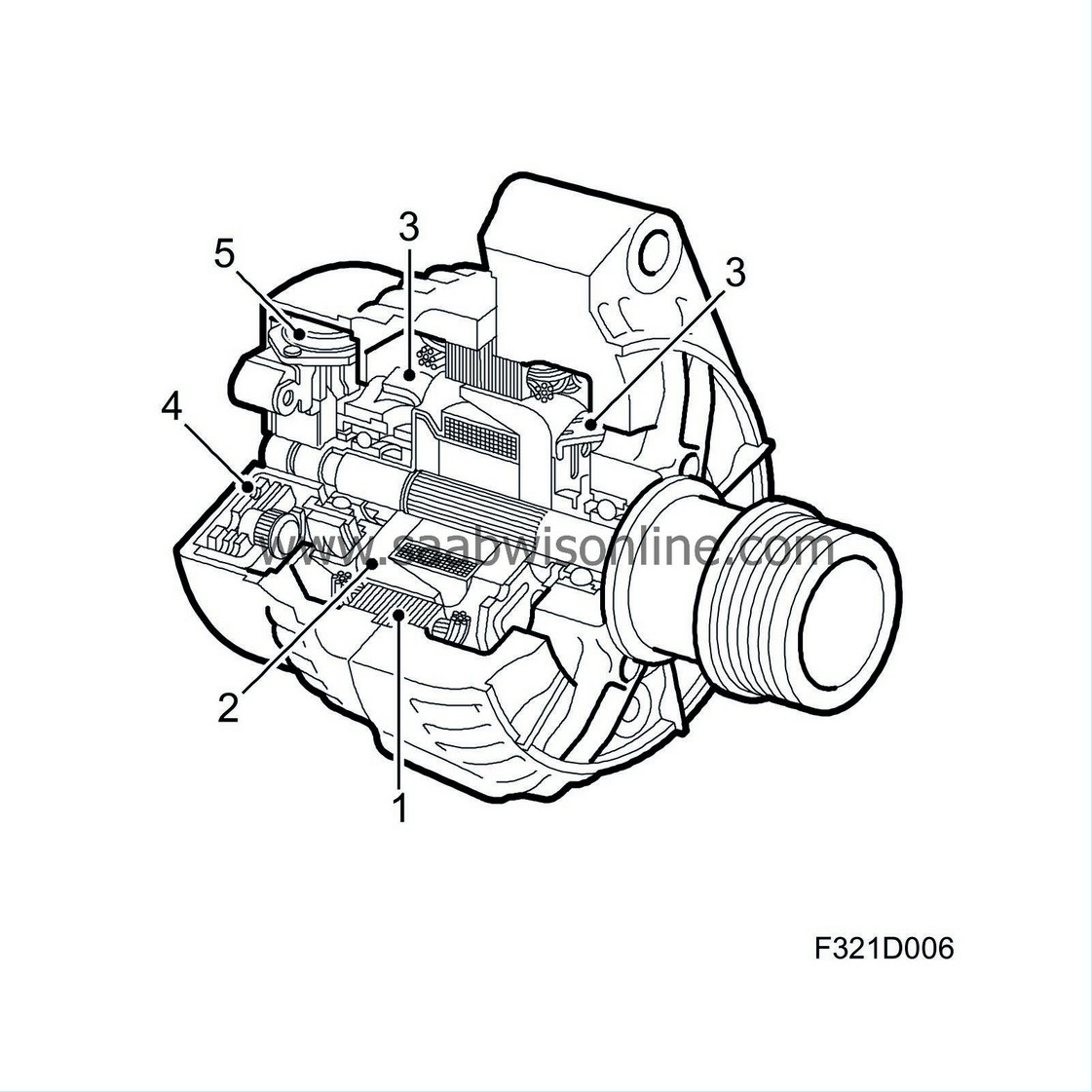

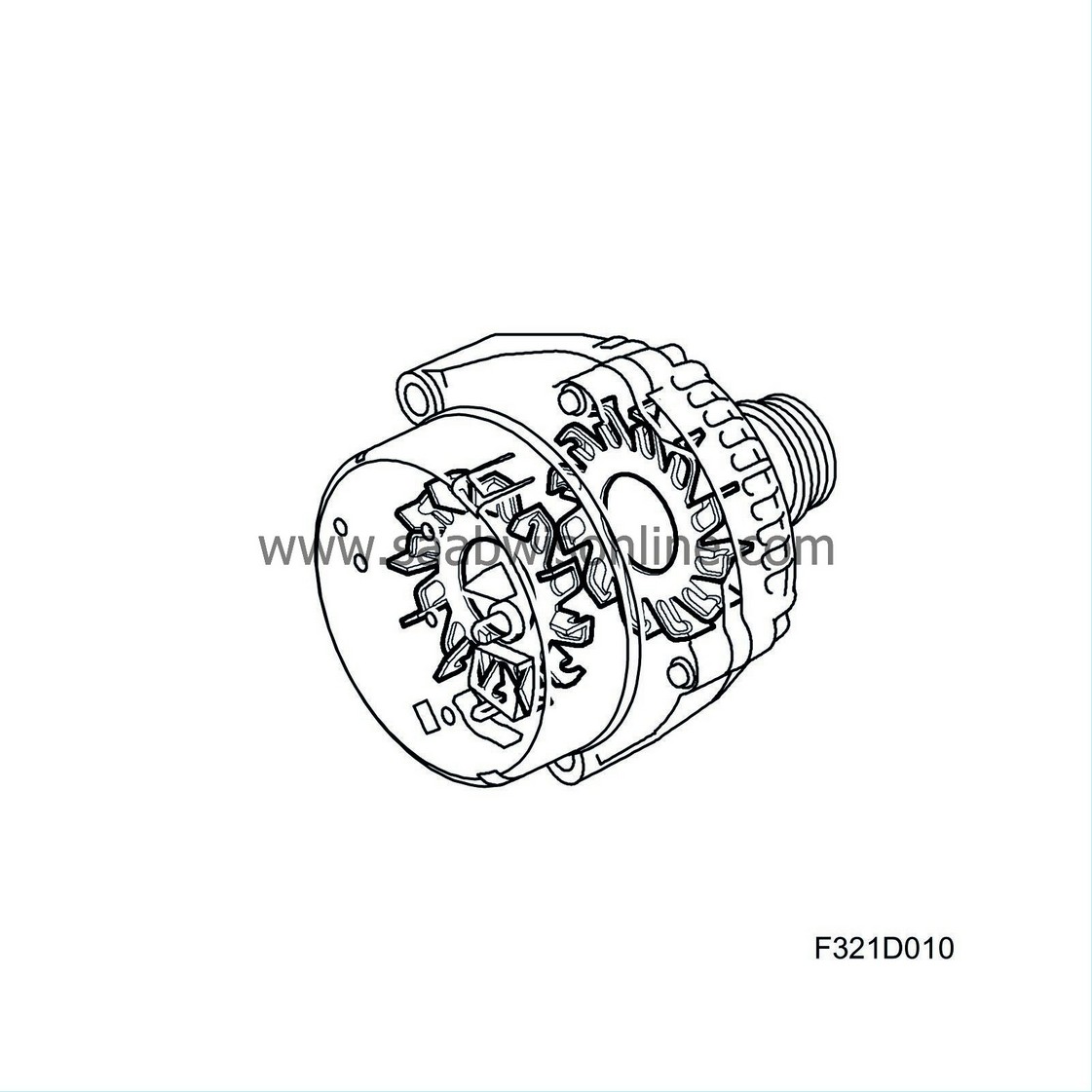

Detailed description

| Detailed description |

| 1. |

Stator

|

|

| 2. |

Rotor with slip rings

|

|

| 3. |

Integral fans

|

|

| 4. |

Rectifier

|

|

| 5. |

Voltage regulator

|

|

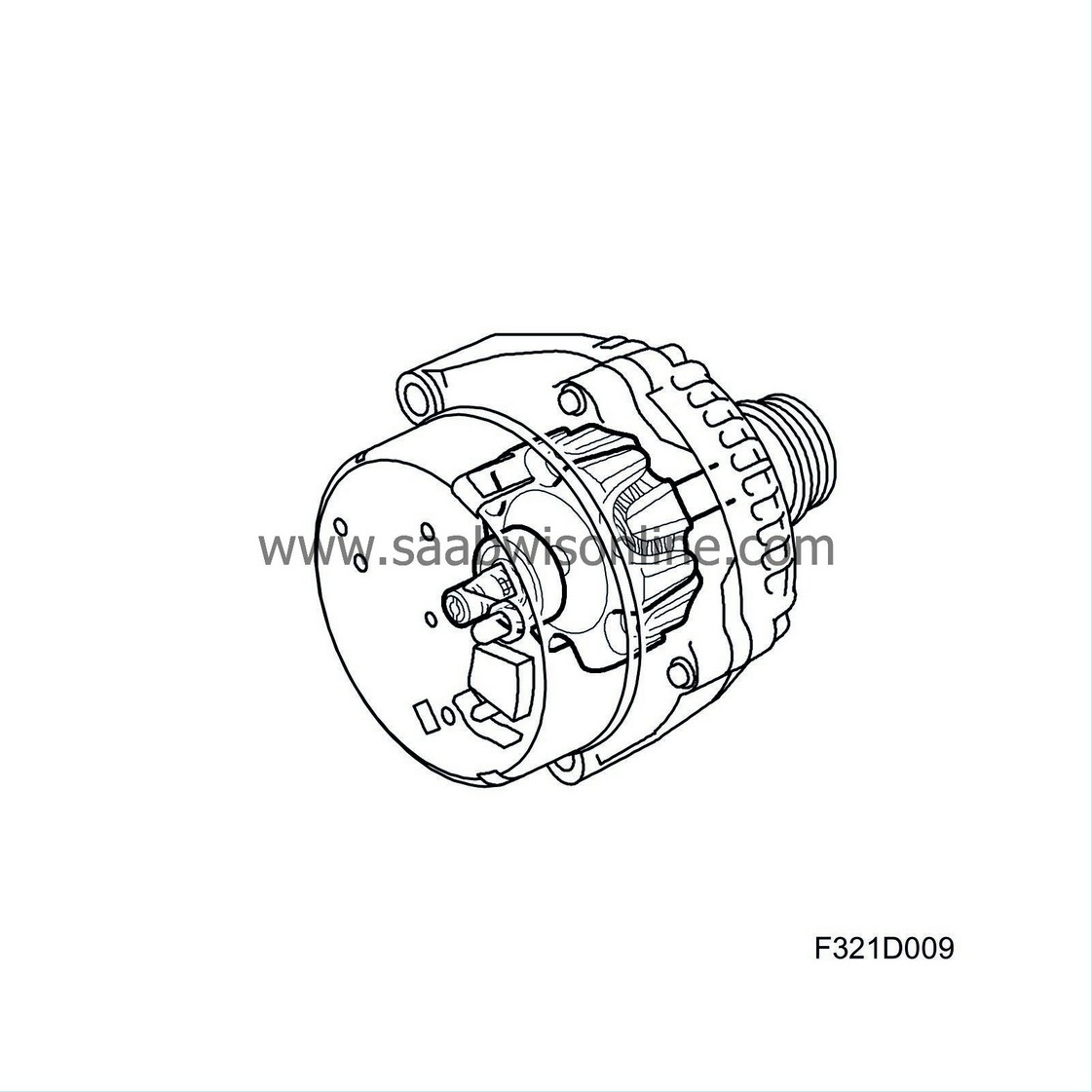

The alternator is driven by the engine with a poly-V belt from the crankshaft pulley. The gear ratio between the engine and alternator is shown for each alternator in the technical data.

