Rocker Outer Panel Sectioning

| Rocker Outer Panel Sectioning |

| Removal Procedure |

| 1. |

Refer to

Approved Equipment for Collision Repair Warning

.

See Warning during the repair of collision damage with repair sheet metal . See Fuel/Fuel vapor Warning .

Disable the SIR system. See SIR Disabling and Enabling . |

|||||||

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Remove all related panels and parts.

|

|

| 4. |

It is necessary to remove the sealing and corrosion materials from the repair area.

|

|

| 5. |

Repair as much as possible of the damaged area. See

Format - Body

.

|

|

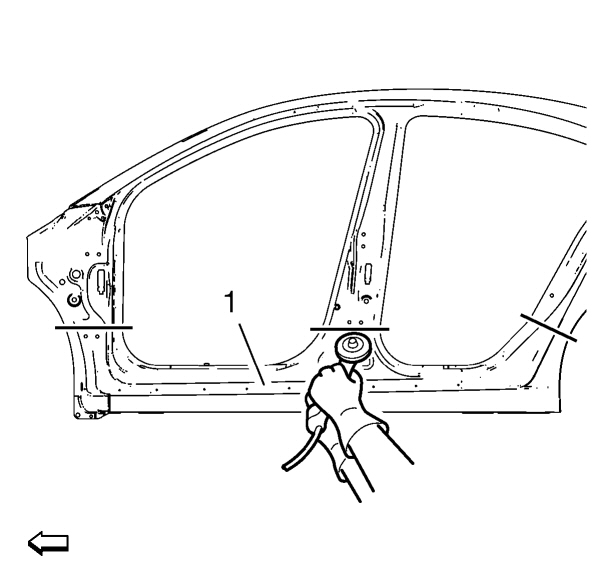

