Complete automatic transmission

|

|

Complete automatic transmission

|

|

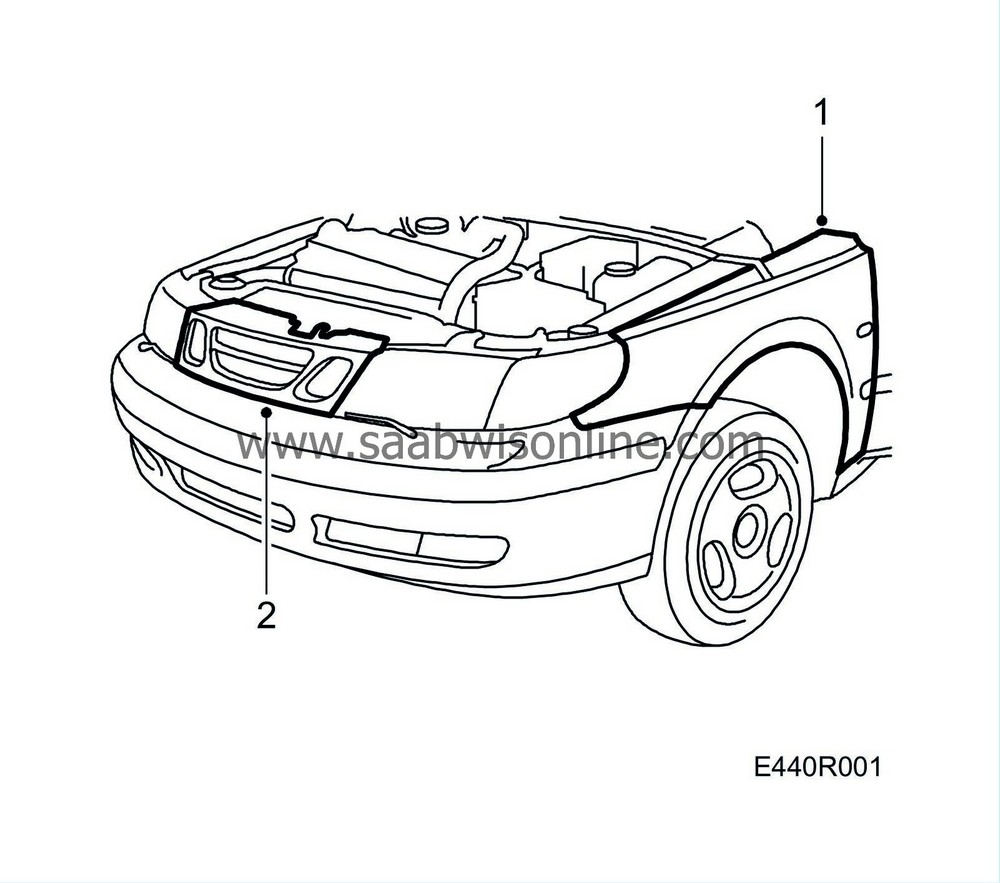

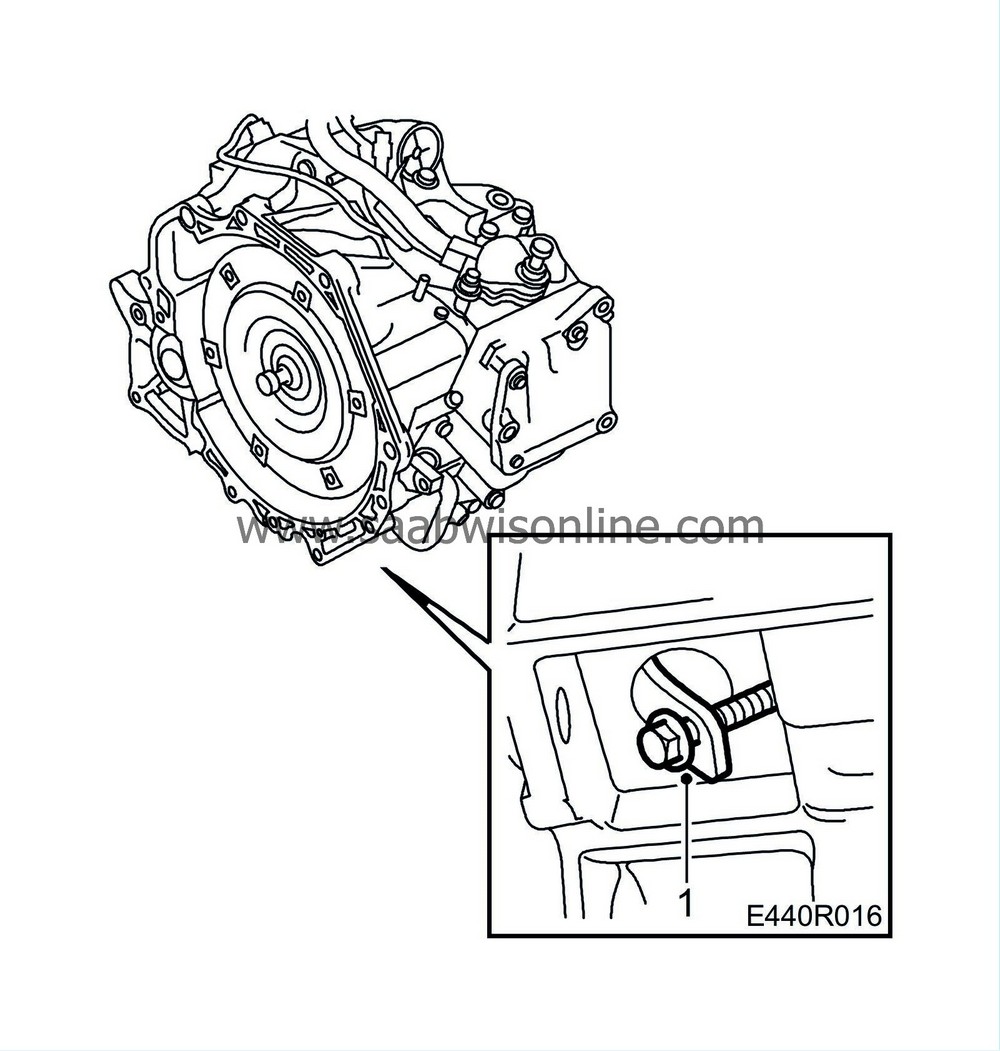

1.

|

Place drapes over the wings to keep the paintwork clean and protect it from damage.

|

|

3.

|

Remove the cover from the intake manifold.

|

|

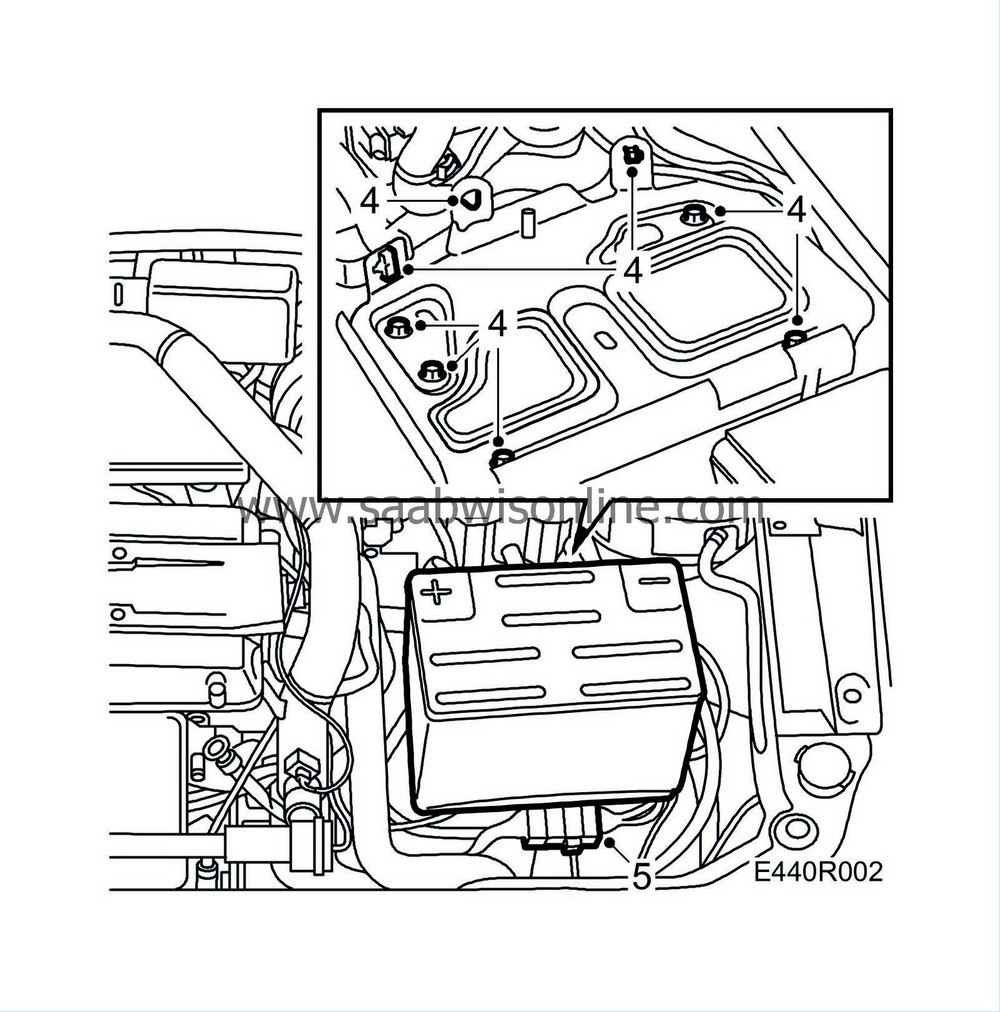

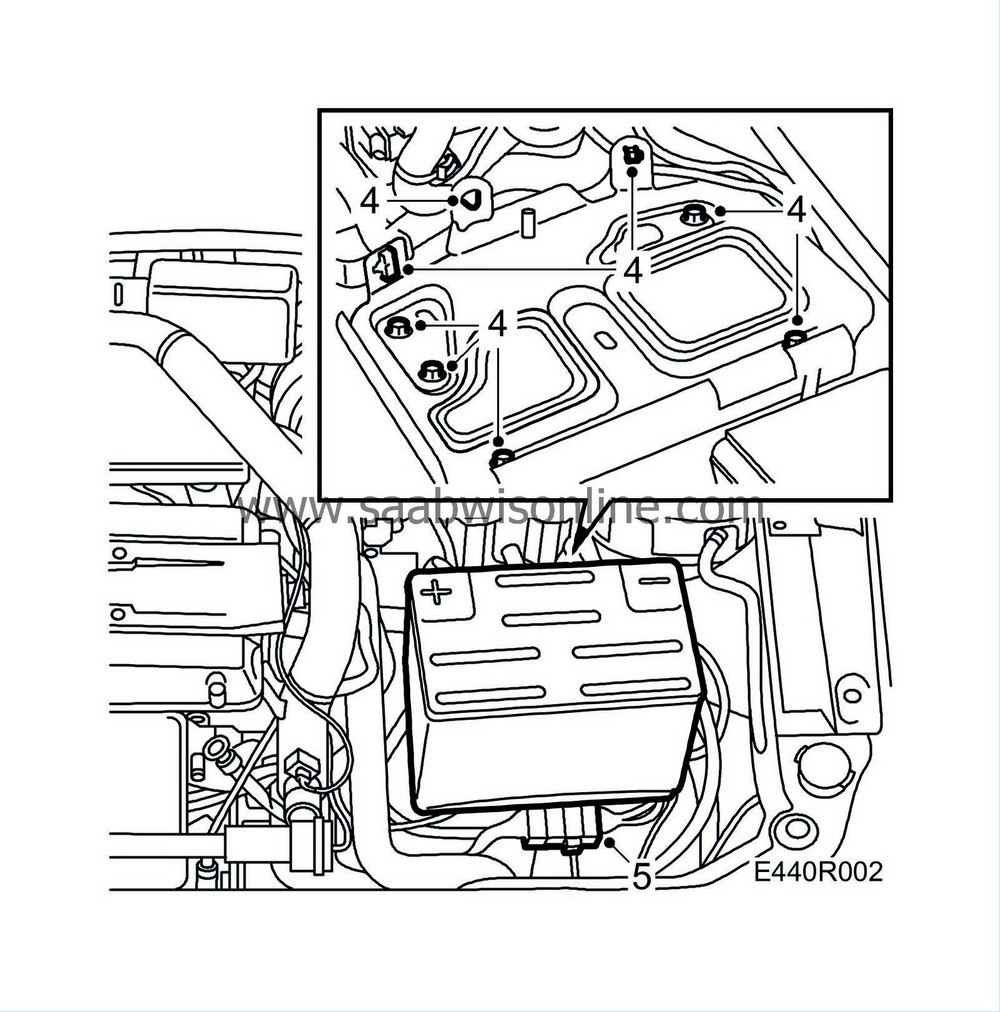

4.

|

Remove the battery cover, battery and battery tray.

|

|

5.

|

Unplug the 16-pin and 10-pin connectors, mounted in a holder.

|

|

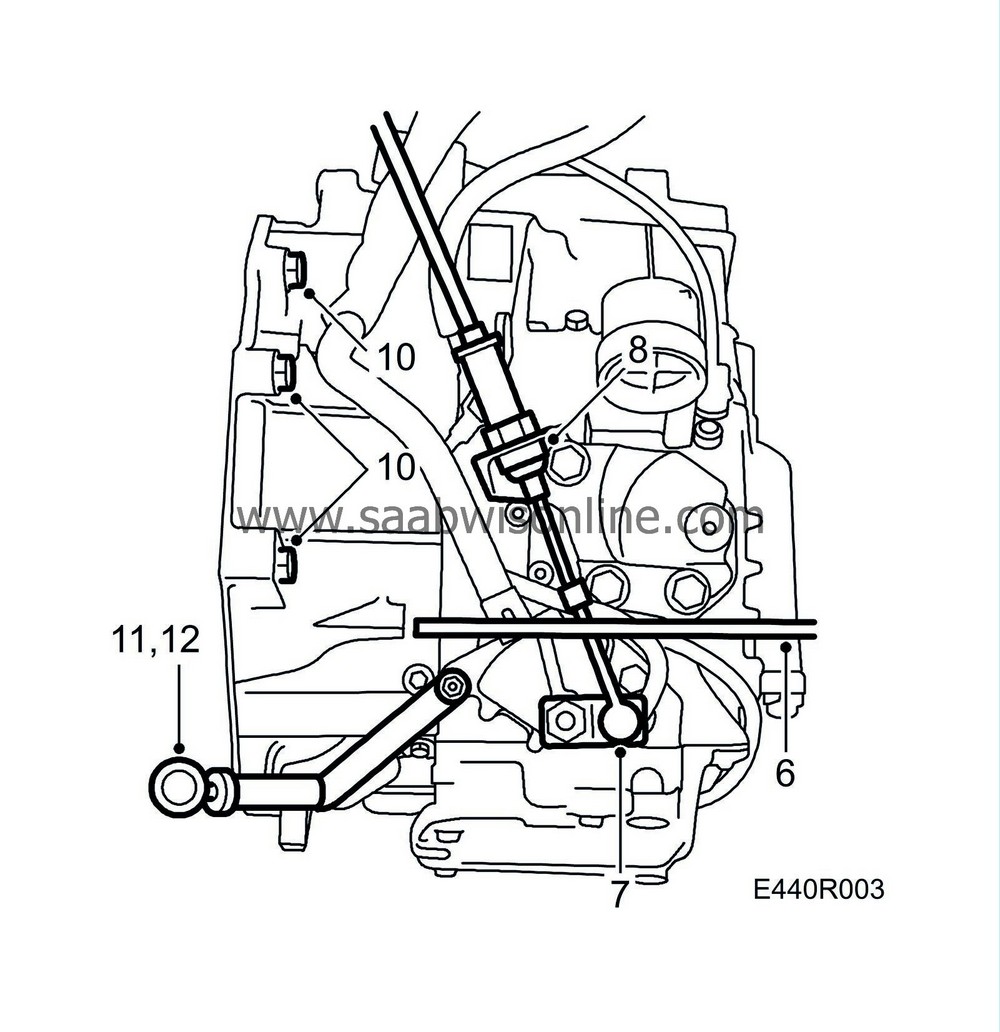

6.

|

Remove the breather hose from the transmission.

The hose is positioned differently depending on engine variant.

|

|

7.

|

Remove the gear selector arm from the transmission. The selector lever must be in position 1.

|

|

8.

|

Remove the clamp and press out the shifting cable, using a suitable screwdriver.

|

|

9.

|

4-cyl: Undo the clamp on the positive lead.

V6: Detach the cable channel from the engine and transmission casing.

|

|

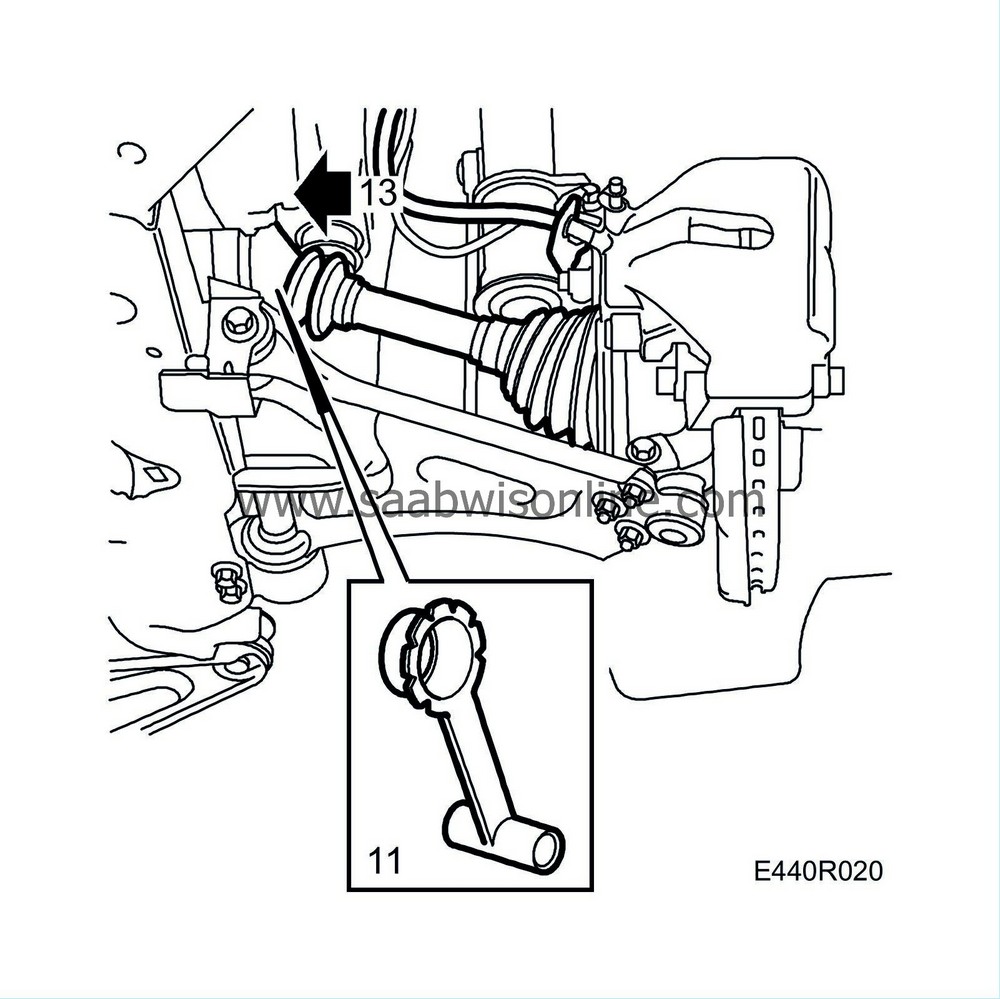

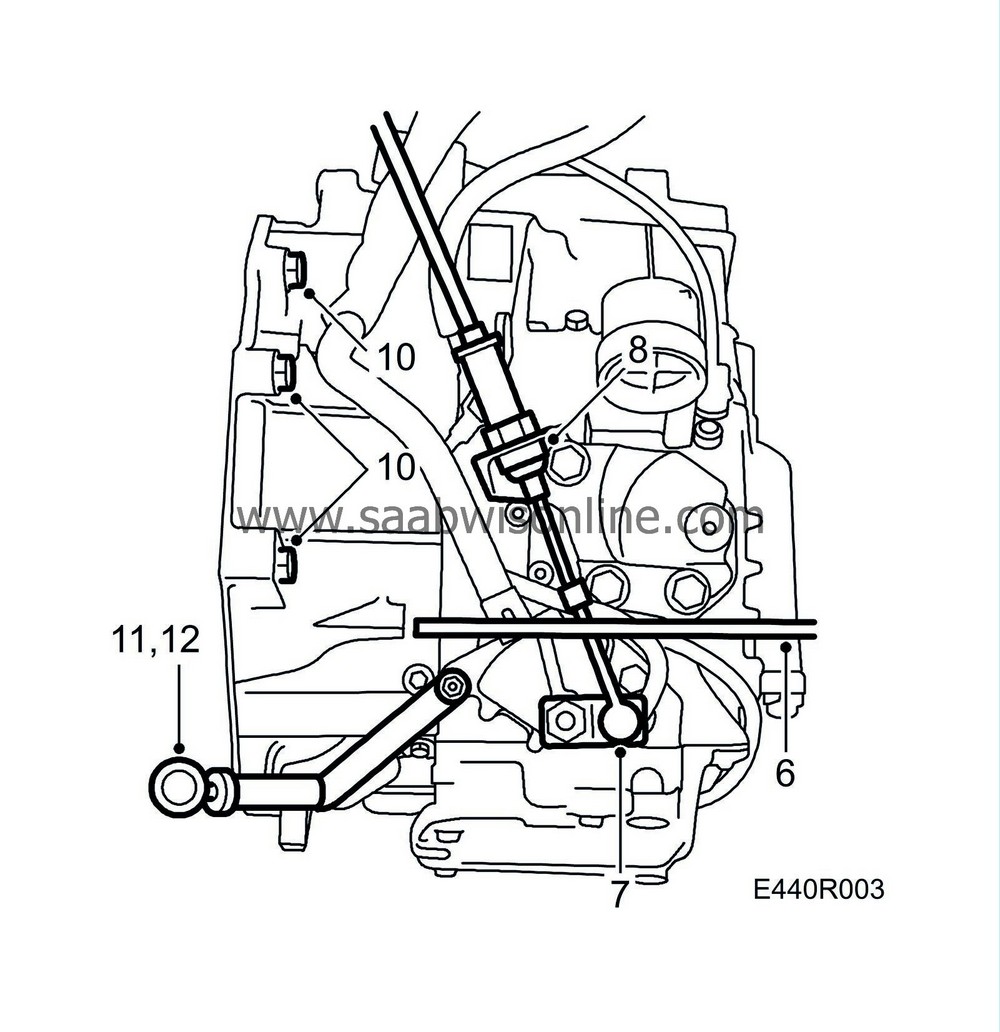

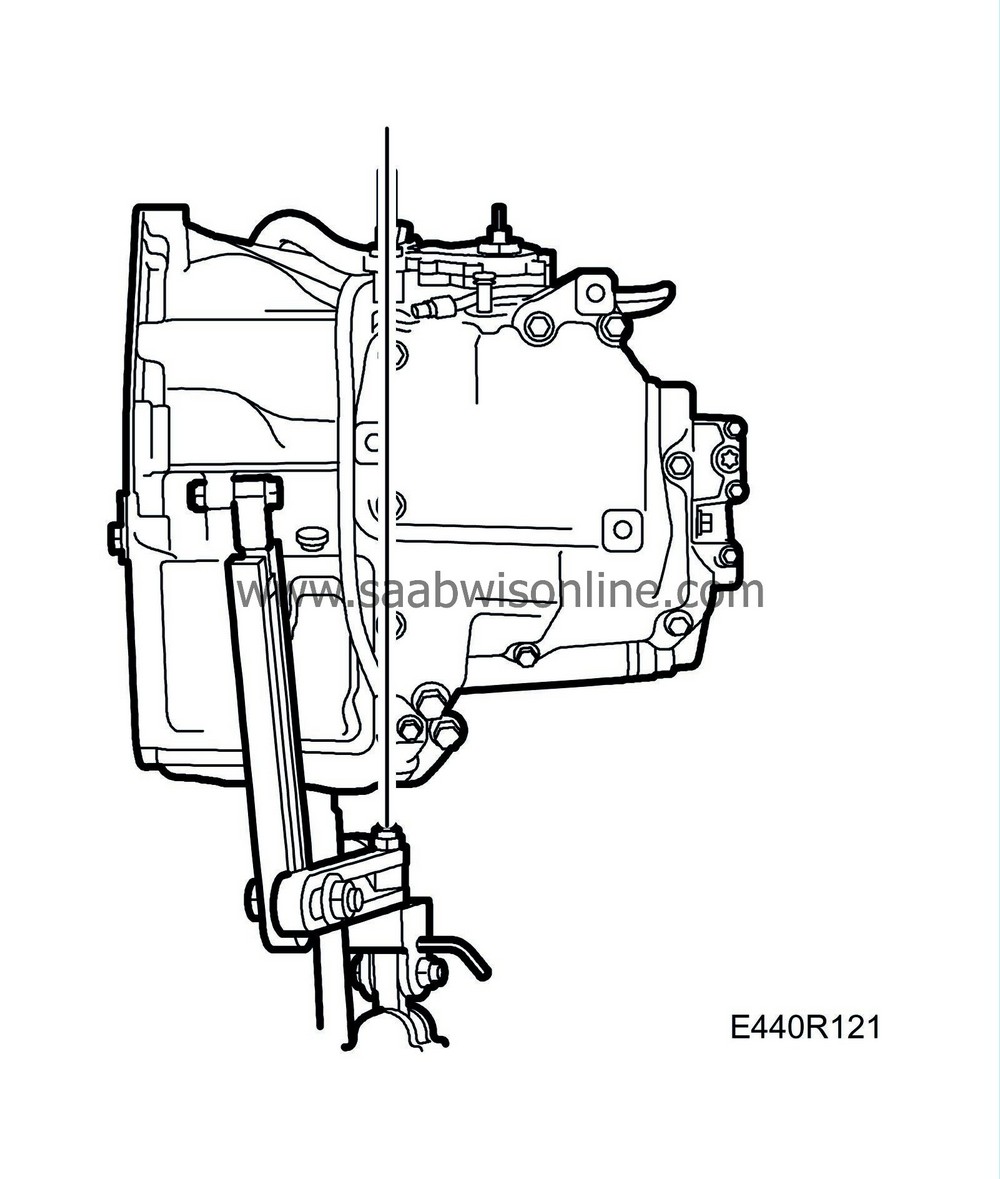

11.

