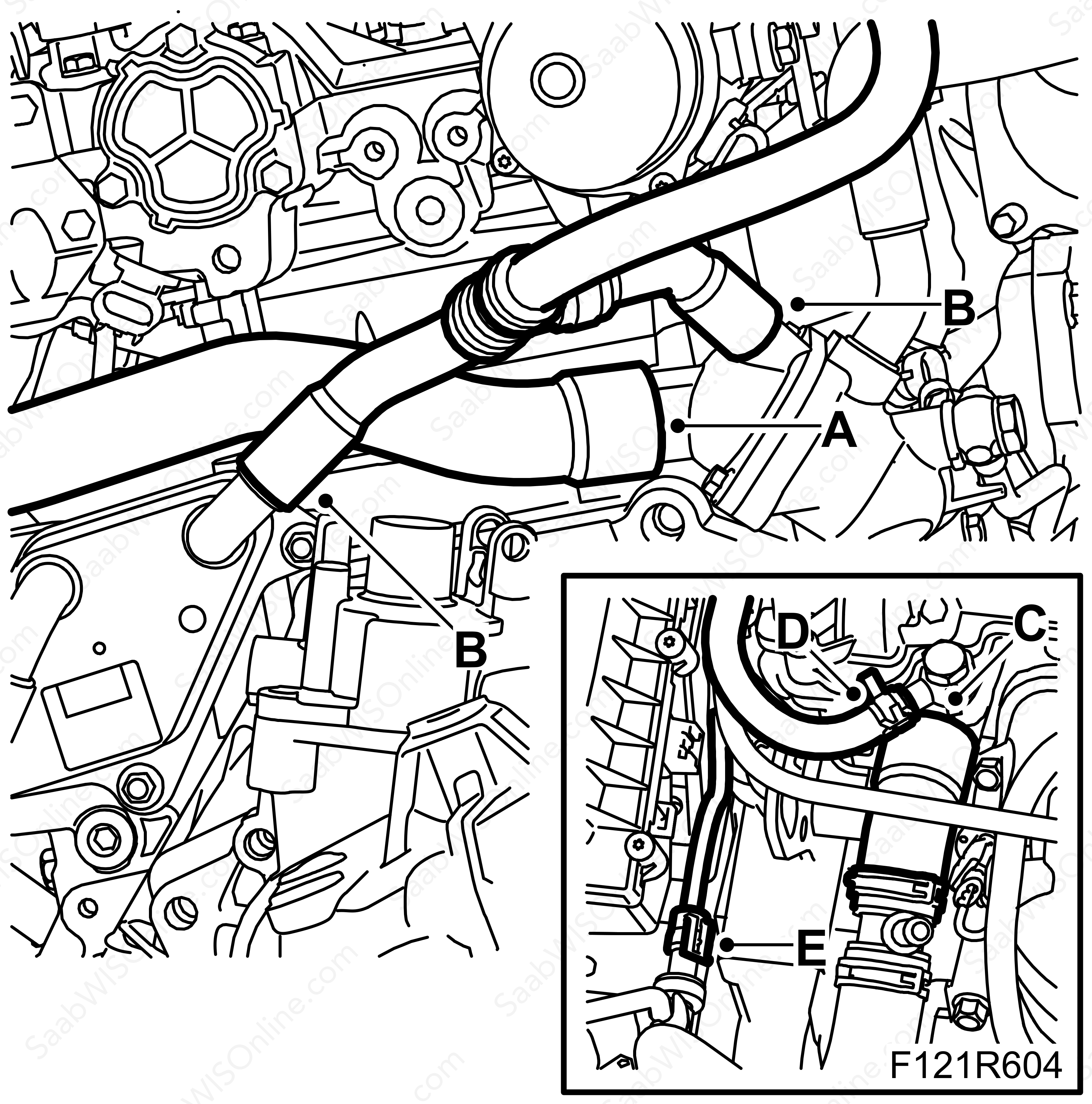

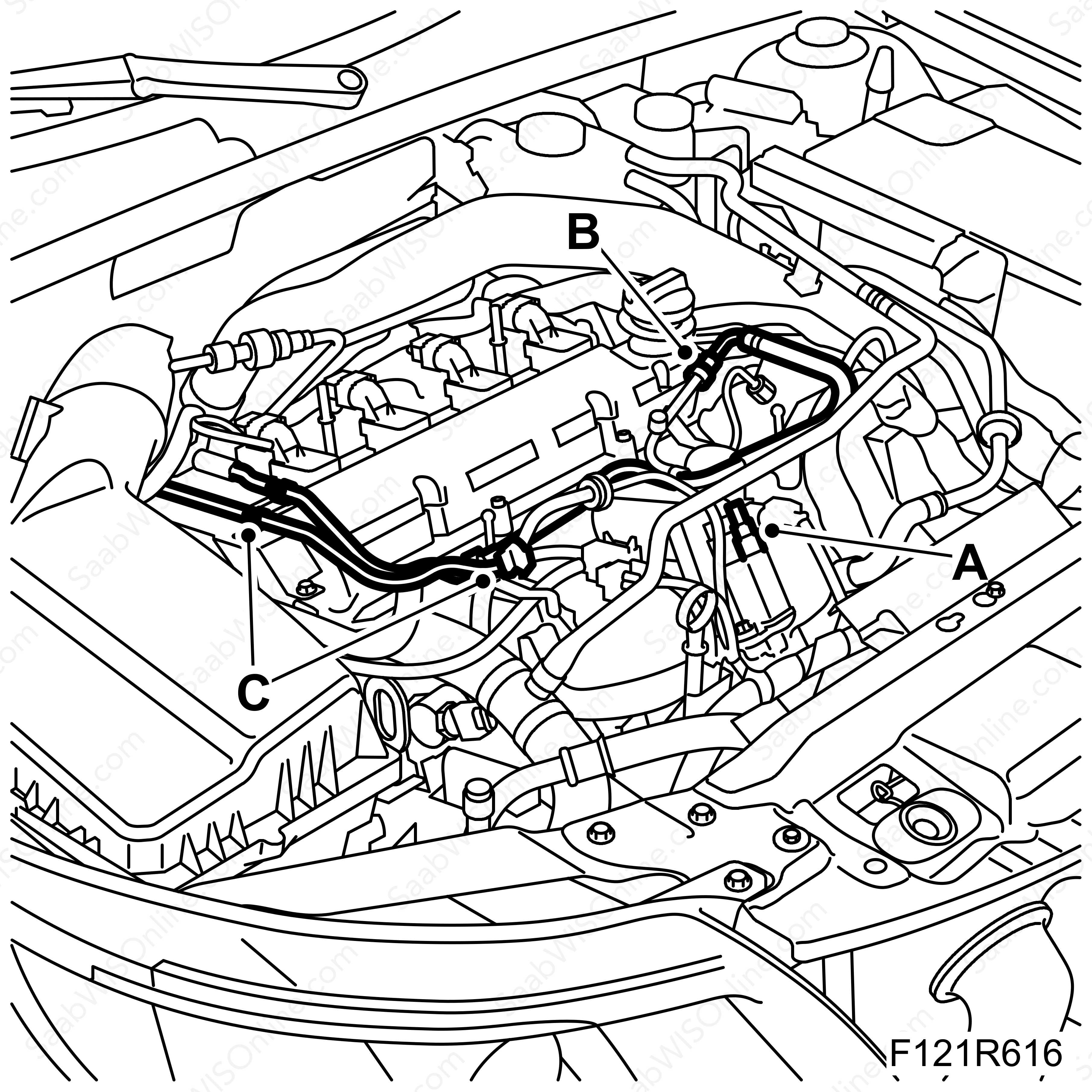

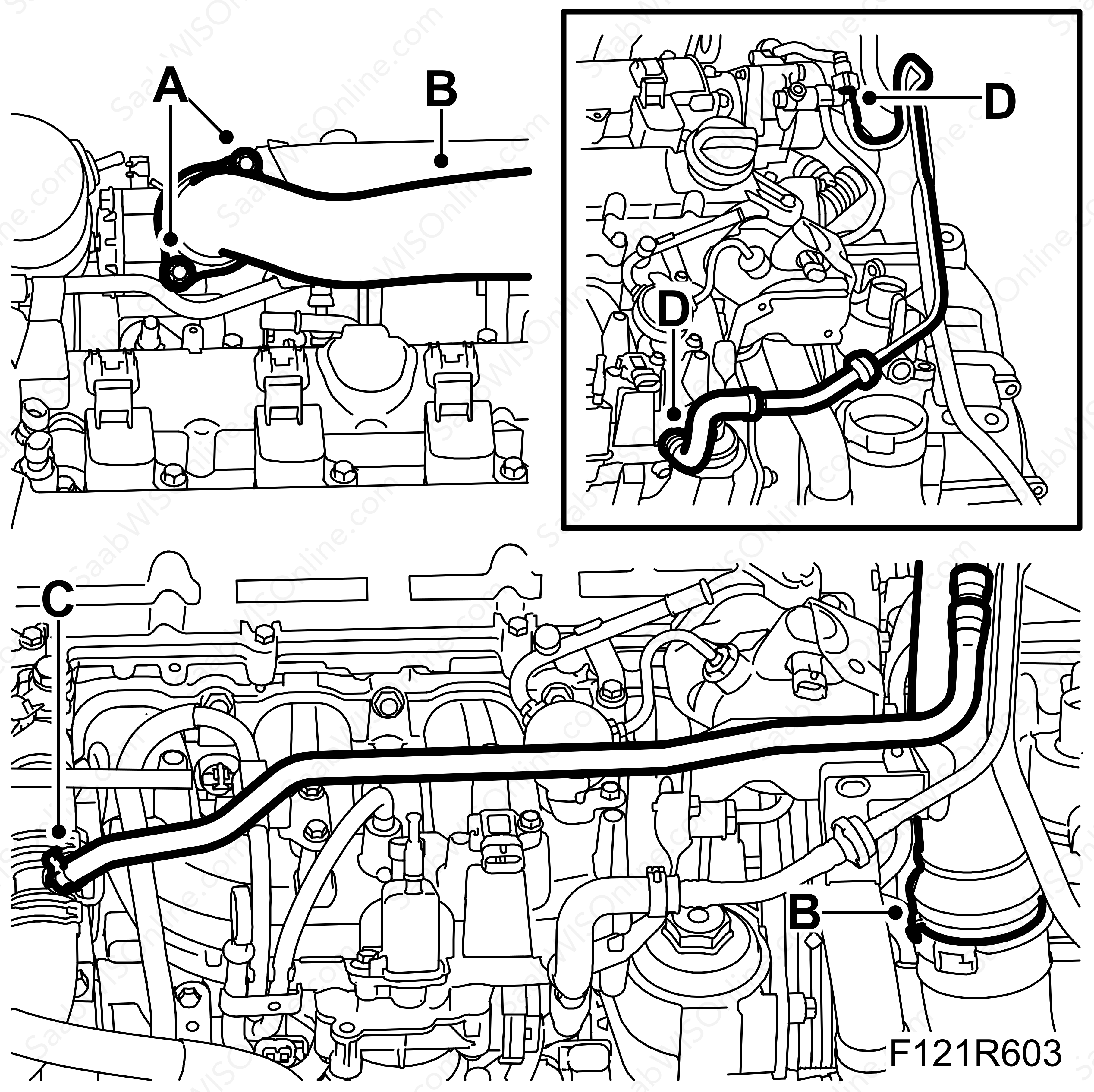

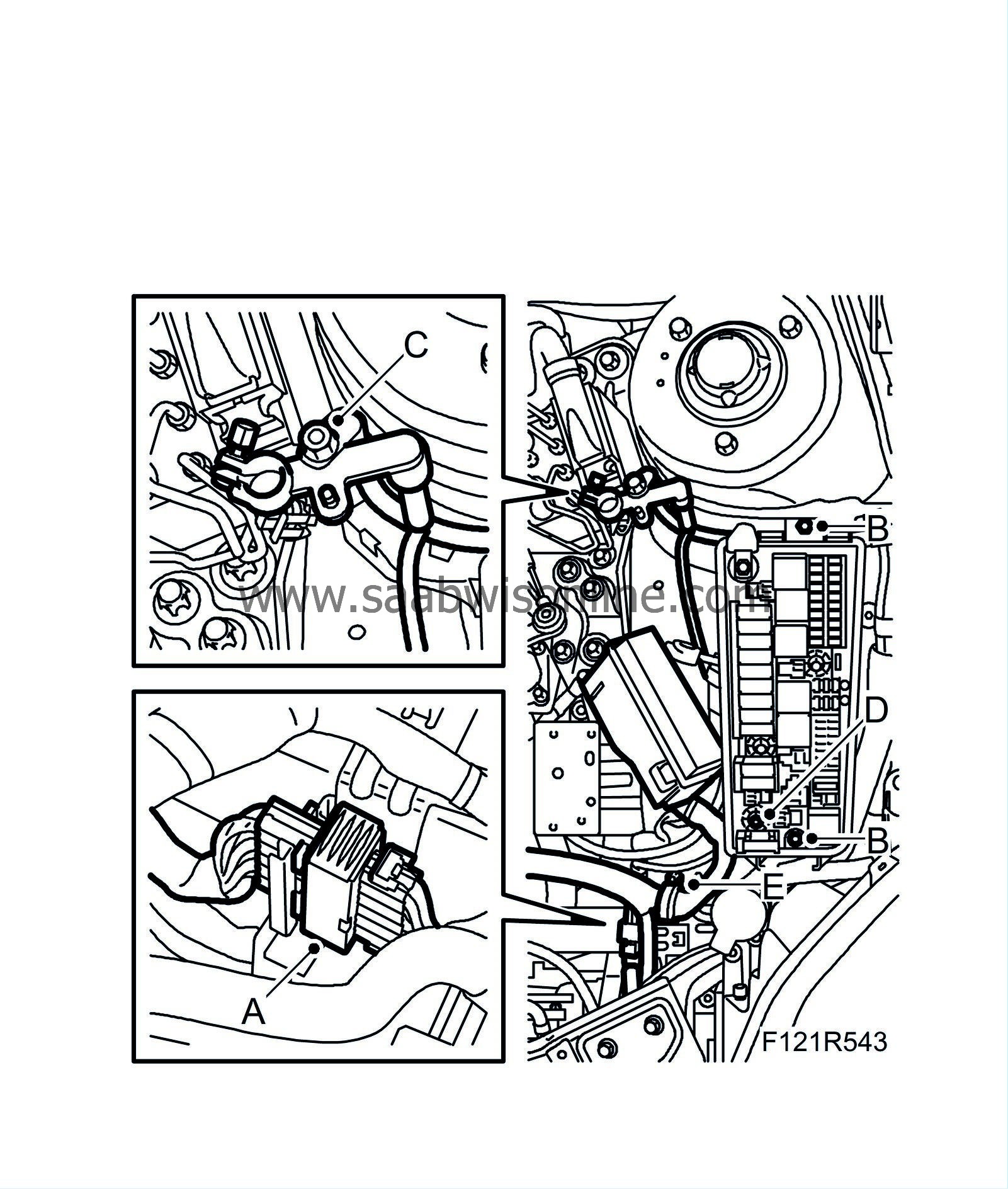

Remove the charge air pipes screws from the turbo (A).

|

|

12.

|

Remove the charge air pipe (B).

|

|

13.

|

Detach the bleeder hose from the engine (C).

|

|

14.

|

Undo the vacuum hose quick coupling (D) from the vacuum pump and intake manifold.

|

|

15.