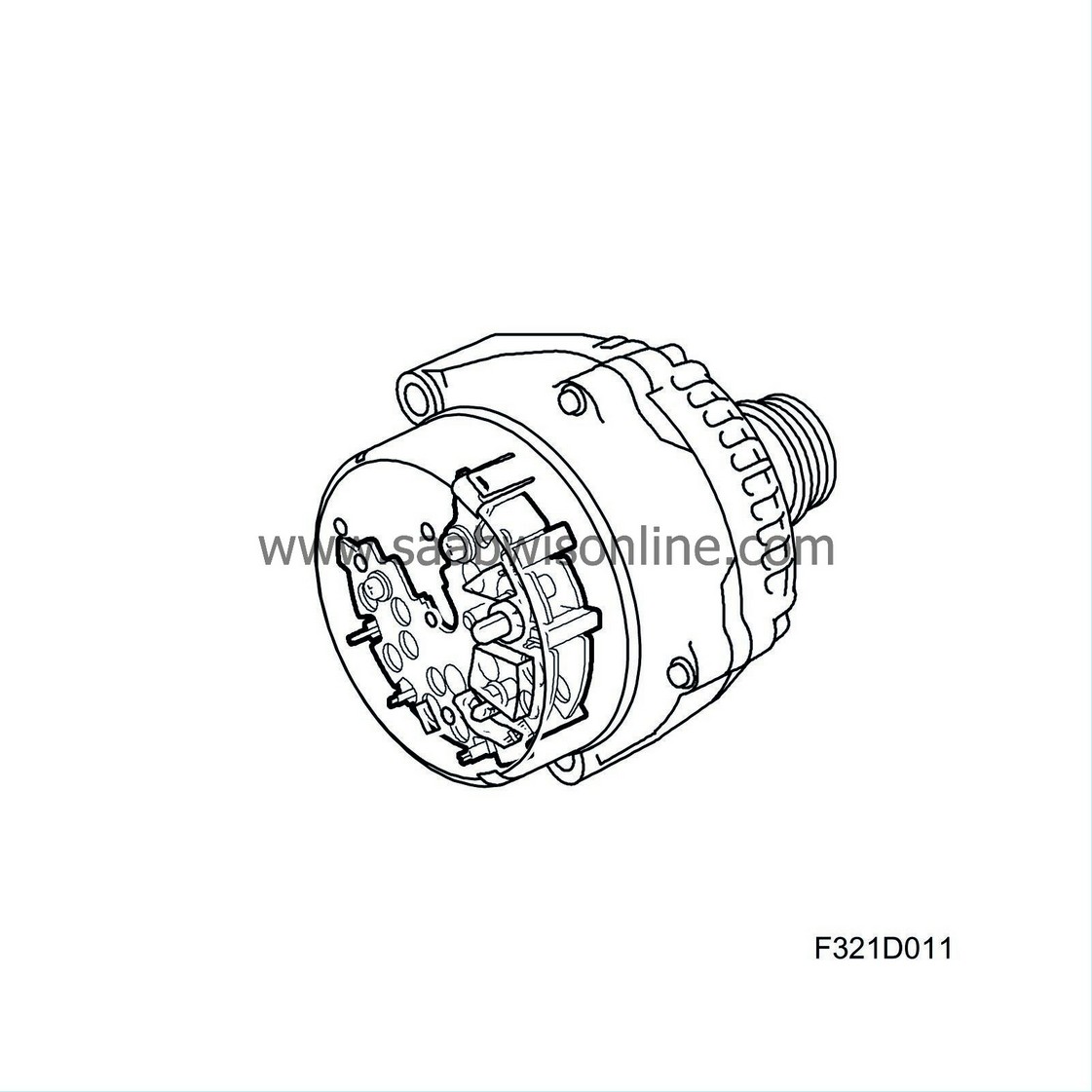

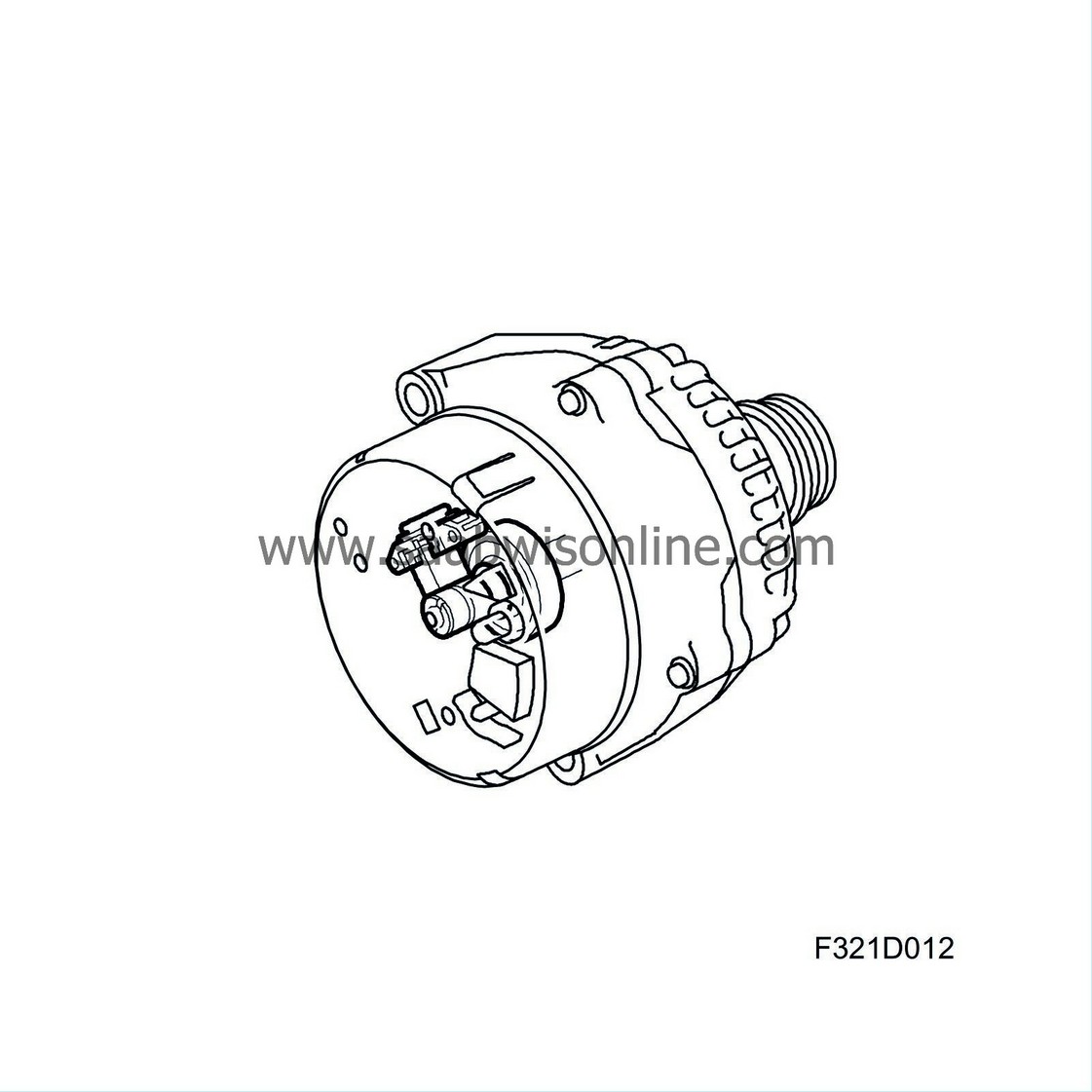

Cars with 4-cylinder petrol engine

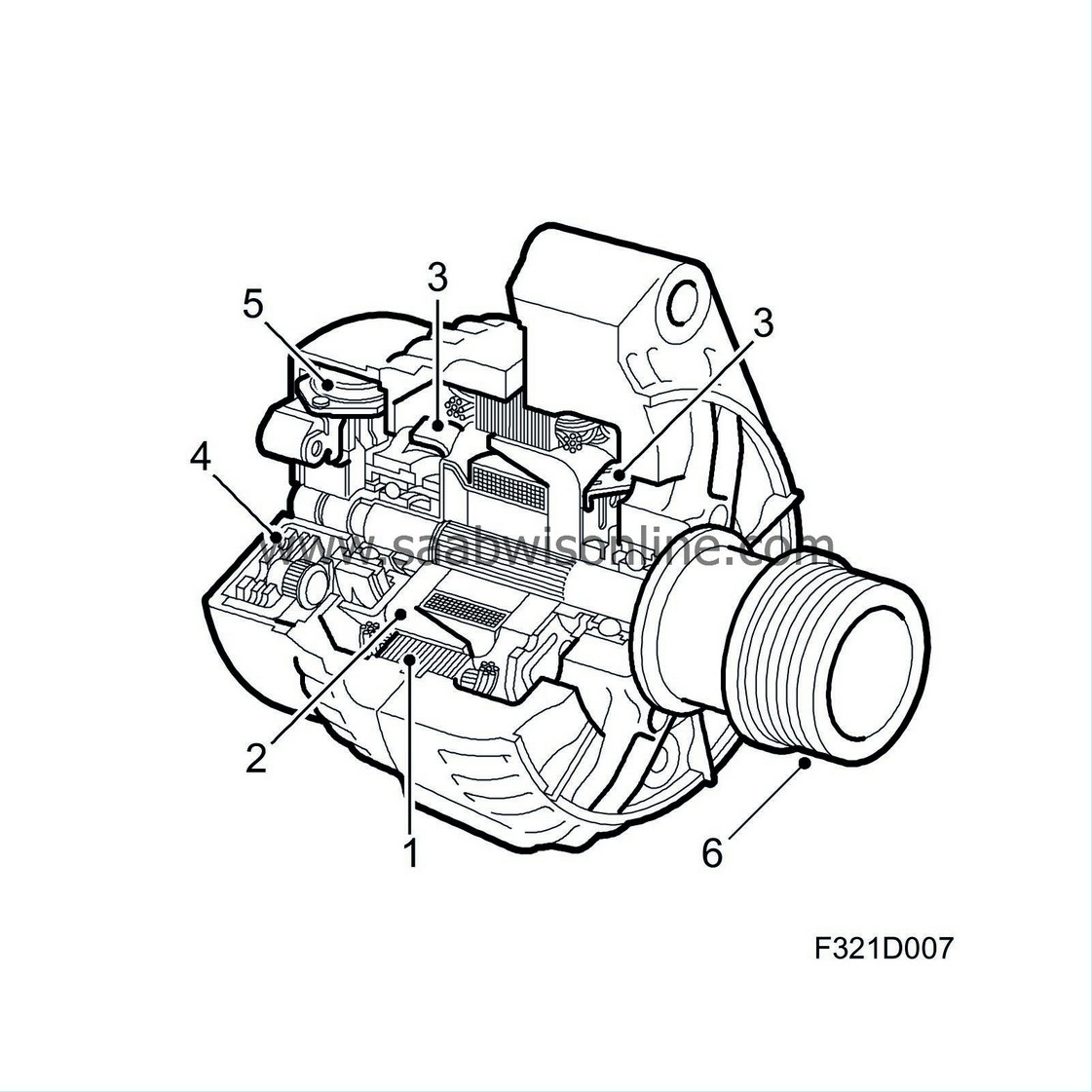

The alternator is of the AC type with integral charge regulator. The alternator is driven by the engine via a poly-V belt from the crankshaft pulley. Because of the variations in rotation which occur between the engine cycles, a freewheel function is introduced in the pulley which gives a more even rotation for the belt cycle. This in turn results in a longer service life of the poly-V belt.

| 1. |

Stator

|

|

| 2. |

Rotor with slip rings

|

|

| 3. |

Integral fans

|

|

| 4. |

Rectifier

|

|

| 5. |

Voltage regulator

|

|

| 6. |

Pulley with freewheel function

|

|

| Stator |

The stator is fixed and consists of plates with individually insulated grooves compressed together to a plate package. The stator winding's wave shaped coils are located in the grooves. They are delta connected at 120°, giving three-phase alternating current that is led directly to the rectifier.

| Rotor with slip rings |

The rotor consists of two halves (claw poles) which engage with each other. The halves are pressed onto the rotor shaft and there are twelve claws on the rotor, that is, twelve poles. One half has six north poles and the other half six south poles. Between the claw pole halves are magnetisation windings attached to the rotor shaft. The magnetisation windings consist of a circular coil surrounded by the claw poles. Between the claws, which rest on the slip rings, a magnetisation voltage is applied from the regulator.

| Integral fans |

The heat developed in the alternator during operation can cause damage to the alternator. The alternator has two integral fans to dissipate the heat. The fans are driven by the alternator rotor shaft.

| Rectifier |

The alternating current produced by the alternator's stator winding must be converted to direct current before it can be used in the car's electrical system. The current is converted by means of six Zener diodes, two per phase winding.

| Voltage regulator |

The purpose of the regulator is to keep the alternator voltage constant over the entire engine speed range, irrespective of the alternator load and rotation speed. If the generated voltage exceeds the specified nominal value (approx. 14 V), depending on load, the regulator lowers the magnetisation flow. The alternator magnetisation diminishes and the voltage from the stator windings drops. When the voltage has dropped below the nominal value (approx. 14 V), the magnetisation flow increases and hence the alternator voltage rises until the nominal voltage is again exceeded. This process is repeated continuously.