|

Clean the area round the dipstick tube where it enters the transmission.

|

|

12.

|

Remove the dipstick tube and plug the hole.

|

|

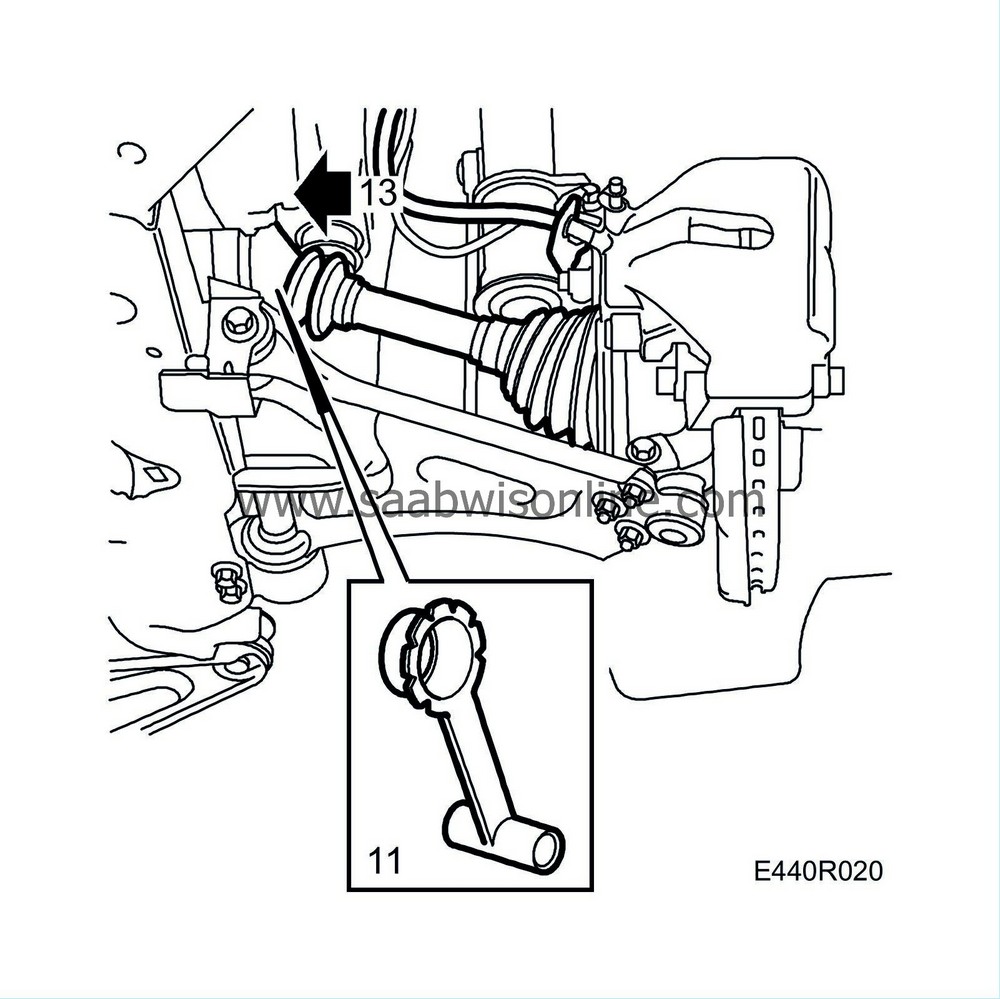

13.

|

Unplug the connector from the securing point for the oxygen sensor's electrical lead.

|

|

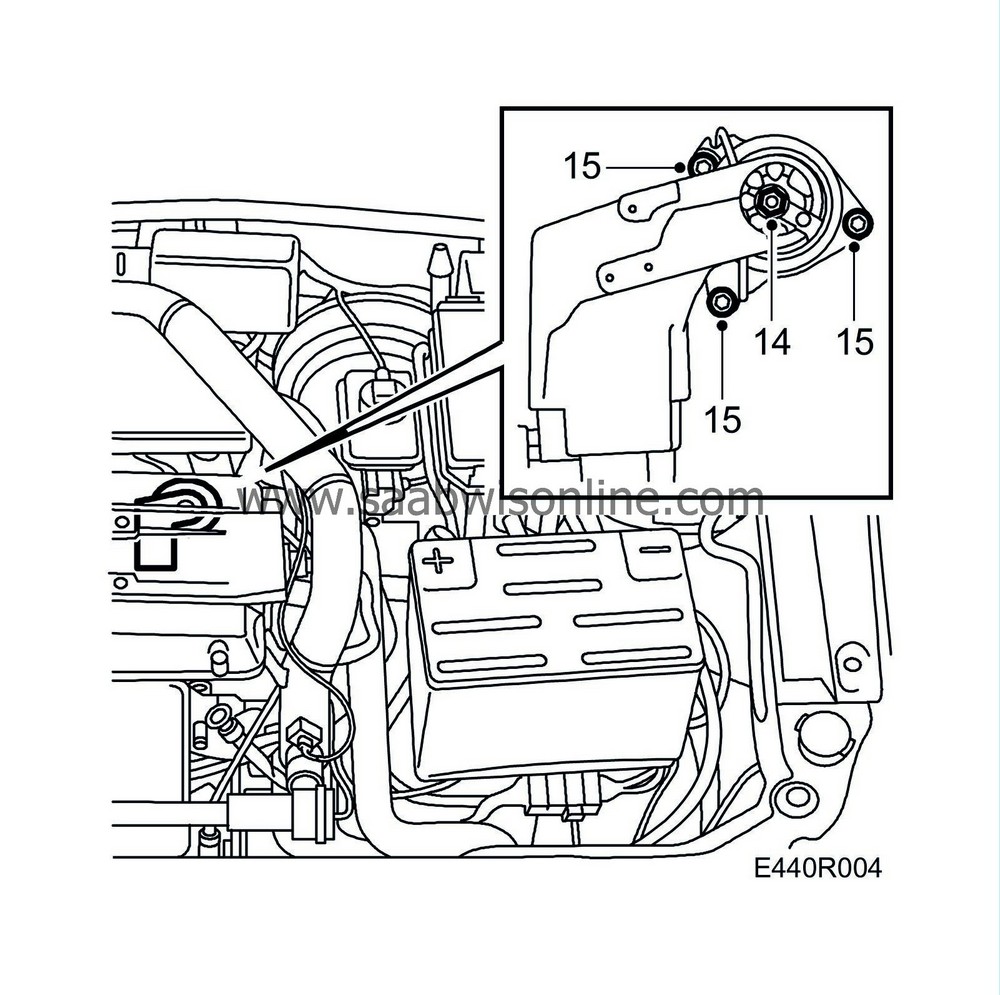

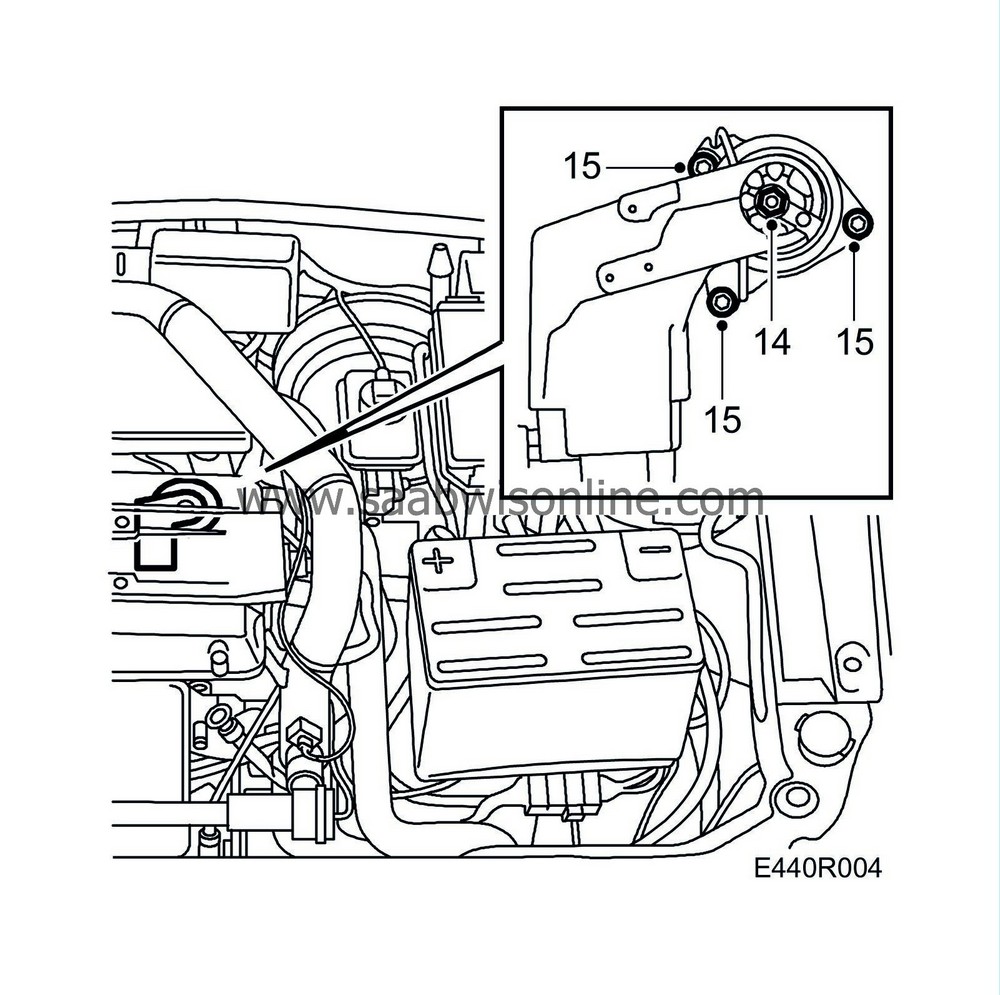

14.

|

Remove the nut for the rear engine mounting.

|

|

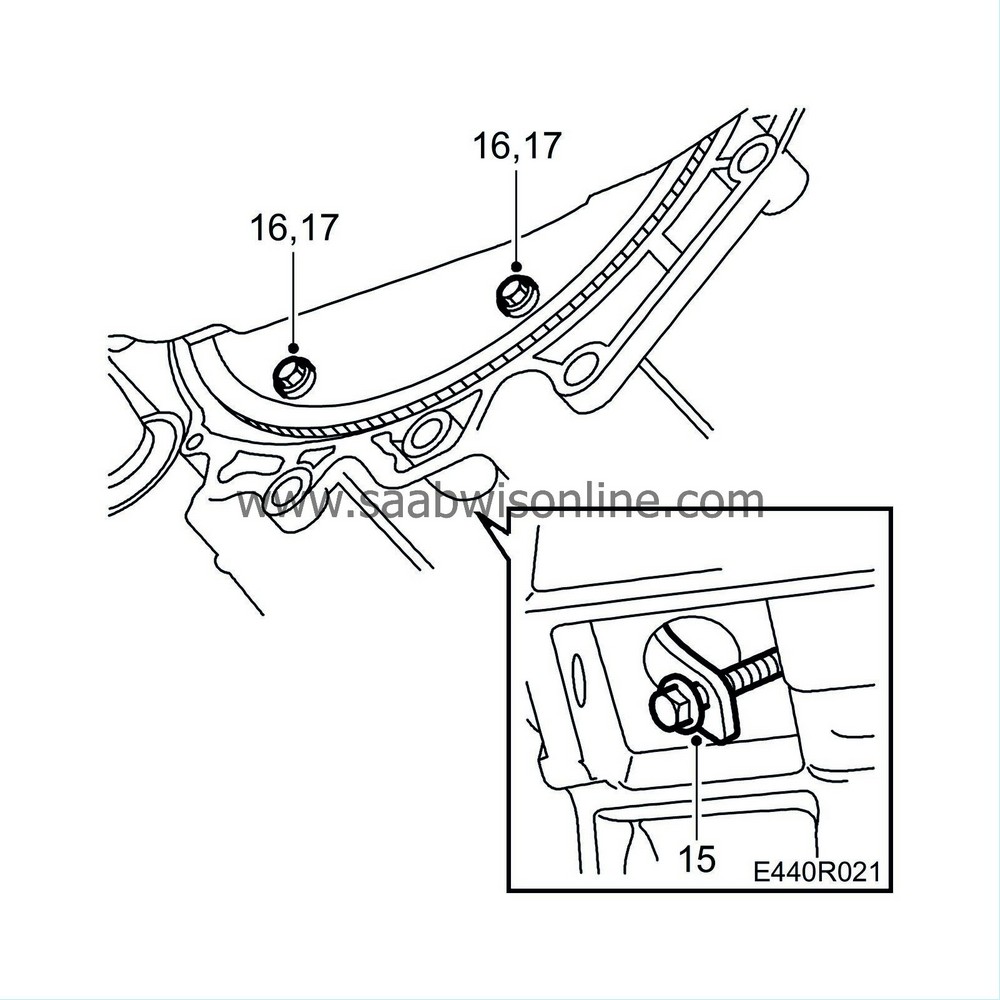

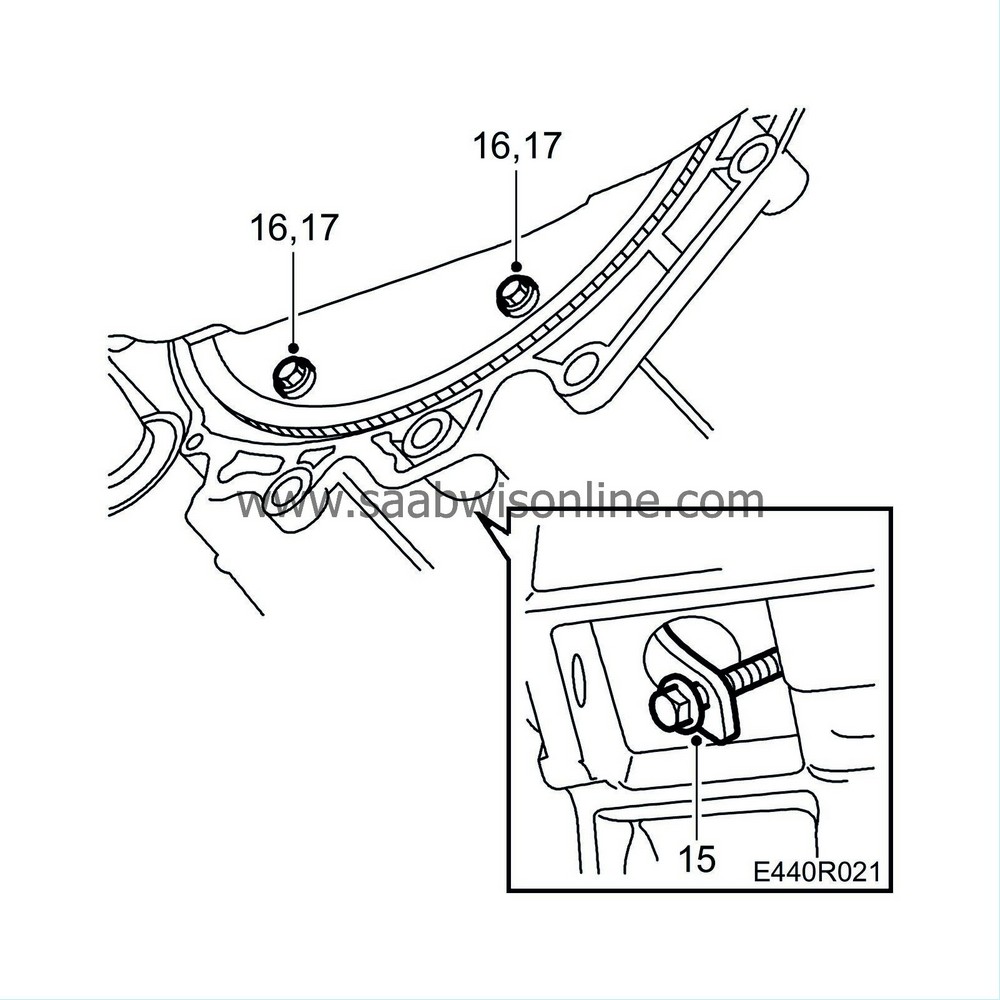

15.

|

Undo the three bolts securing the rear engine cushion, leaving the screws in place.

|

|

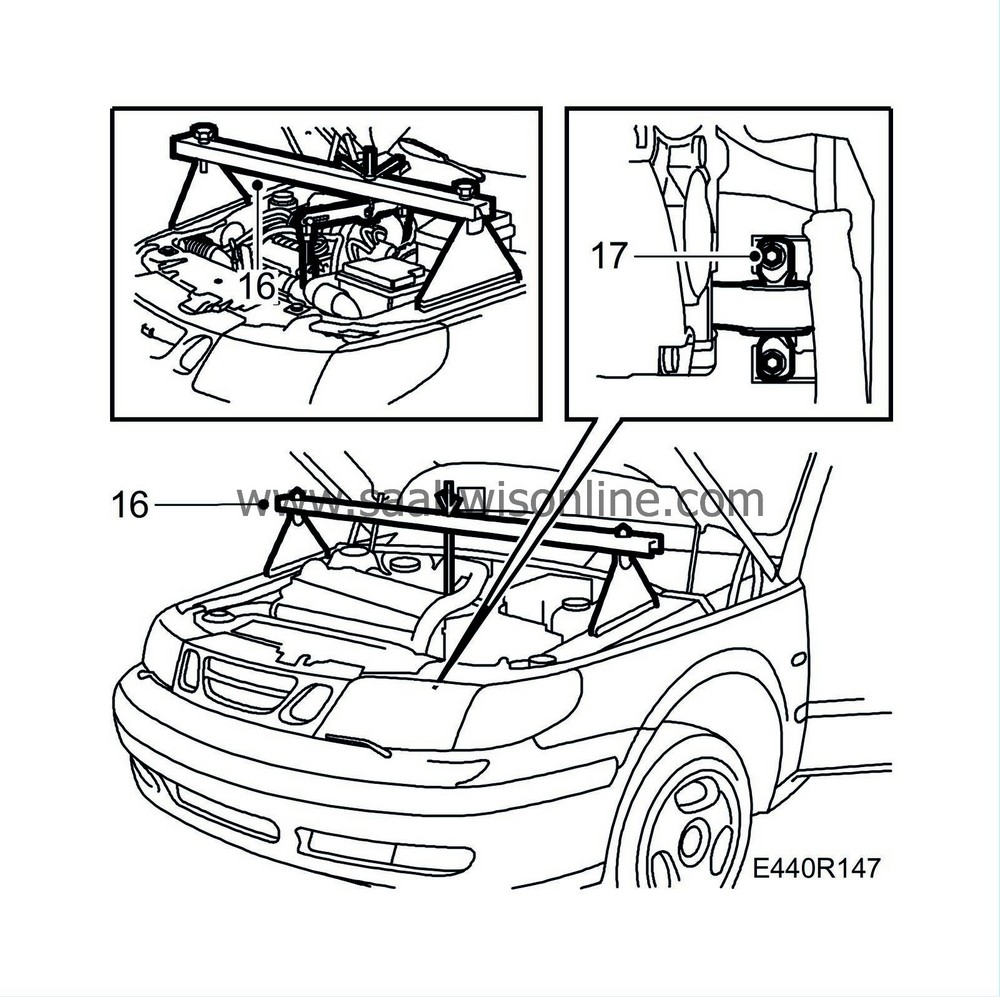

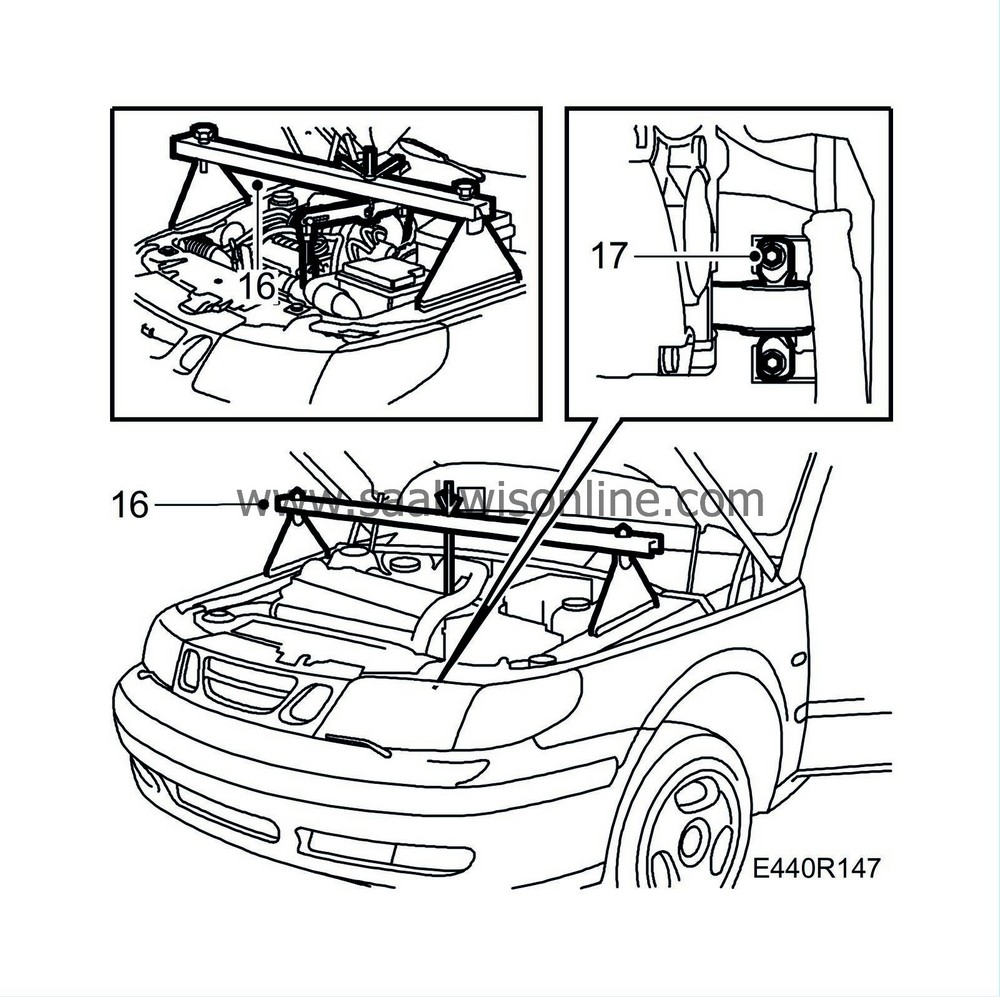

16.

|

V6: Fit lifting eyes, one on the rear of the cylinder head and one on the front (first remove existing bolt. Fit

83 95 287 Holder

).

