B-Pillar, Sectioning - Outer

| B-Pillar, Sectioning - Outer |

| To remove |

| 1. |

Refer to

Approved Equipment for Collision Repair Warning

.

Refer to Warning during the repair of collision damage with repair sheet metal Refer to Fuel/Fuel vapor Warning .

Disable the SIR system. Refer to SIR Disabling and Enabling . |

|||||||

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Remove all related panels and components.

|

|

| 4. |

Remove sealant and anti-corrosion materials from repair area, if necessary and note their placement.

|

|

| 5. |

Repair as much as possible of the damaged area. Refer to

Body dimensions

.

|

|

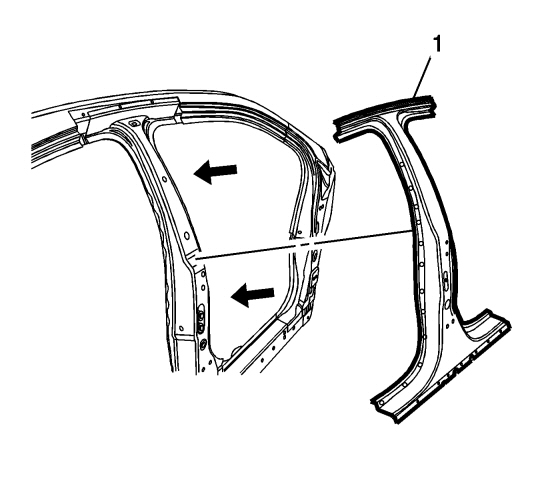

| 6. |

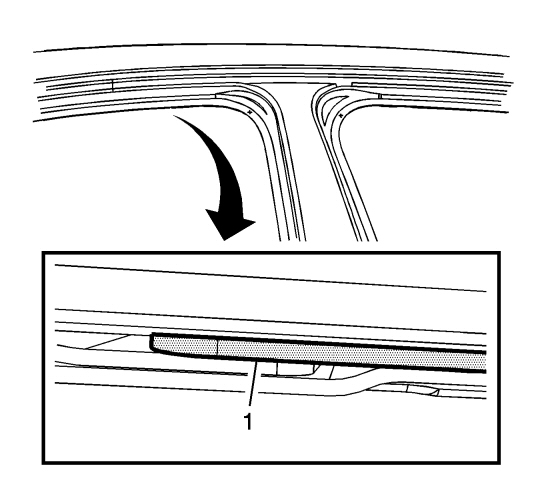

Remove the weatherstrip, note the flange in the center pillar. There will be a 3-metal stack-up. The middle layer is the center pillar's inner reinforcement (1).

|

|

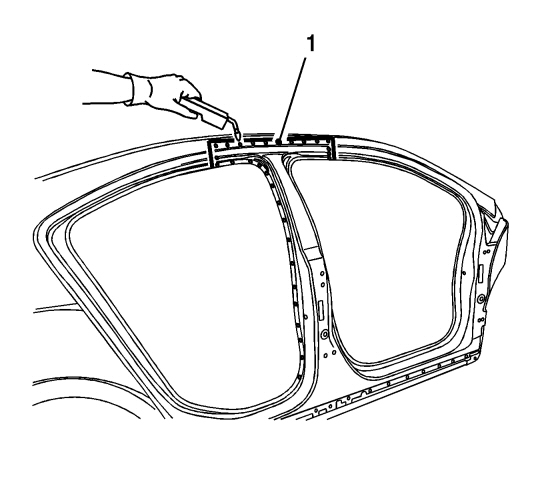

| 7. |

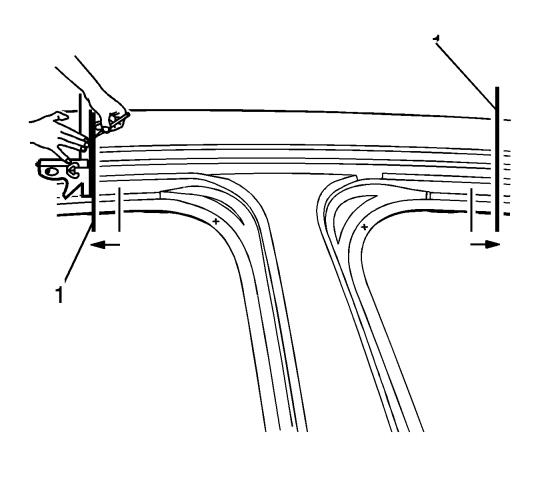

Measure 13 mm (1/2 in) from the front and rear edges of the center pillar's inner reinforcement and mark a vertical line (1).