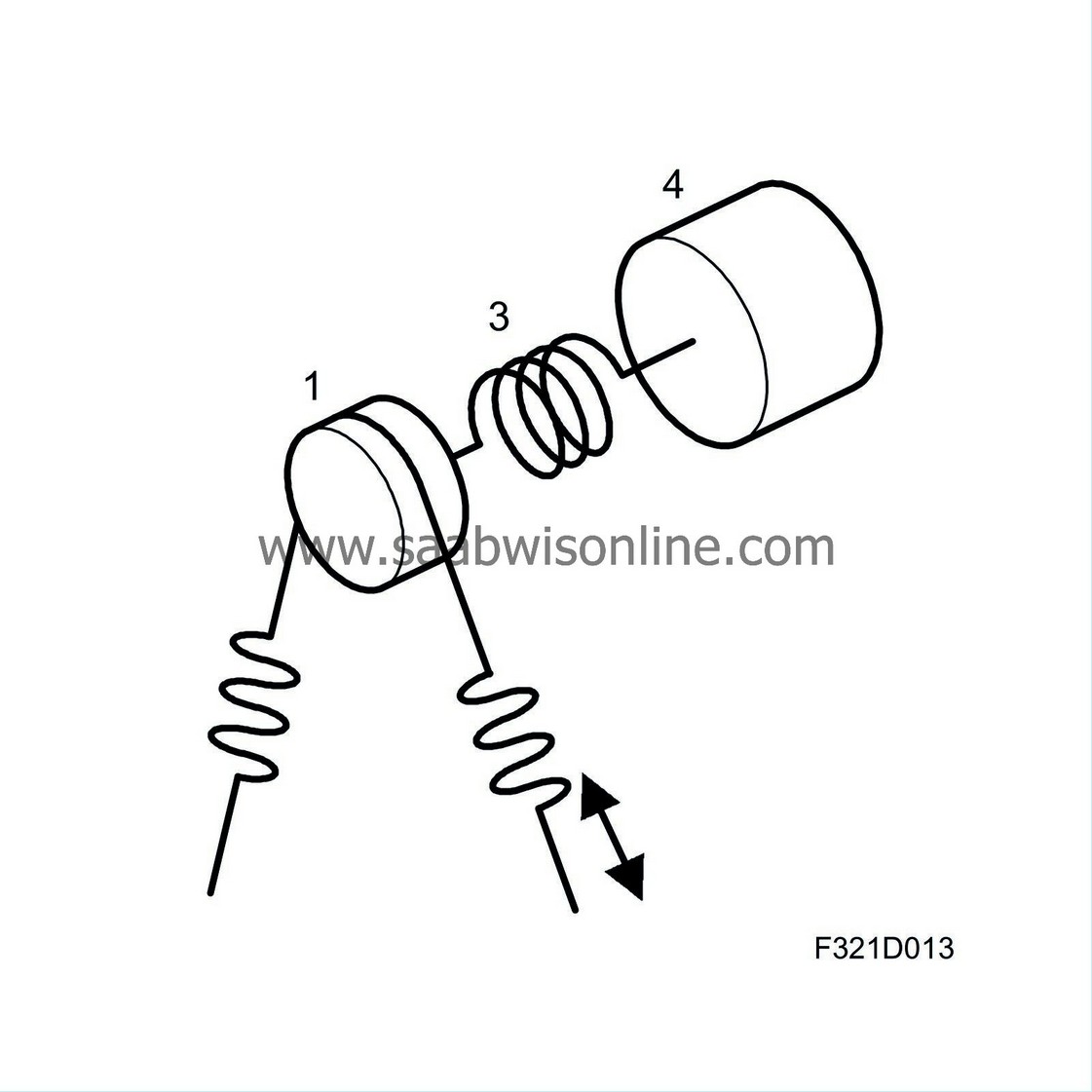

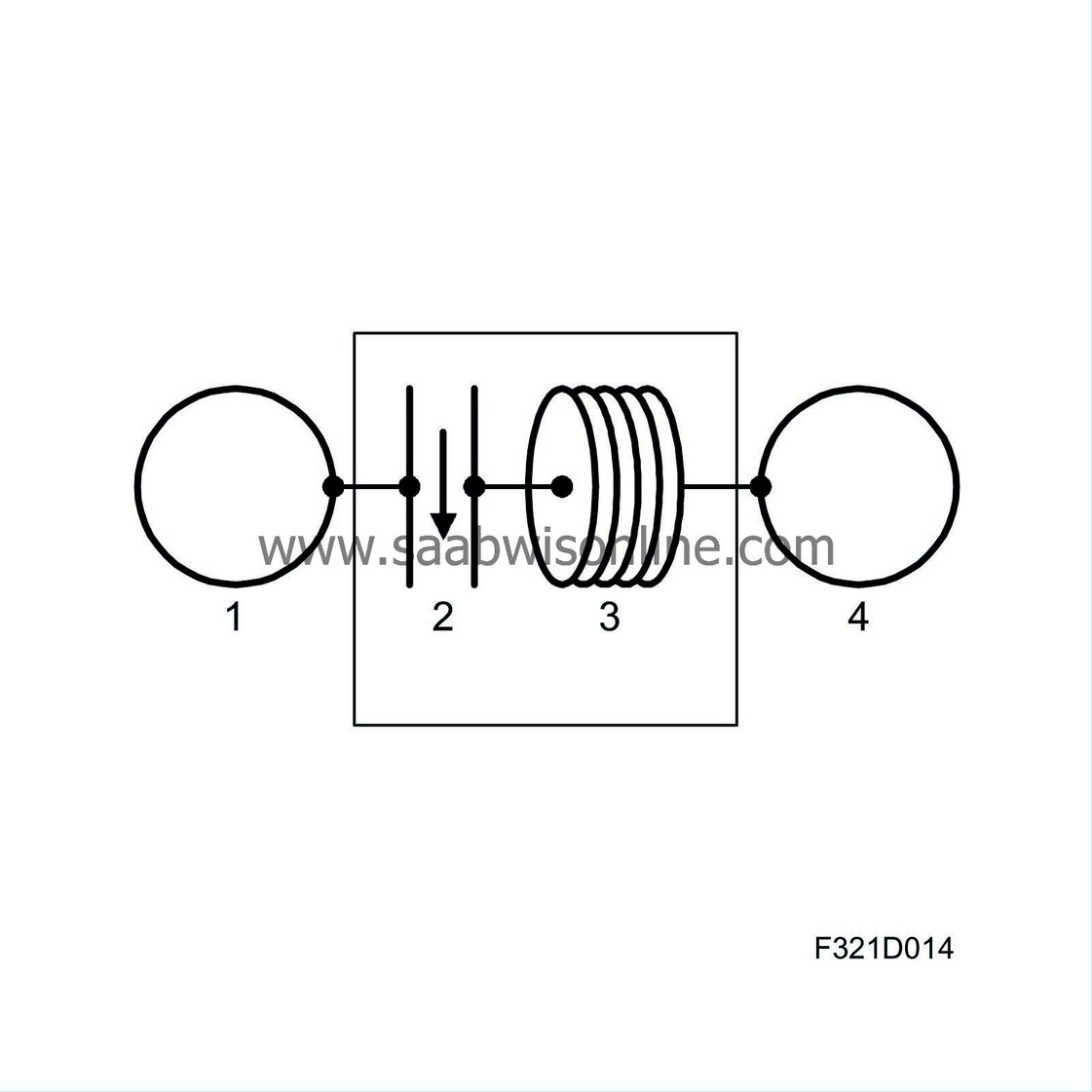

| Pulley with freewheel function, 4-cylinder petrol engine |

| 1. |

Belt pulley

|

|

| 2. |

Freewheel

|

|

| 3. |

Vibration damper

|

|

| 4. |

Alternator

|

|

The engine speed decreases slightly between power strokes, which means the alternator's rotation is slowed by the engine. To avoid this, while gaining smoother running over the belt circuit, with less jerking on the poly-V belt, the alternator is equipped with a freewheel built into the belt pulley. The belt pulley's freewheel function gives the poly-V-belt a longer life.