Put

83 94 850 Lifting beam

in position and relieve the weight on the engine and transmission.

|

Important

|

|

Place suitable protective pads or the like under the feet of the lifting beam to avoid damaging the paintwork.

|

|

|

|

|

17.

|

Remove the torque arm from the subframe.

|

|

19.

|

Remove the front wheels.

|

|

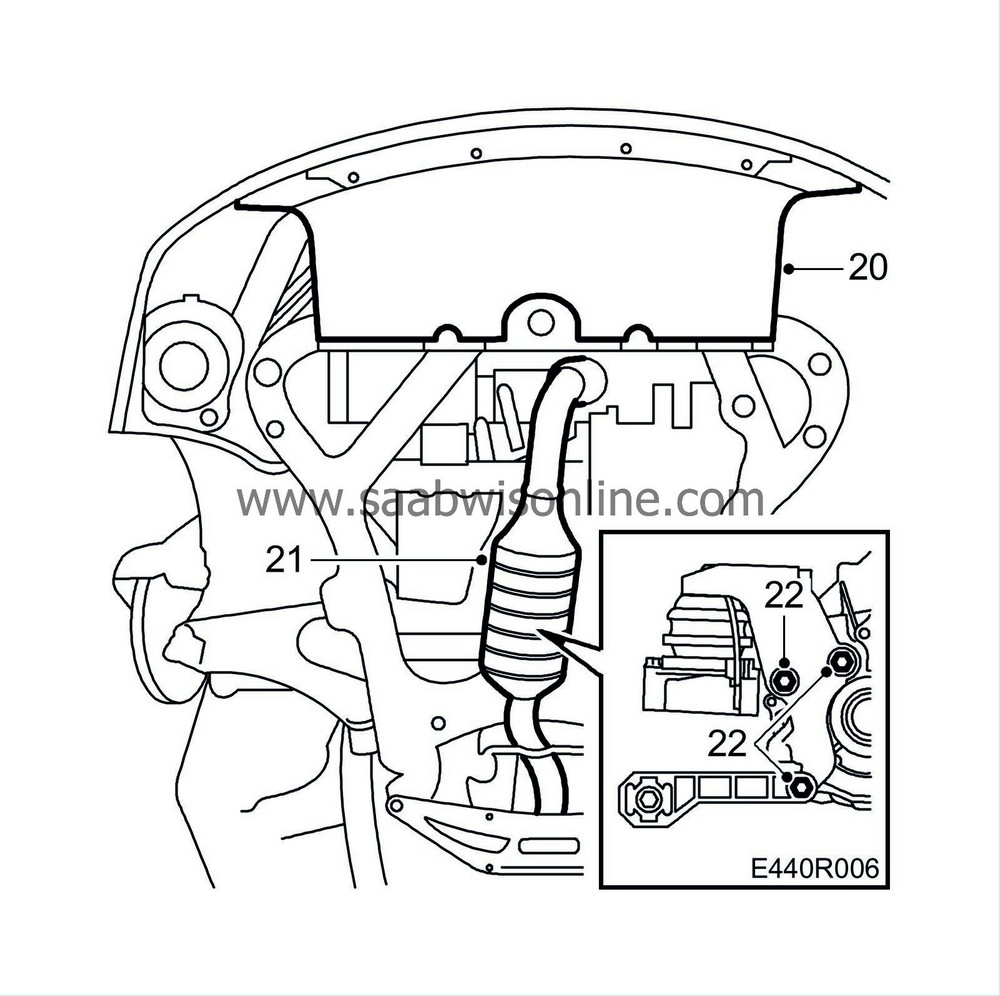

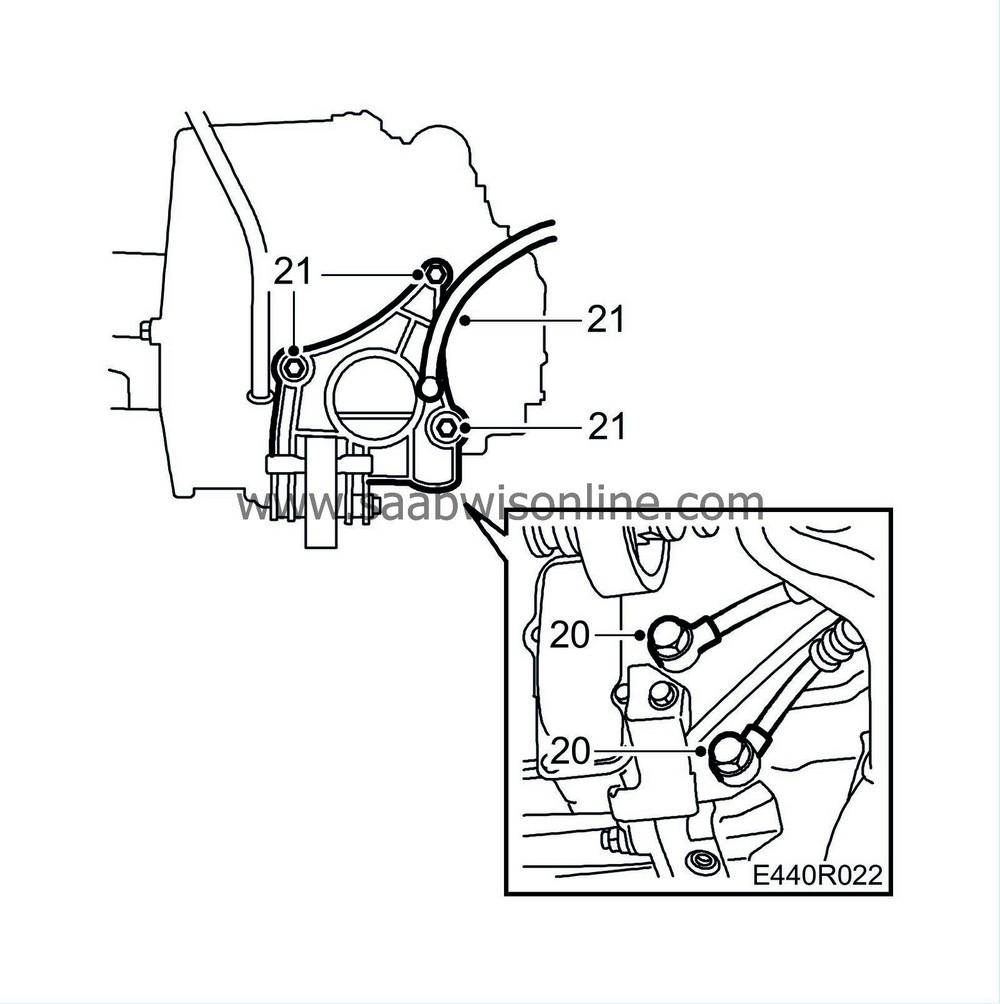

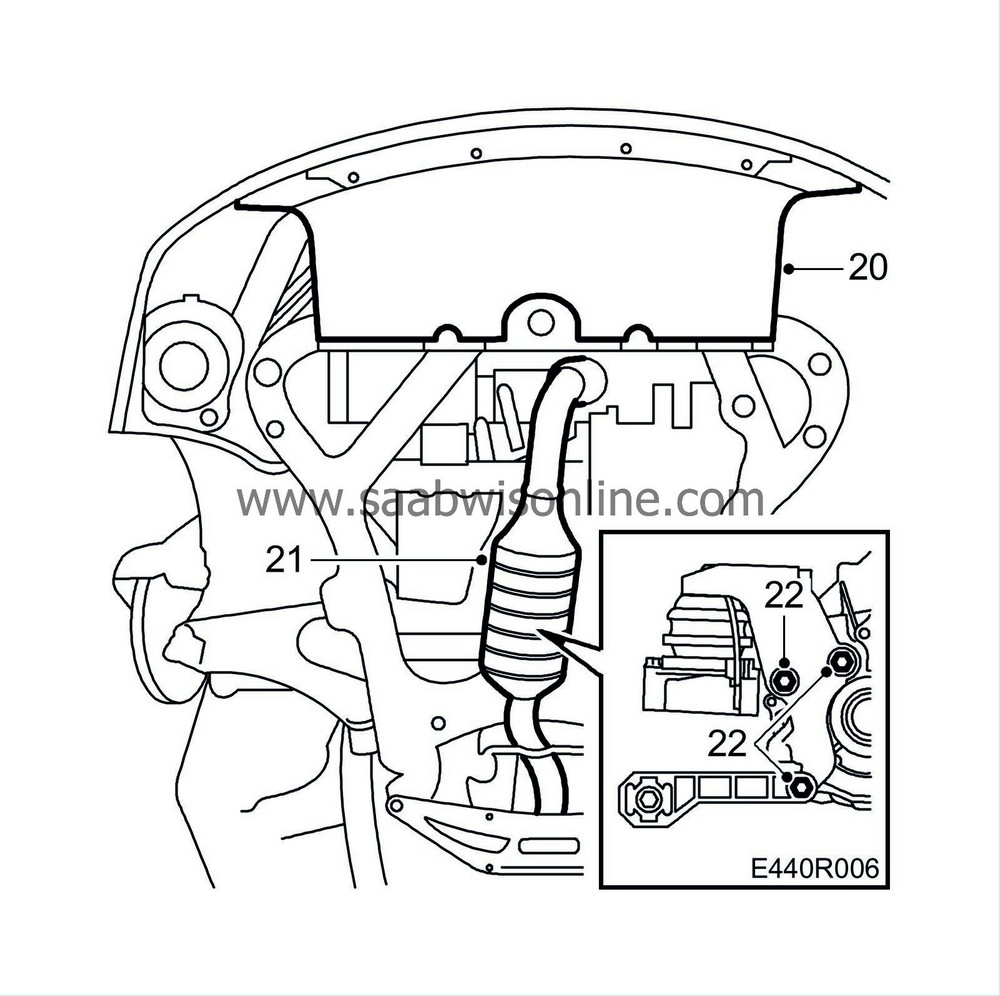

20.

|

Remove covers.

|

|

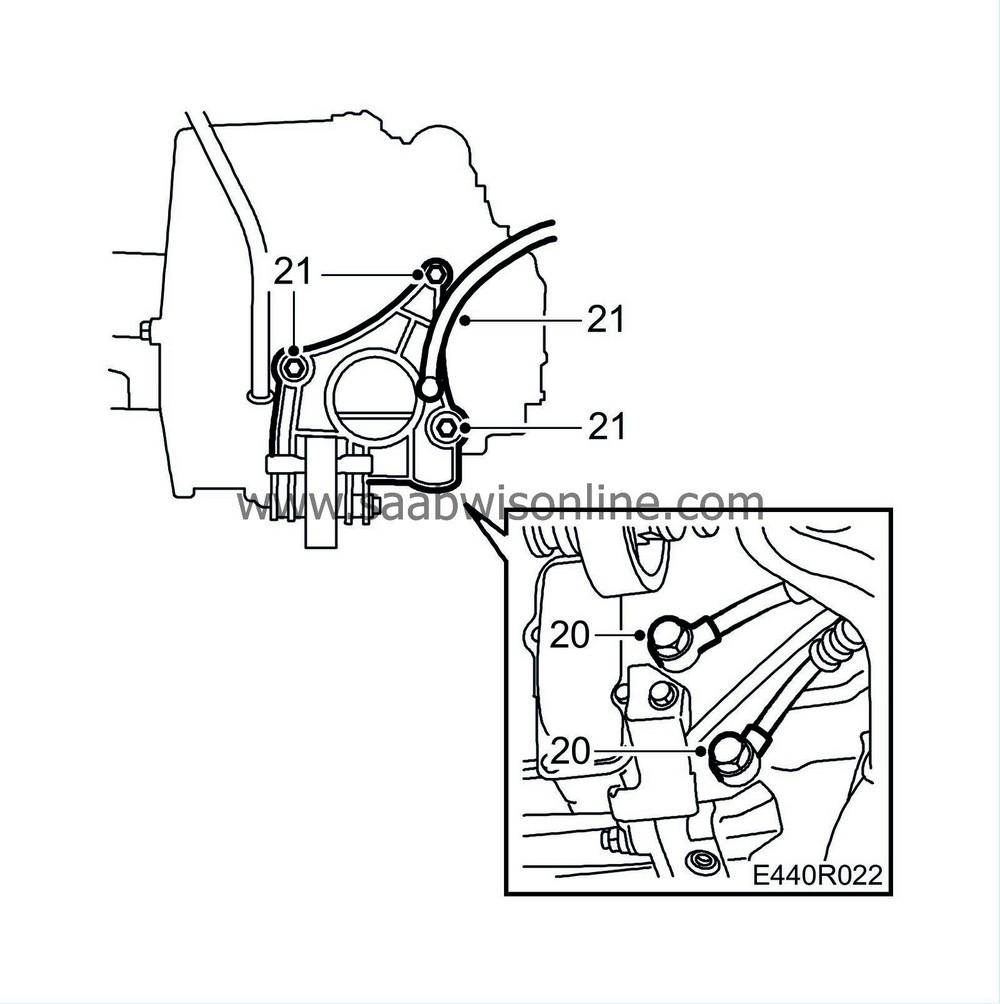

21.

|

Remove the front exhaust system, taking care to avoid damaging the oxygen sensor.

|

|

22.

|

4-cyl: Remove the rear engine mounting, engine pad and torque rod.

|

|

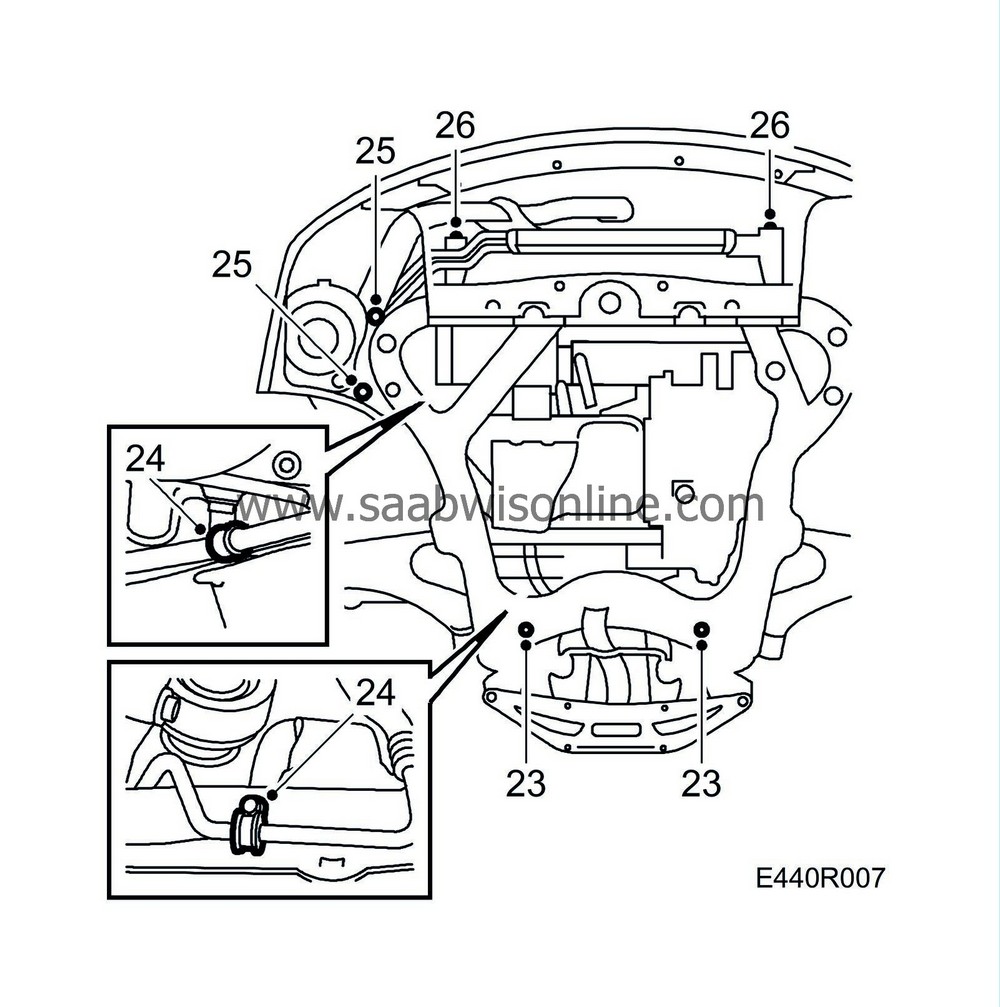

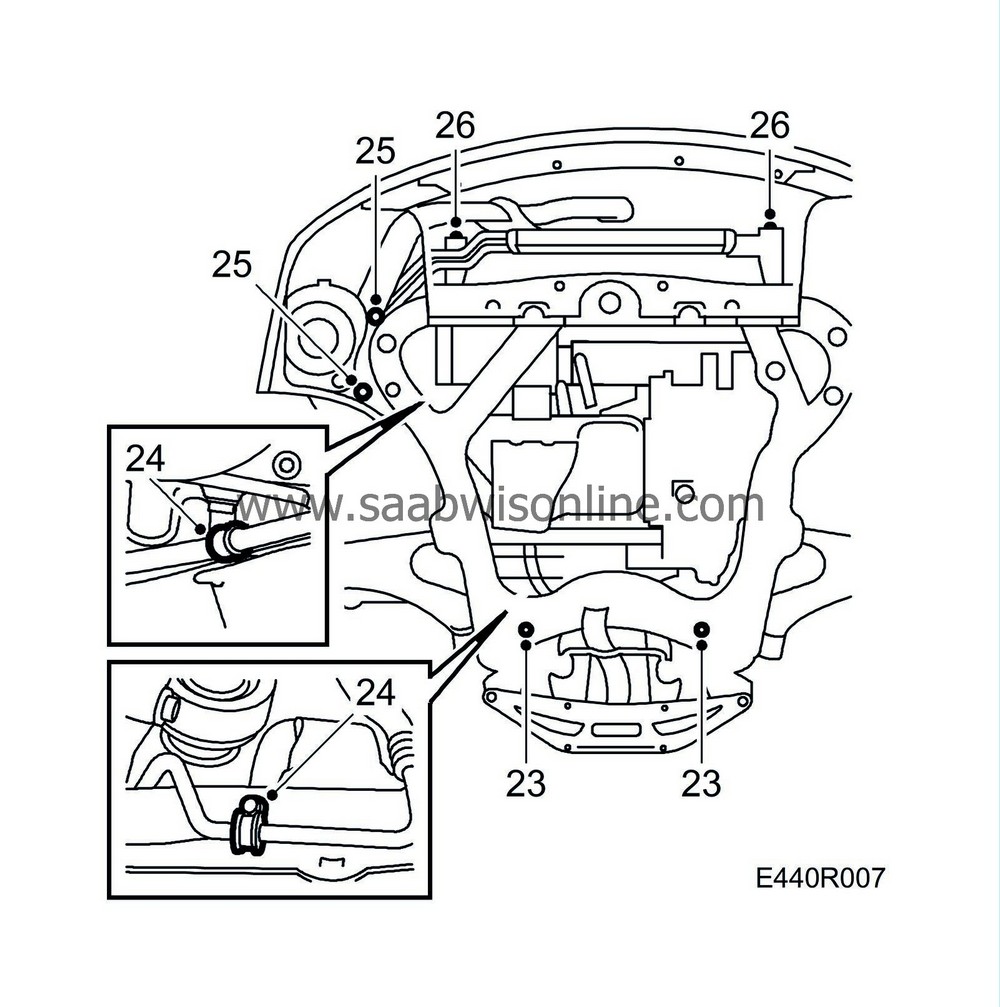

23.

|

Remove the screws securing the steering gear.

|

|

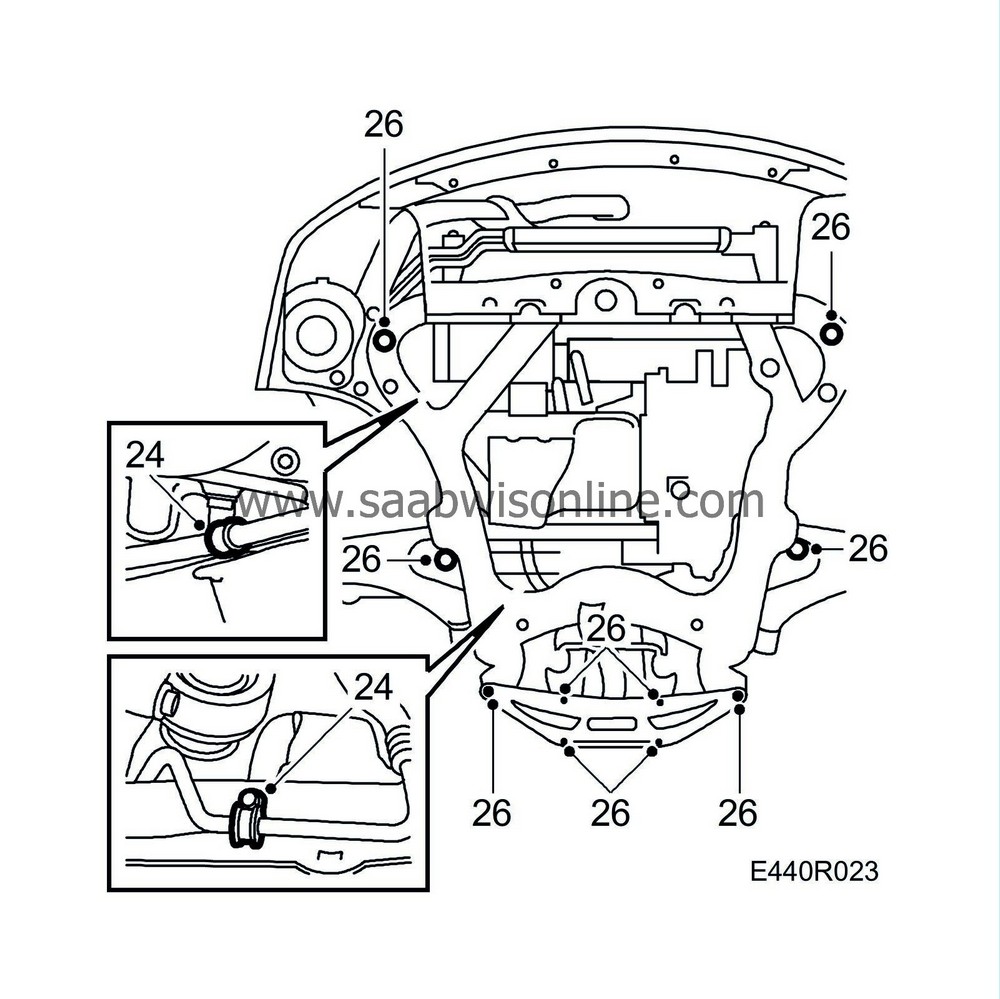

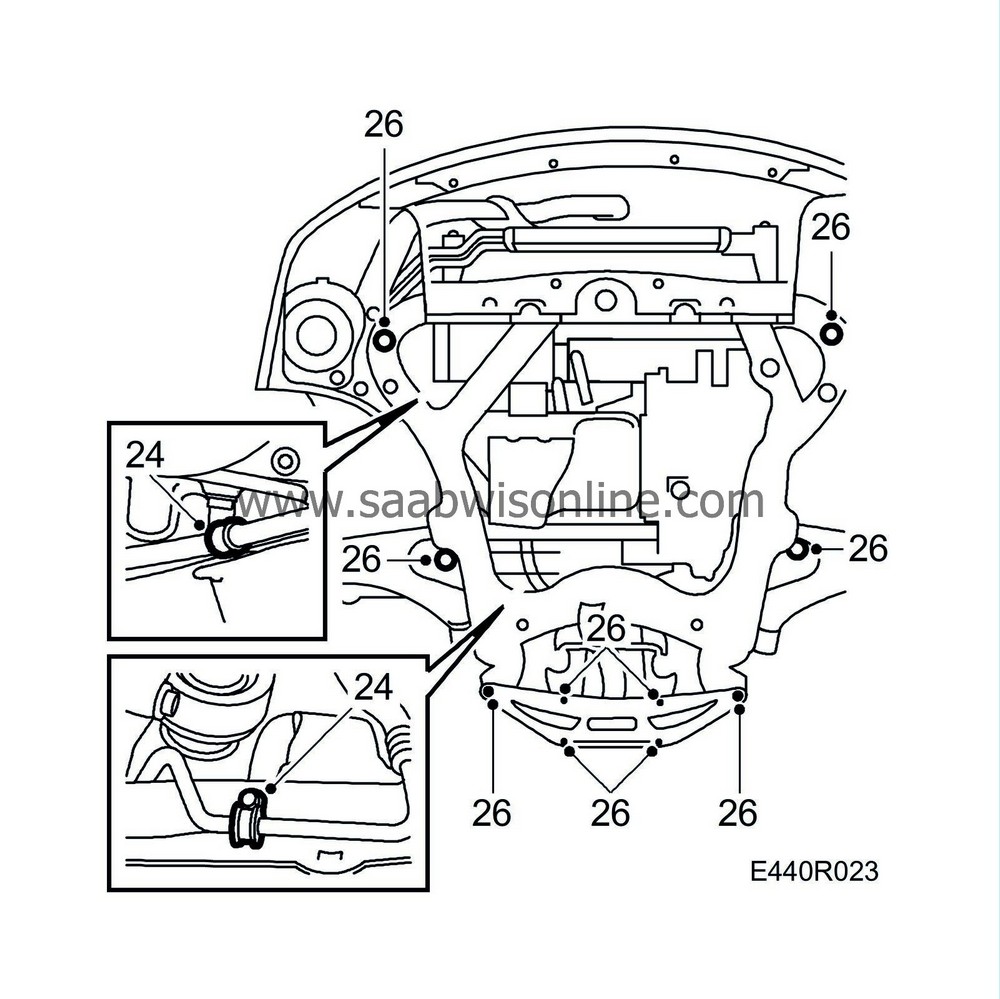

24.

|

Remove the two rear clamps securing the power steering delivery pipe to the subframe. Remove the AC pipes from the plastic clips on the subframe at the same time.

|

|

25.

|

Remove the air cleaner casing from the subframe.

|

|

26.

|

4-cyl: Detach the engine oil cooler from the charge air cooler.