| 6. |

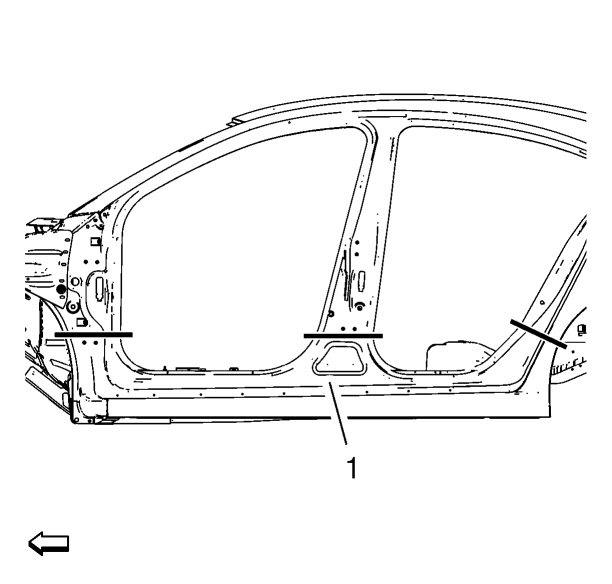

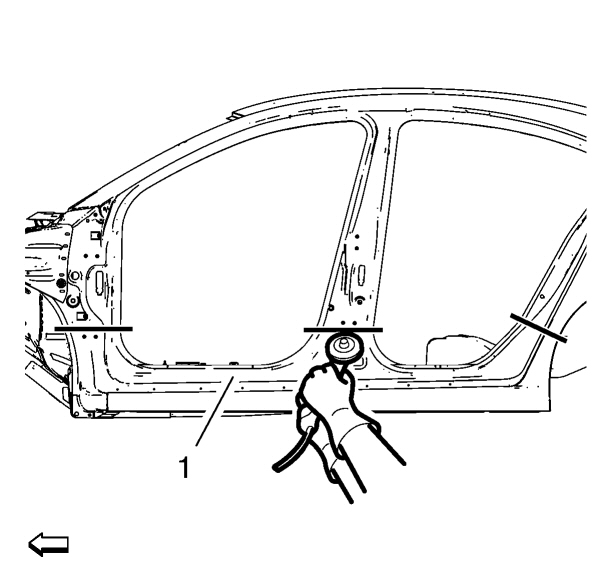

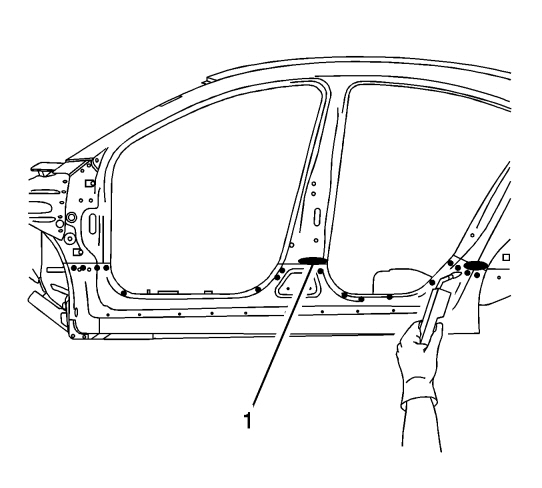

Cut slits in the rocker panel (1).

|

|

| 7. |

Perform additional repairs depending on how damaged the vehicle is. See

Quarter Outer Panel Sectioning

,

Front Hinge Pillar Body Sectioning

, or

B-Pillar, Sectioning - Outer

.

|

|

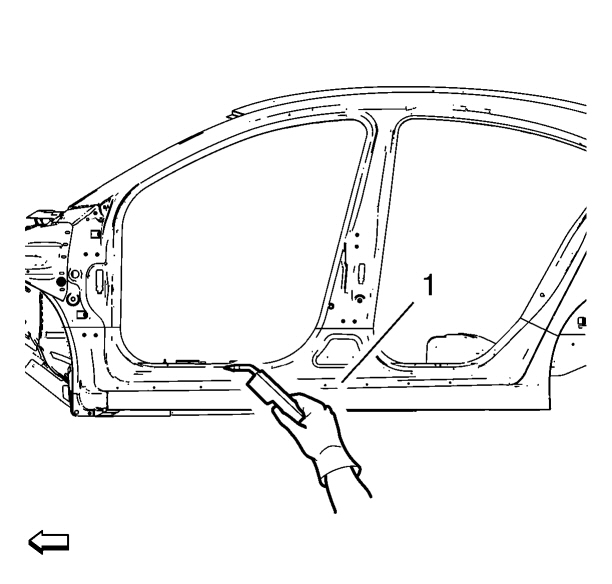

| 8. |

Cut the rocker panel (1) where the repair must be made.

|

|||||||

| 9. |

Locate and note all factory welds on the rocker panel (1).

|

|

| 10. |

Drill out all factory welds.

|

|

| 11. |

Remove the damaged rocker panel (1).

