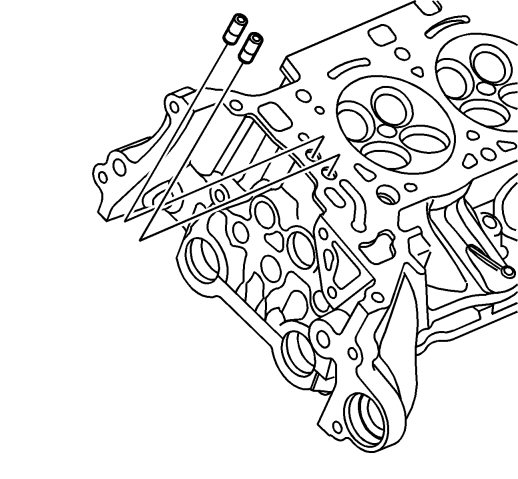

Cylinder Head Cleaning and Inspection

|

|

Cylinder Head Cleaning and Inspection

|

Special Tools

|

•

|

GE 8001

Dial Indicator Set

|

|

•

|

GE 8358

Carbon Removal Brush

|

|

•

|

EN 28410

Gasket Remover

|

|

•

|

EN 42096

Valve Guide Reamer

|

|

•

|

EN47909

Injector Bore and Sleeve Cleaning Kit

|

For equivalent regional tools, refer to

Special Tools

.

|

1.

|

Remove any old thread sealant, gasket material or sealant using

EN 28410

remover.

|

|

2.

|

Clean all cylinder head surfaces with non-corrosive solvent.

|

|

4.

|

Remove any carbon deposits from the combustion chambers using the

GE 8358

brush

|

|

5.

|

Clean any debris or build-up from the lifter pockets.

|

|

1.

|

Inspect the cylinder head camshaft bearing surfaces for the following conditions:

|

|

|

•

|

Excessive scoring or pitting

|

|

|

•

|

Discoloration from overheating

|

|

|

•

|

Deformation from excessive wear

|

|

|

•

|

If the camshaft bearing journals appear to be scored or damaged, the cylinder head must be replaced. DO NOT machine the camshaft bearing journals.

|

|

2.

|

If any of the above conditions exist on the camshaft bearing surfaces, replace the cylinder head.

|

|

3.

|

Inspect the cylinder head for the following:

|

|

|

•

|

Cracks, damage or pitting in the combustion chambers

|

|

|

•

|

Debris in the oil galleries - Continue to clean the galleries until all debris is removed.

|

|

|

•

|

Coolant leaks or damage to the deck face sealing surface - If coolant leaks are present, measure the surface warpage as described under Cylinder Head Measurement - Deck Flatness Inspection.

|

|

|

•

|

Burrs or any defects that would degrade the sealing of the NEW secondary camshaft drive chain tensioner gasket

|

|

|

•

|

Damage to any gasket surfaces

|

|

|

•

|

Damage to any threaded bolt holes

|

|

|

•

|

Burnt or eroded areas in the combustion chamber

|

|

|

•

|

Cracks in the exhaust ports and combustion chambers

|

|

|

•

|

External cracks in the water passages

|

|

|

•

|

Restrictions in the intake or exhaust passages

|

|

|

•

|

Restrictions in the cooling system passages

|

|

|

•

|

Rusted, damaged or leaking core plugs

|

|

4.

|

If the cylinder head is cracked or damaged, it must be replaced. No welding or patching of the cylinder head is recommended.

|

|

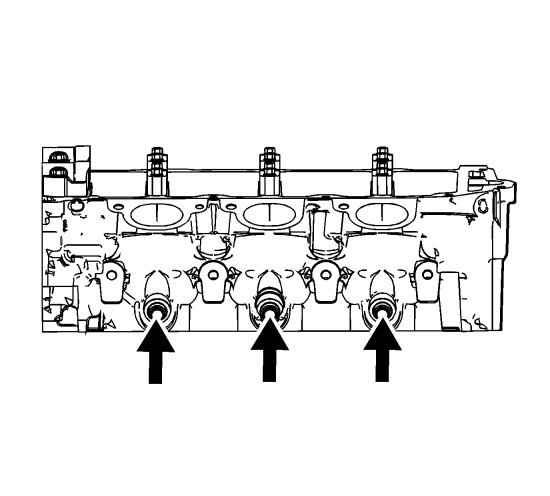

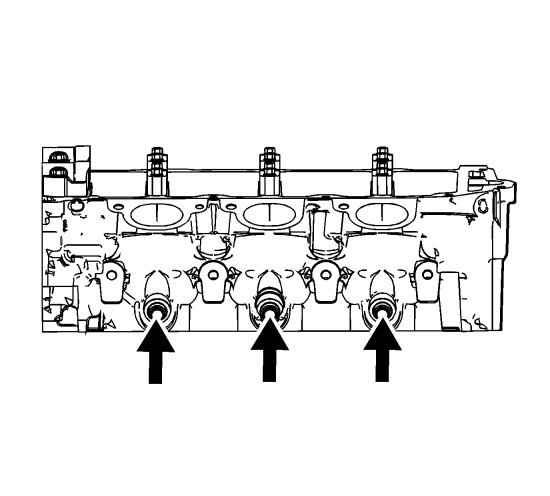

6.

|

Inspect the fuel rail injector bores and clean with

EN-47909

kit, if required .

|

|

Cylinder Head Measurement

|

Camshaft Journal Clearance

|

1.

|

Install the camshaft bearing cap in the cylinder head without the camshaft.

|

|

2.

|

Refer to

Fastener Caution

.