|

|

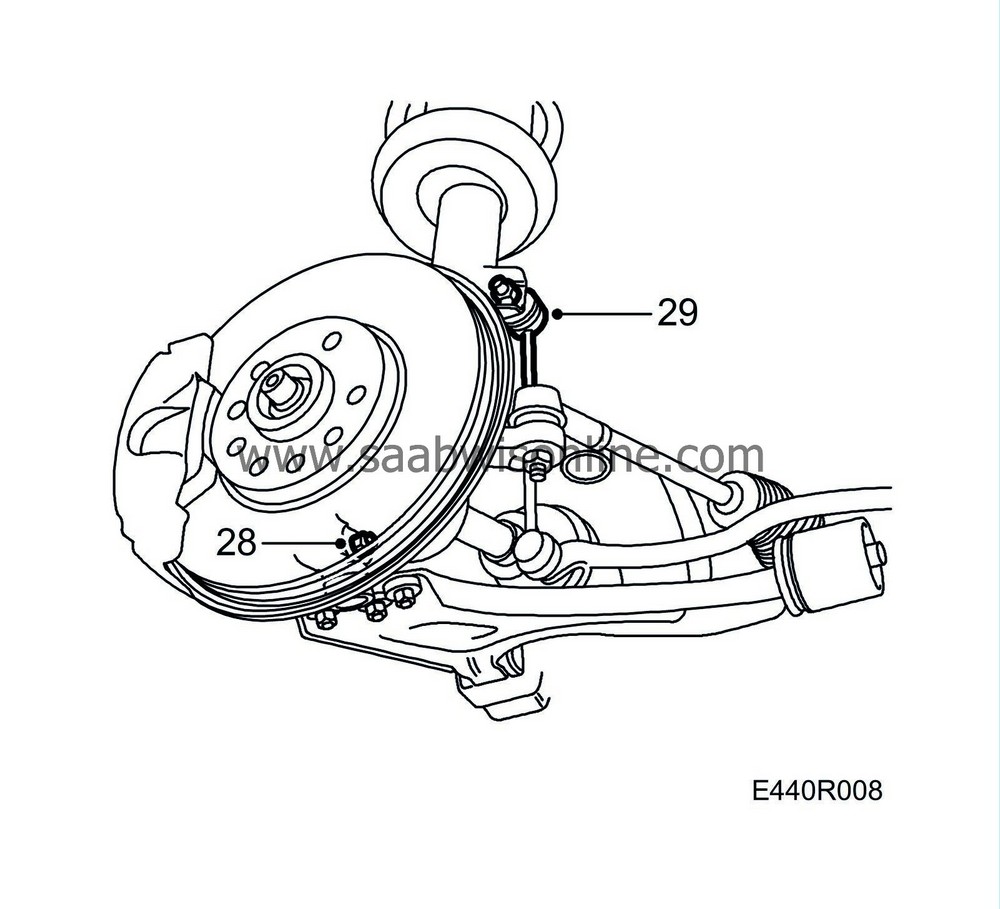

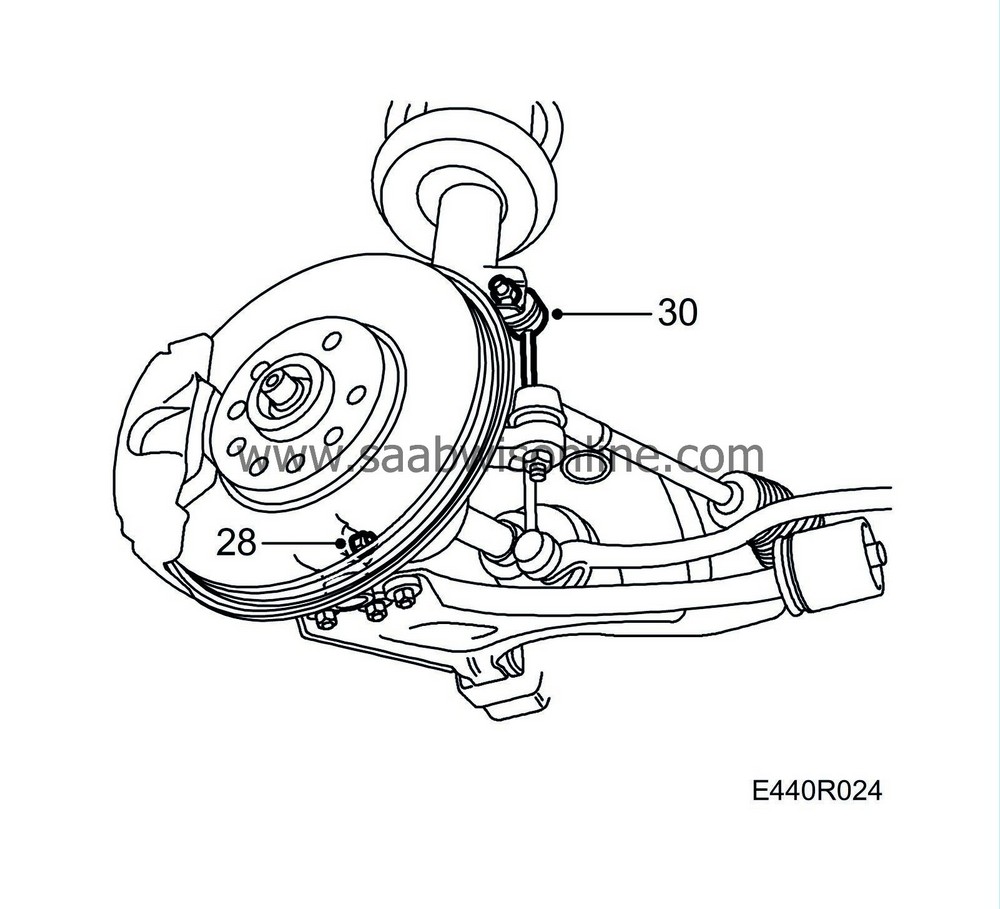

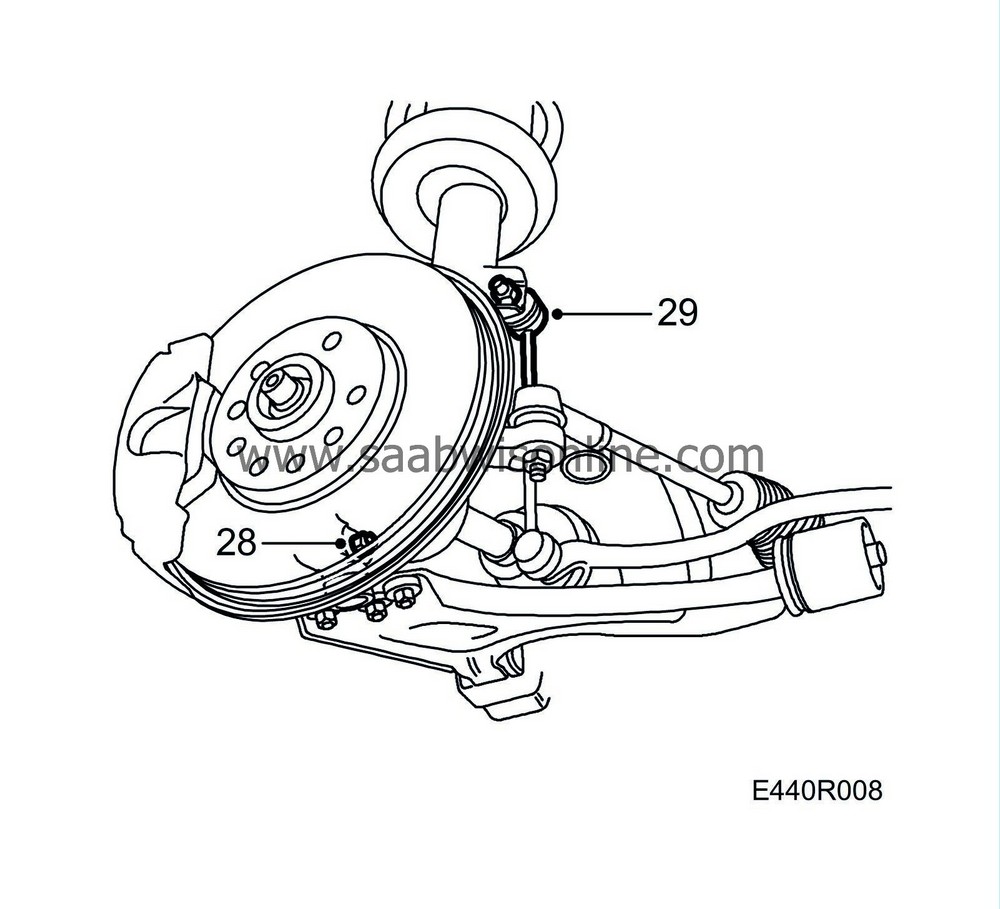

28.

|

Remove the bolts securing the outer ball joints to the steering knuckle housing on both sides.

|

|

29.

|

Detach the upper anti-roll bar ball joints. Use a 17 mm spanner to prevent the boot from twisting. If the spanner is too wide to fit between the boot and the suspension strut, it must be ground narrower.

|

|

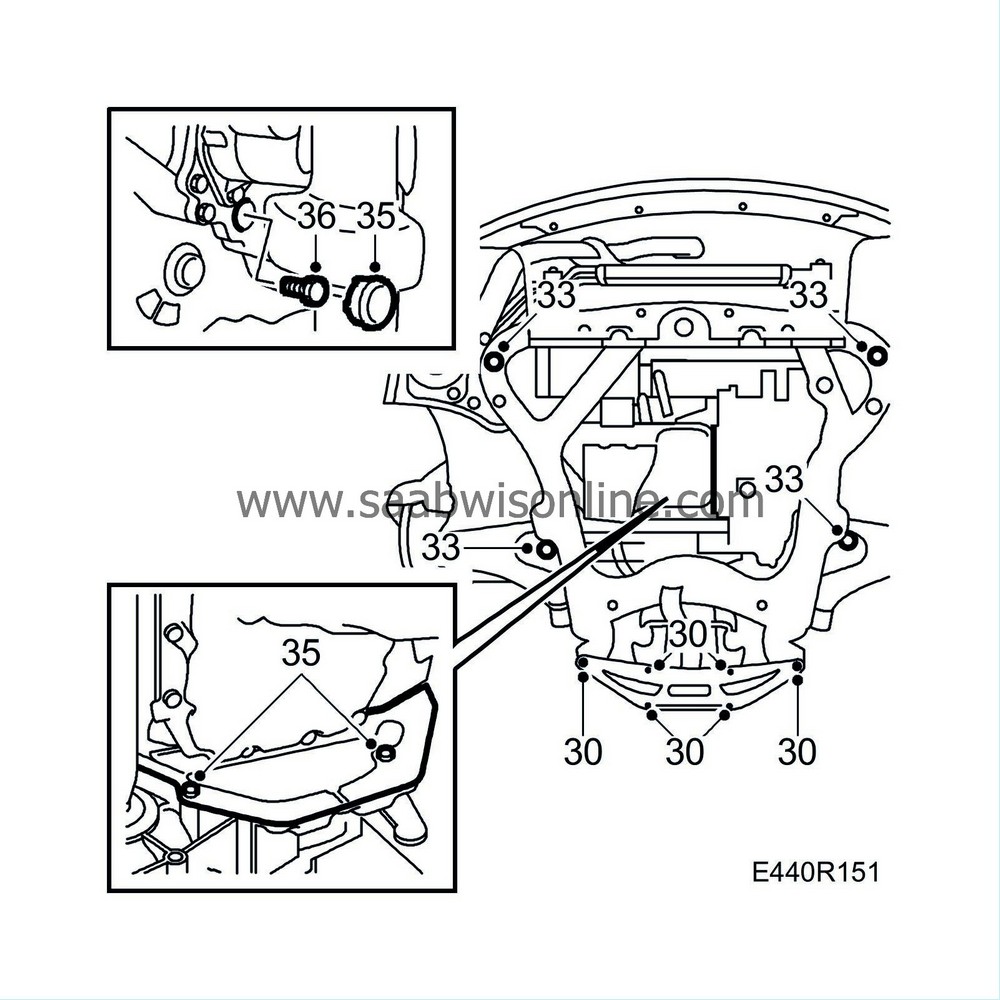

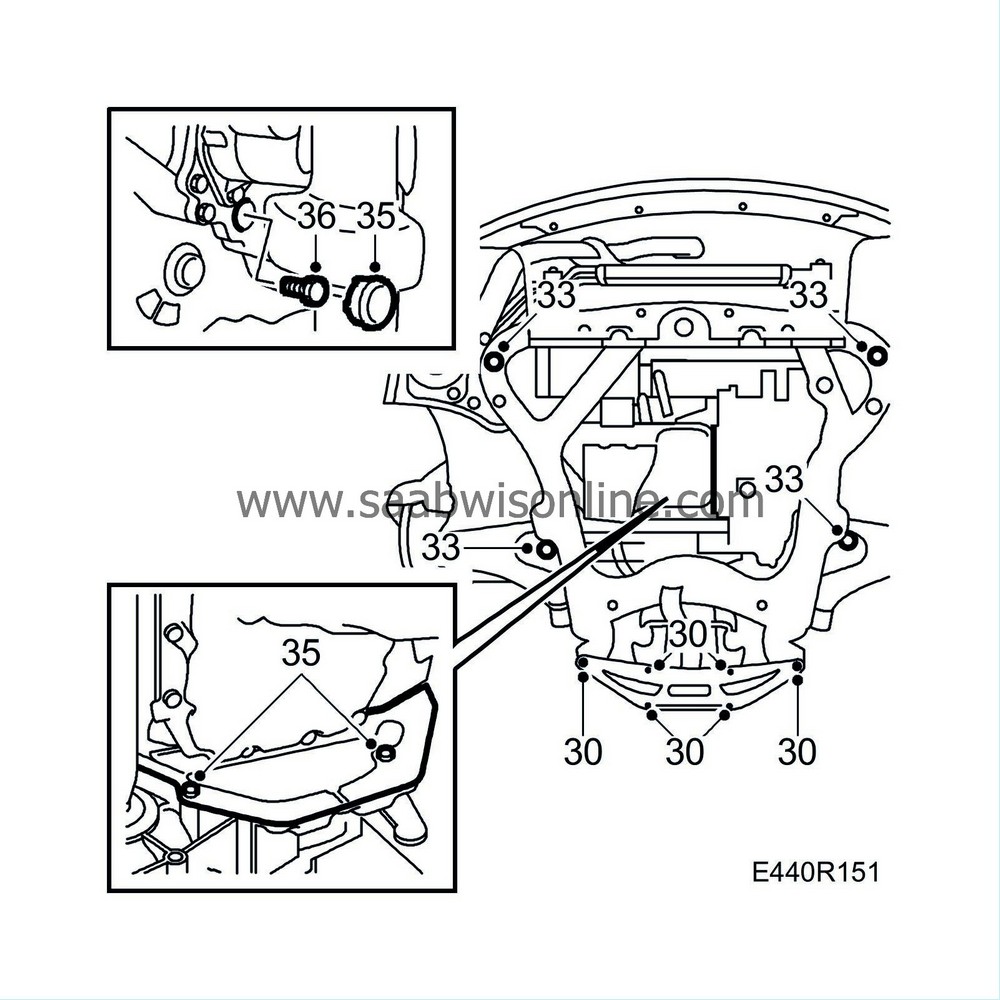

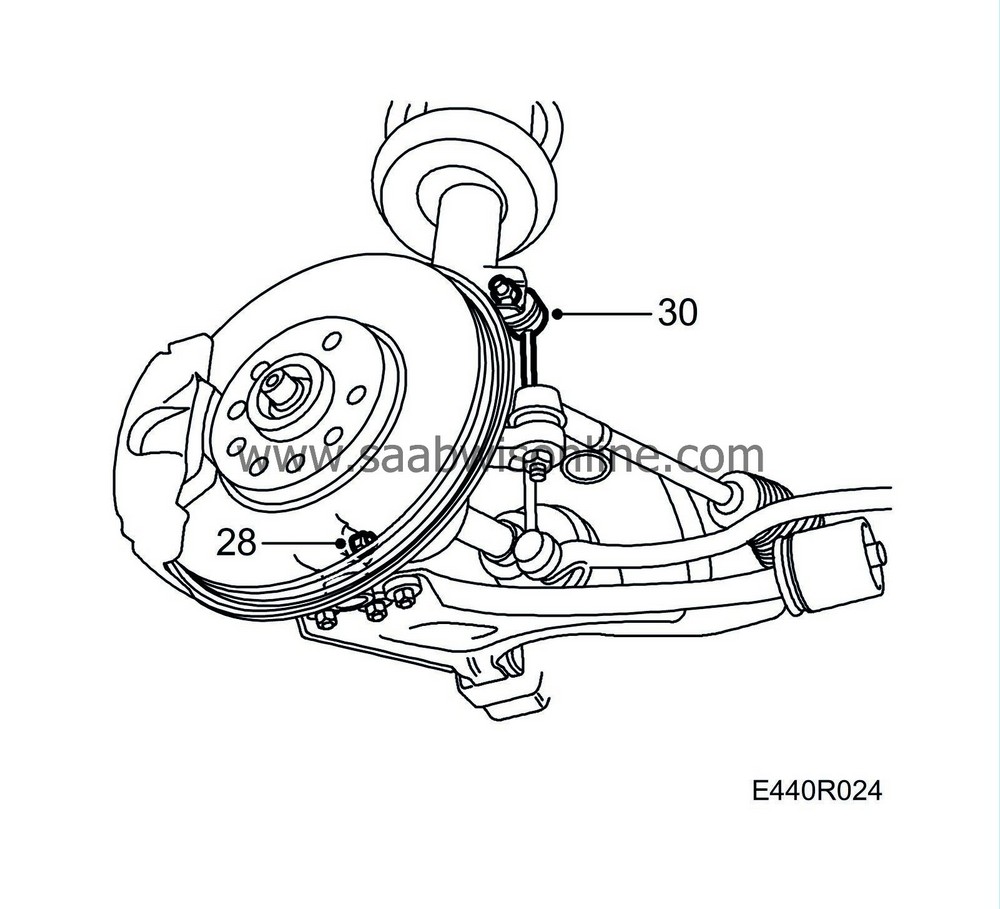

30.

|

Remove the rear support plates. Keep the spacer washers between the support plate and the bush found on cars with VIN up to and including W3050999.

|

|

32.

|

Position the lifting trolley with lifting table and holder under the subframe. Raise the lifting table, being careful to position it correctly.

|

|

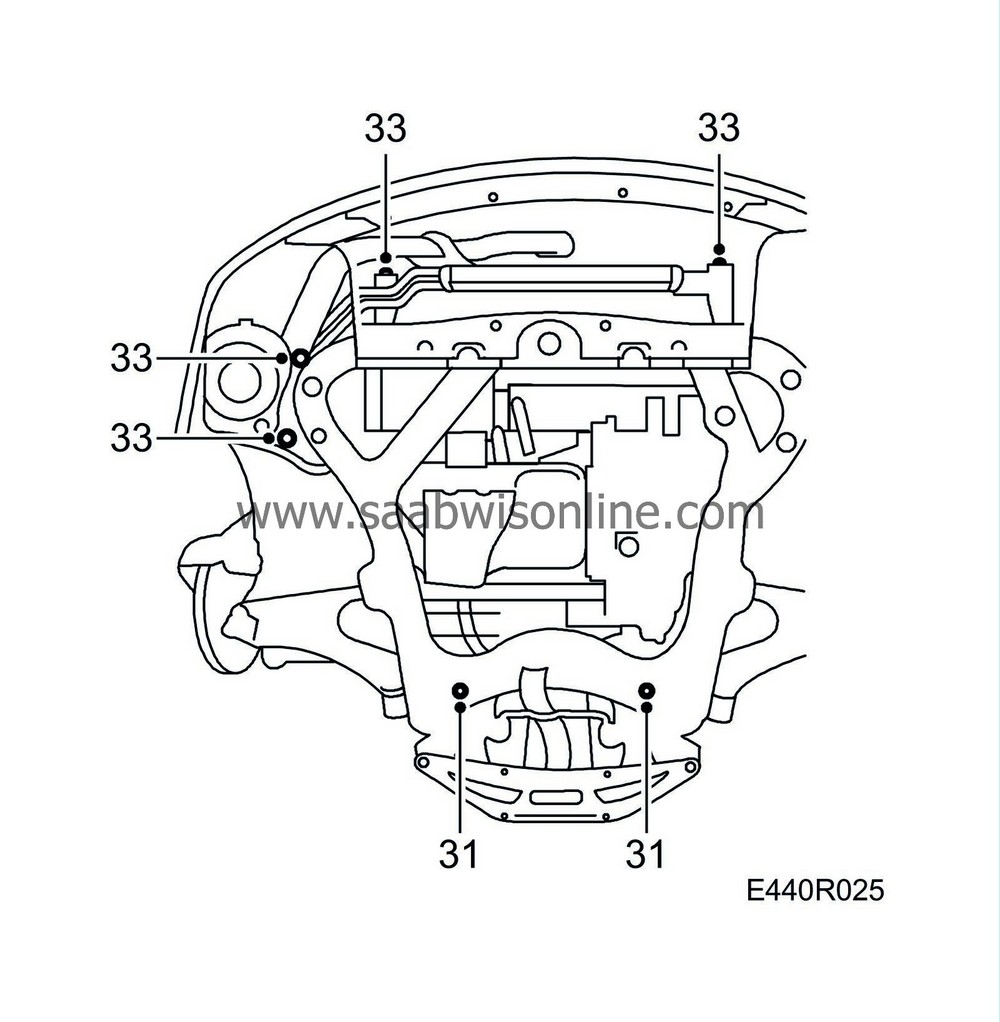

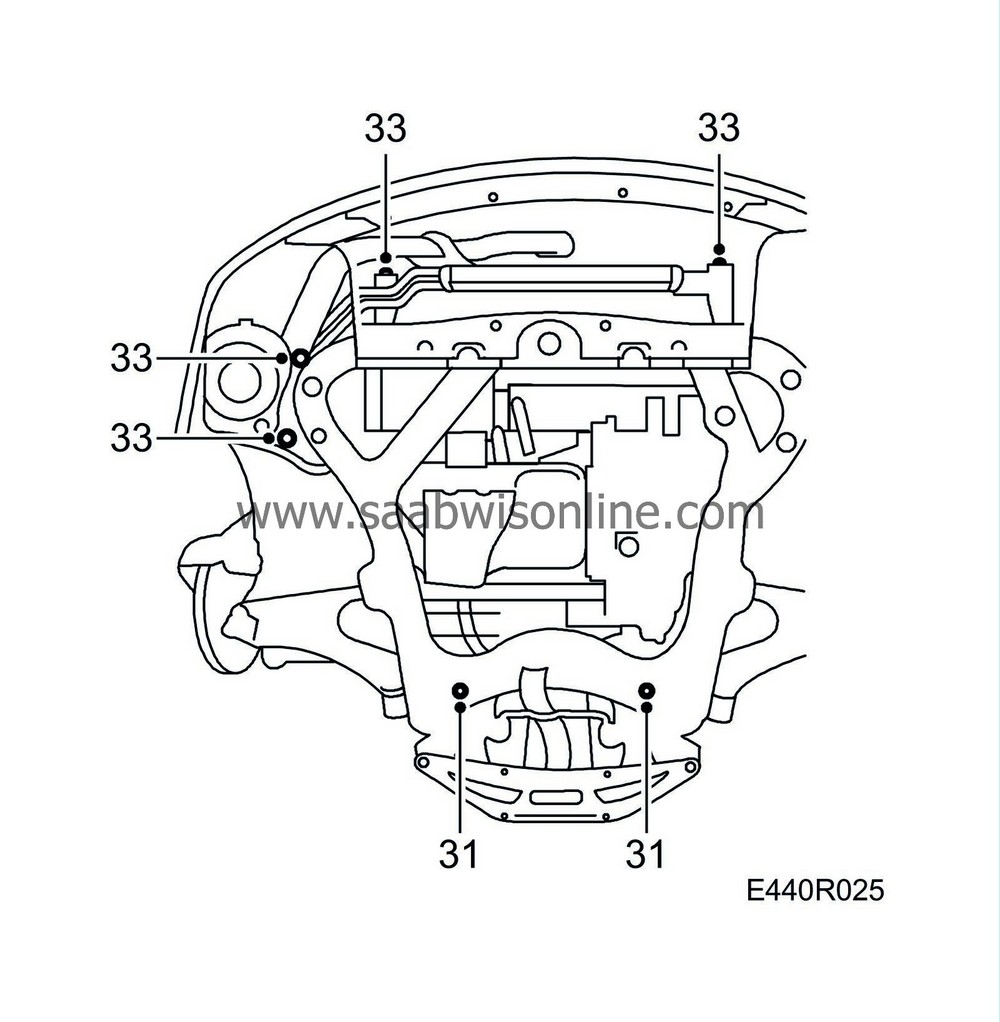

33.

|

Remove the last 4 bolts securing the subframe. Retain the spacer washers between the washer and bushing on cars up to and including VIN W3050999.

|

|

34.

|

Lower the subframe approx. 5 cm so that the two front clamps holding the power steering delivery pipe in place can be removed. Remove the clamps, lower the subframe and move the lifting trolley out of the way.

|

|

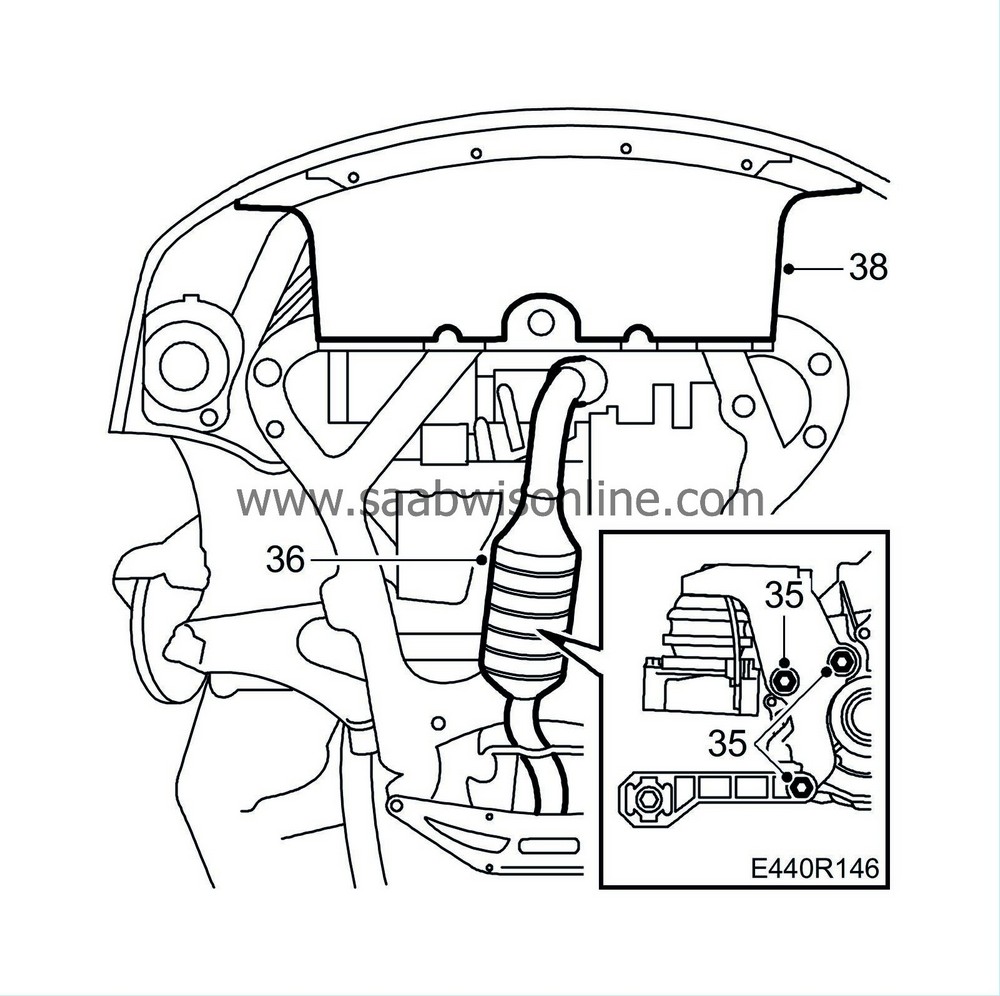

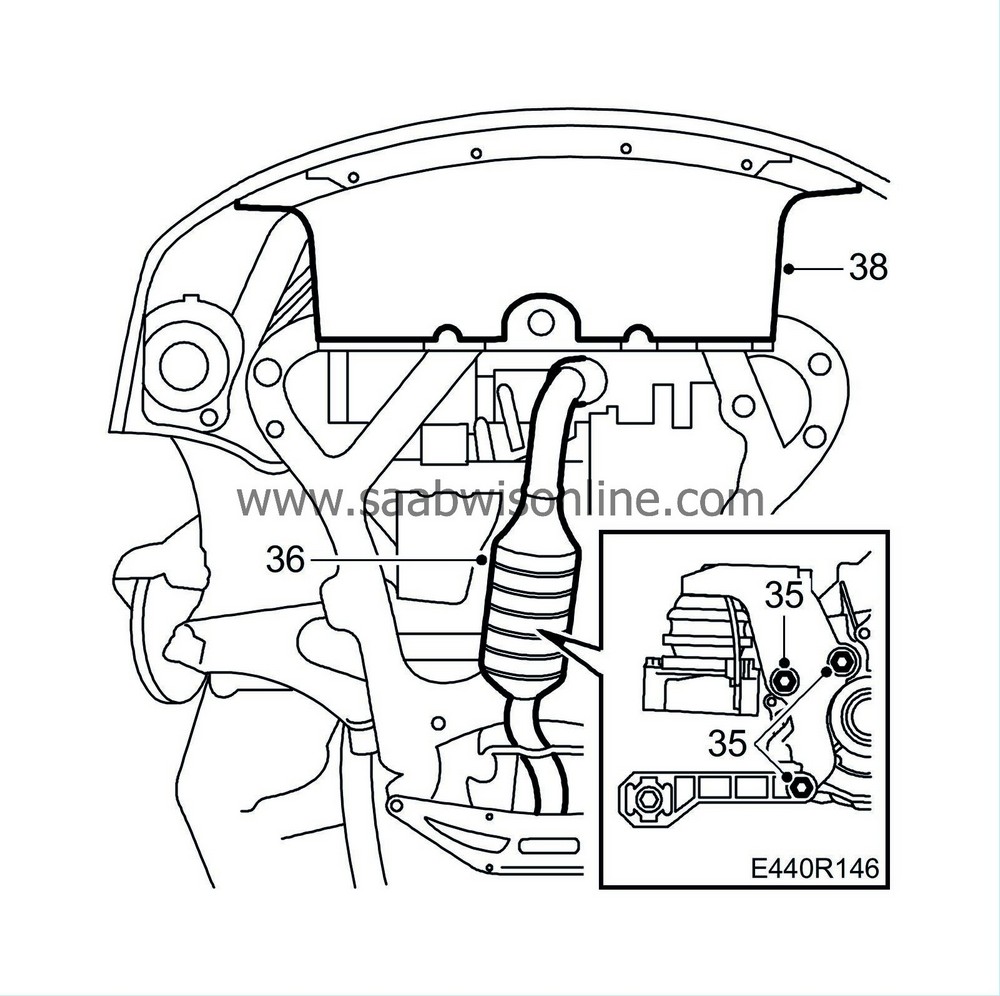

35.

|

4-cyl: Remove the splash plate (secured with two bolts to the transmission casing) to access the torque converter mounting on the drive plate.