|

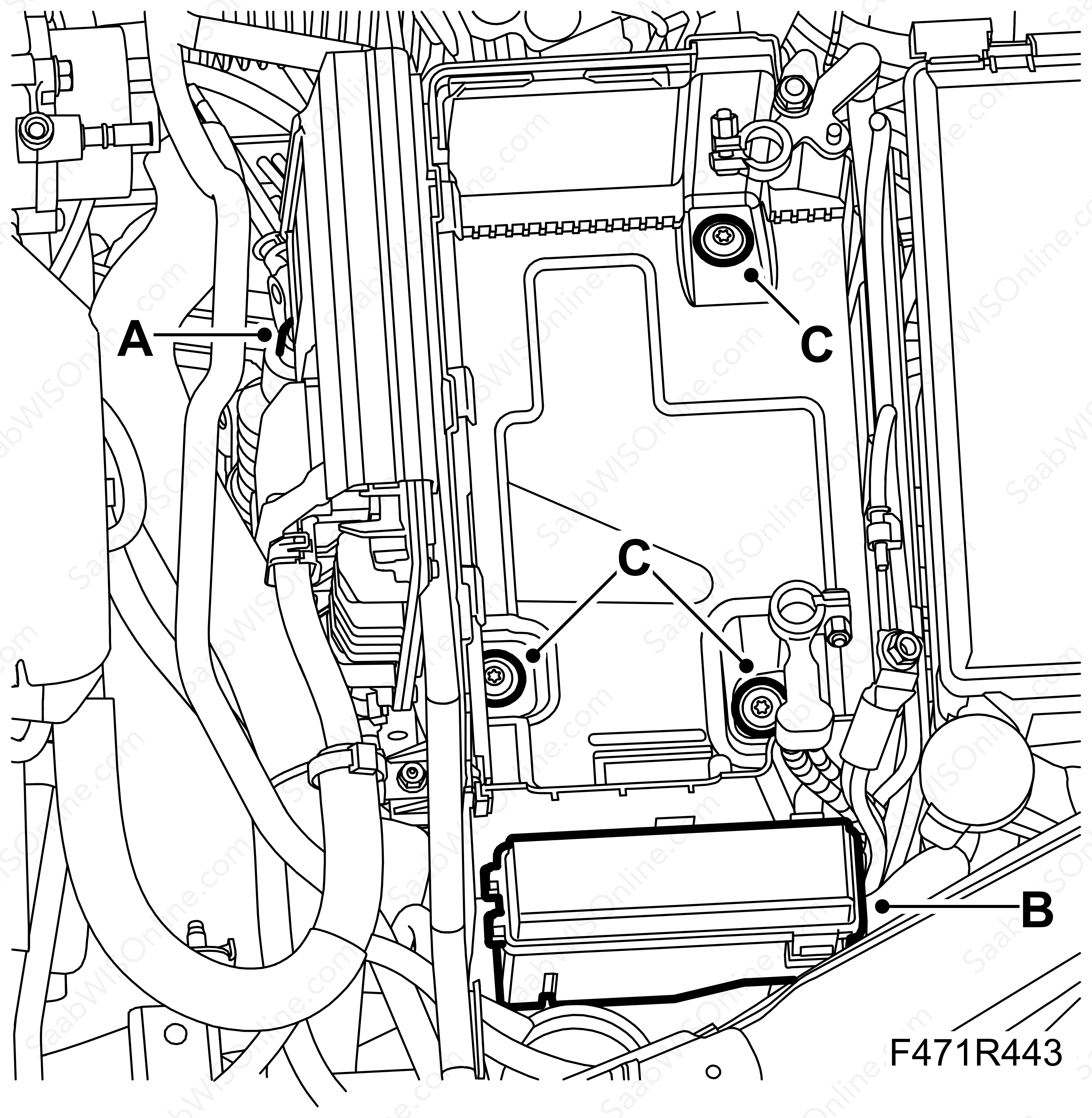

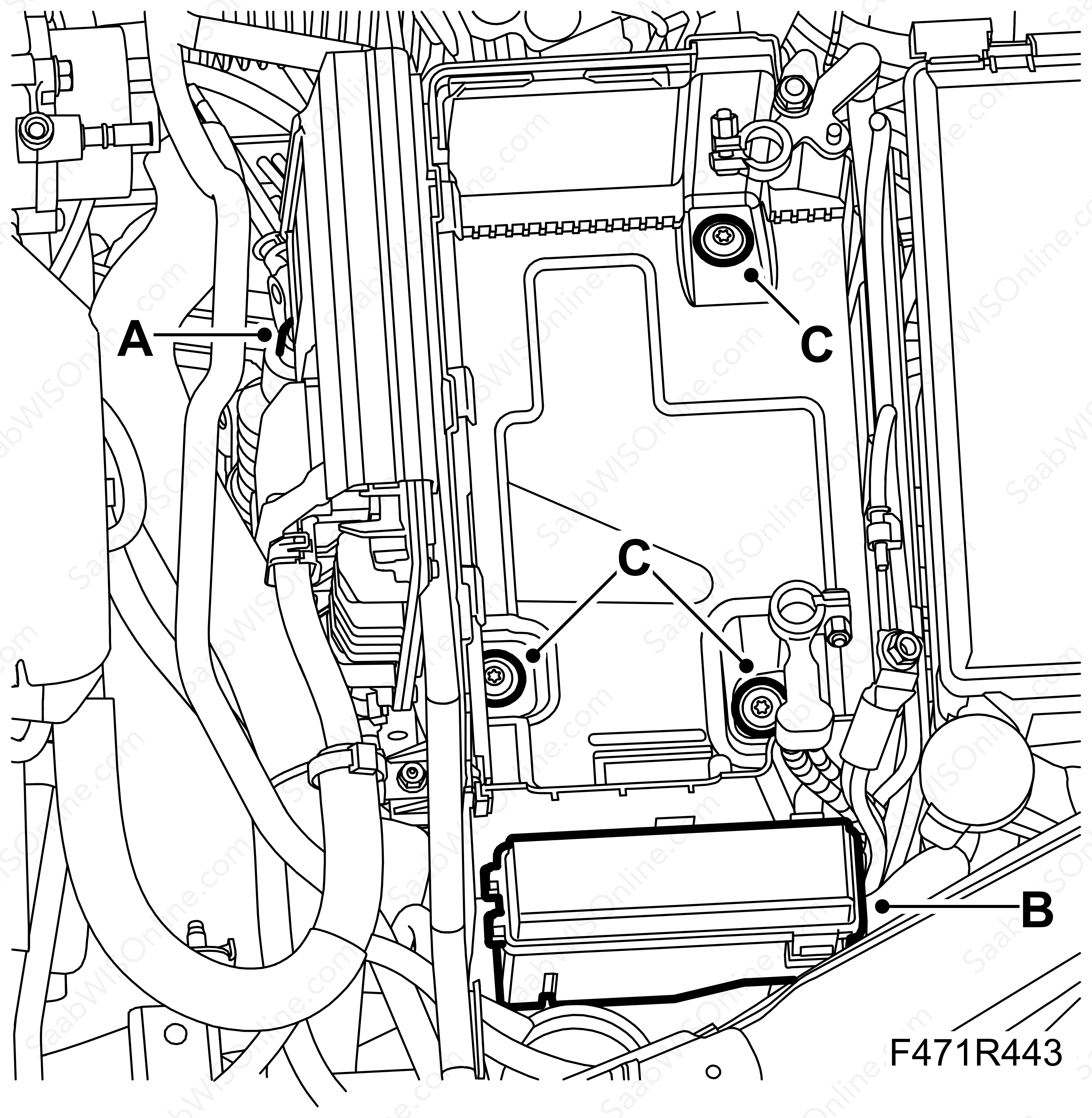

Remove the ECM from the battery tray (A).

|

|

16.

|

Detach the electrical centre (B) in front of the battery tray and move it aside.

|

|

17.

|

Unplug the bonnet switch connector, undo the cable clip and remove the battery tray (C).

|

|

18.

|

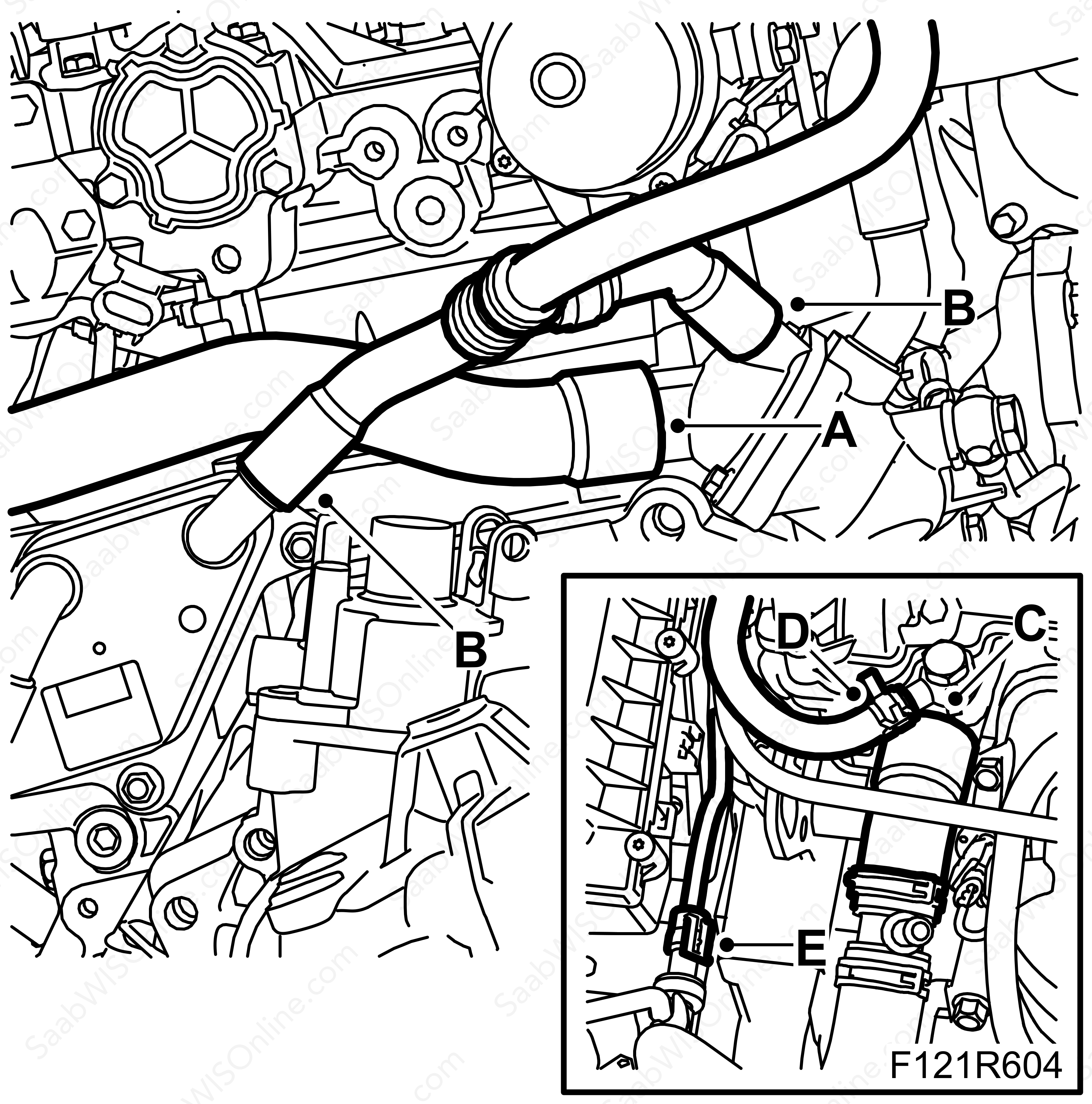

Remove the lower radiator hose (A) from the thermostat housing, then cut the cable tie and fold aside the hose.

|

|

19.

|

Remove the hose from the oil cooler and thermostat housing (B).

|

|

20.

|

Remove the upper radiator hose (C) from the engine and the hose (D) to the turbo.

|

|

21.

|

Unplug the connector (E) for the A/C pressure sensor.

|

|

24.

|

Remove the cover on the electrical centre and undo the two retaining bolts (B).

|

|

25.

|

Disconnect the positive cable (C) from the positive terminal of the battery.

|

|

26.

|

Slacken the retaining bolt (D) for the engine harness connector in the electrical centre and remove the connector.

|

|

27.

|

Remove the cable tie (E) for the engine harness from the body.

|

|

28.

|

Man:

Remove the connector from the reversing light switch and speed sensor.

|

|

29.

|

Bend up the engine harness and secure it to the engine with e.g. one

83 95 212 Strap

.

|

|

30.

