Wheel Drive Shaft Outer Joint Inspection

|

|

Wheel Drive Shaft Outer Joint Inspection

|

|

2.

|

Remove any lubricant from the CV joint.

|

|

3.

|

|

Note

|

|

Position the cage and the inner race so they are level.

|

Install the outer CV joint assembly in a soft jawed vise.

|

|

4.

|

|

Note

|

|

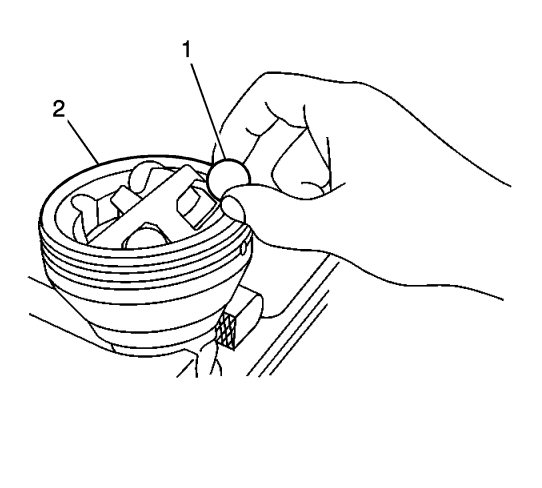

The following procedure will have to be repeated until all the ball bearings are removed from the cage.

|

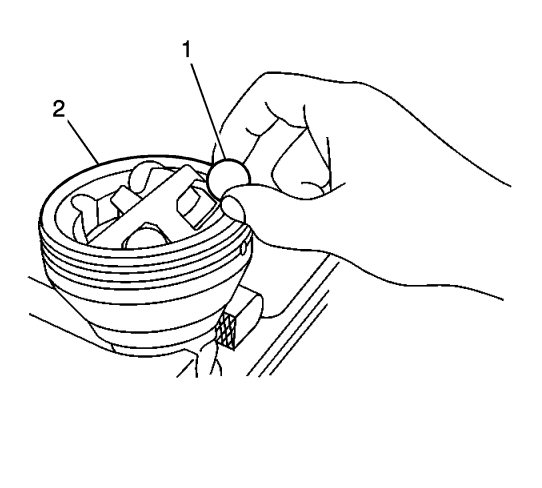

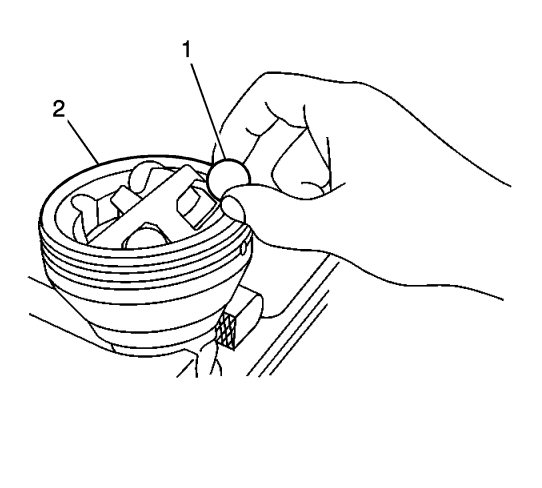

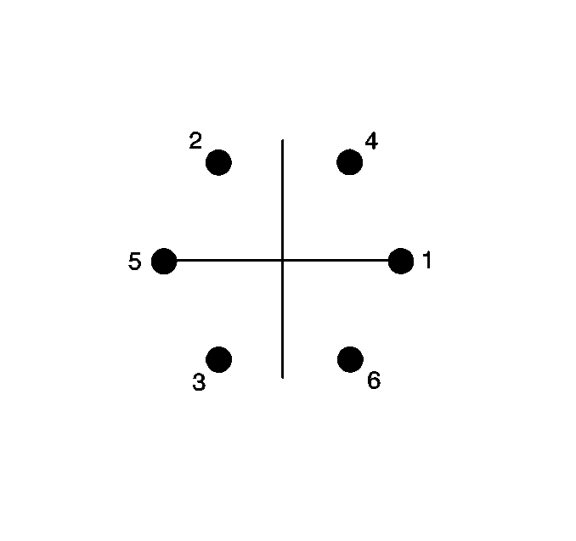

Using a brass drift (2), gentle tap the cage until the ball bearing can be removed from the cage.