V6: Remove the plug (under the starter motor) covering the bolts to the torque converter.

|

|

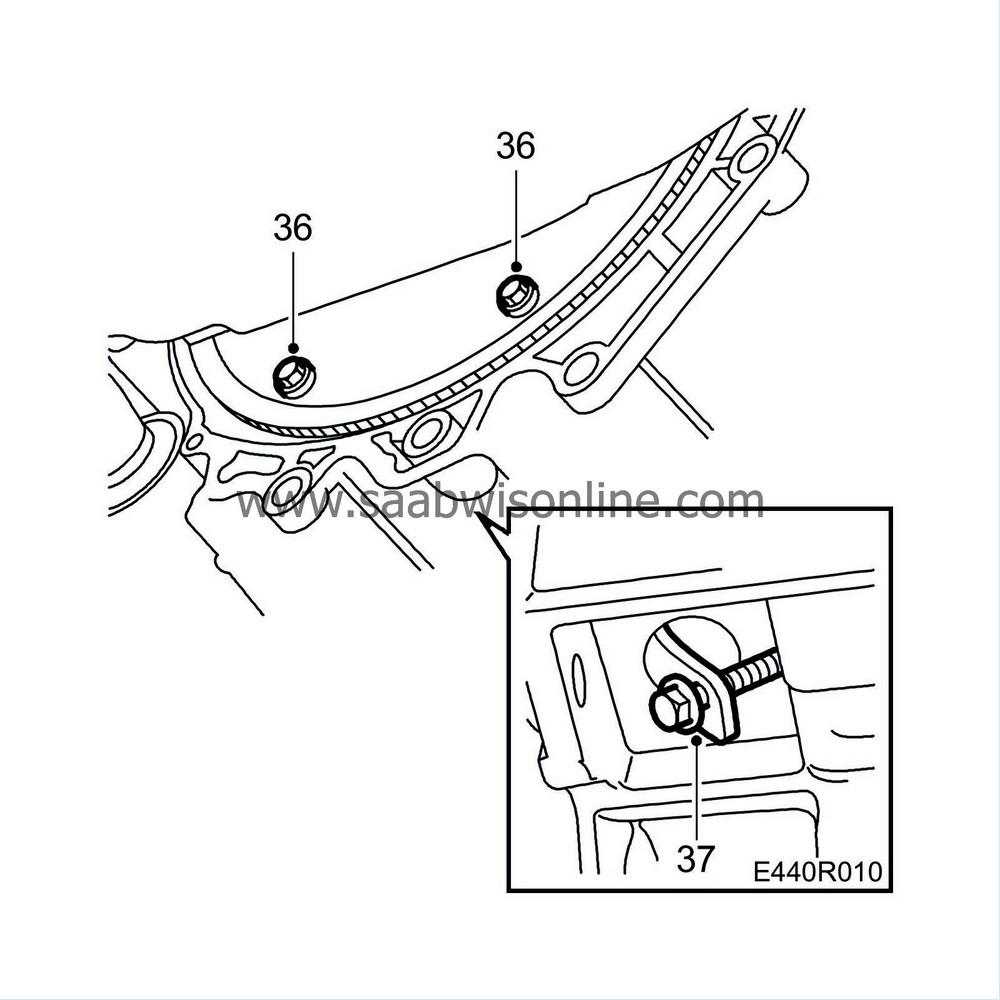

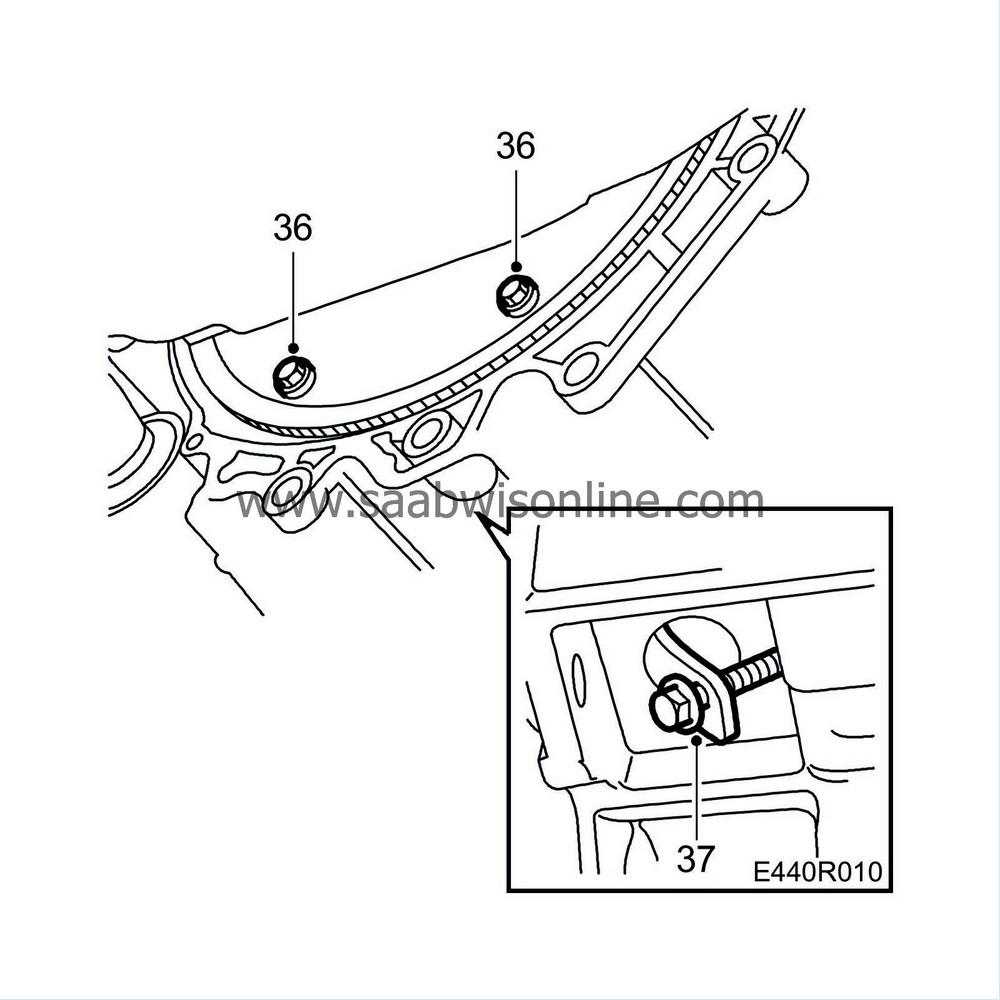

36.

|

Undo the 6 bolts securing the torque converter to the drive plate. Rotate the plate together with the pulley.

|

Note

|

|

The crankshaft will have to be rotated in order to gain access to all the bolts.

|

|

|

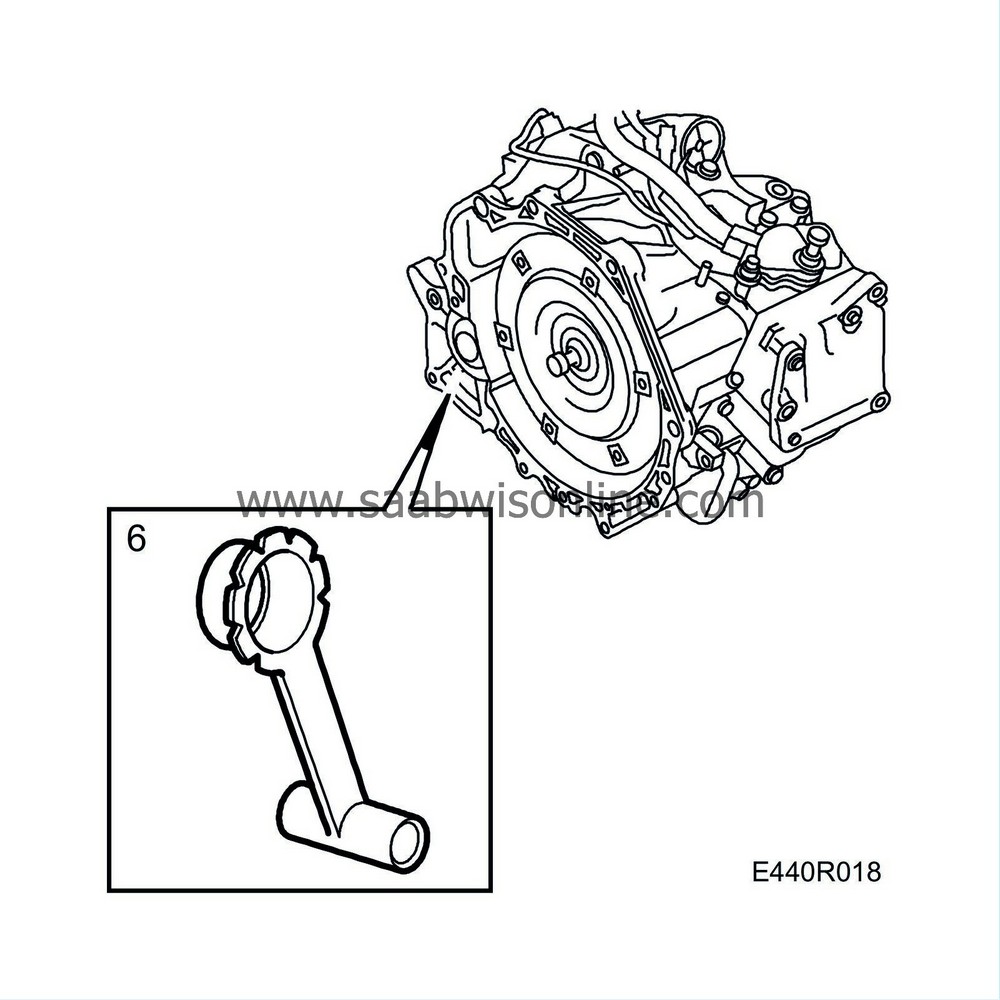

37.

|

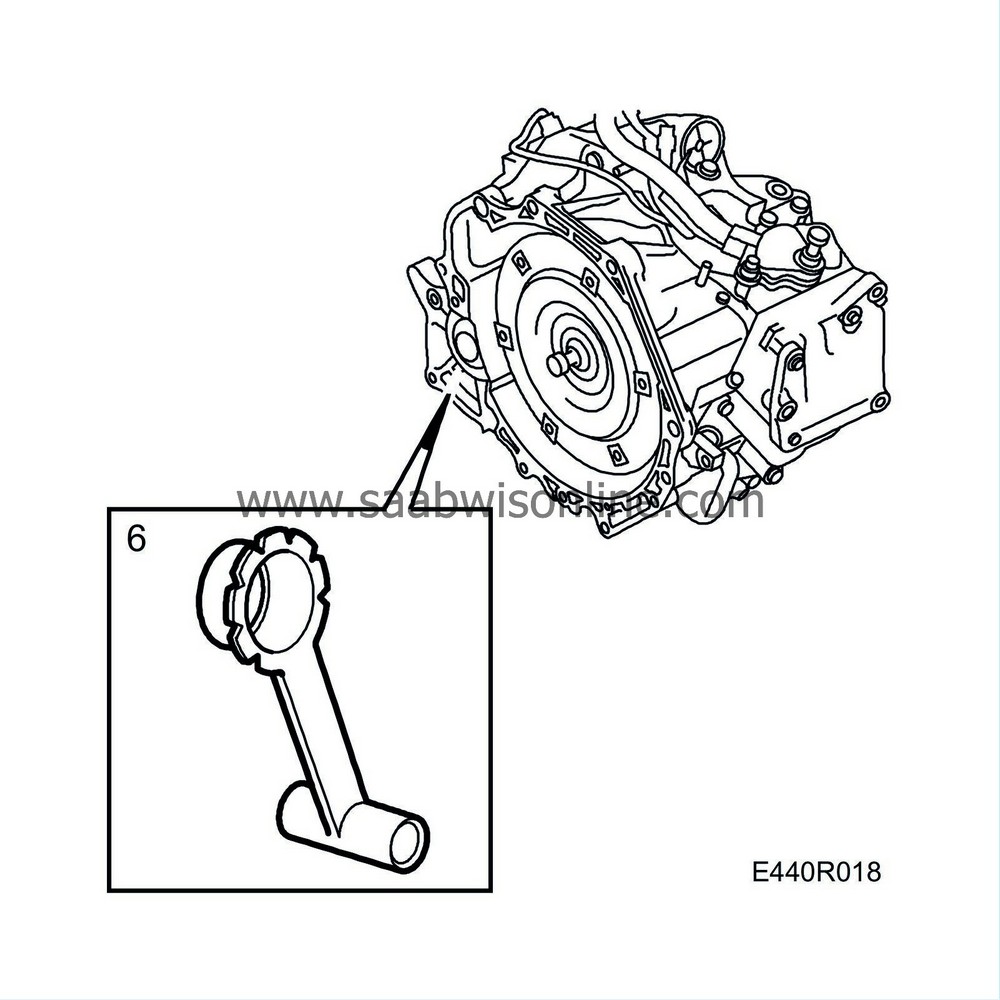

Press the torque converter towards the gearbox and fit

87 92 574 Holder

to keep it in place while the gearbox is removed.

|

|

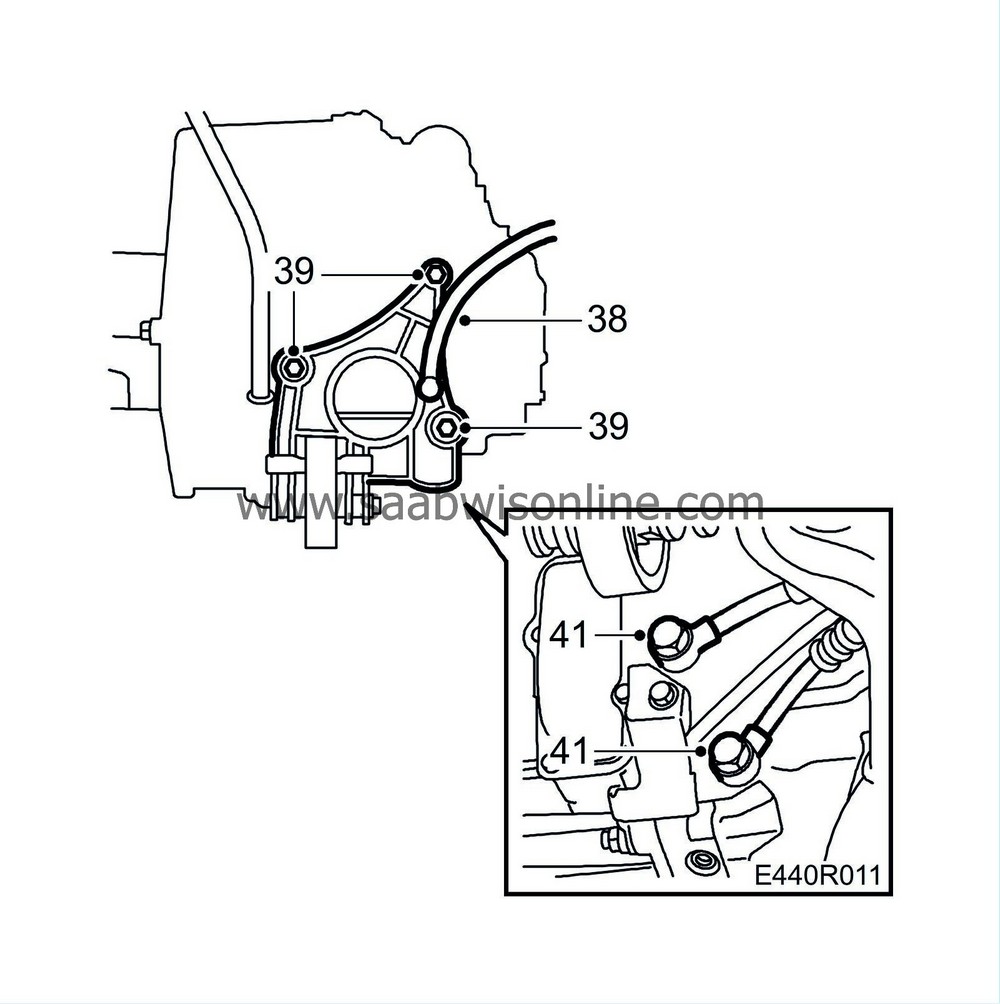

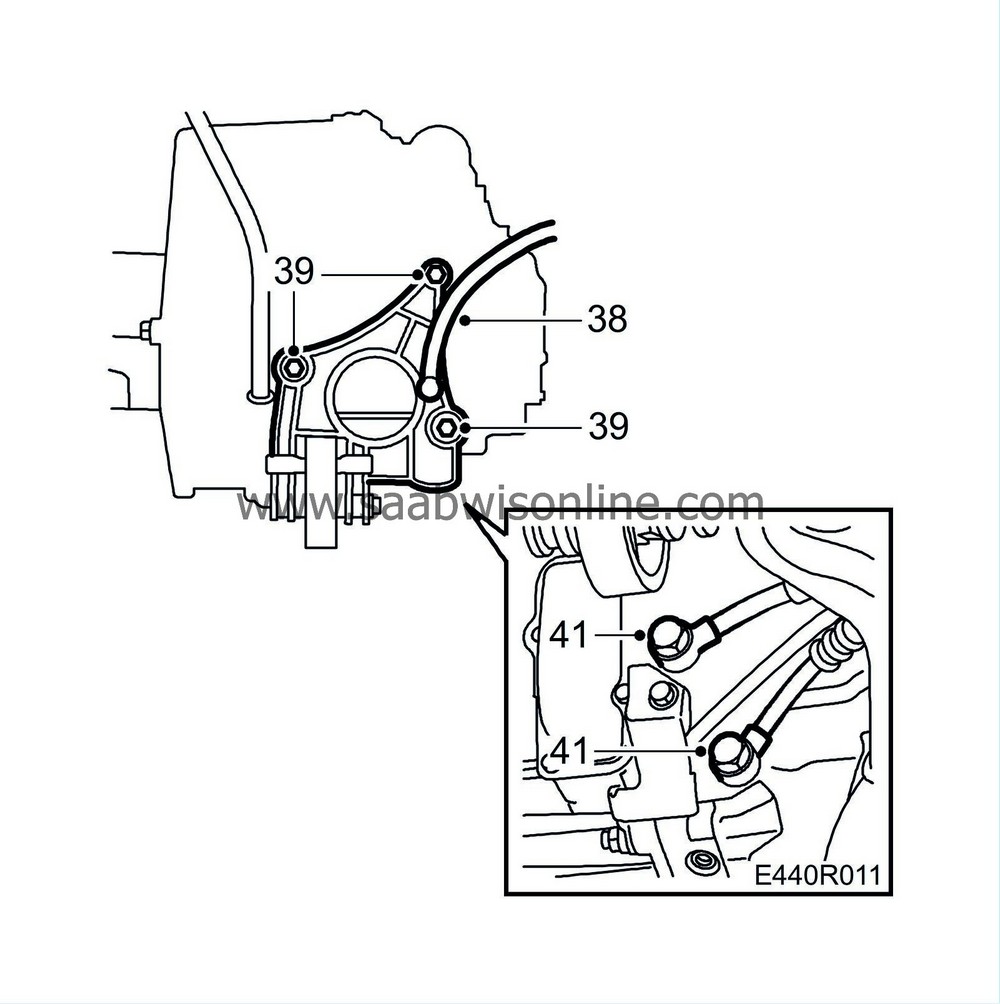

38.

|

Disconnect the ground leads.

|

|

39.

|

Remove the torque arm with bracket.

|

|

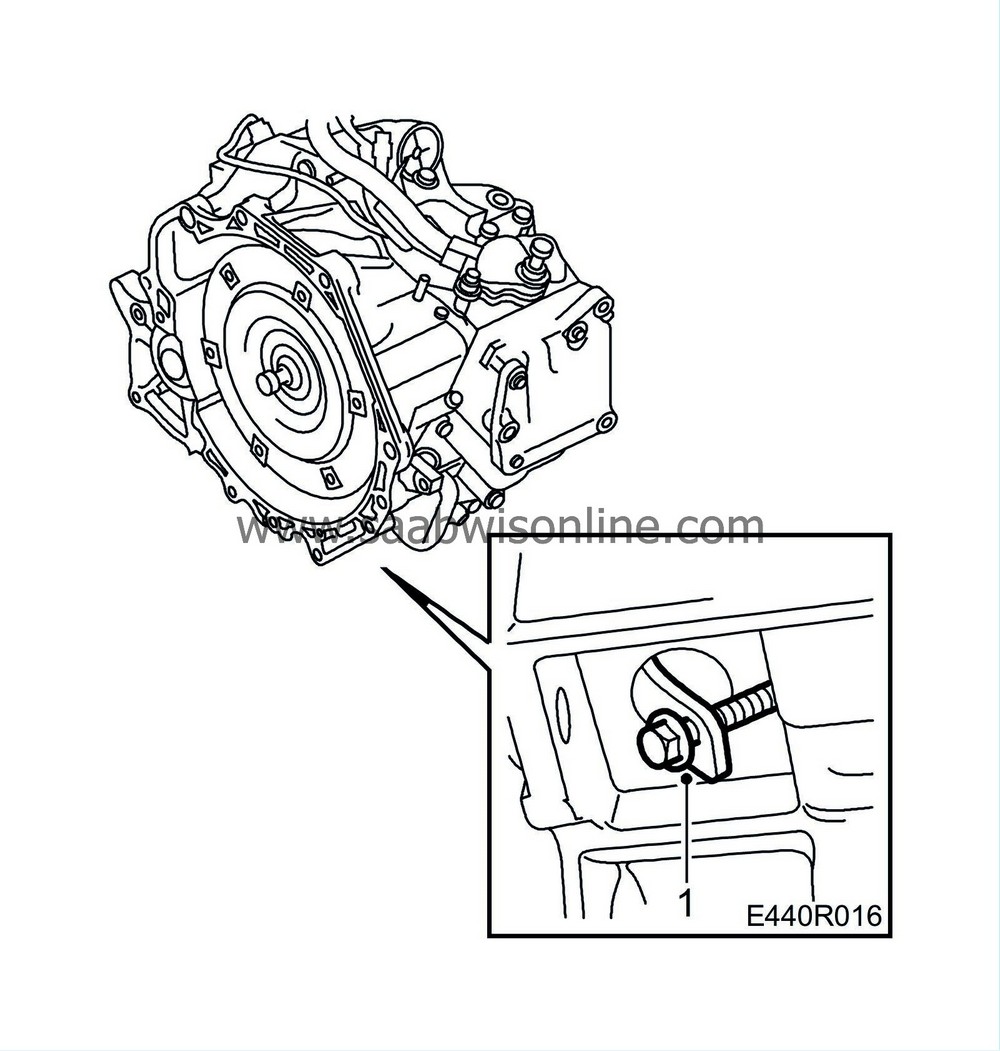

40.

|

Drain the transmission fluid, fit the drain plug.