|

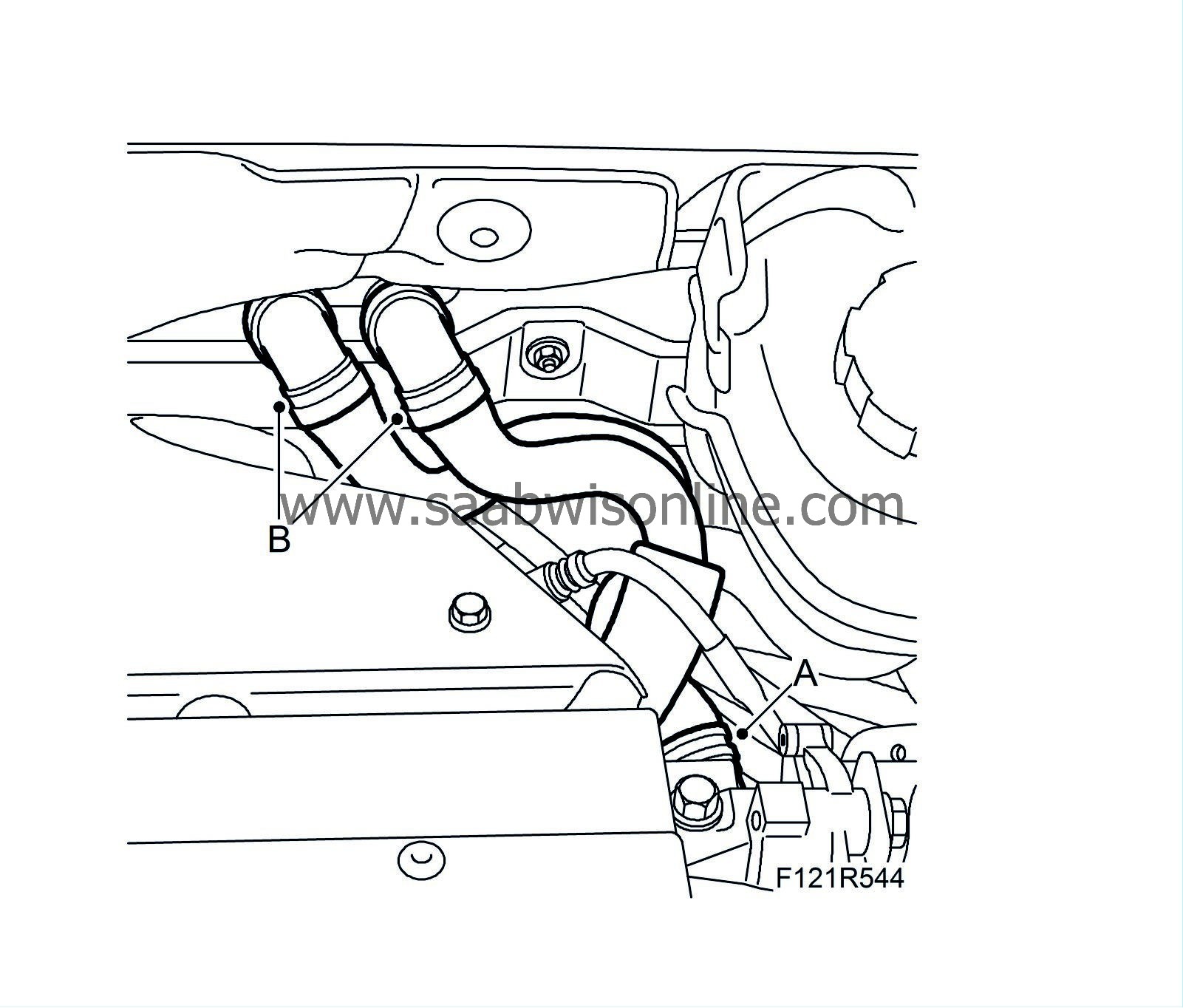

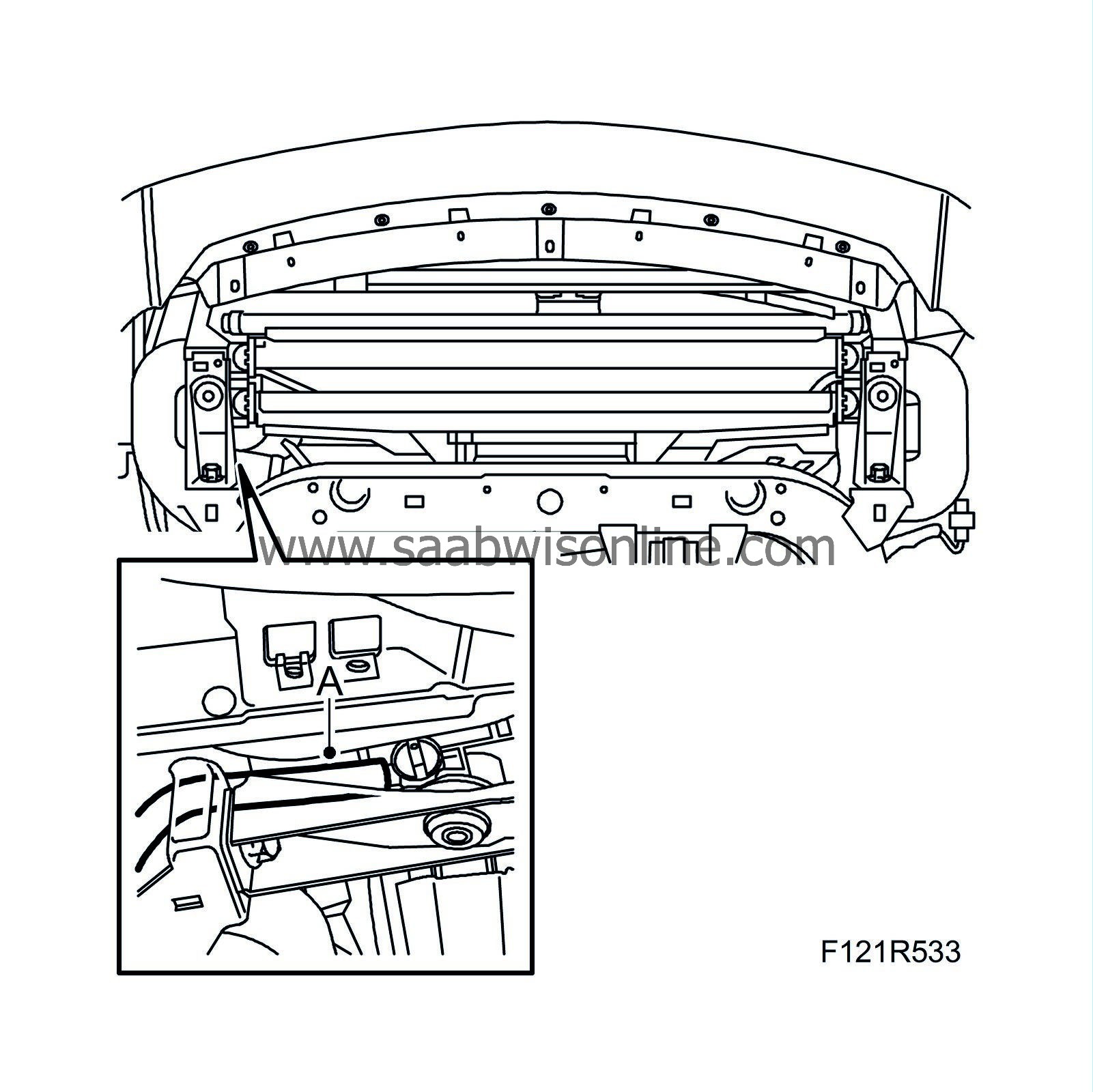

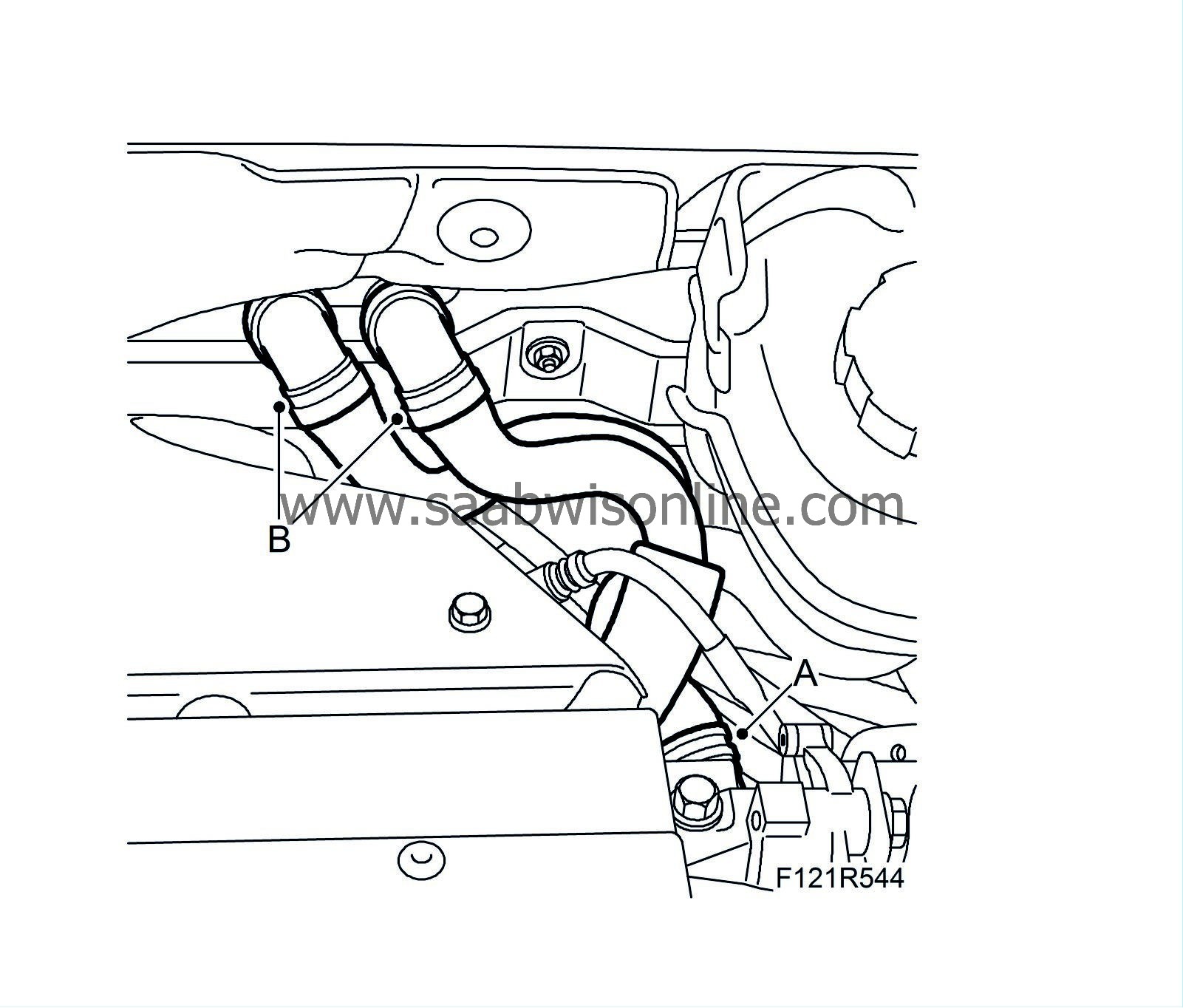

Remove the coolant hose (A) from the thermostat housing.

|

|

31.

|

Undo the coolant hose quick couplings (B), while trapping any coolant spill, turn aside and secure the hoses to the engine.

|

|

32.

|

Lift the cable connections from the gear selector arms on the gearbox and detach the cables from the cable retainers on the gearbox by pulling back the locking sleeves (A).