When the engine speed, between the power strokes is lower than that of alternator, the freewheel will disengage the alternator from the bely circuit. When the engine speed is greater than that of alternator, the freewheel is locked and drives the alternator.

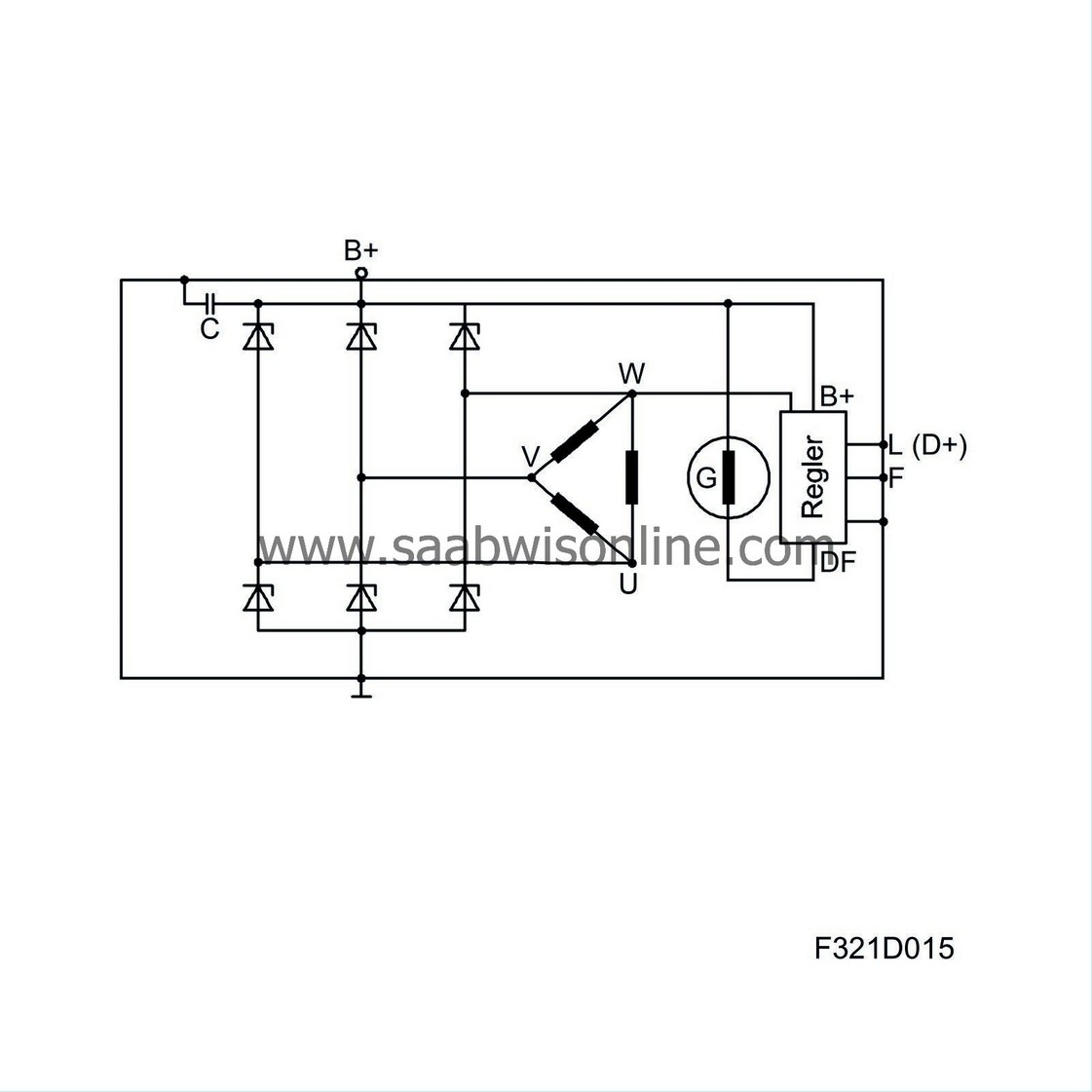

| Internal circuitry |

To convert the AC voltage produced by the stator windings into DC voltage, sex Zener diodes are used. The stator windings form three phases and are delta-coupled.

The magnetisation voltage comes from the engine control module when the engine starts, which means that the alternator begins to charge. When the alternator charges, the magnetisation voltage comes from the B+ connection. This means that no separate magnetisation diodes are required.

The sex rectifier diodes are bridge-coupled. The diodes are pressed into a diode holder. Depending on polarity, the diode holder is either isolated from the casting or directly connected to it. The magnetisation winding sits on the rotor which is designed with pole claws. Every other claw serves as a north pole and every other claw as a south pole. The magnetisation winding ends are connected to slip rings via which the magnetisation current is supplied.

| Alternator, description of operation |

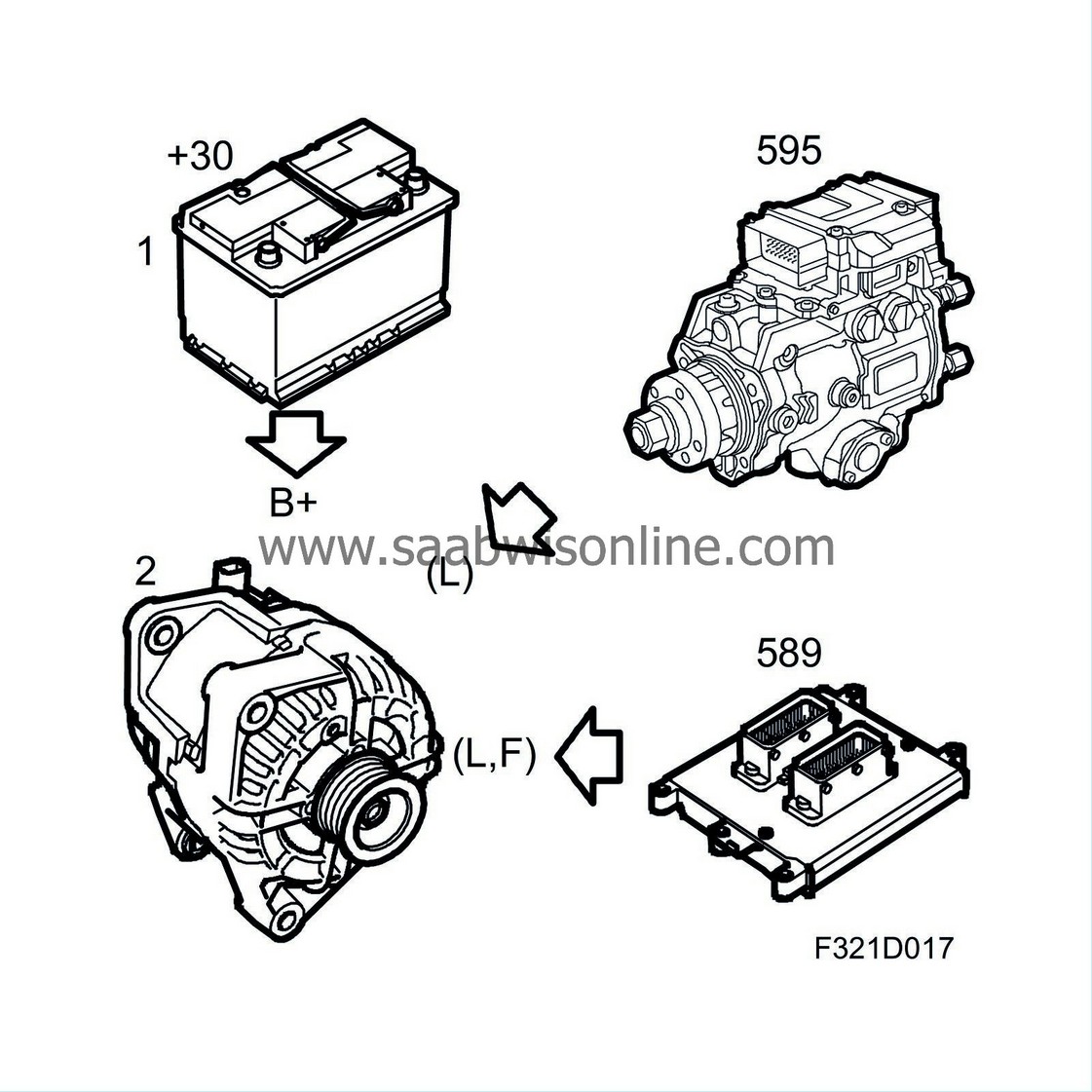

When the engine starts, the engine control module (ECM) sends a signal to the alternator connection L. The alternator connection L is coupled to the magnetisation winding, which means that the alternator begins to charge. To maintain the charge, the engine control module continuously sends out a signal to connection L.