Tightening torque: 40 Nm (30 lbf ft)

|

|

41.

|

Disconnect the oil cooler's inlet and outlet hoses. Plug the inlet and outlet passages on the transmission and also plug the hoses.

|

|

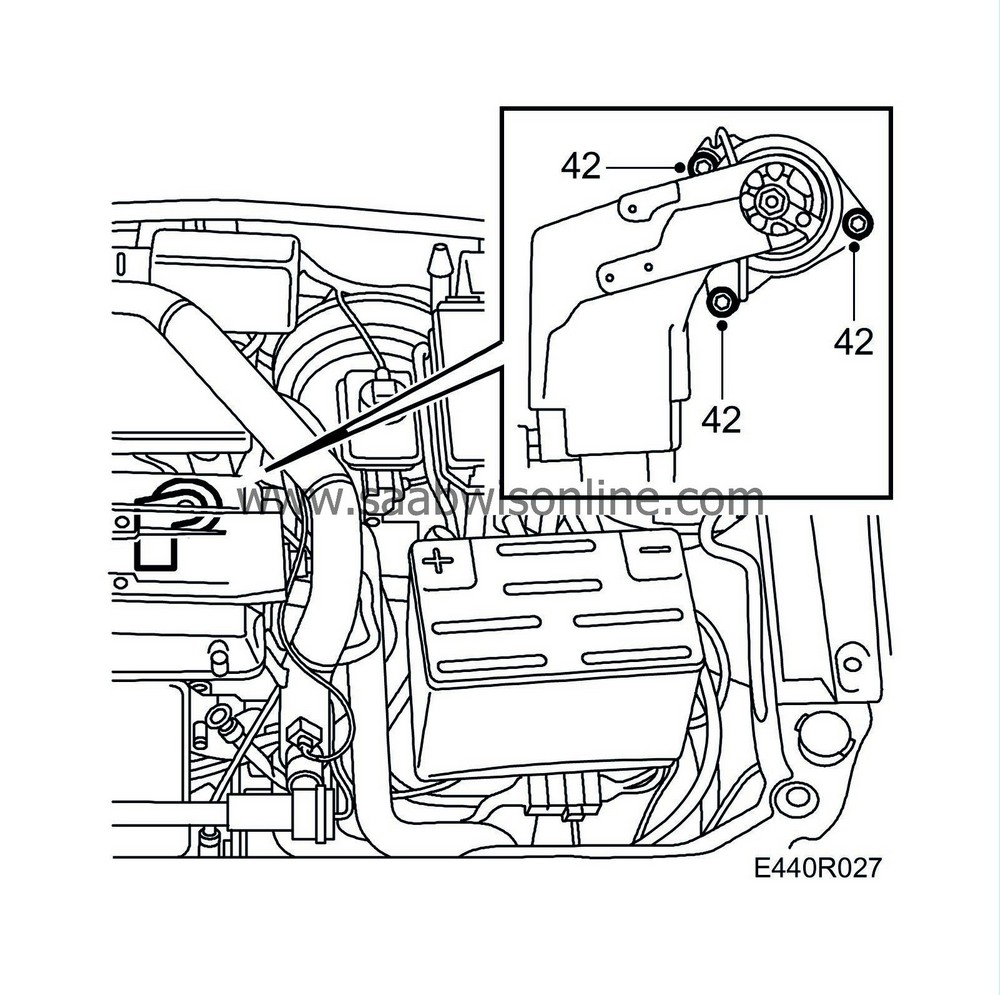

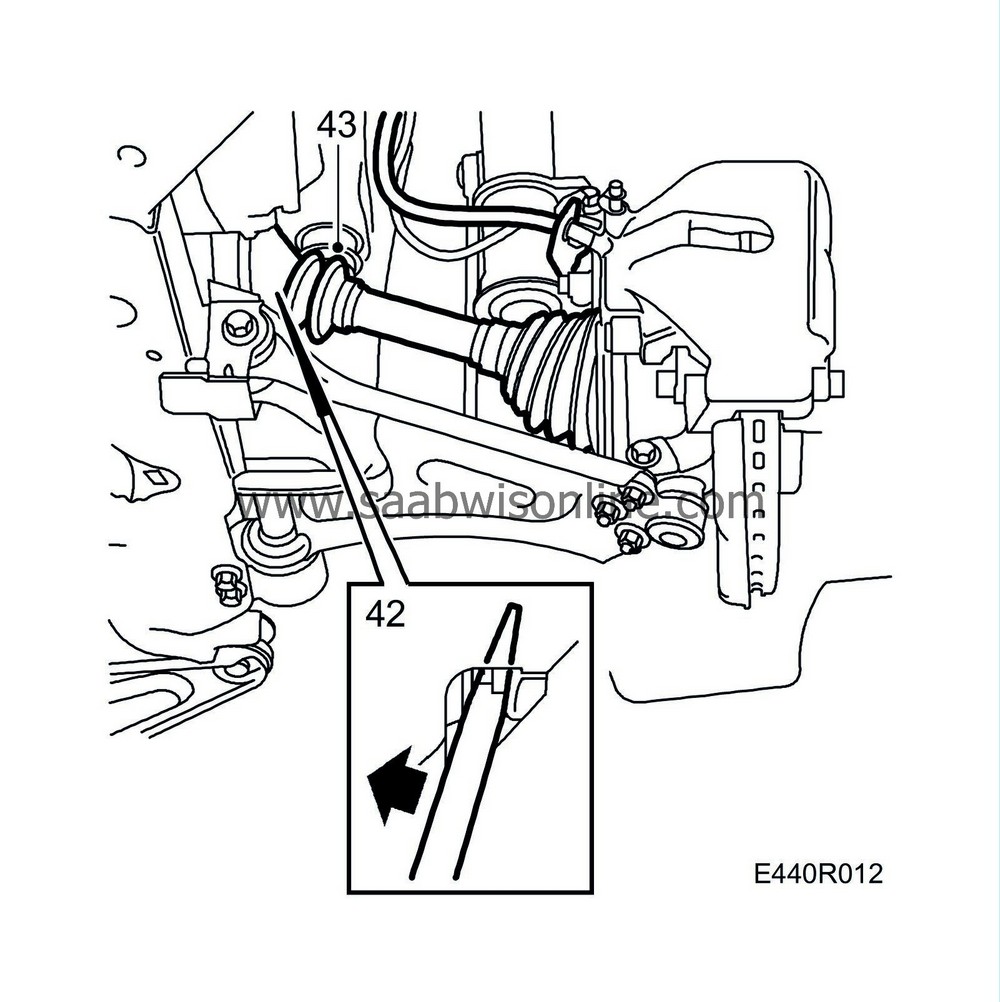

43.

|

Suspend the shaft by means of a cable tie.

|

|

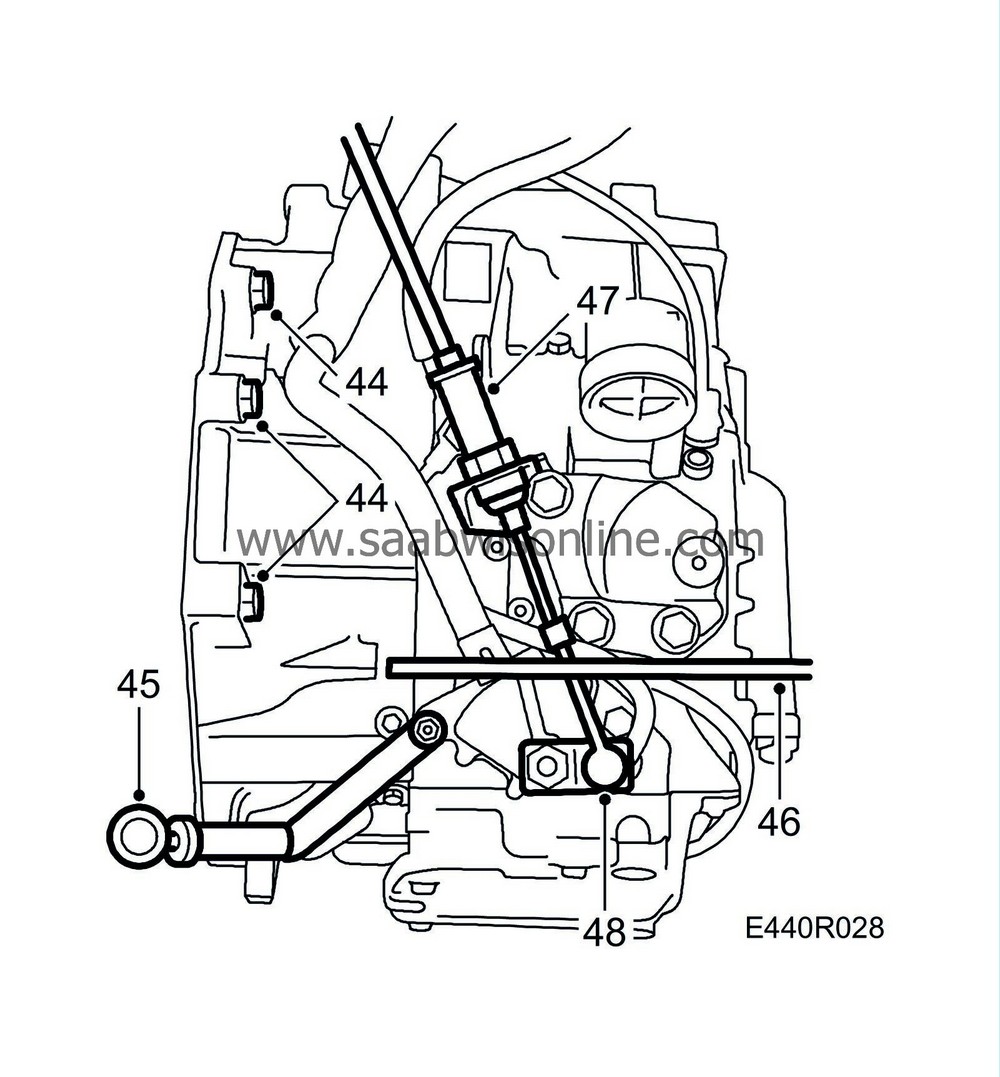

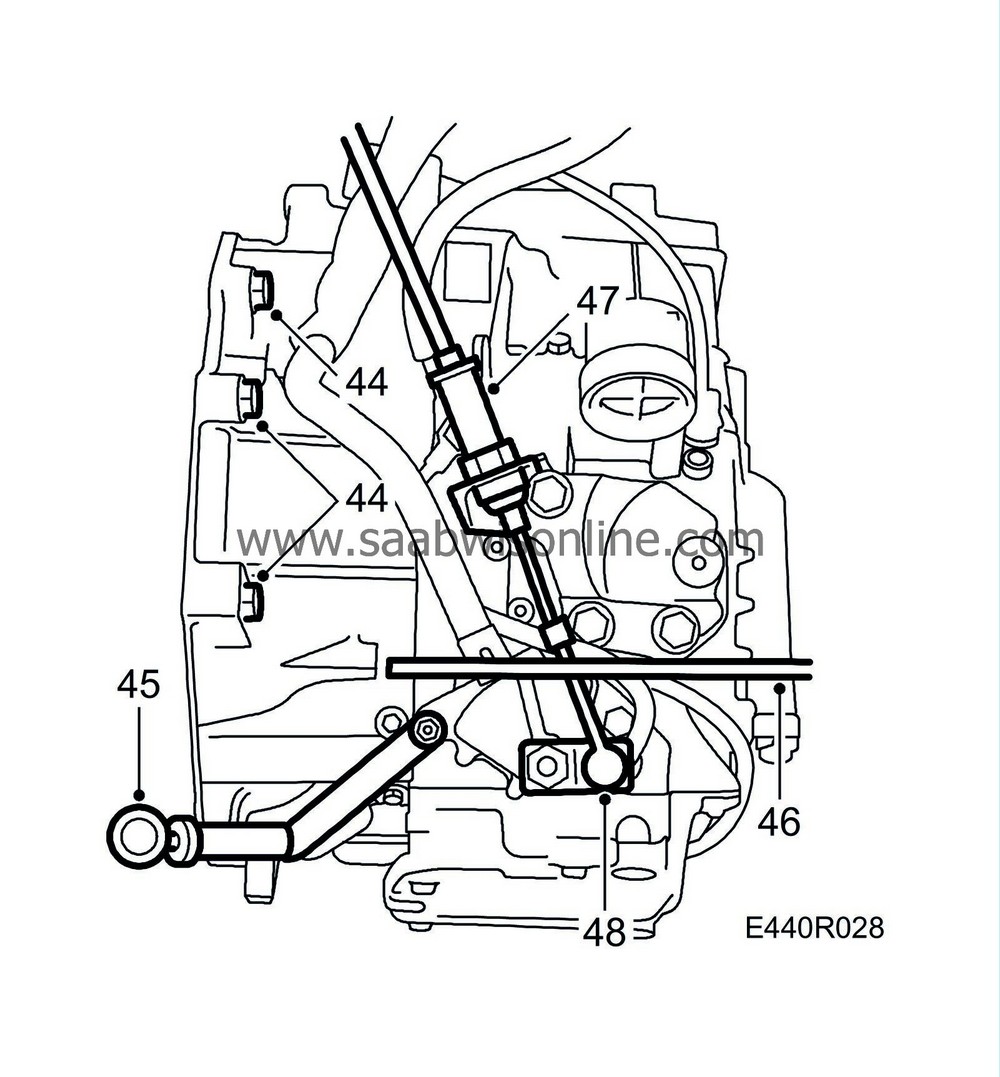

44.

|

Lower the car to the floor.

|

|

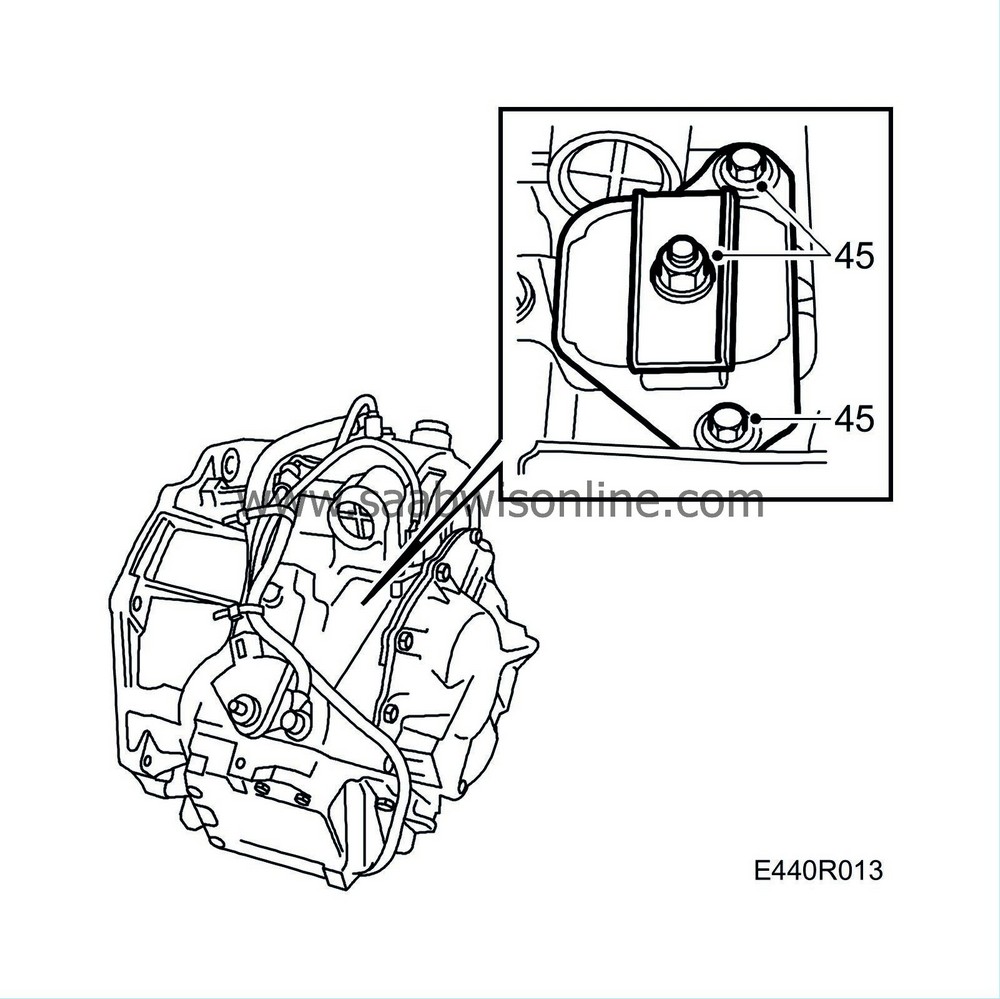

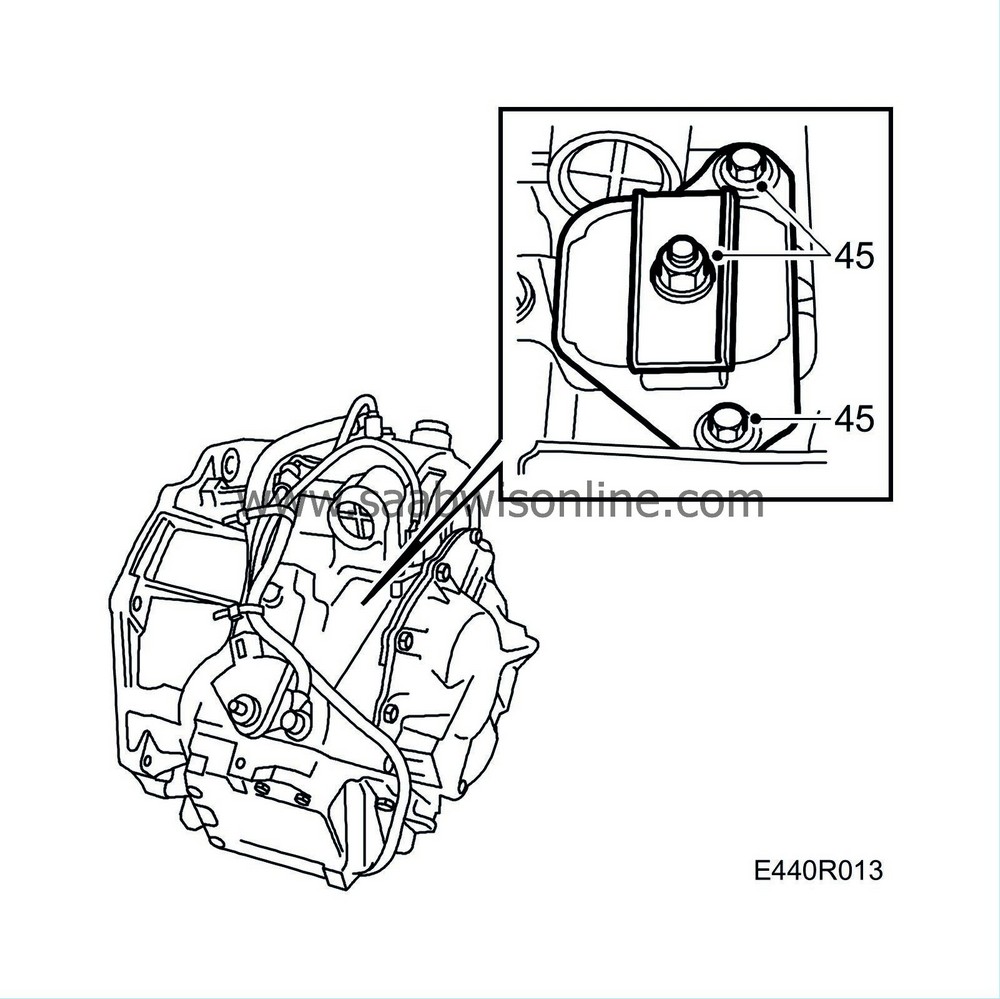

45.

|

Remove the left-hand engine pad.

|

|

46.

|

Lower the unit approx. 100 mm so that the transmission clears the structural member. Remove the transmission bracket from the transmission.