Aut:

Only one cable.

|

|

33.

|

Man:

Fit

30 07 739 Hose pinch-off pliers

on the clutch hose and remove the quick coupling (B) from the clutch slave cylinder.

Warning

Warning

|

|

The work involved in removing the fuel pipe requires working with the vehicle's fuel system. The following points should therefore be heeded in conjunction with these measures:

|

|

• Have a class BE fire extinguisher on hand! Be aware of the risk of sparks, i.e. in connection with electric circuits, short-circuiting, etc.

|

|

• Absolutely No Smoking!

|

|

• Ensure good ventilation! If there is approved ventilation for evacuating fuel fumes then this must be used.

|

|

• Wear protective gloves! Prolonged exposure of the hands to fuel can cause irritation to the skin.

|

|

• Wear protective goggles.

|

|

|

|

|

|

|

|

34.

|

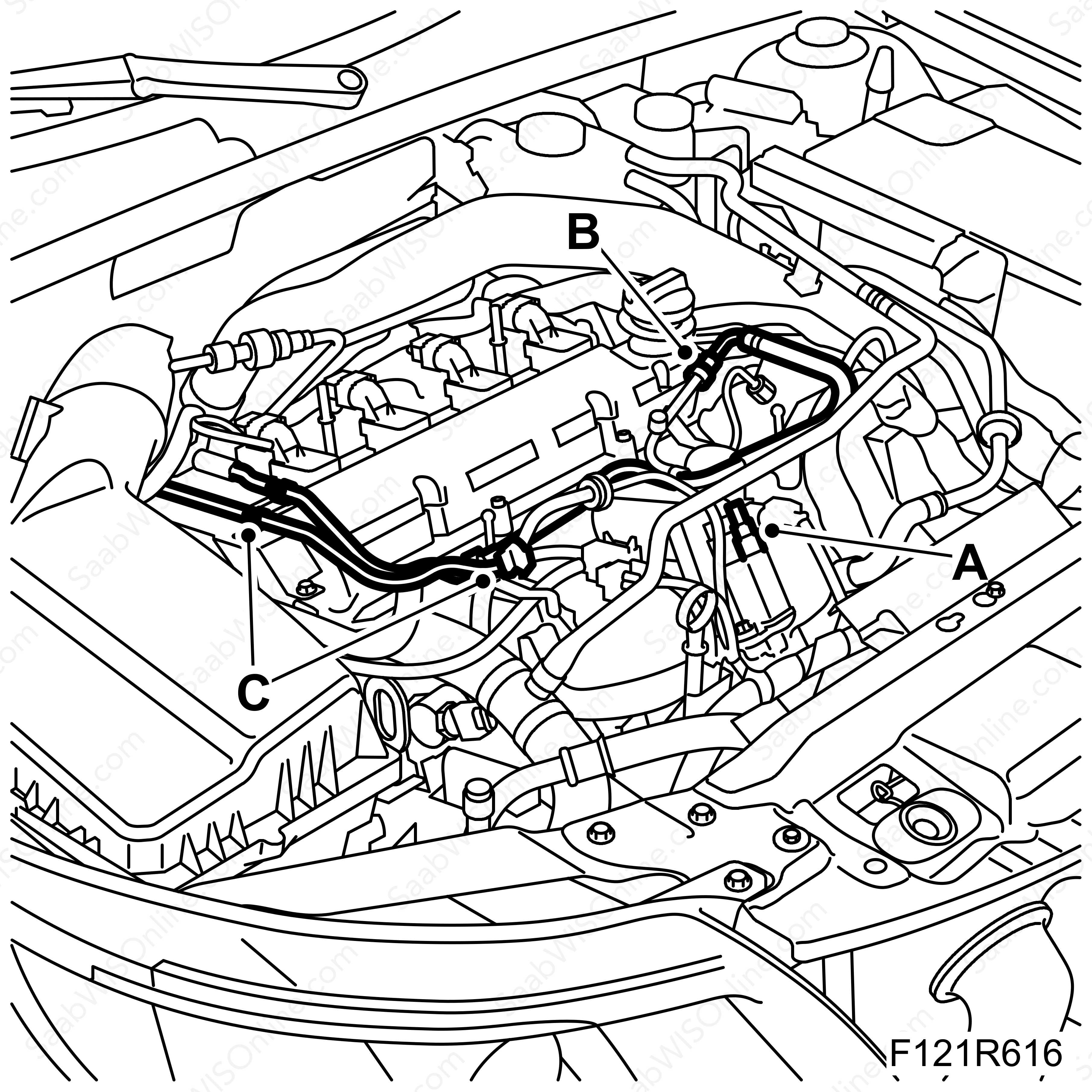

Release any pressure in the fuel system by carefully pressing the service valve needle. Collect any fuel spill. Detach the fuel line (A) from the high-pressure pump. Plug the fuel lines. Use

82 92 948 Plugs, A/C system assy

.

|

|

35.

|

Disconnect the quick coupling (B) for the breather line and detach the fuel line and bleeder lines from the clips (C) on the camshaft cover.

|

|

36.

|

Check and adjust the steering wheel and the steering assembly so that they are pointing straight ahead.

Warning

Warning

|

|

In order to avoid the contact roller for the airbag twisting and breaking the steering wheel must be secured via the steering column lock or by taping it to the panel.

|

|

|

|

|

|

|

|

37.

