Bumper and spoiler, deep scratches and cracks

|

|

Bumper and spoiler, deep scratches and cracks

|

|

1.

|

Clean the part. It is essential that no grit or other particles remain in the area to be welded.

|

|

2.

|

Wash the repair area with Teroson FL cleaner.

|

|

3.

|

Identify the type of plastic. See

or

or

.

.

|

|

4.

|

Select the correct welding filler and set the temperature of the welding gun so that it agrees with the type of plastic. See

|

|

5.

|

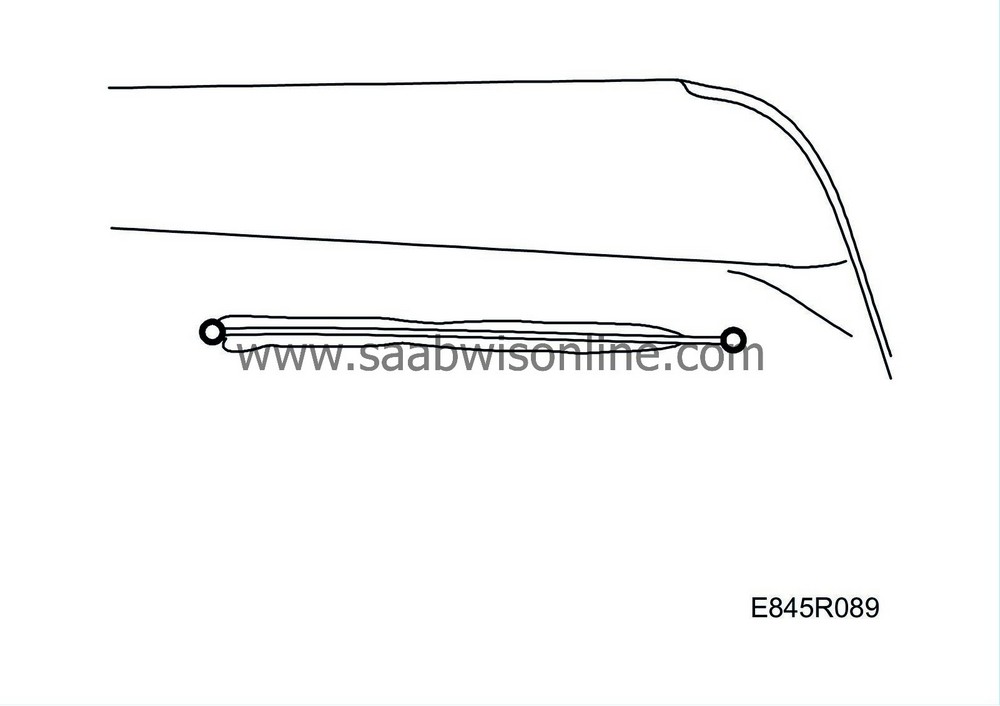

If the damage is a crack, the ends must first be drilled so that the crack does not spread. Use a 3.5 mm drill and drill a hole at both ends of the crack.

|

|

6.