|

|

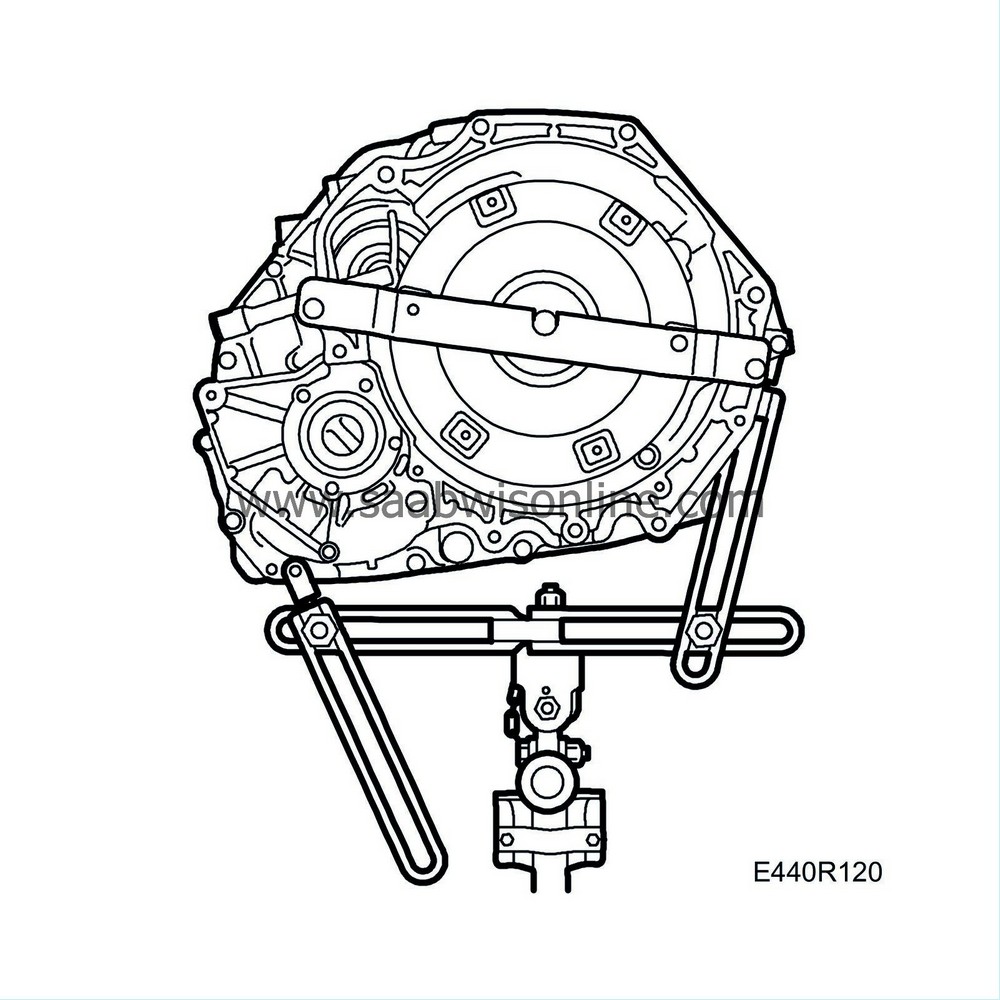

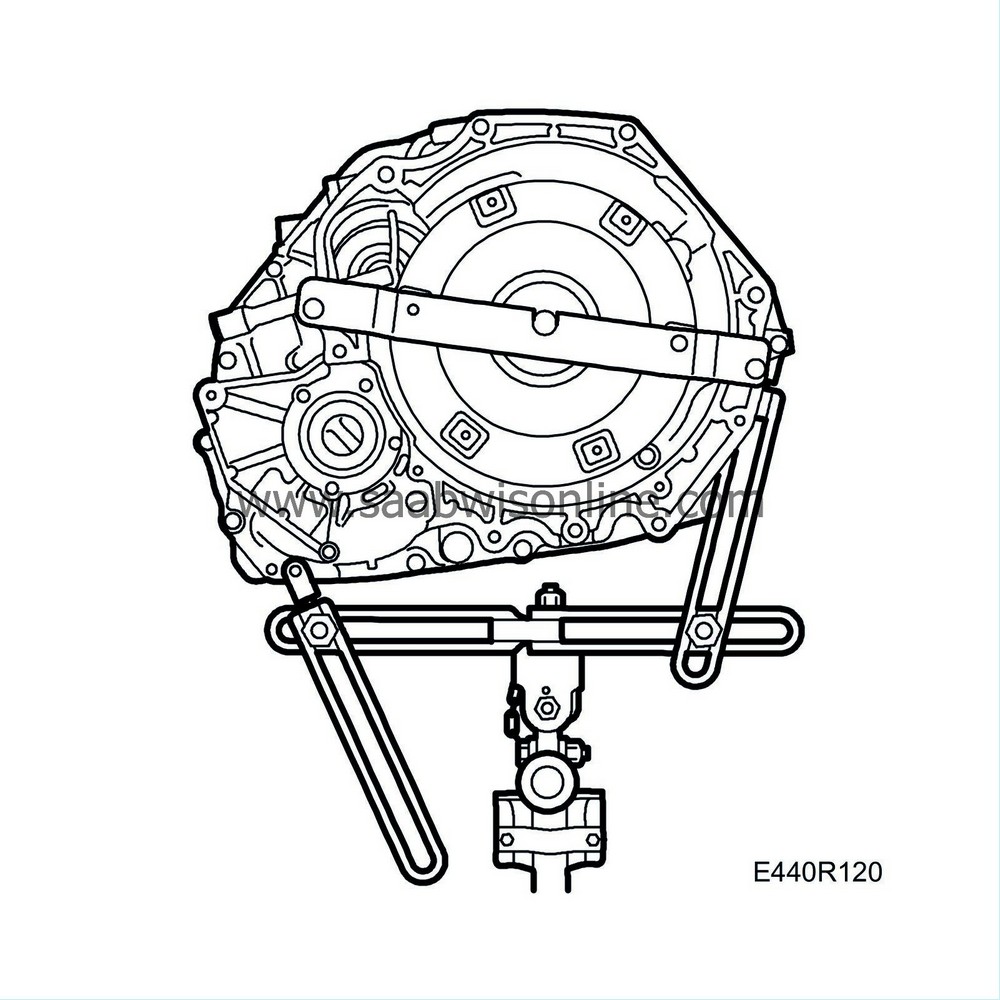

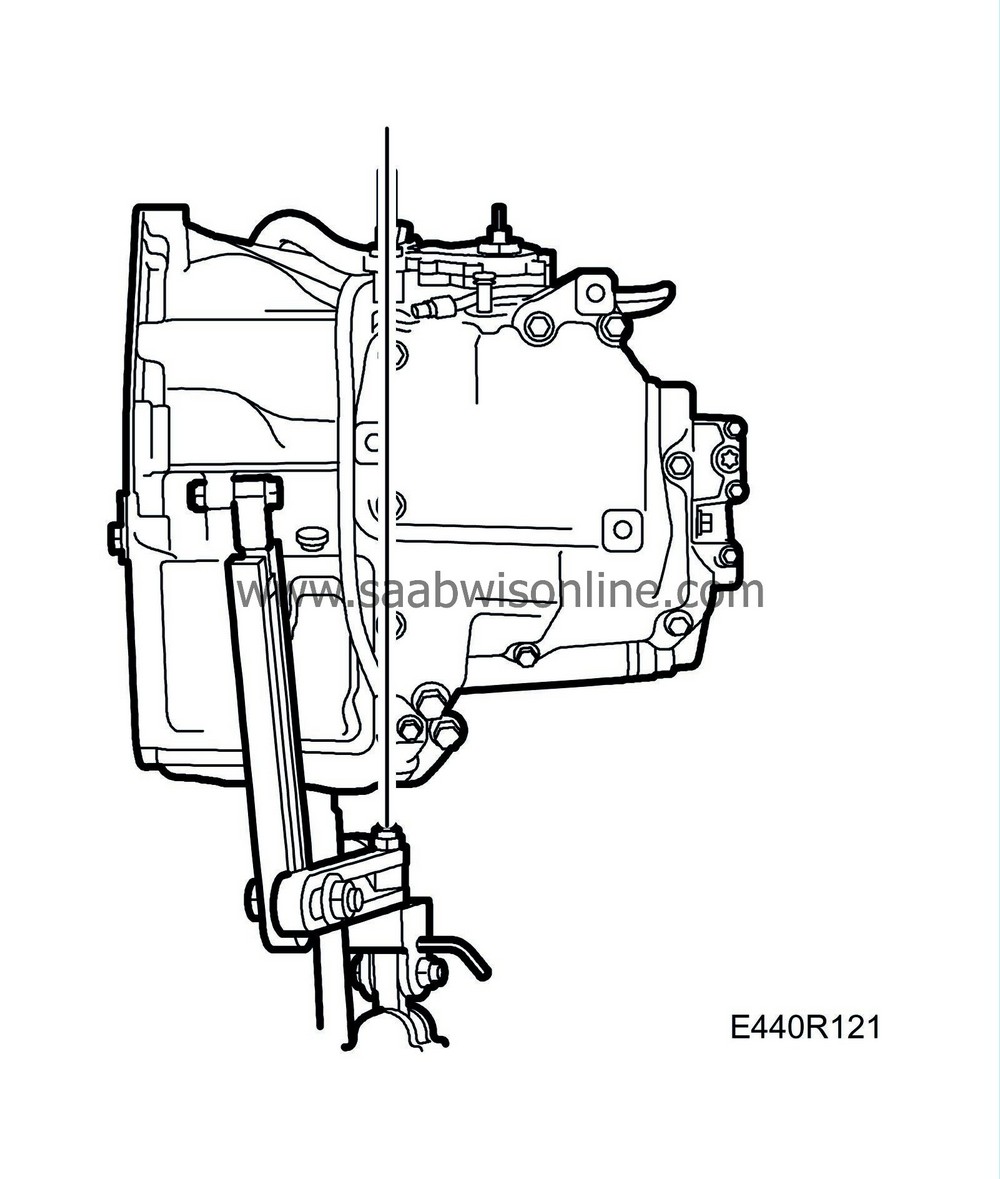

48.

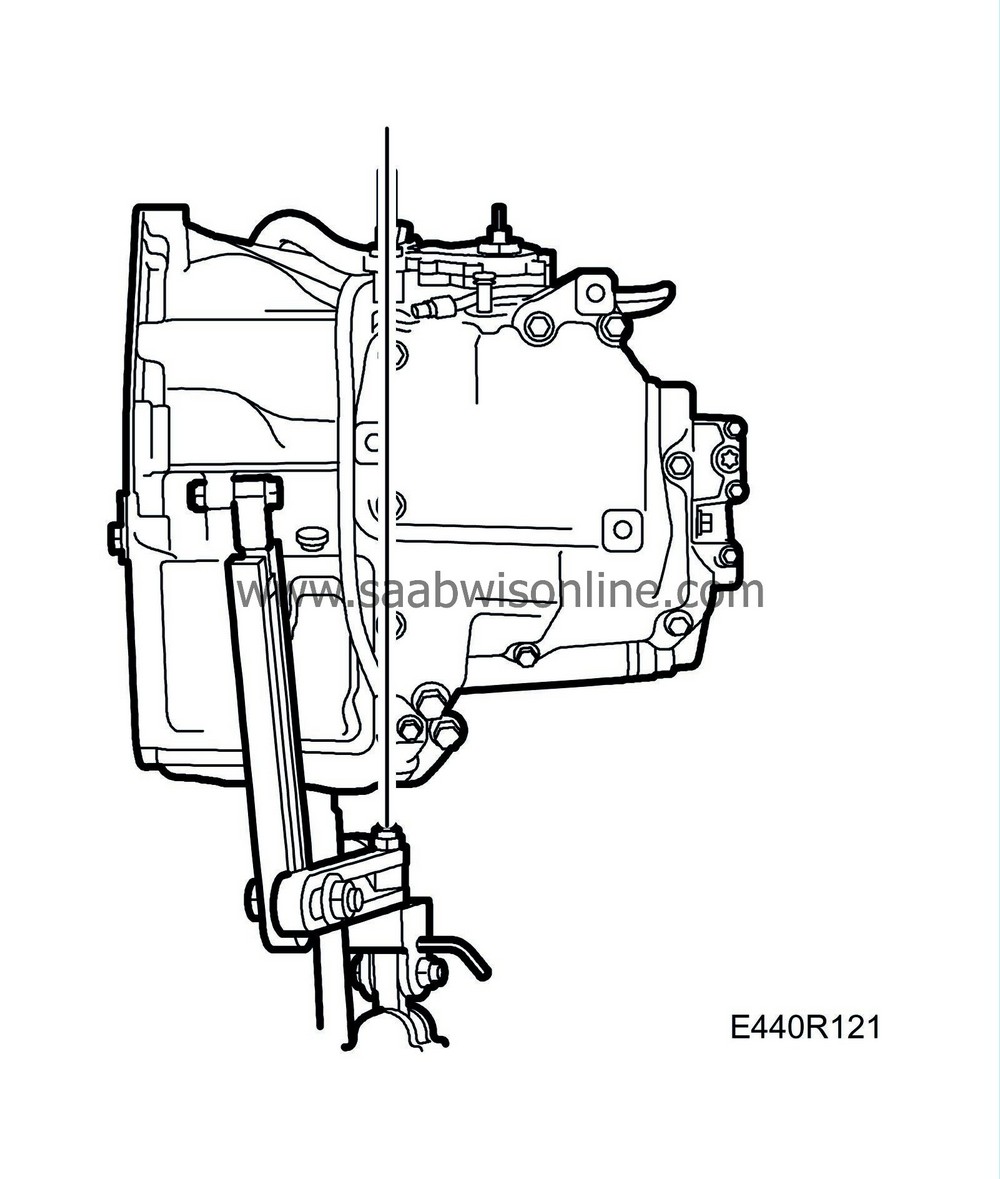

|

Fit lifting tool MKM-886, part no. 87 92 608, onto a pillar-type jack. Adjust the tool so that it centres on the lifting lug on top of the transmission casing and secure it to the lifting lugs.

|

|

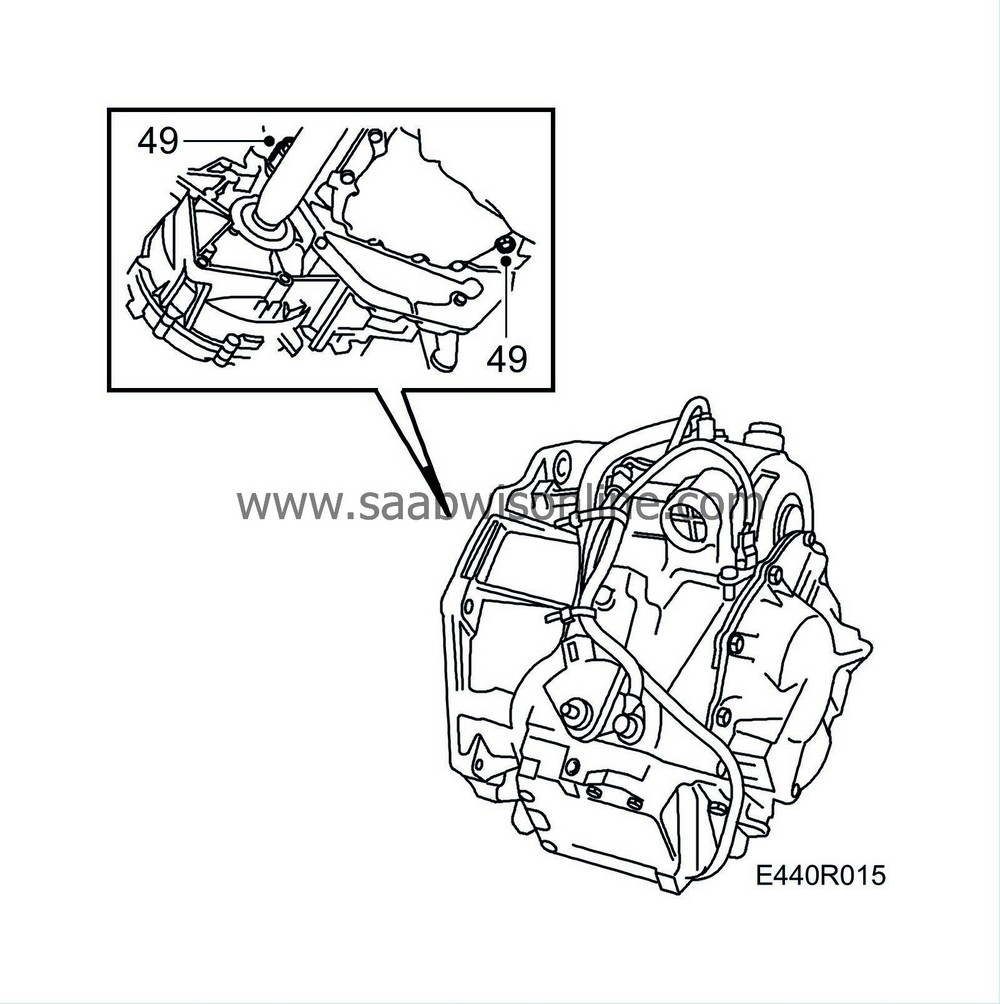

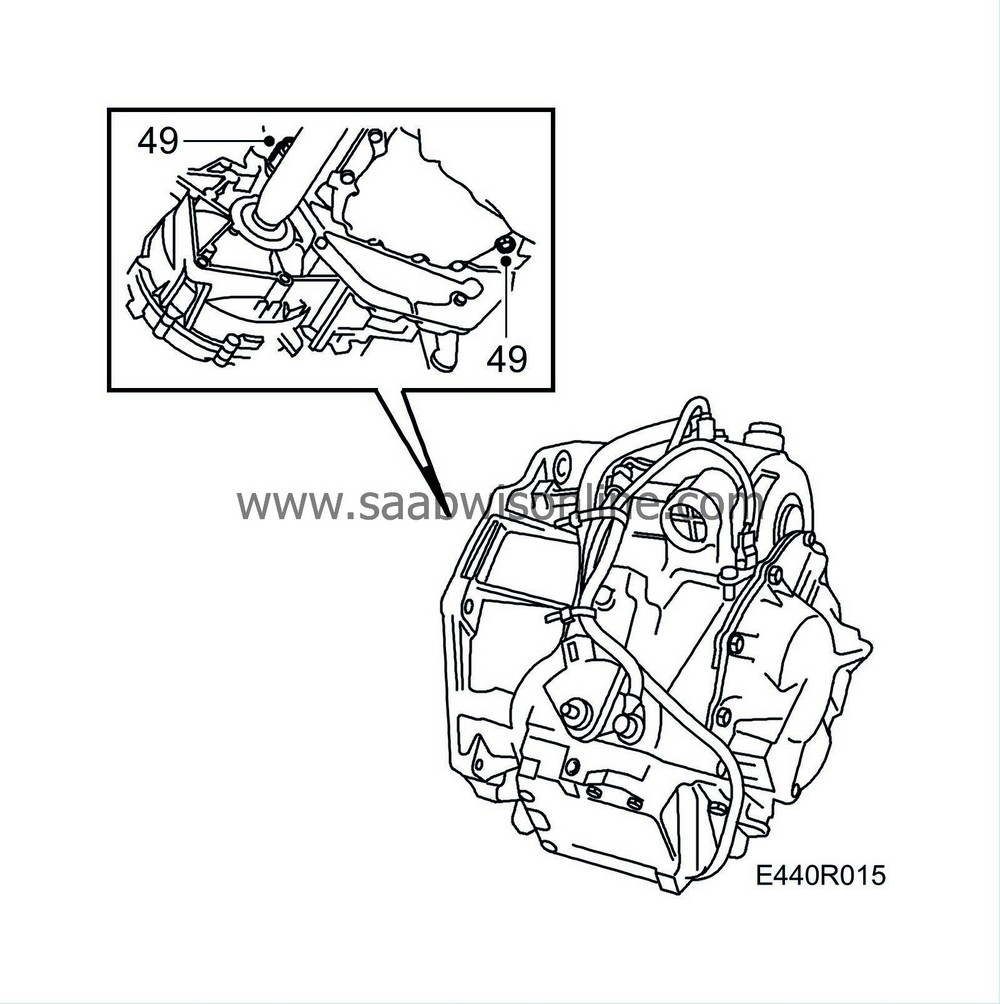

49.

|

Remove the remaining bolts securing the transmission to the engine.

|

|

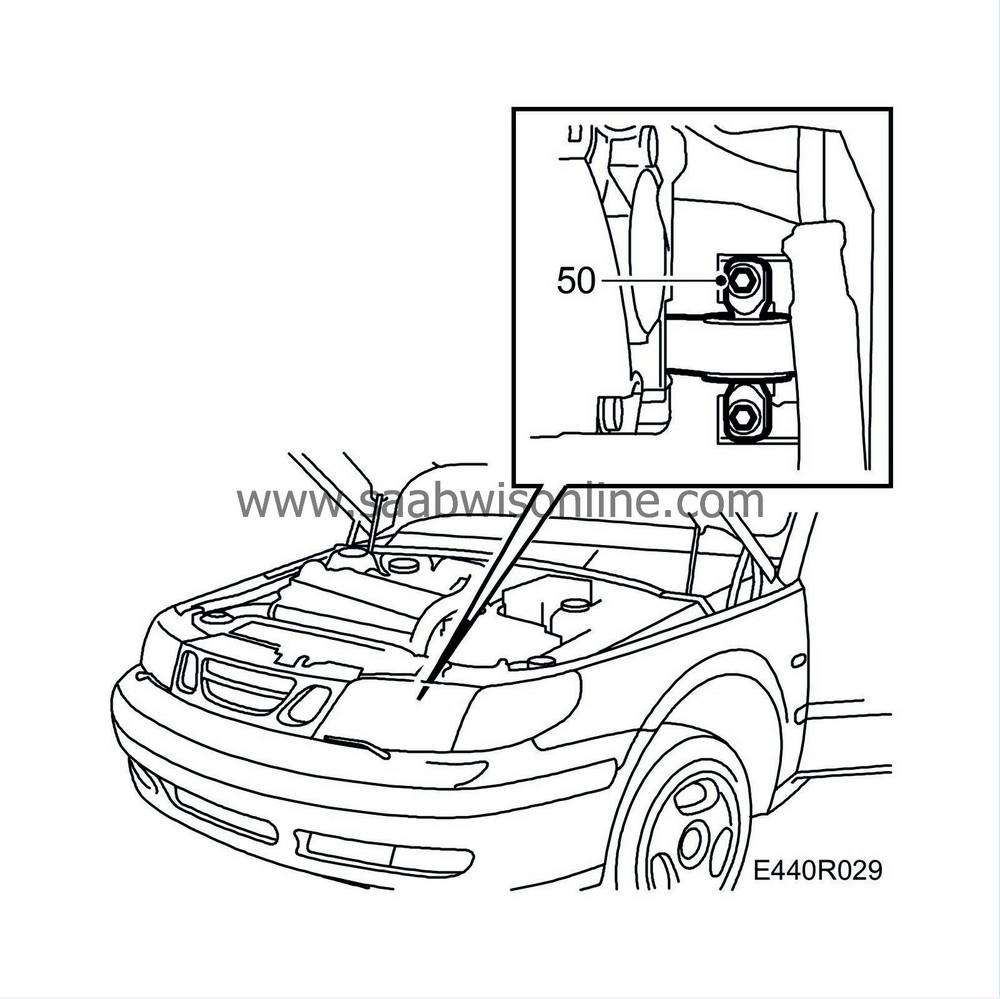

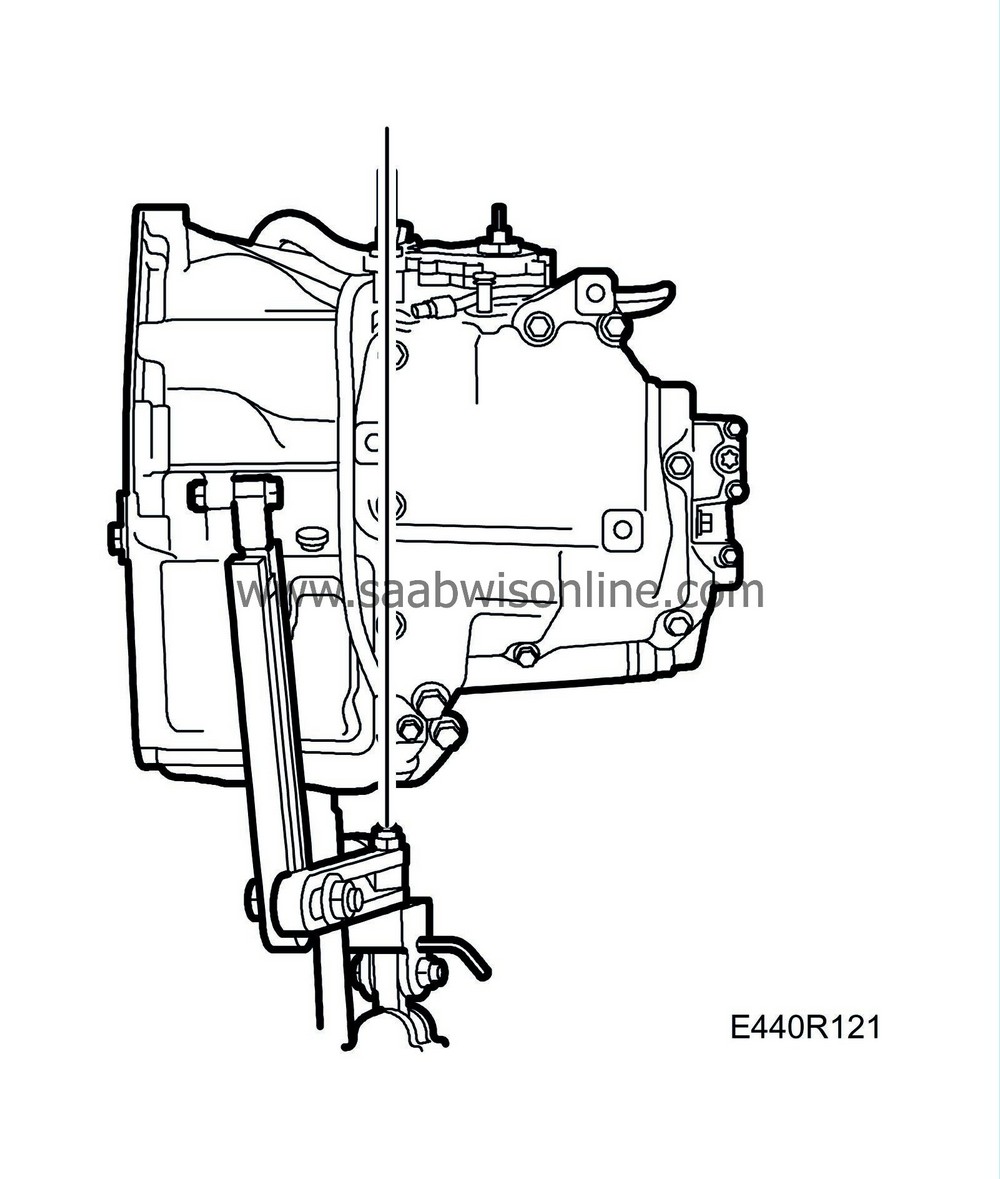

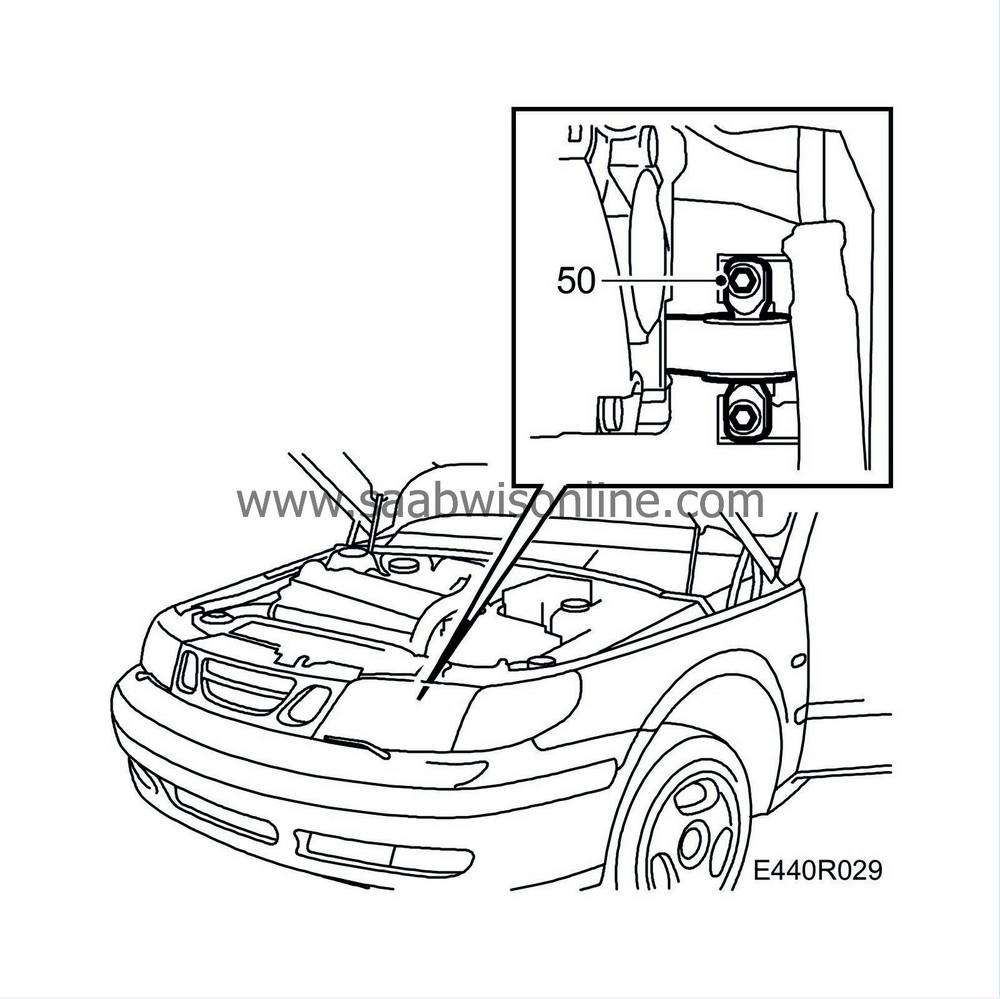

50.

|

Pull out and lower the transmission casing.

|

Important

|

|

The pillar-type jack may tip over. Exercise care.

|

|

|

|

|

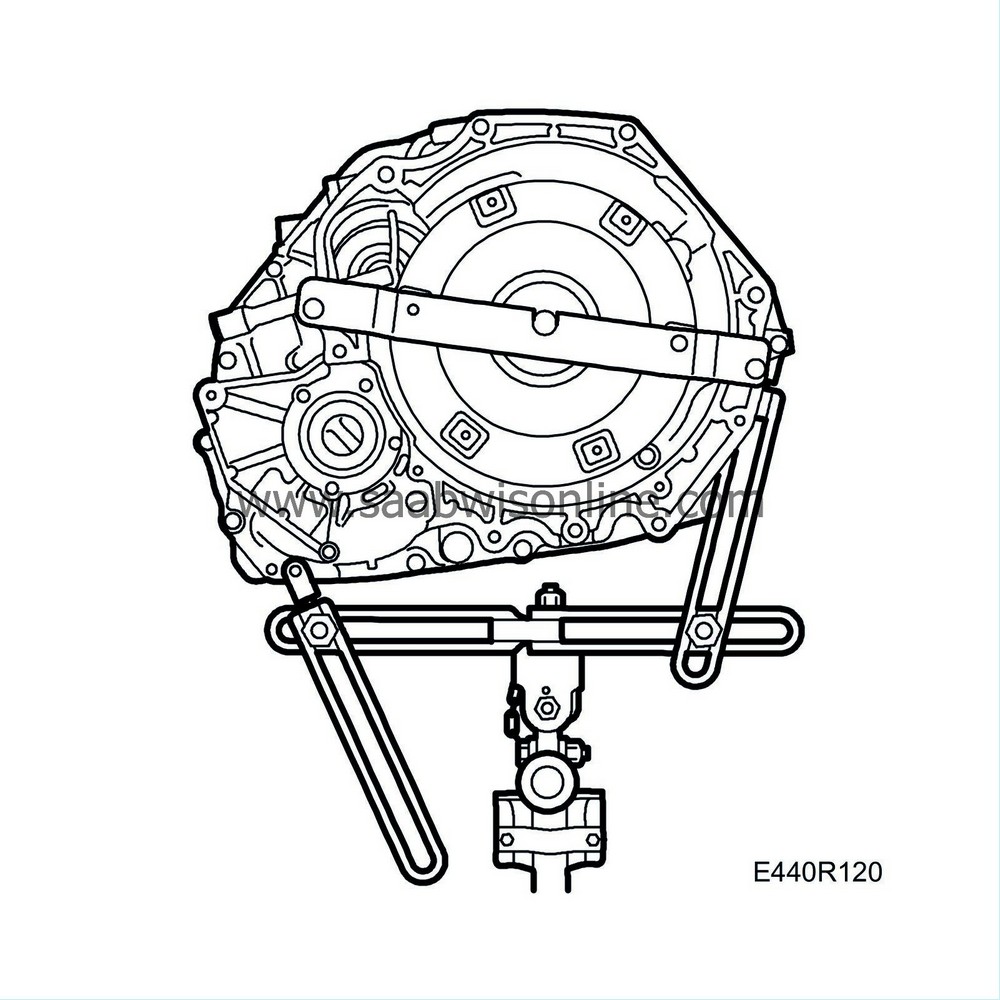

51.

|

Lift down the gearbox from the pillar jack using an engine hoist and

87 92 442 Lifting cable

while removing the lifting tool from the gearbox.

|

When fitting a new transmission, transfer the holder for the torque converter from the new transmission to the old one.

|

1.

|

Turn the torque converter so that the bolt holes line up with the holes in the drive plate.