|

|

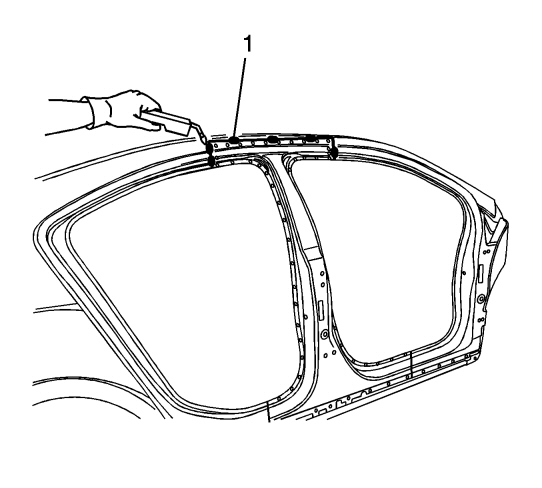

| 8. |

Measure 2.5 cm from the door opening's function line (1) and mark up a horizontal line.

|

|

| 9. |

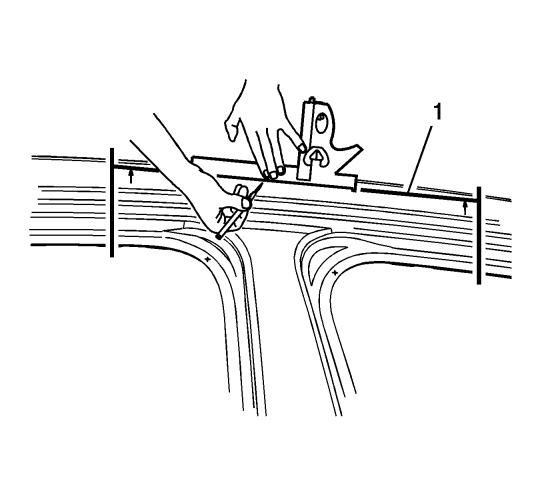

Cut the window (1) in the outer center pillar.

|

|

| 10. |

Perform additional sectioning which may be necessary depending on the damage to the vehicle. Refer to

Quarter Outer Panel Sectioning

,

Rocker Outer Panel Sectioning

, or

Front Hinge Pillar Body Sectioning

.

|

|

| 11. |

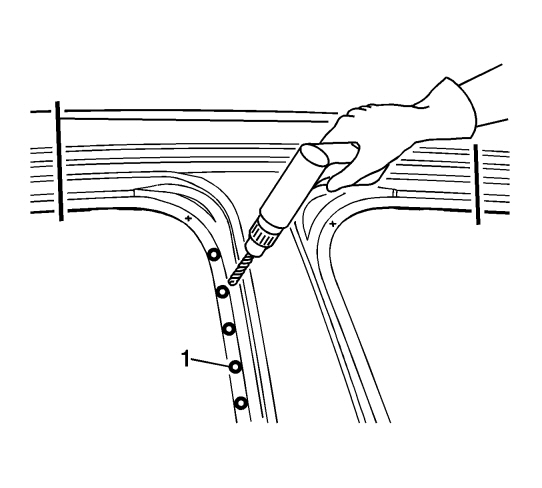

Locate and drill out all factory welds (1). Note the number and location of the welds for installation of the service part.

|

|

| 12. |

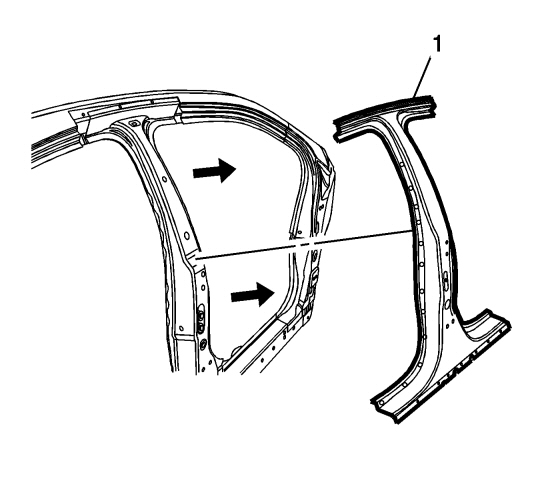

Remove the damaged outer center pillar section (1).