|

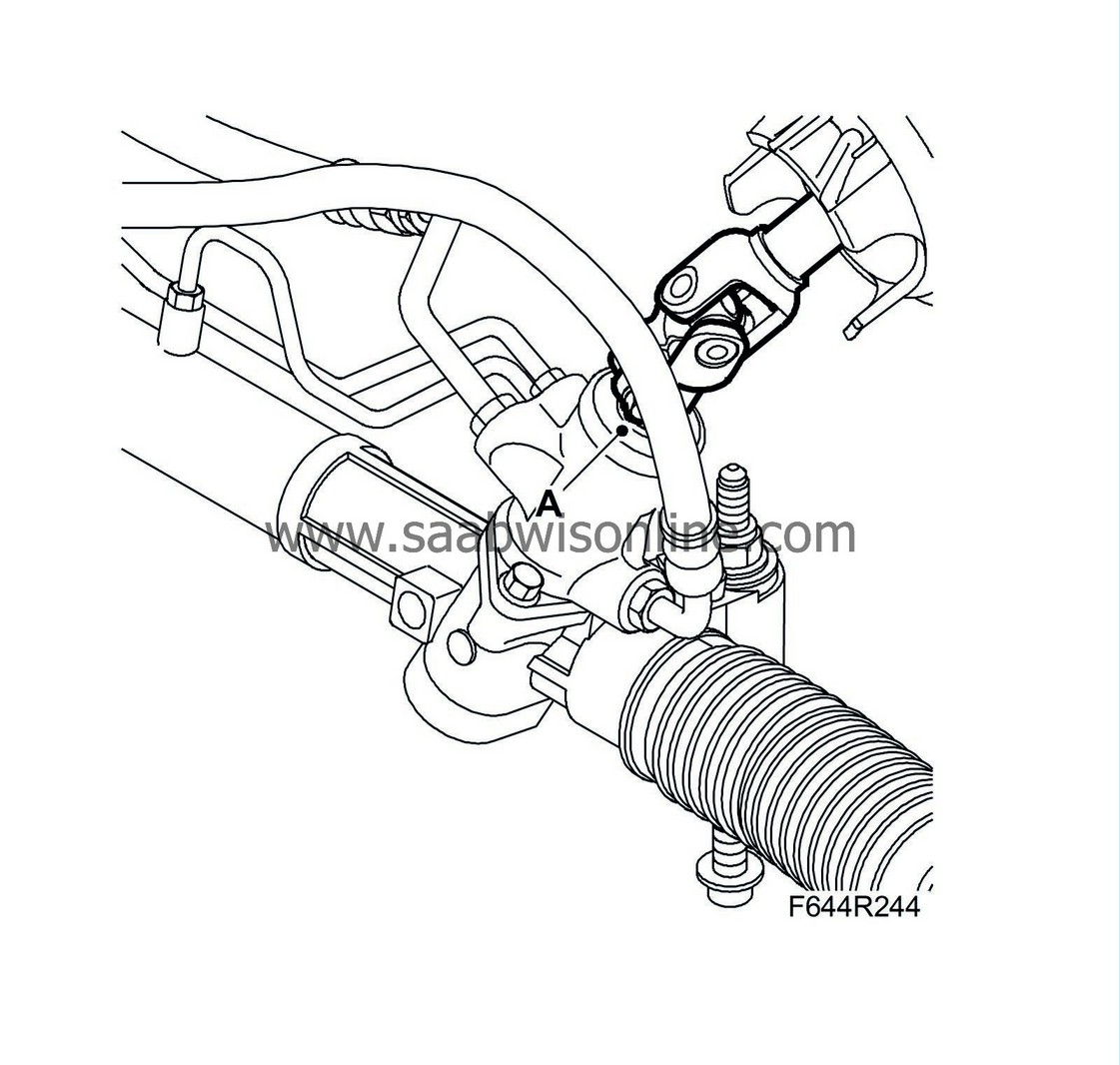

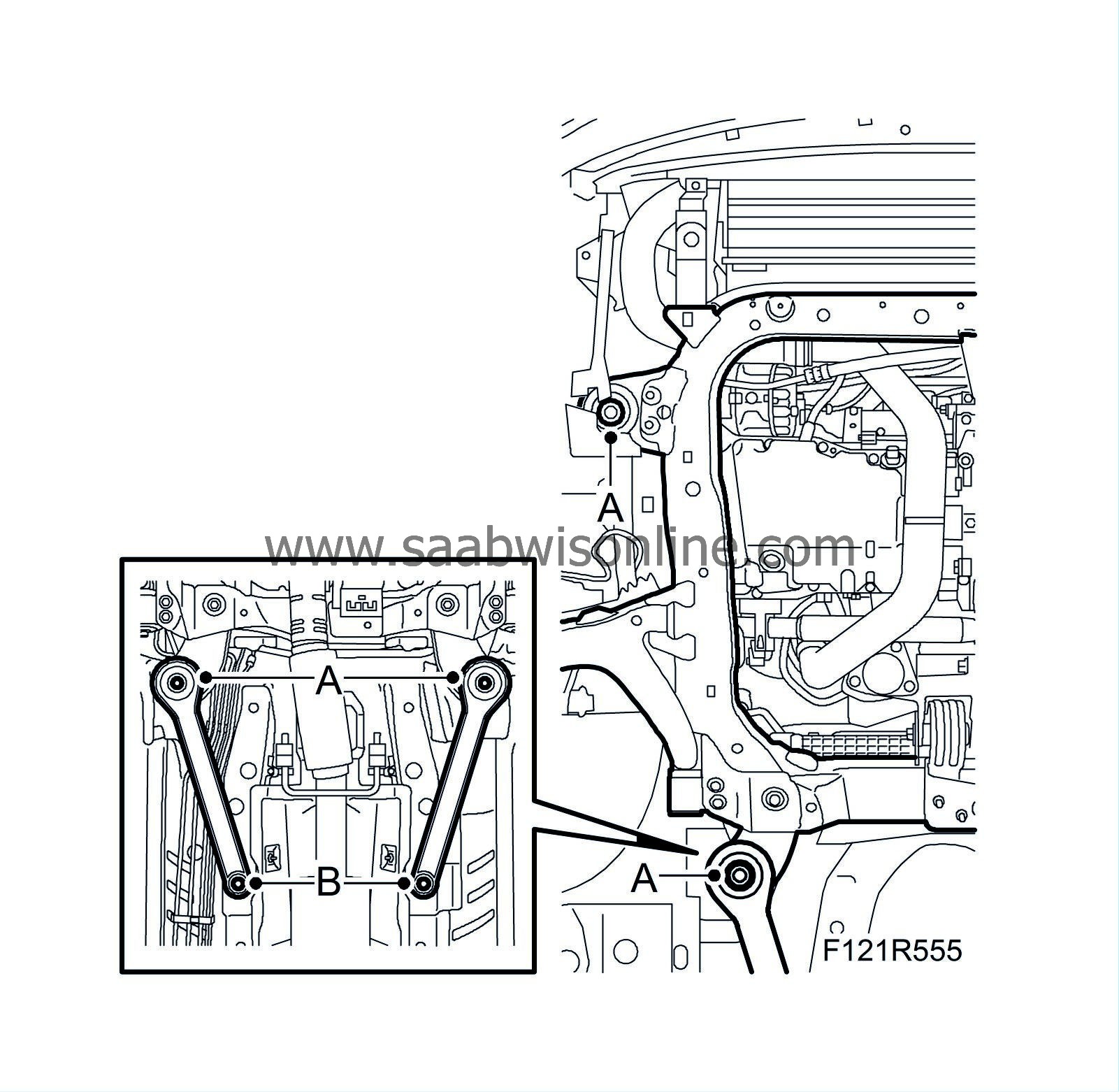

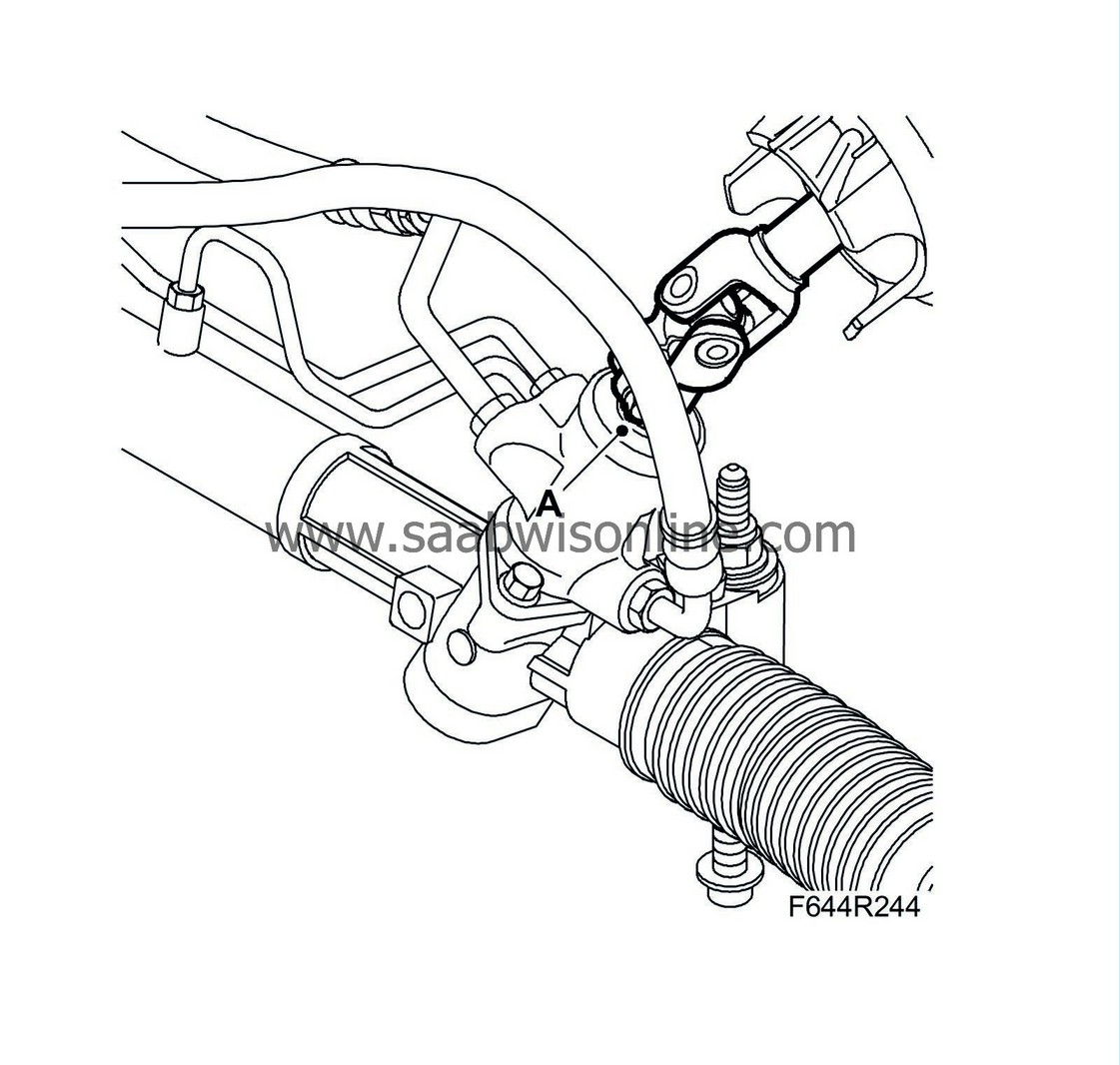

Raise the car and detach the steering shaft (A) from the steering gear.

|

|

39.

|

Unplug the AC compressor connector and remove the A/C compressor retaining bolts (B).

|

|

41.

|

Release the clips (A) holding the power steering pipe to the subframe.

|

|

42.