Fit

87 92 574 Holder

to keep the torque converter in place while fitting.

|

|

2.

|

Make sure the two guide sleeves are on the engine and apply anti-corrosion agent to the sleeves.

Fit the new drive shaft seals, lubricate them before fitting.

|

|

5.

|

Adjust the tool so that it centres on the lifting lug on top of the transmission casing and secure it to the lugs.

|

Important

|

|

The pillar-type jack may tip over. Exercise care.

|

|

|

|

|

6.

|

Fit protective collar 83 95 162 in the right-hand shaft seal on the transmission to protect the seal when the transmission is being fitted.

|

|

7.

|

Place the transmission in position.

|

Important

|

|

Push the transmission into place until approx. 20 mm remains and then remove tool 83 95 162.

|

|

|

|

|

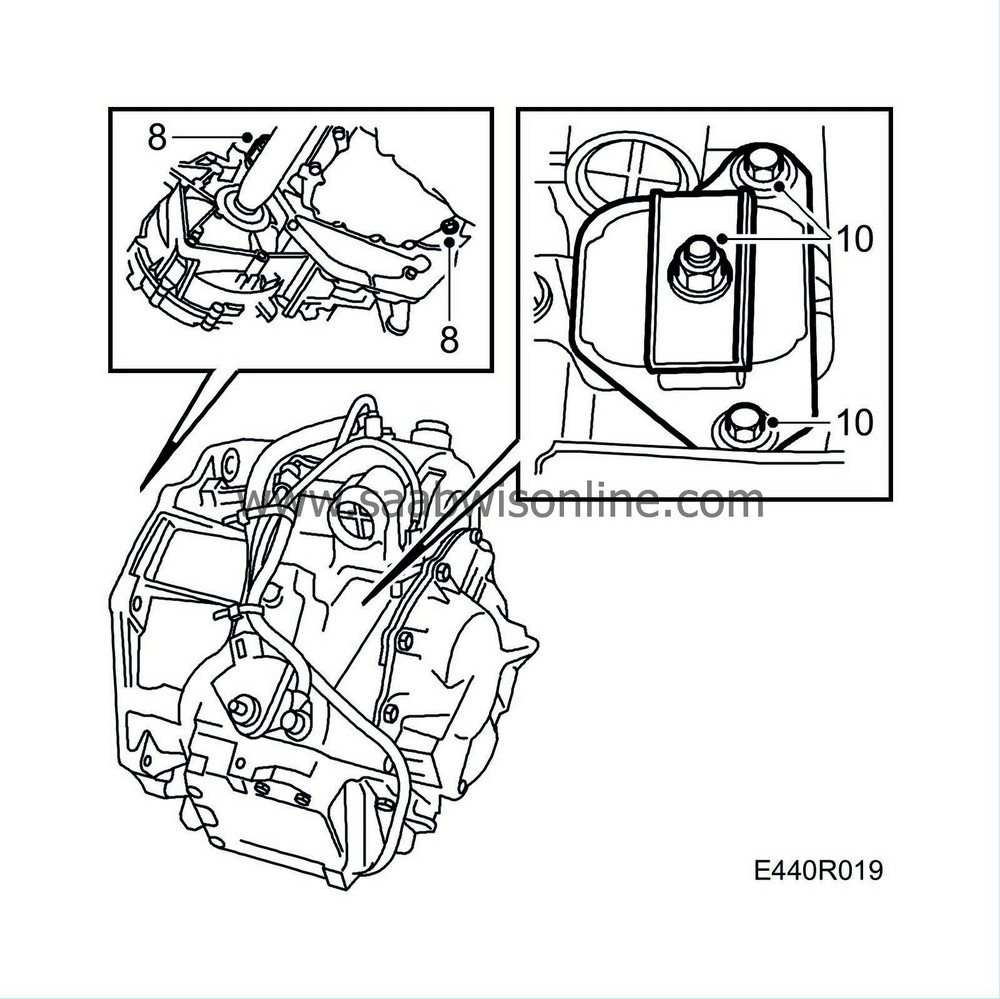

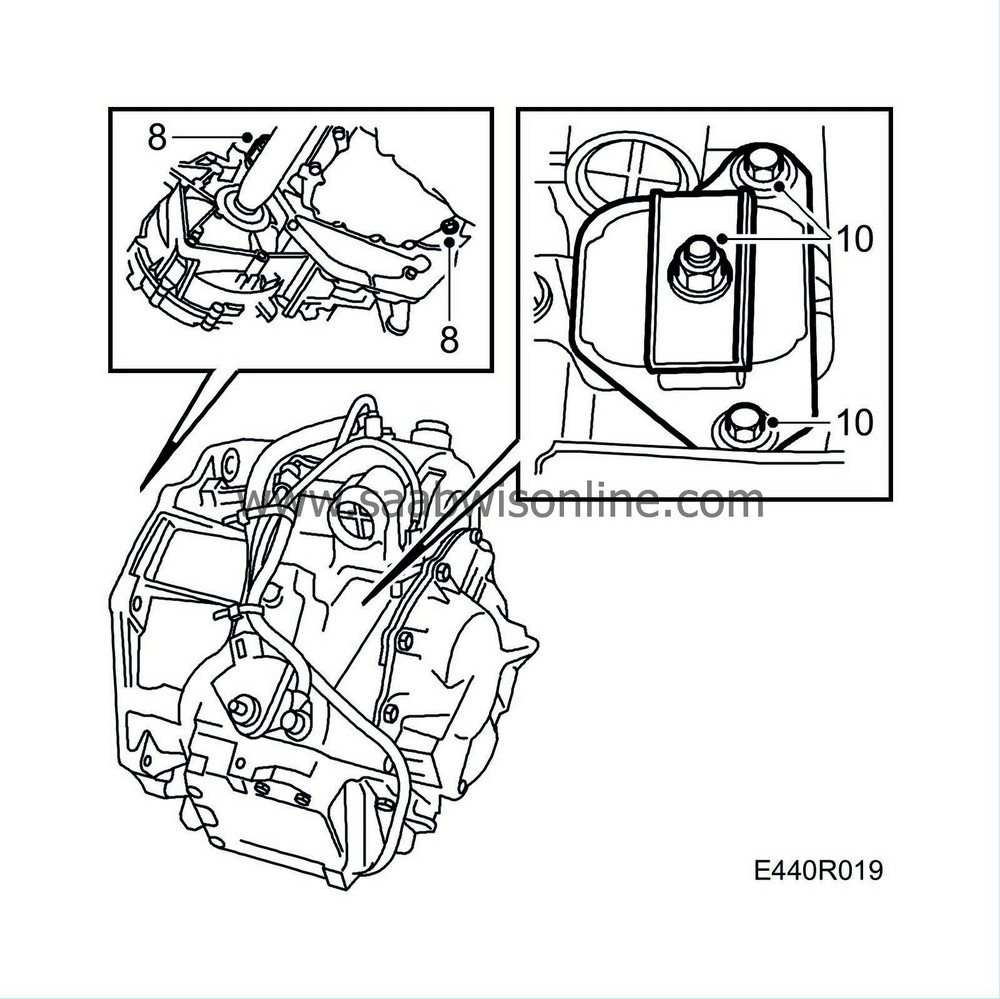

8.

|

Tighten the bottom bolts between the engine and the transmission.

Tightening torque: 75 Nm (55 lbf ft)

B6: Tighten the bolts between the oil pan and the transmission.

Tightening torque: 47 Nm (34 lbf ft)

|

|

9.

|

Remove the lifting beam from the transmission and move the jack out of the way.

|

|

10.

|

Fit the bracket for the engine pad on the transmission.

Tightening torque: 84 Nm (62 lbf ft)

Lift up the unit and loosely fit the bolts securing the engine pad to the body.

Tighten the engine cushion retaining nut.

Tightening torque: 84 Nm (62 lbf ft)

|

|

11.

|

Fit protective collar 83 95 162 in the sealing ring.

|

|

12.

|

Make sure that the drive shaft is clean and then align it with the tool.

|

Important

|

|

Insert all but 20 mm of the drive shaft in the transmission and then withdraw the tool before the shaft's sealing surface reaches the shaft seal.

|

|

|

|

|

13.

|

Push in the rest of the shaft until the circlip clicks in.

|

|

15.

|

Remove tool 87 92 574, which is keeping the torque converter in place, and press it against the drive plate. Fit the plug.

|

|

16.

|

Apply Loctite 242 thread-locking adhesive to the bolts securing the torque converter to the drive plate.

|

Note

|

|

Use the original bolts and their washers. If excessively long bolts are fitted, the torque converter will be damaged. The length of the bolts should be 10 mm, measured from the washer.

|

|

|

17.

|

Fit the 6 bolts without tightening them.

Rotate the engine with the pulley

|

|

18.

|

Tighten them when they are all fitted in place.

Tightening torque: 30 Nm (22 lbf ft)

|

|

19.

|

4-cyl: Fit the splash plate.

V6: Fit the plug.

|

|

20.

|

Fit the oil cooler hoses. The hoses must run horizontally so that they do not chafe against the subframe. Use new seals lubricated with petroleum jelly.

Tightening torque 27 Nm (20 lbf ft)

|

|

21.

|

Fit the bracket for the torque arm on the transmission.

|

|

22.

|

Connect the ground cable to the bracket and to the transmission.

|

|

23.

|

Place the subframe on the lifting trolley and raise it slightly.

|

|

24.

|

Fit the power steering delivery pipe's clamps.

|

|

25.

|

Raise the subframe and guide it into position by means of the holder's studs. At the same time, guide the following into place:

|

|

|

•

|

The radiator core's studs

|

|

26.

|

Fit the subframe bolts and the rear support plates (fit spacer washers if they were present before removal, up to and including VIN W3050999). Adjust the subframe so that the guide pins on the holder are aligned with the holes in the body before tightening the bolts.

Tightening torques:

Subframe bolts 100 Nm (74 lbf ft) + 45°

Support plate bolts: 60 Nm (44 lbf ft)

|

Note

|

|

Make sure that the transmission's oil cooler hoses do not rest against the subframe.

|

|

|

27.

|

Remove the lifting trolley.

|

|

28.

|

Fit the bolts securing the outer ball joint to the steering knuckle housing.

|

|

29.

|

Tighten the bolts.

Tightening torque 85 Nm (63 lbf ft)

|

|

30.

|

Tighten the anti-roll bar link. If the wrench used to hold it is too wide to fit between the boot and the suspension strut, it must be ground narrower. Alternatively, hold the hexagonal pin with a socket.

Tightening torque 84 Nm (62 lbf ft)

Tightening torque, nut with steel lock: 95 Nm (66 lbf ft)

|

|

31.

|

Fit the steering gear bolts and tighten them.

Tightening torque: 90 Nm (66 lbf ft)

|

|

32.

|

Remove the strap round the radiator core.

|

|

33.

|

Fit the engine oil cooler. 4-cyl: Tighten the air filter housing.

|

|

34.

|

Fit the rear engine cushion in place. Screw in the bolts but do not tighten them.

|

|

35.

|

Bolt the rear engine mounting in place.

Tightening torque: 70 Nm (52 lbf ft)

|

|

36.

|

Fit the front exhaust system.

Tightening torque 4-cyl: 25 Nm (18.4 lbf ft)

Tightening torque V6:

to the turbo 24 Nm (18 lbf ft)

to the exhaust manifold 40 Nm (30 lbf ft)

|

|

37.

|

Run the wiring for the oxygen sensor into the engine bay.

|

|

39.

|

Lower the car to the floor.

|

|

40.

|

Remove the lifting beam.

V6: Remove the lifting tool and its mountings from the engine.

|

|

41.

|

Connect the oxygen sensor.

|

|

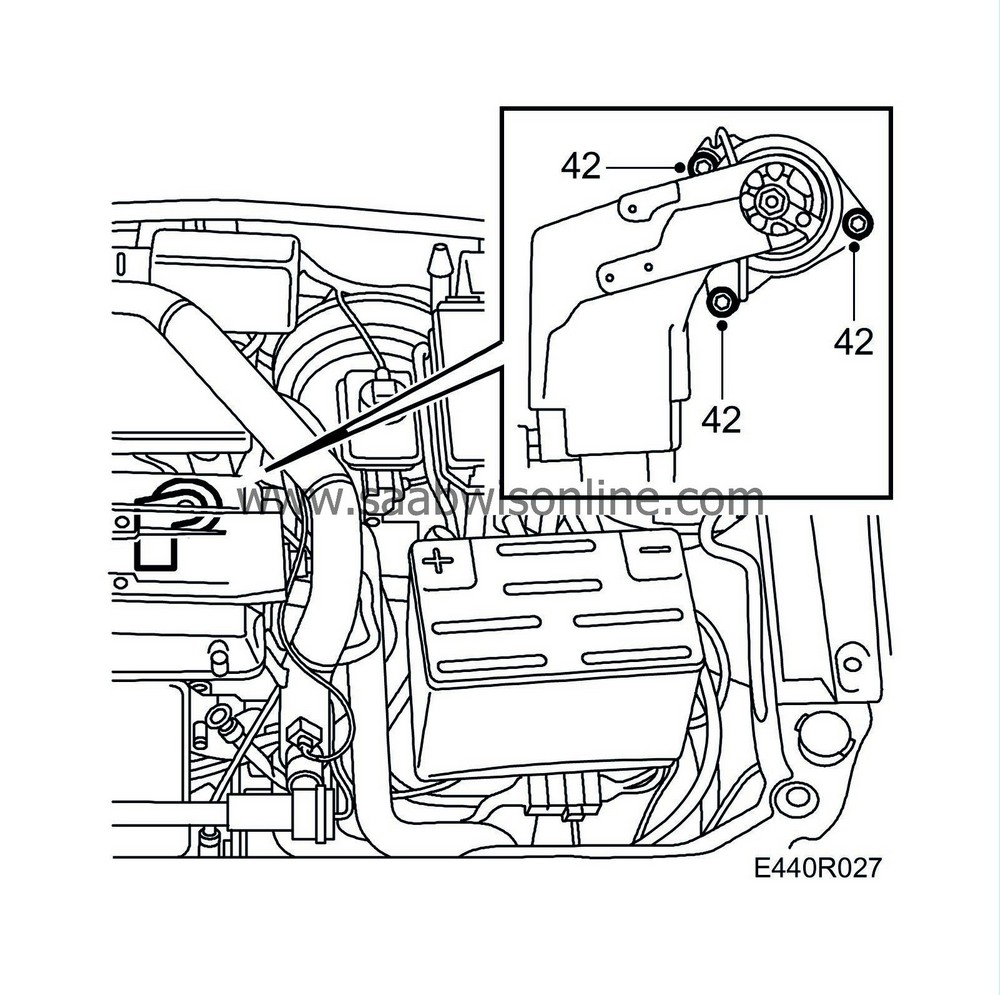

42.

|

Shake the unit to ensure there is no tension in the engine pads.

Tighten the rear engine pad retaining nut and 3 bolts.

Tightening torque: bolts 24 Nm (18 lbf ft)

Tightening torque: nut 45 Nm (33 lbf ft)

|

|

43.

|

Place a jack under the transmission and lift it up until the left-hand engine pad is hanging free from the body and is not under load. Then lower the unit and tighten the bolts.

Tightening torque: 63 Nm (46 lbf ft)

|

|

44.

|

Fit the bolts securing the transmission to the engine and tighten them.

Tightening torque: 70 Nm (52 lbf ft)

Fit the clamp on the positive cable (4-cyl.). Screw on the cable channel to the engine and transmission (V6).

|

|

45.

|

Clean and fit the dipstick tube.

|

|

46.

|

Fit the transmission's breather hose.

|

|

47.

|

Fit the shifting cable to the bracket on the transmission. Fit the clamp.

|

|

48.

|

Fit the shifting cable to the selector lever in position P.

|

|

49.

|

Check and if necessary adjust the selector lever positions, see

.

.

|

|

50.

|

Fit the two bolts securing the torque rod to the subframe and tighten them.

Tightening torque: 30 Nm (22 lbf ft)

Raise the car.

Undo the bolt to the front torque rod and centre the rubber pad in the rod. Tighten the bolt.

Tightening torque: 47 Nm (34 lbf ft)

Centre the rear torque rod and tighten it (4-cyl.).

Tightening torque: 47 Nm (34 lbf ft)

Lower the car to the floor.

|

|

51.

|

Plug in the transmission's connectors.

|

|

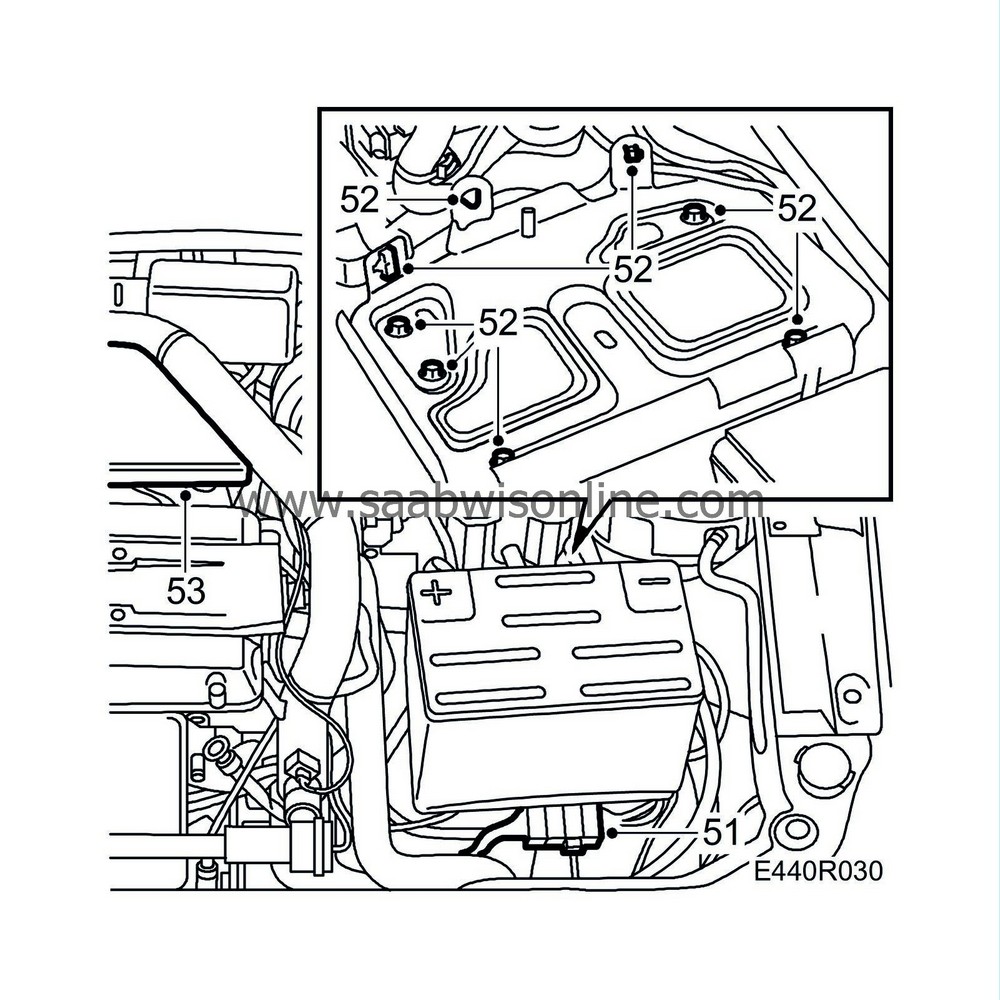

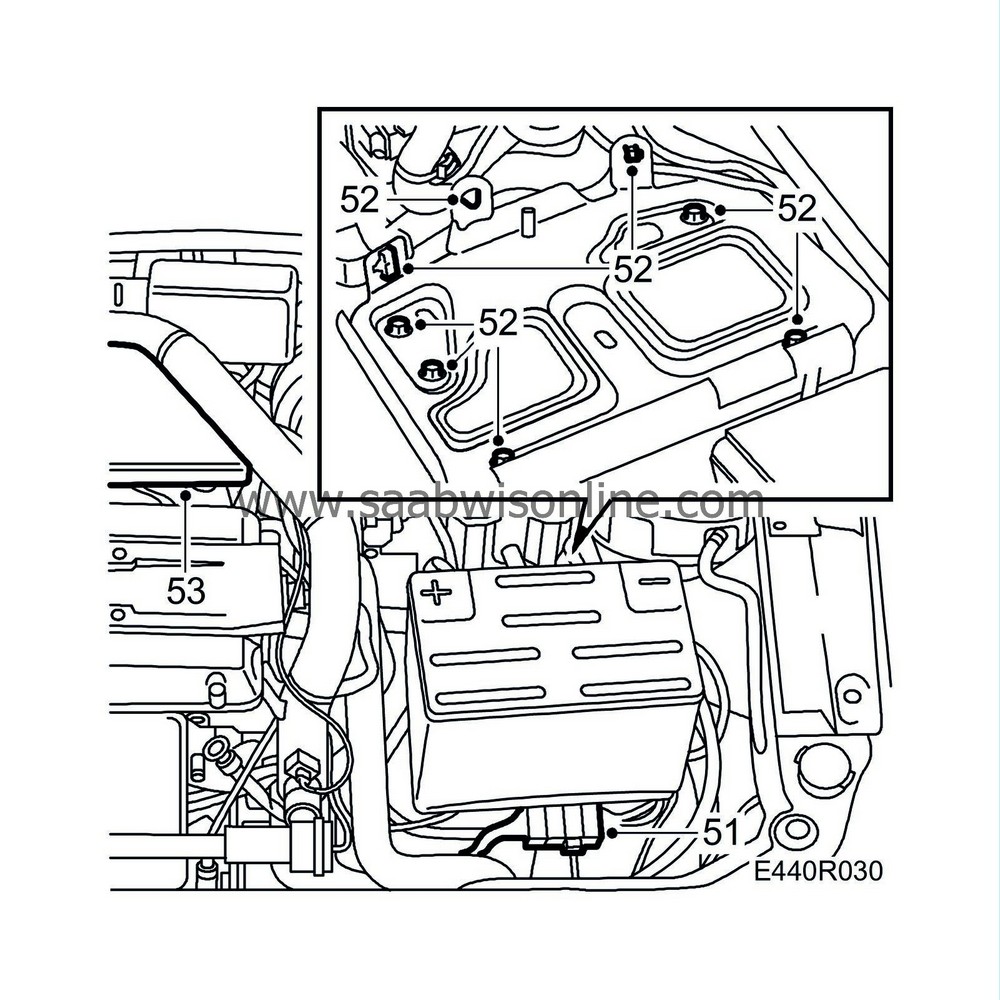

52.

|

Move the battery tray sideways away from the engine as far as possible. Fit the battery tray, battery and battery cover.

|

|

53.

|

Fit the cover over the intake manifold.

|

|

55.

|

Fit the front wheels. Tighten the bolts using a torque wrench.

Tightening torque: 110 Nm (81 lbf ft)

|

|

56.

|

Fill with transmission fluid, Texaco Texamatic DEXRON III (7045 EU, TL1863 US), to the correct level.

|

|

57.

|

Test drive the car with varying engine loads and rpm and read any trouble codes that are generated. Also check the position of the steering wheel when driving straight ahead on a level road. Adjust if needed.

|

|

58.

|

Set the right time on the clock.

|

.

.