|

|

| Installation Procedure |

| 1. |

From the service part, cut the panel at corresponding points in order to overlap the remaining original panel by 25 mm (1 in) at every common point (1).

|

|

| 2. |

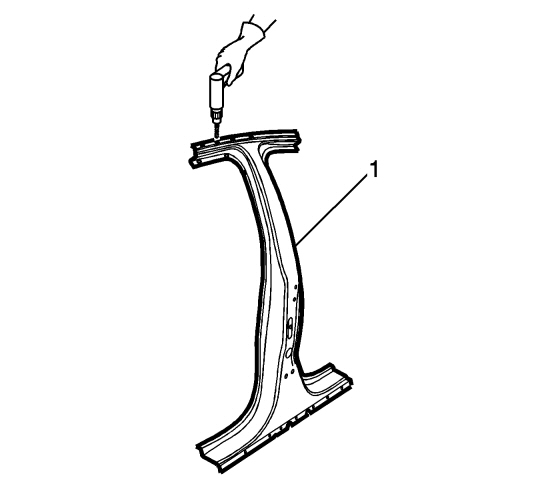

Drill 8 mm (5/16 in) plug the weld holes in the service side (1), if necessary, at corresponding points noted on the original panel and along common sections

|

|

| 3. |

If necessary, prepare surfaces for welding.

|

|

| 4. |

Apply GM approved welds through coating or equivalent on all surfaces.

|

|

| 5. |

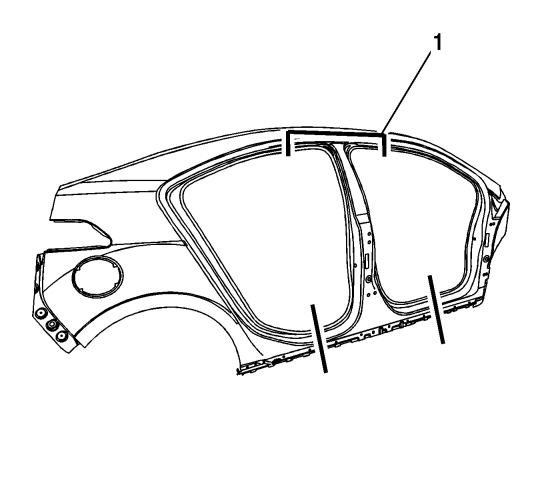

Place the outer center pillar (1) in the vehicle with the 3- dimensional measuring equipment. Secure the pillar in place.

|

|

| 6. |

Plug the welds according to (1) .

|

|

| 7. |

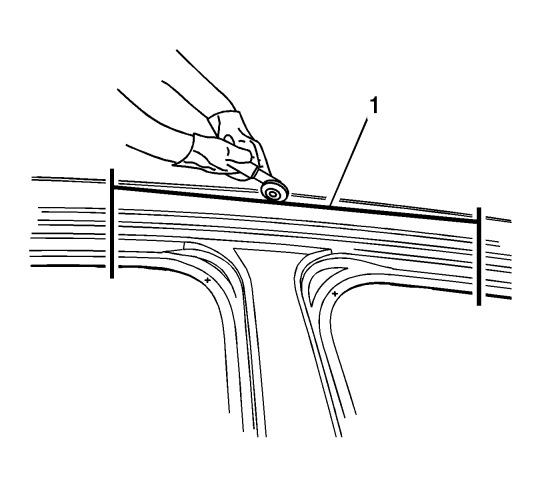

To create a solid weld with minimum heat distortion, make a 25 mm (1 in) Weld bead along 25 mm (1 in) the parts between them. Then go back and complete the weld (1).

|

|

| 8. |

Clean and prepare all welded surfaces.

|

|

| 9. |

Apply sealant and, if necessary, corrosion material to the repair area.

|

|

| 10. |

Paint the repair area. See

Basecoat/Clearcoat Paint Systems

.

|

|

| 11. |

Install all related panels and components.

|

|

| 12. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 13. |

Activate the SIR system. Refer to

SIR Disabling and Enabling

.

|

|