When the rotor rotates in the alternator, the magnetic field around the rotor also starts the rotor to rotate and in doings so an alternating current is generated in the stator. The alternating current is rectified when it passes the diodes and is then fed to the car's electrical system via B+. The voltage obtained from the stator winding also goes to the voltage regulator and affects its control function.

When the voltage rises above the nominal value (approx. 14 V) the voltage regulator reduces the current through the magnetisation winding. The strength of the magnetic field decreases as well as the alternating voltage generated in the stator winding. When the voltage drops below the nominal value, the magnetisation current increases again, the magnetic field increases and with that the charge.

If the engine idle speed falls below the programmed speed, the signal from the engine control module to the connection L is broken. This means that the alternator does not receive any magnetisation and does not charge. The engine load is reduced and the risk of stalling avoided.

Connection L is also the diagnostic lead from the alternator to the engine control module. If the alternator does not charge, a symbol and a warning indicator are displayed on MIU and the engine control module generates a diagnostic trouble code.

Connection F on the alternator in cars with petrol engine B207 / A20NFT/LHU informs the engine control module of the alternator load, that is to say, how much it is charging, so that the engine control module can correct the engine torque to avoid the engine speed changing as the alternator load changes. Connection F on the alternator is not used in cars with a diesel engine.

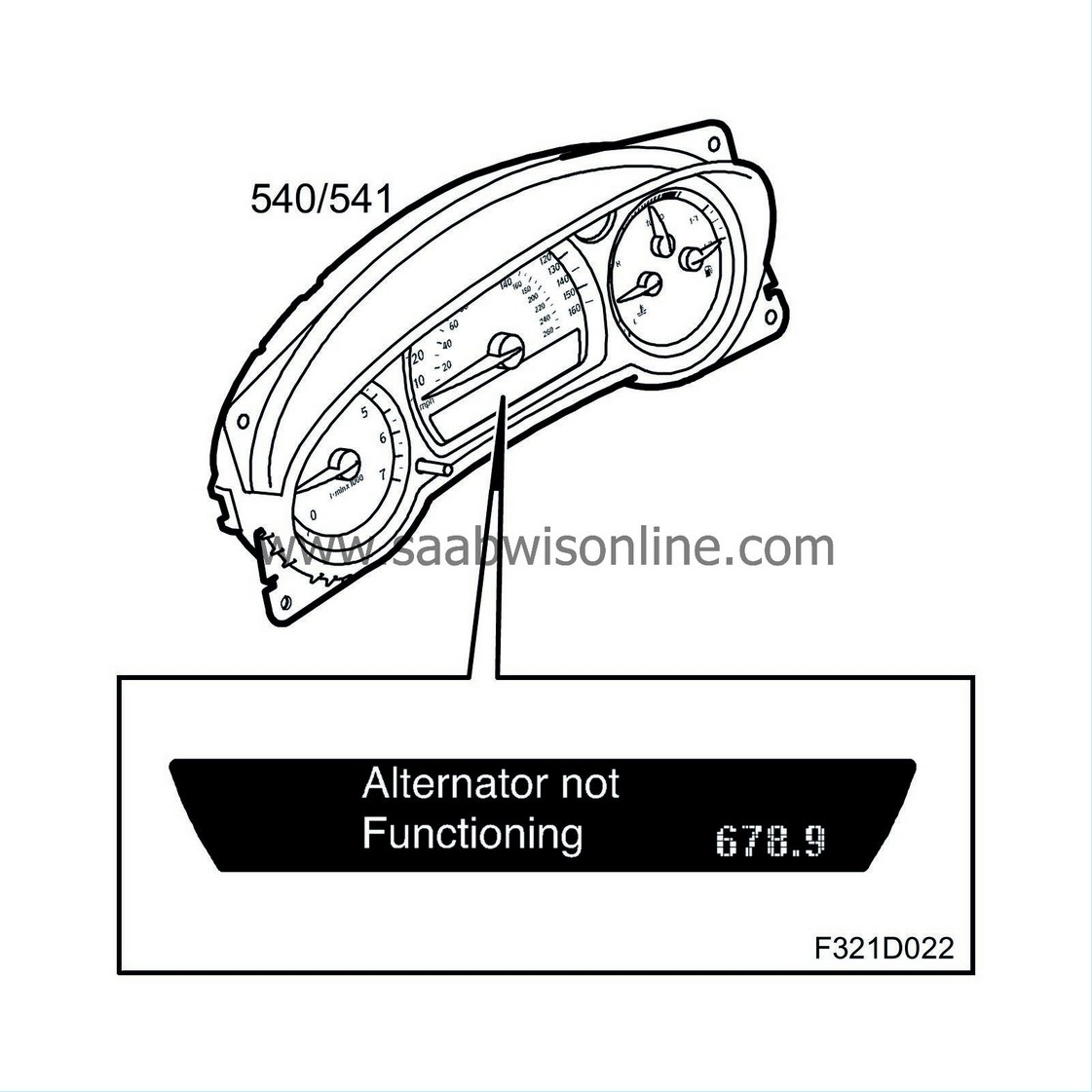

| Warning indicator for charging |

The warning indicator for charging provides the driver with an indication that the alternator is charging or not. If the alternator is not charging a symbol appears in MIU's right-hand instrument (a battery symbol) and a warning message in the middle of MIU ("Battery not charging. Stop immediately"). When no warning message is displayed the alternator is charging

Information about the alternator's charge state is sent via the line to control module, E39 (590). MIU receives information via a bus message from the control module, E39 whether the alternator is charging or not. A warning indicator is shown in MIU. When the ignition is on, and the engine is not running, you will not receive a warning message in MIU. A diagnostic trouble code is generated in control module, E39 when charging fails.

| Battery |

The terminal voltage of the battery is 12V and the capacity is dependent on the engine variant. The battery delivers current to the starter motor for starting the engine and supplies other power consumers with current while the engine is not running. The positive battery terminal is connected to the starter motor and to the main fuse box in the engine bay and its negative terminal is connected to the body and the engine.