|

|

5.

|

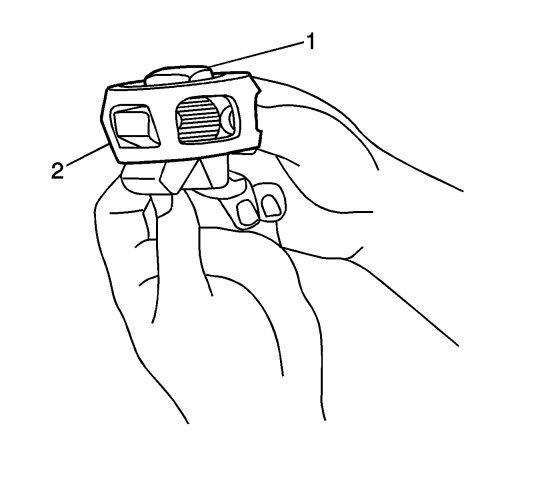

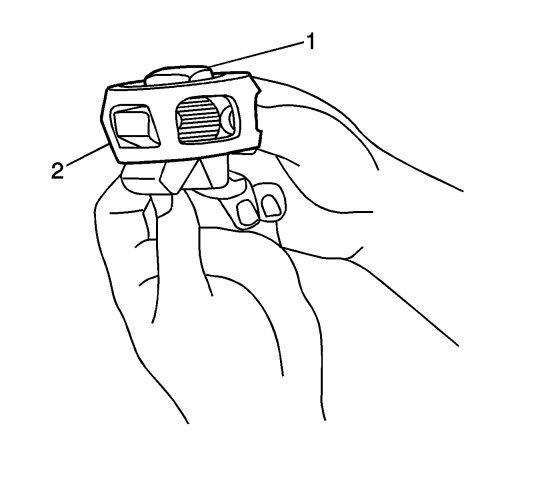

Using a small screwdriver, remove the ball bearings (1) from the CV joint (2).

|

|

6.

|

|

Note

|

|

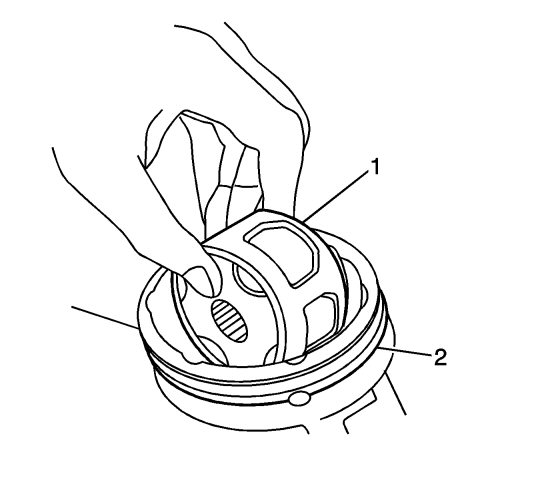

Position the cage so that the larger radius corners of the cage windows are facing up.