|

|

| Installation Procedure. |

| 1. |

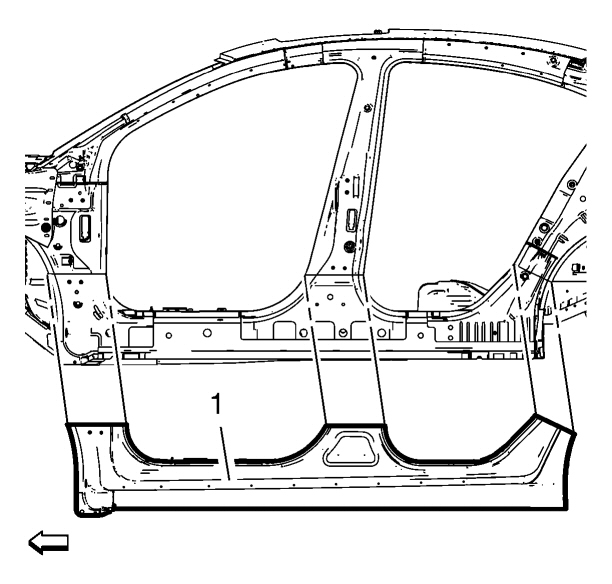

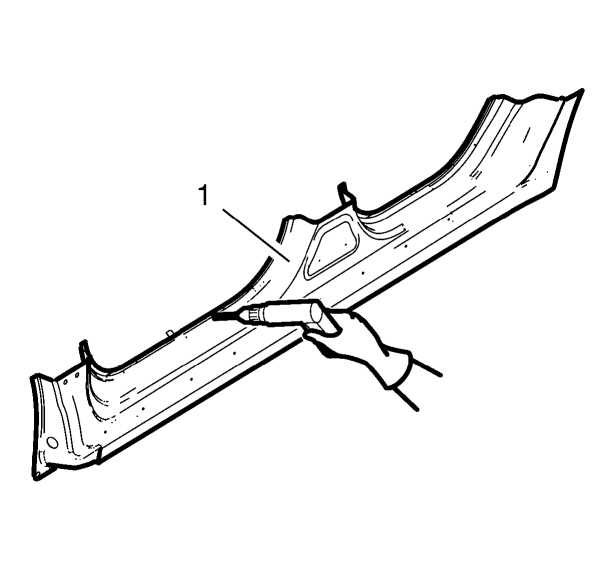

Spare part (1), divide the panel with the corresponding size so that it overlaps the original panel by at least 25 mm (1 inch) on each side.

|

|

| 2. |

It is necessary to prepare all the matching surfaces.

|

|

| 3. |

Drill 8 mm (5/16 in) plug weld holes in the spare part (1). This is necessary in areas where the original panel and the spare part are to be welded together.

|

|

| 4. |

Clean and prepare the surfaces to be welded together.

|

|

| 5. |

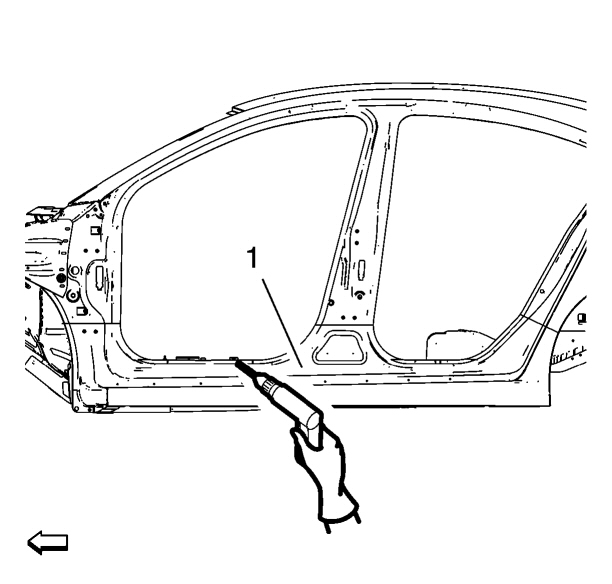

Apply GM approved Weld - this is applied or the like on all matching surfaces.

|

|

| 6. |

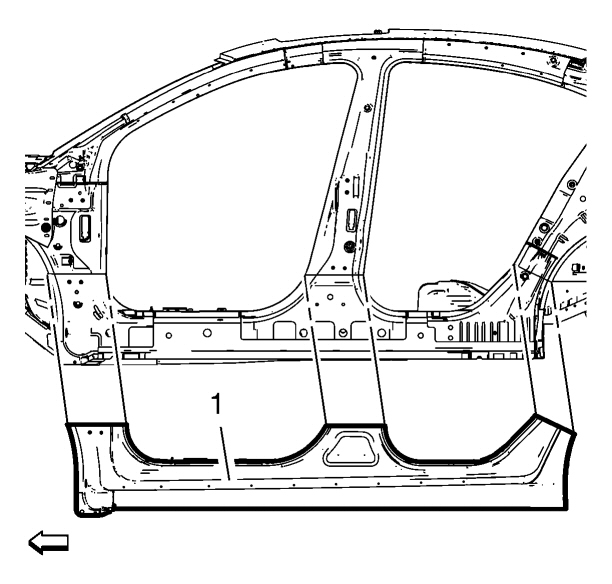

Position the rocker panel (1) against the car by using the 3-dimensional measuring equipment. Clamp the part in the correct place.

|

|

| 7. |

Plug weld the rocker panel (1)

|

|

| 8. |

In order to perform the weld with a minimum heat distortion make 25 mm (1 in) stitch welds along the seam with 25 mm (1 in) gaps between. Then go back and complete the weld.

|

|

| 9. |

It is necessary to apply sealant and corrosion materials on the repaired surface.

|

|

| 10. |

Paint the repaired surface. See

Basecoat/Clearcoat Paint Systems

.

|

|

| 11. |

Refit all related panels and parts.

|

|

| 12. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 13. |

Activate the SIR system. See

SIR Disabling and Enabling

.

|

|