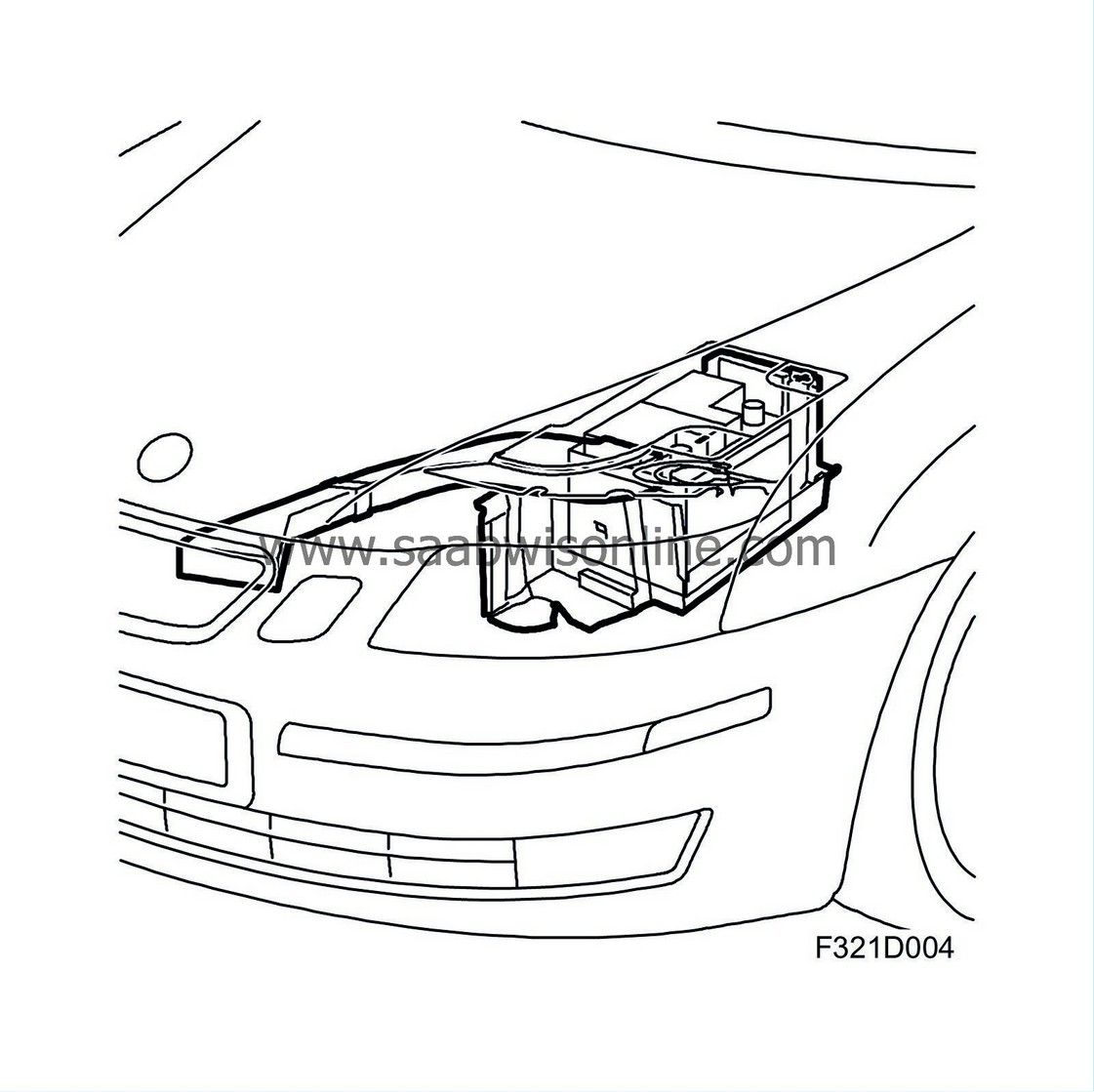

The battery is located on the left-hand side of the engine bay. On some variance, it is contained in a battery cover to reduce heating. An air duct takes in air via the car's grille. The air from the air duct passes through the battery cover and consequently cools down the battery.

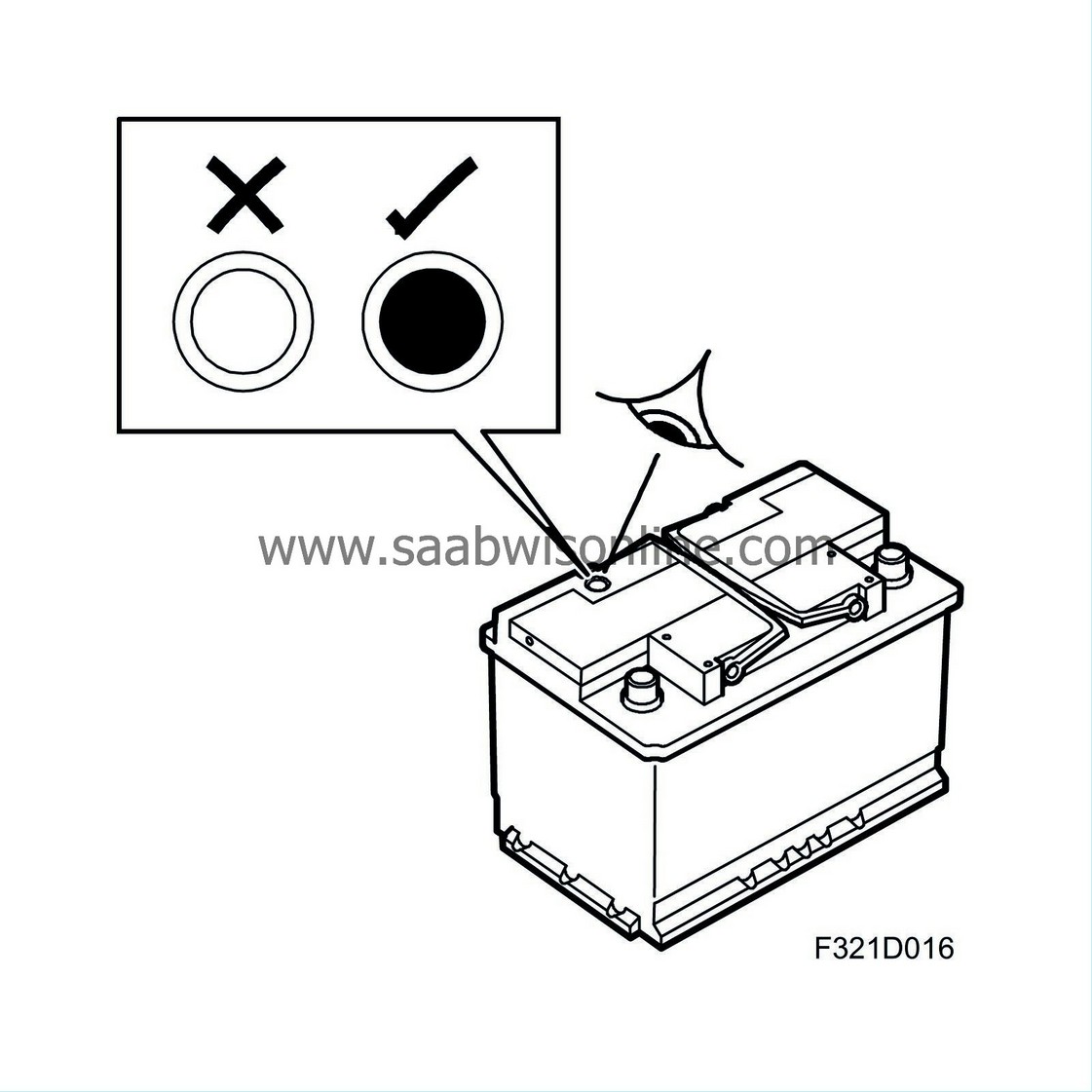

The battery electrolyte cannot be topped up. The battery electrolyte level is indicated by an indicator point on the top of the battery. If the indicator is dark, the level is OK. On low level the indicator is light and the battery should be changed.