|

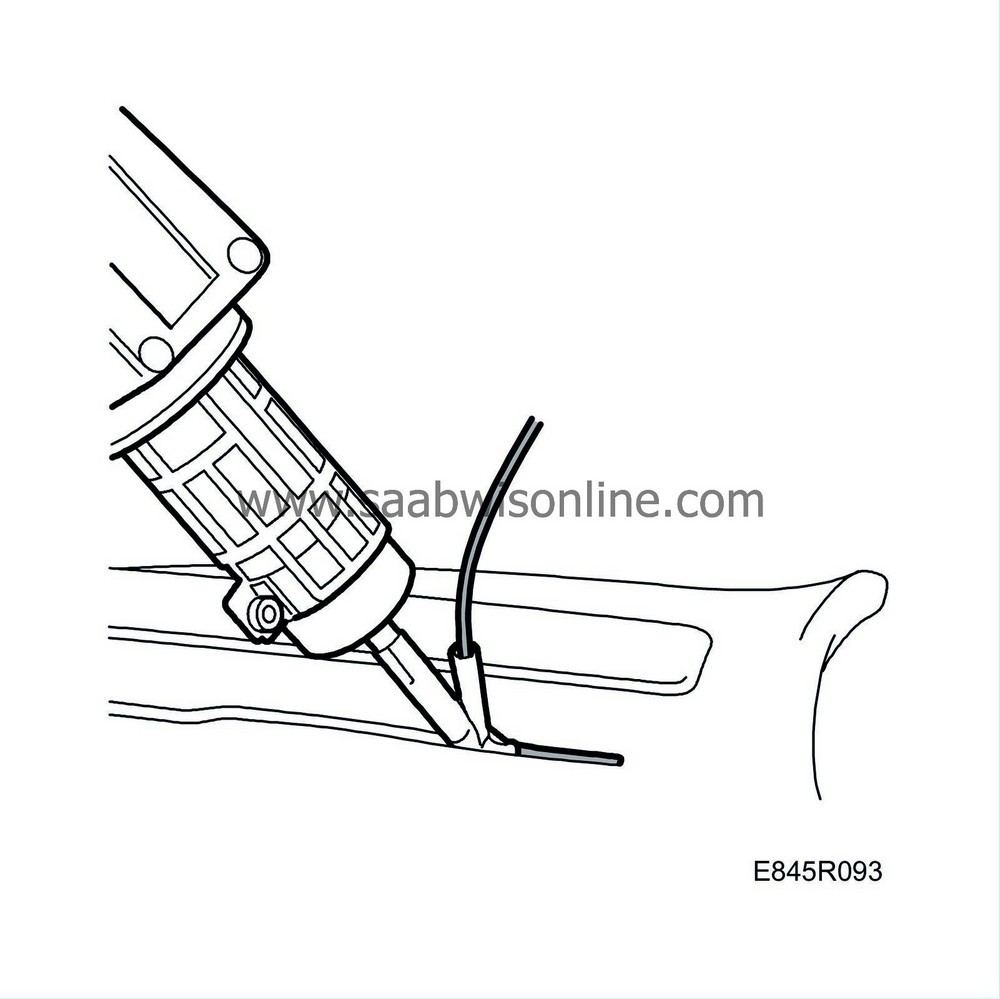

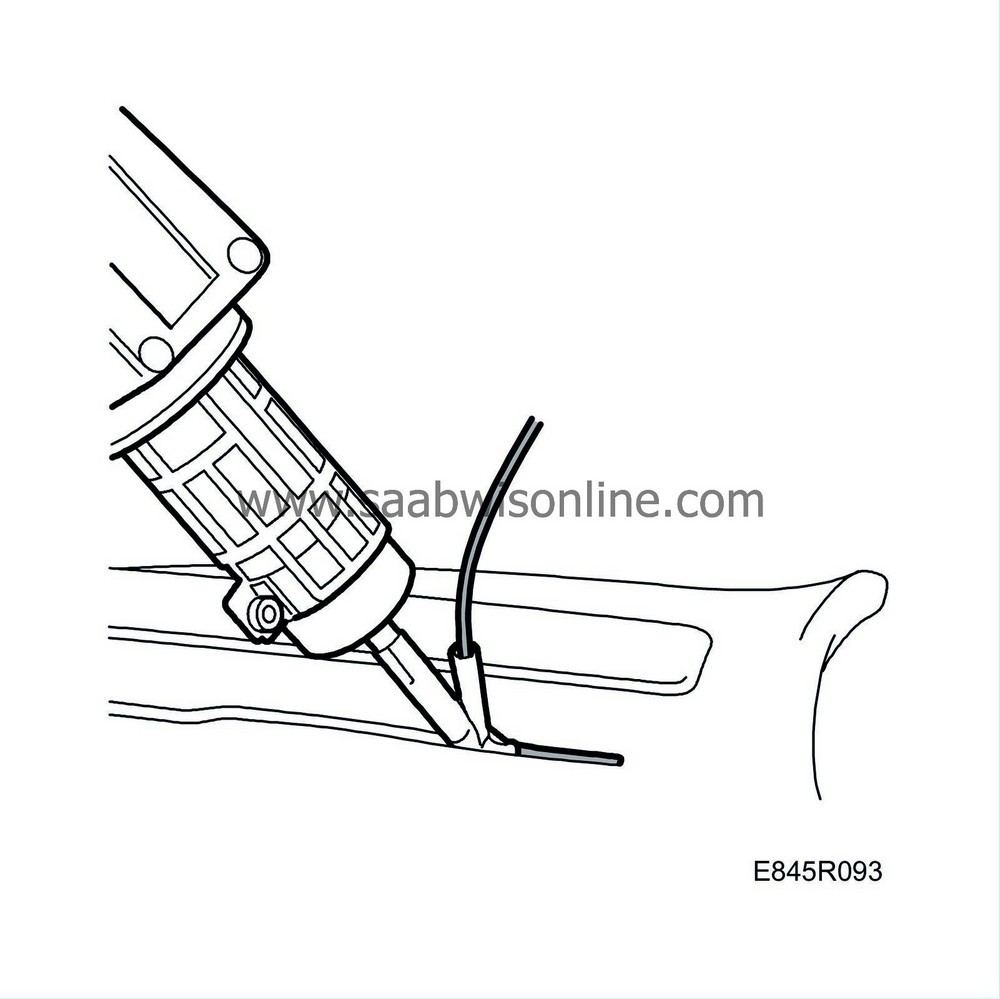

Mill a 90° V-shaped groove in the reverse. Only use a low speed grinder.

|

|

7.

|

Select the correct welding temperature on the welding gun, so that it agrees with the type of plastic. See

.