|

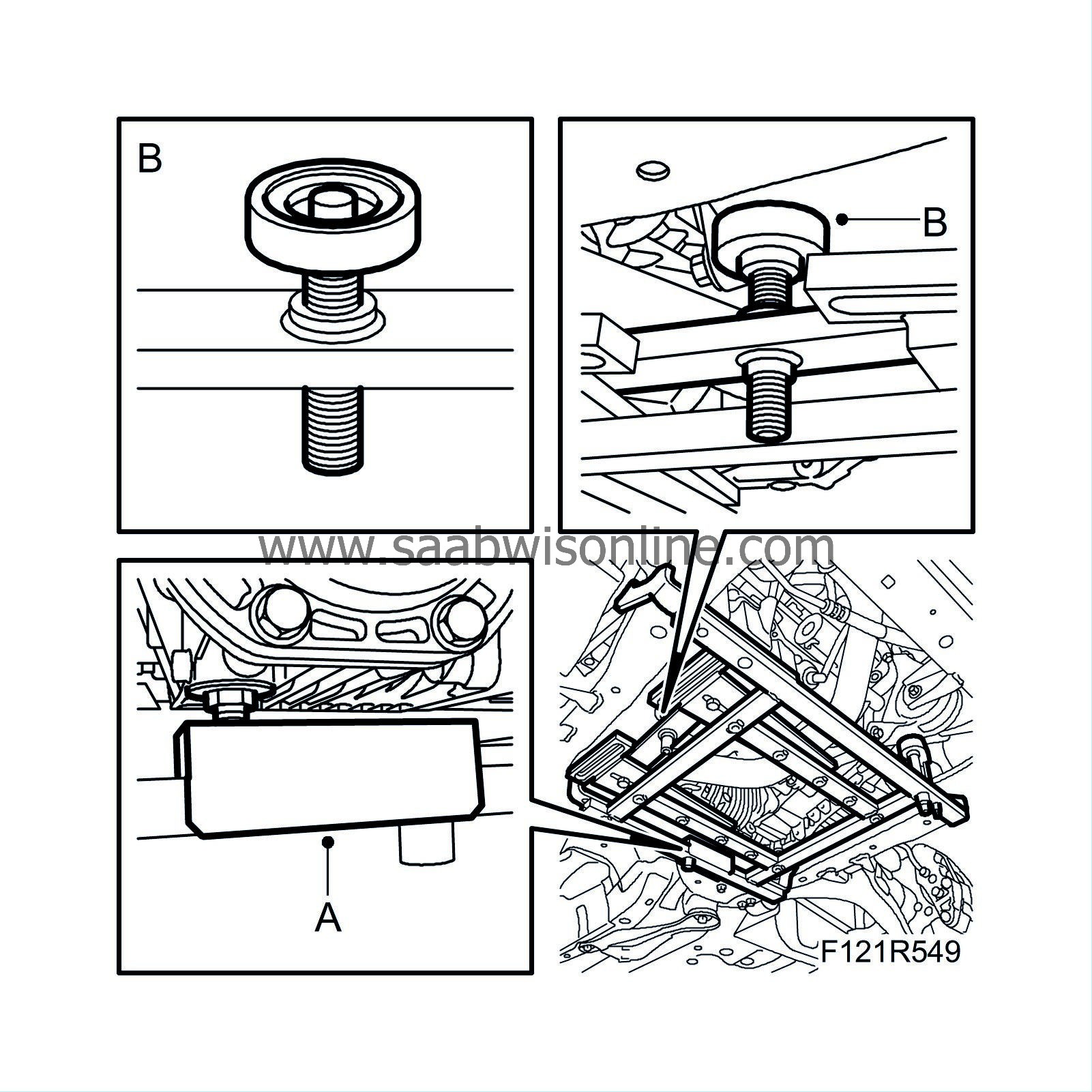

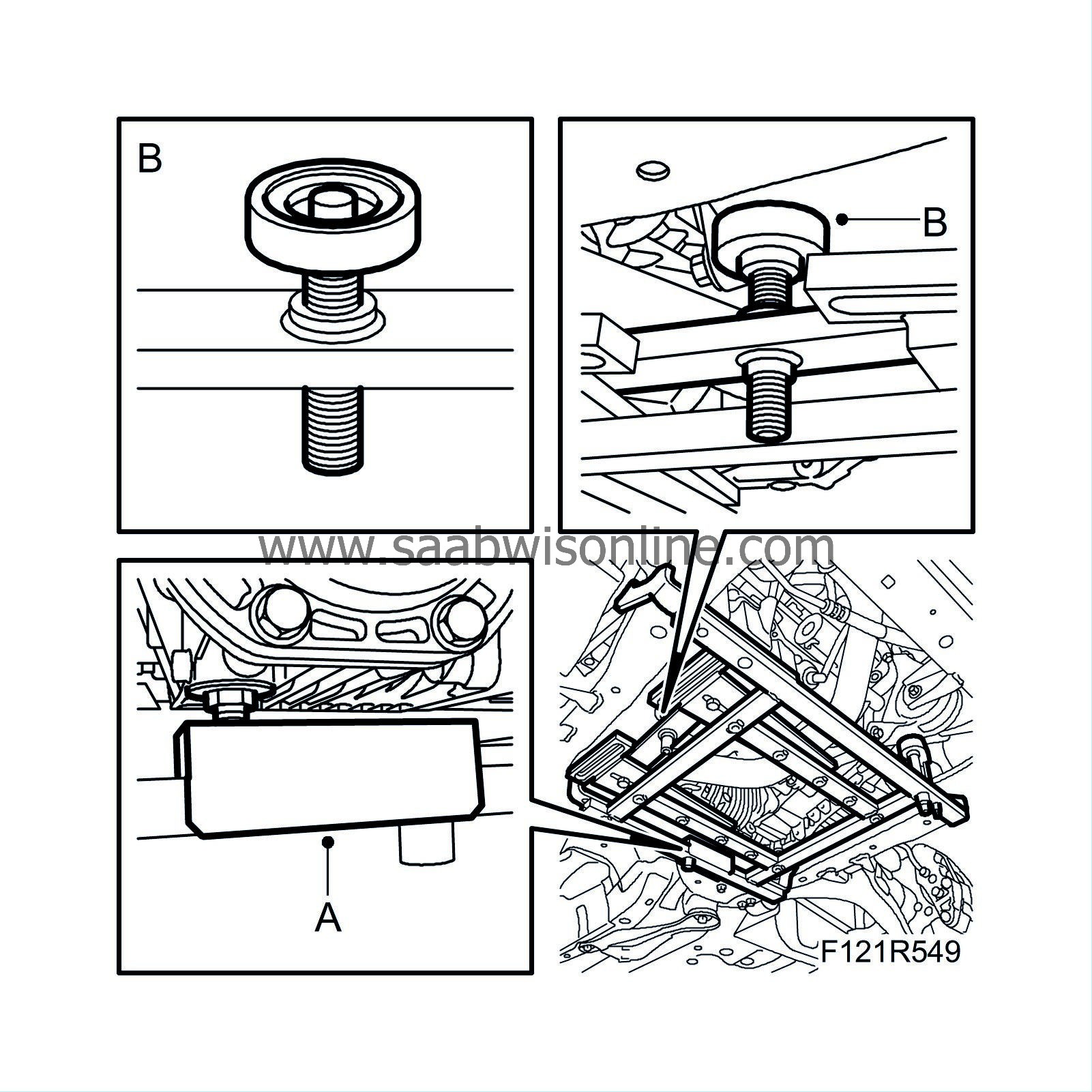

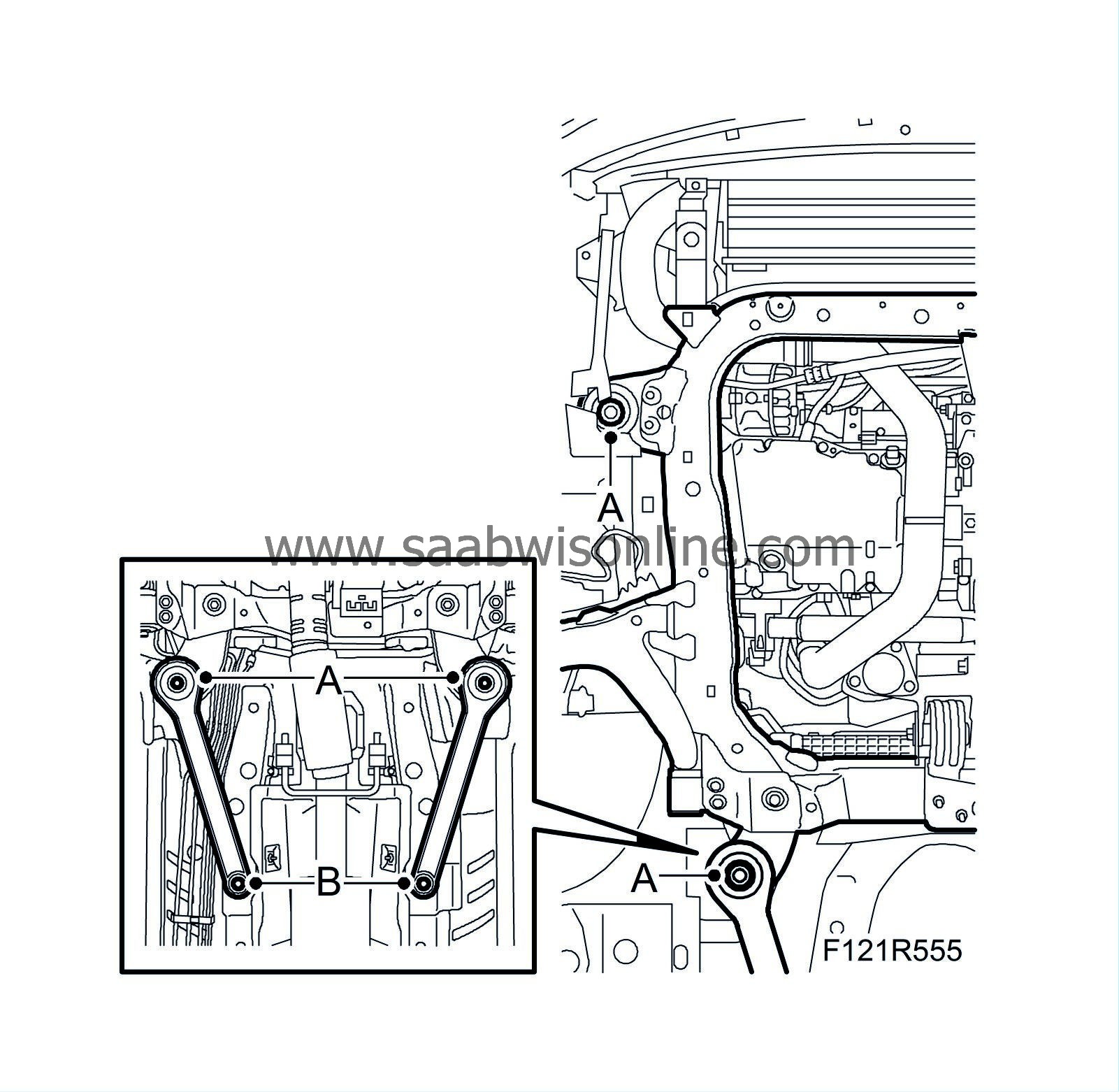

Fit parts of KM -6313 with KM 6313-200, see

Centring tool, engine and subframe

. Replace the rear adjusting screw for KM-6313-300 Support (A). Fit tool 89 96 878 (B) to KM 6313-200. Adjust the supports up so that they are aligned against the unit.