|

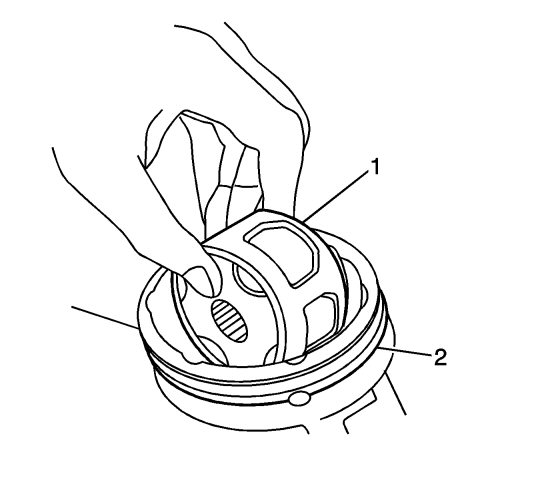

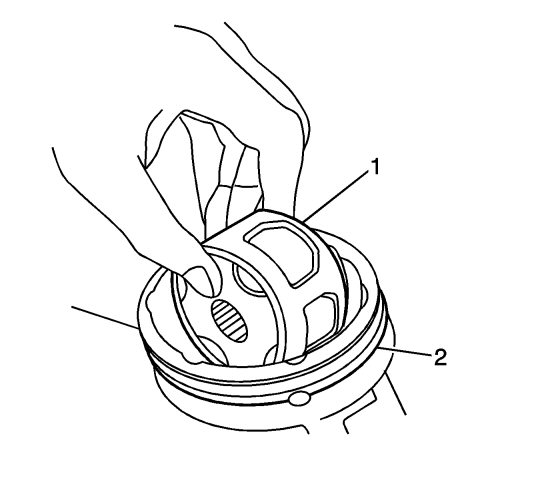

Position the cage (1) at a 90 degrees to the centerline of the outer race (2).

|

|

7.

|

Align the cage windows with the lands of the outer race (2).

|

|

8.

|

Lift and remove the cage (1) and the inner race from the outer race (2).

|

|

9.

|

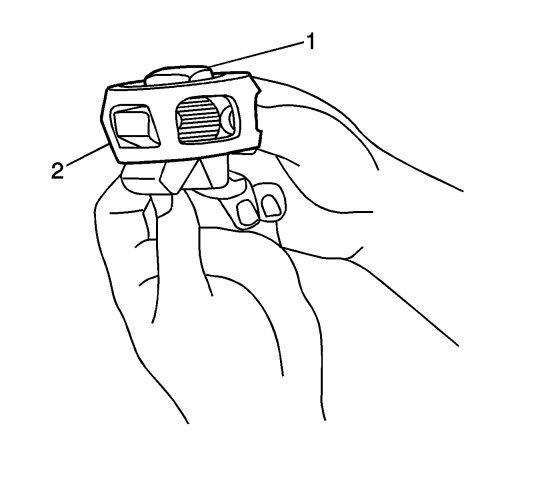

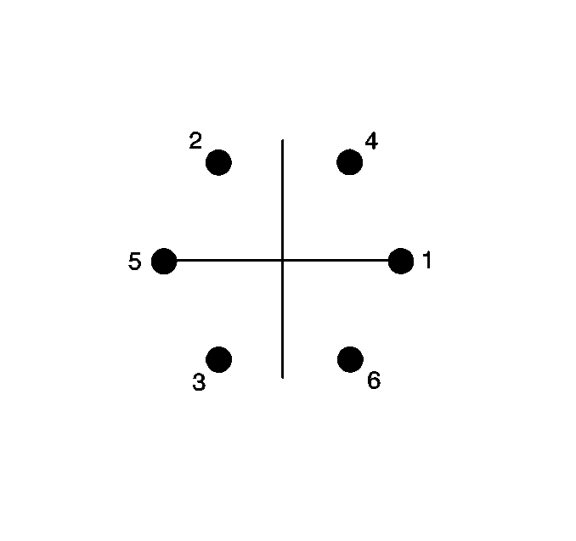

Position the cage (2) and the inner race (1) so that the larger radius corners of the cage windows are up.

|

|

10.

|

Rotate the inner race (1) 90 degrees to the center line of the cage (2).

|

|

11.

|

Align the lands of the inner race (1) with the windows of the cage (2).

|

|

12.

|

Move the inner race (1) land into the cage window (2).

|

|

13.

|

Rotate the inner race (1) down and remove it from the cage (2).

|

|

14.

|

Clean the following items thoroughly with the proper cleaning solvent:

|

|

|

•

|

The exposed end of the wheel drive shaft

|

|

15.

|

|

Note

|

|

The internal parts of the CV joint are NOT SERVICED separately. The outer CV joint is serviced as an assembly.

|

If any of the above items are found to have excessive wear or are damaged, replace the outer CV joint as an assembly.

|

|

1.