Install the camshaft cap bolts and tighten to

10 Nm (89 lb in)

.

|

|

3.

|

Measure the camshaft bearings using an inside micrometer.

|

|

4.

|

Subtract the camshaft journal diameter from the camshaft bearing diameter. This will provide the running clearance. If the running clearance exceeds specifications and the camshaft journals are within specification, replace the cylinder head.

|

Camshaft Journal Alignment

|

1.

|

Ensure the camshafts are serviceable.

|

|

2.

|

Inspect the cylinder head camshaft bearing surfaces for any imperfections or scratches that could inhibit proper camshaft clearances. Repair minor imperfections or scratches.

|

|

3.

|

Install the camshafts in the cylinder head.

|

|

4.

|

Install the camshaft bearing caps.

|

|

5.

|

Install the camshaft cap bolts and tighten to

10 Nm (89 lb in)

.

|

|

6.

|

Ensure the camshafts spin freely in the cylinder head. If the camshaft does not run freely, replace the cylinder head.

|

Deck Flatness Inspection

|

1.

|

Ensure the cylinder head decks are clean and free of gasket material.

|

|

2.

|

Inspect the surface for any imperfections or scratches that could inhibit proper cylinder head gasket sealing.

|

|

3.

|

Place a straight-edge diagonally across the cylinder head deck face surface.

|

|

4.

|

Measure the clearance between the straight-edge and the cylinder head deck face using a feeler gauge at 4 points along the straight-edge.

|

|

5.

|

If the warpage is less than 0.05 mm (0.002 in), the cylinder head deck surface does not require resurfacing.

|

|

6.

|

If the warpage is between 0.05-0.20 mm (0.002-0.008 in) or any imperfections or scratches that could inhibit proper cylinder head gasket sealing are present, the cylinder head deck surface requires resurfacing.

|

|

7.

|

If resurfacing is required the maximum amount that can be removed is 0.25 mm (0.010 in).

|

|

8.

|

If the cylinder head deck surface requires more than 0.25 mm (0.010 in) material removal the head must be replaced.

|

Valve Guide Measurement

|

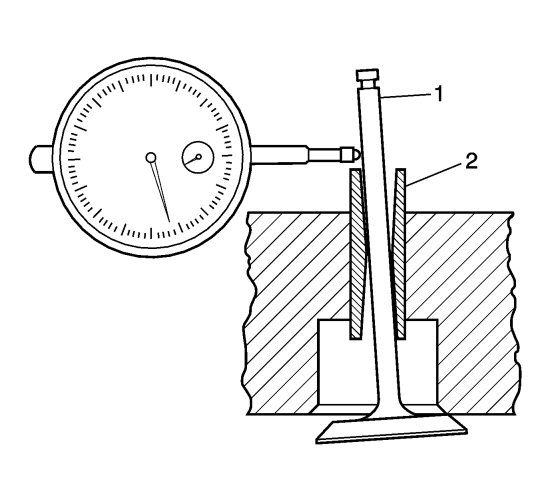

1.

|

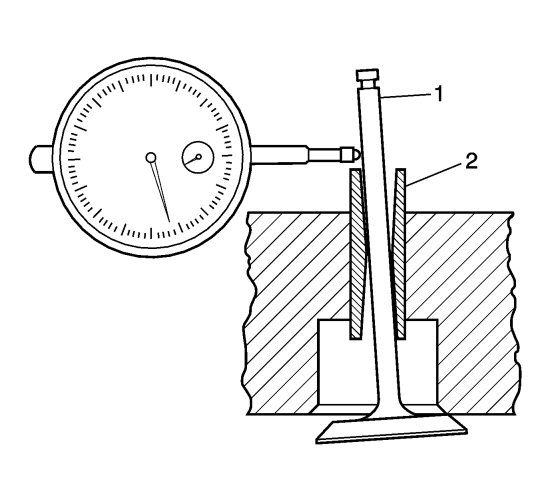

Measure the valve stem (1)-to-guide (2) clearance. Excessive valve stem-to-guide clearance may cause an excessive oil consumption and may also cause a valve to break. Insufficient clearance will result in noisy and sticky functioning of the valve and will disturb the engine assembly smoothness.

|

|

2.

|

Clamp the

GE 8001

set to the cylinder head at the camshaft cover rail.

|

|

3.

|

Locate the dial indicator so that the movement of the valve stem from side to side, crossways to the cylinder head, will cause a direct movement of the indicator stem. The dial indicator stem must contact the side of the valve stem just above the valve guide.

|

|

4.

|

Drop the valve head about 0.064 mm (0.0025 in) off the valve seat.

|

|

|

•

|

If the clearance for the valve is greater than specifications and a new standard diameter valve stem will not bring the clearance within specifications, the valve guide may be oversized by 0.075 mm (0.003 in) using the

EN 42096

reamer. There is 1 size of oversized valve stem available for service.

|

|

|

•

|

Valve guide wear at the bottom 10 mm (0.390 in) of the valve guide is not significant to normal operation.

|

|

|

•

|

If oversizing the guide does not bring the clearance within specifications, replace the cylinder head.

|