.

|

|

8.

|

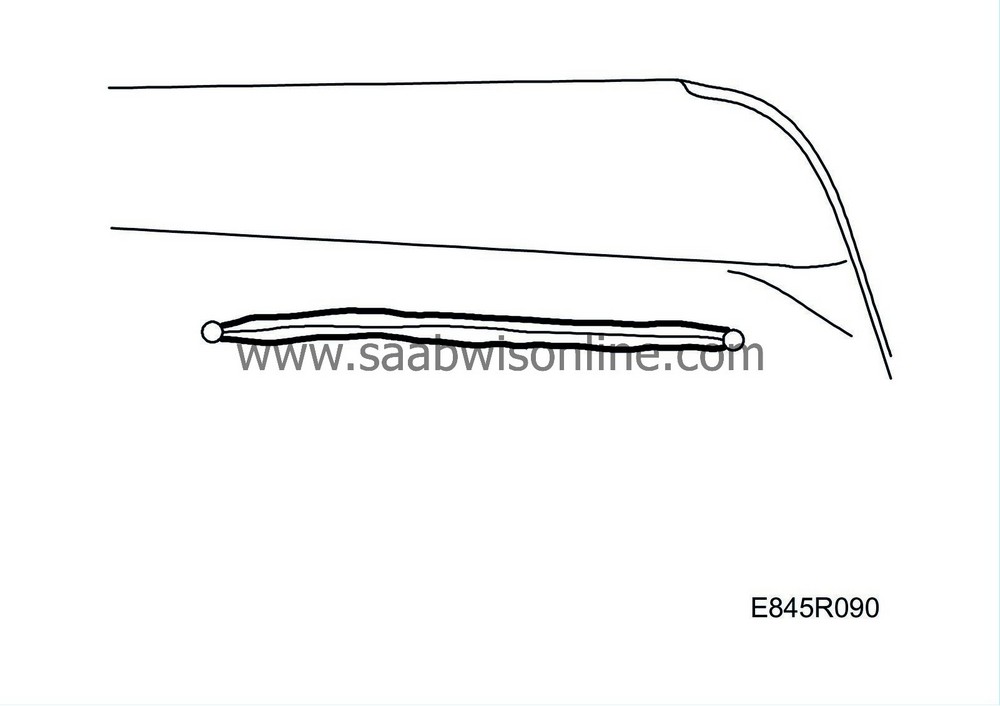

Weld the reverse side of the crack.

|

|

9.

|

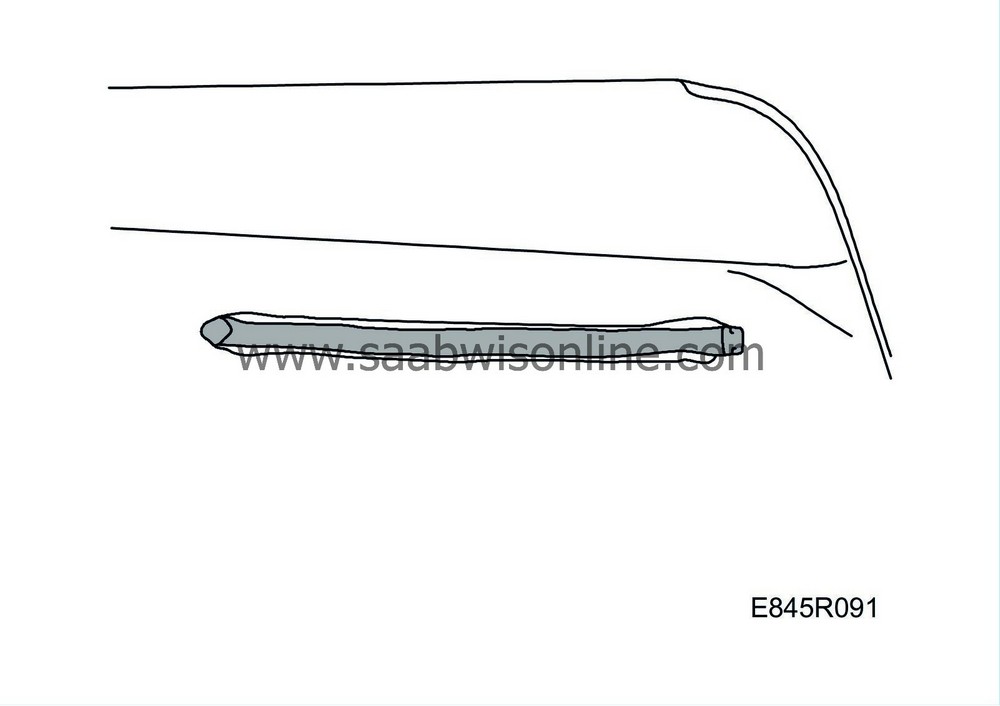

Grind off any paint from around front of the damaged area.

|

|

10.

|

Check the working temperature of the gun.

|

|

11.

|

Weld the front with welding filler.

|

|

12.

|

Allow the welded area to cool.

|

|

13.

|

Grind away any excess welding material from the welded area.

|

|

14.

|

Perform the finishing measures 1 - 10, see

|

or

or

.

.

.

.