|

|

45.

|

Attach one

83 95 212 Strap

over the radiator member, lower the strap and wind it an extra turn round the A/C compressor to unload it.

|

|

46.

|

Remove the right-hand engine mounting (A).

|

|

47.

|

Remove the bolts (A) for the left-hand engine mounting.

|

|

48.

|

Lift the car and detach the drive shafts' centre nuts. Remove the drive shafts from the hubs approx. 10 mm. Use

89 96 951 Puller, drive shaft

.

|

|

50.

|

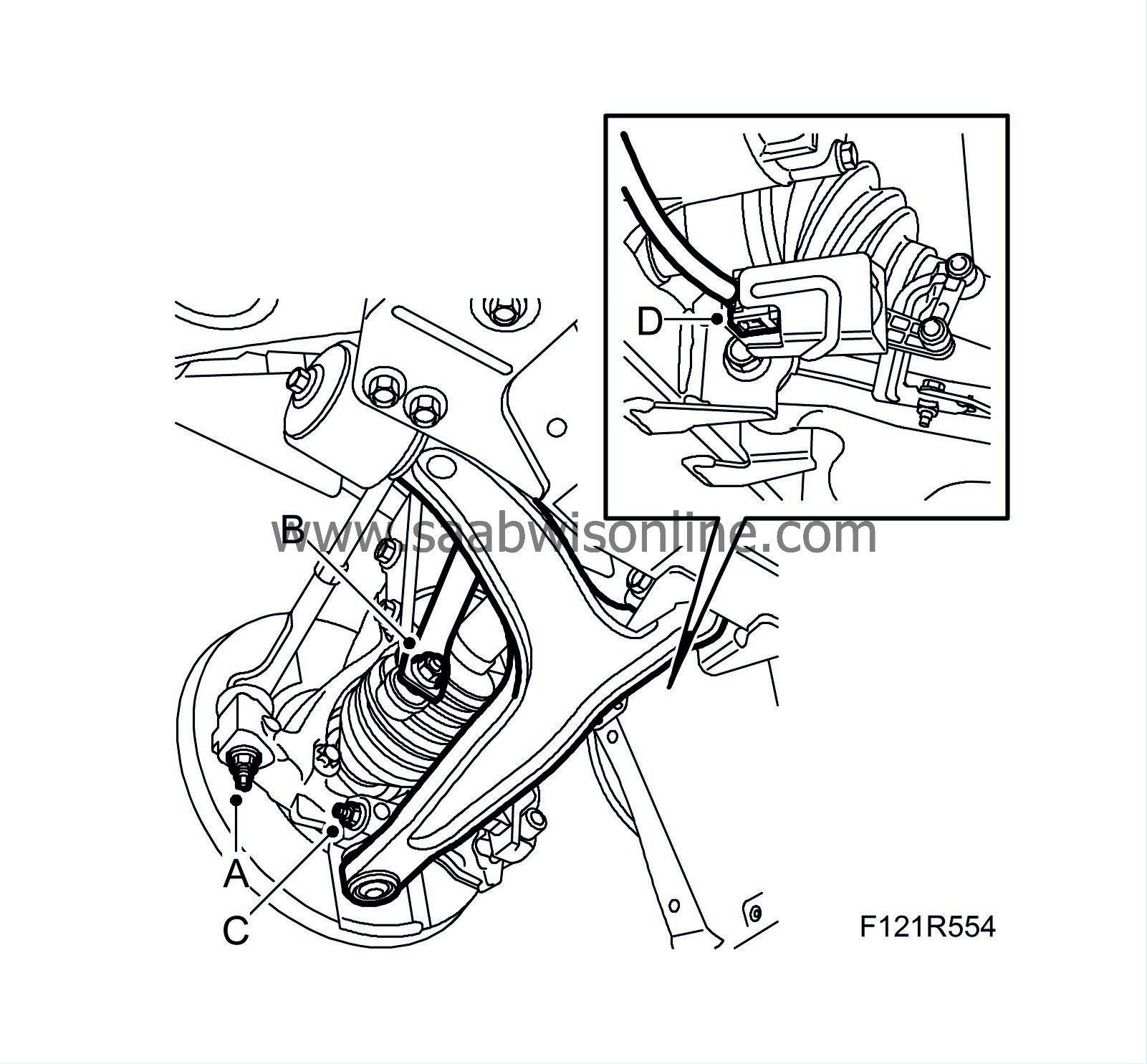

Undo the anti-roll bars' lower links (B) while gripping the flats with a thin spanner.

|

|

51.

|

Loosen the lower swivel joints (C) from the steering swivel members.

|

|

52.

|

Remove the cable tie and connector (D) for the angle sensor (option).

|

|

55.

|

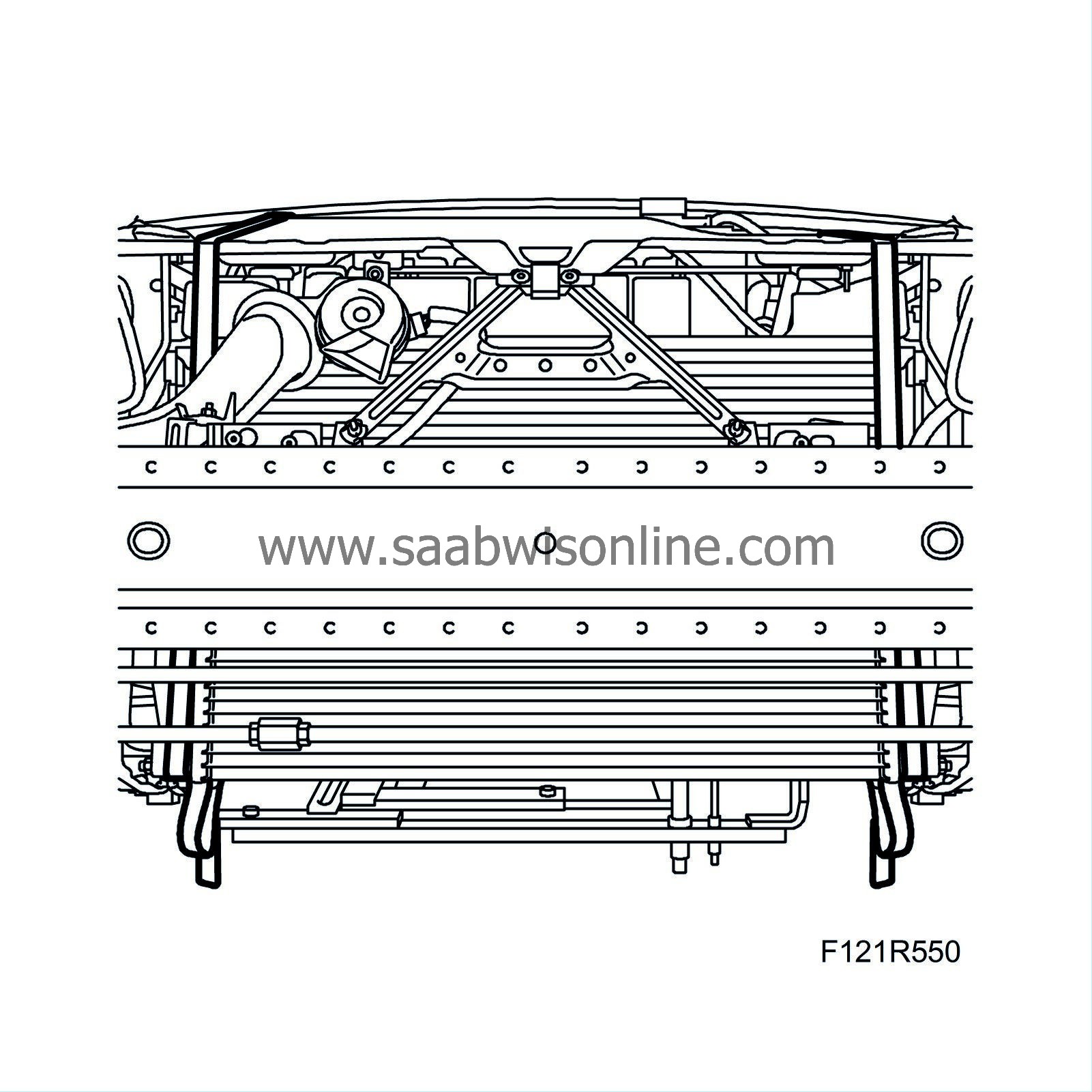

Raise the trolley lift slightly for firm contact and loosen the subframe's bolts (A) and the stays' bolts (B) from the body.

|

|

56.

|

Carefully lower the power unit using the trolley lift and turn down the suspension arms, and pull the drive shafts from the wheel hubs. Hold the A/C compressor out of the way. Make sure that nothing catches or sustains damage.

|

Warning

Warning