|

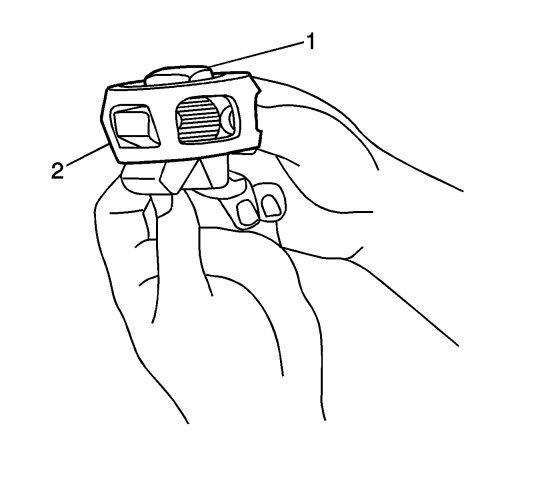

Position the cage (2) so that the larger radius corners of the cage windows are up.

|

|

2.

|

Position the inner race (1) 90 degrees to the centerline of the cage (2).

|

|

3.

|

Insert the inner race (1) through the bottom of the cage (2).

|

|

4.

|

Align the lands of the inner race (1) with the windows of the cage (2).

|

|

5.

|

Move the inner race (1) land into the cage window (2).

|

|

6.

|

Rotate the inner race (1) down and remove it from the cage (2).

|

|

7.

|

Rotate the inner race (1) within the cage (2) so that the grooved surface of the inner race (1) is facing up.

|

|

8.

|

Align the inner race (1) ball bearing tracks with the cage (2) windows.

|

|

9.

|

Wrap a clean shop towel around the CV joint outer race splined shaft.

|

|

10.

|

Place the outer race (2) vertically in a bench vise.

|

|

11.

|

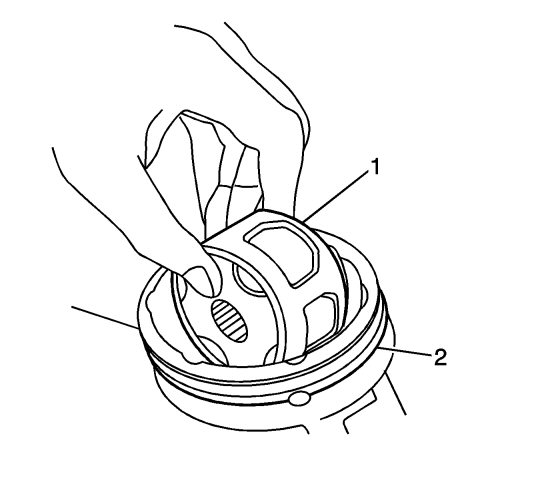

Position the cage (1) and the inner race at a 90 degrees to the centerline of the outer race (2).

|

|

12.

|

With the inner race and the cage (1) assembly in a vertical position, insert the cage and the inner race into the outer race (2).

|

|

13.

|

|

Note

|

|

The larger radius corners of the cage windows should be positioned up and the grooved surface of the inner race should be visible.

|

Position the cage (2) and the inner race so that they are level in the vise.

|

|

14.

|

Rotate the appropriate component(s), and align the cage windows and the inner race ball bearing (1) tracks with the outer race ball bearing tracks.

|

|

15.

|

Position the cage window and the inner race ball bearing track for the ball bearing installation.

|

|

16.

|

|

Note

|

|

When performing the following procedure, the opposing cage (2) window and the inner ball bearing (1) track will be accessible for the ball bearing installation.

|

Press down on the cage following one of the outer race ball bearing (1) tracks.

|

|

17.

|

Install the ball bearing through the cage window onto the inner race ball bearing (1) track.

|

|

18.

|

|

Note

|

|

The following service procedure will have to be performed after each ball bearing (1) has been installed.

|

After the first ball bearing (1) has been installed, use a brass drift and a hammer and gently tap the cage in order to drive the cage and the inner race down completely in the outer race.

|

|

19.

|

|

Note

|

|

After the ball bearing (1) has been installed, there should be NO GAP between the ball bearing and the inner race.

|

Position the cage and the inner race so that they are level.

|

|

20.

|

Install the ball bearings in sequence.

|

|

21.

|

Using a plastic hammer, lightly tap the ball bearing into place.

|

|

22.

|

Repeat steps 18-21 until all the ball bearings are installed.

|

|

23.

|

Install the outer CV joint and boot on the wheel drive shaft.

|