| Important | ||

|

Turn the key to LOCK or remove it whenever the car is not being used. In OFF position, the battery will discharge within a couple of hours. |

||

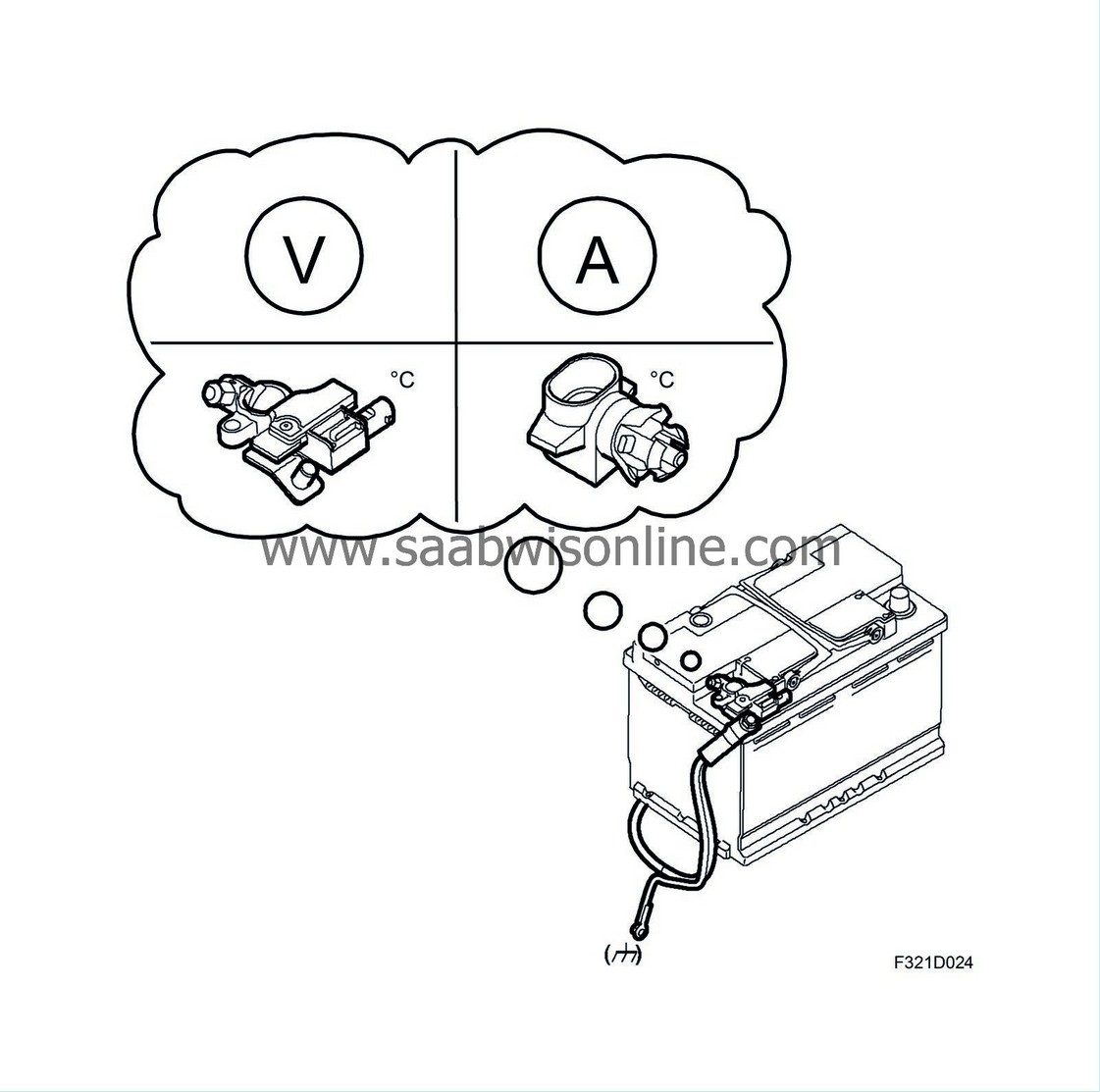

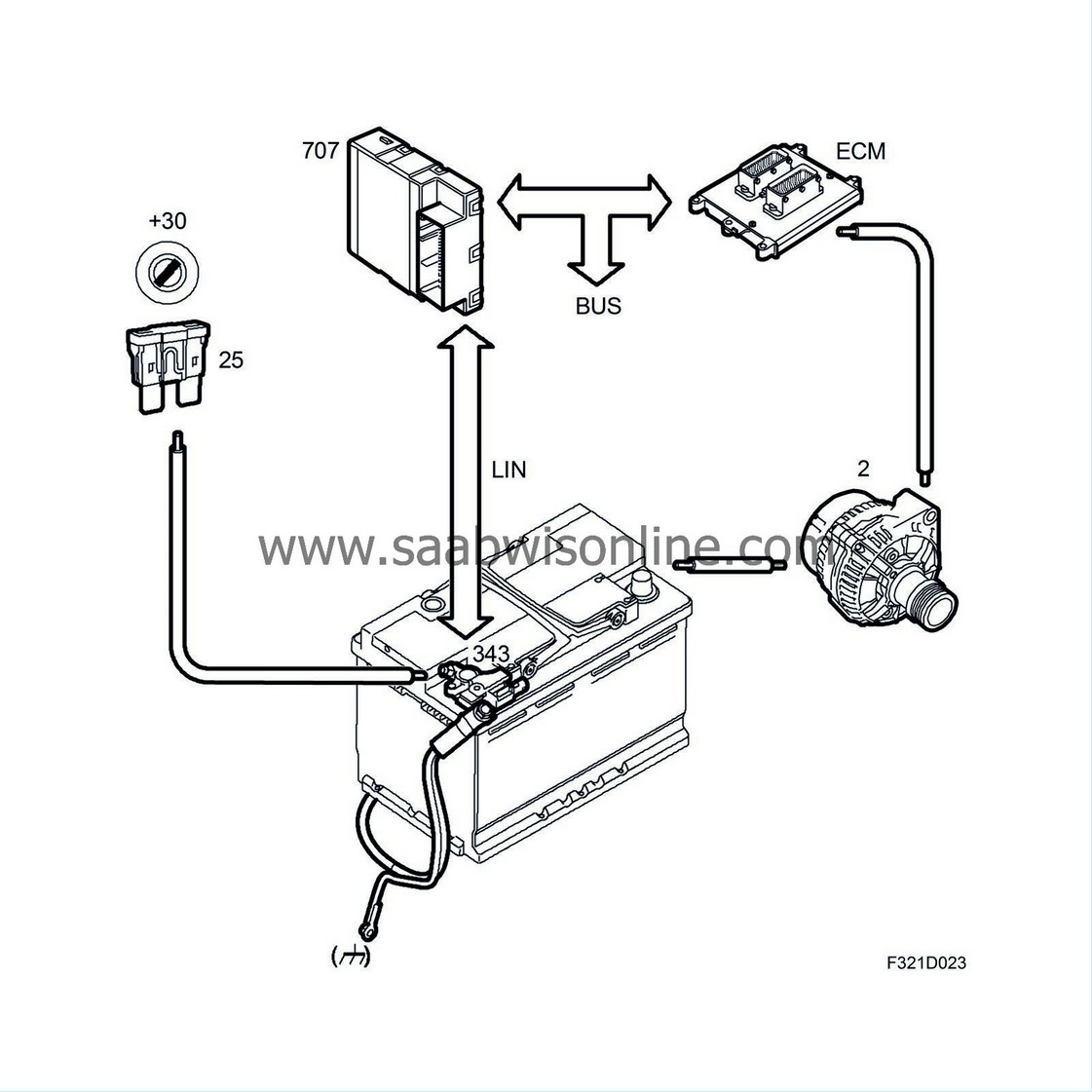

Battery sensor

The battery's SOC (State Of Charge) is calculated from the battery voltage after the battery has been at rest for several hours. Once the car is put in use again, the SOC calculated from the rest potential is used, this value is then corrected with the current (charging/discharging) through the battery.The battery sensor (343) measures the current magnitude and its direction to determine by how much current the battery is charging or discharging. This value forms the basis for calculating the battery's degree of charge, SOC, during operations.

The battery's degree of charge is defined as the battery's present capacity divided by its capacity as set out in the specification. The capacity is measured in ampere-hours, Ah. During the manufacture of the car the battery capacity (Ah) is programmed into the battery sensor. When the battery is replaced the capacity of the new battery needs to be programmed into the new one, if its capacity is different from the factory value.

The current is calculated by measuring the voltage drop over a current shunt built into the battery sensor. To be able to calculate the SOC correctly, the battery voltage and battery temperature must be known. The battery sensor measures the voltage and temperature. To achieve a correct battery temperature, the external temperature is used with a correction to the temperature measured by the battery sensor, this information comes from BCM via the I-bus.

The optimal charge voltage for any given situation is calculated based on the battery voltage, battery current, temperature and SOC.The battery must be charged optimally, neither too much nor too little, in order to reduce fuel consumption, high degree of charge and long battery life.

Should a situation arise where the alternator's charging current is insufficient to maintain the energy balance in the system (decreasing system voltage) then the BCM will request increased idling to increase the alternator's charging capacity. On the other hand, the alternator may, under certain circumstances when the battery SOC is high and the car's own consumption is low, turn off the alternator. This gives a fuel saving.