Grinding (turning) a brake disc, in situ

| Grinding (turning) a brake disc, in situ |

Lathe “VBG 600” and the SAAB/GM 108/4--110/5 connecting plate were used in the development of this method.

| 1. |

Raise the car and remove the wheels on both sides.

|

||||||||||

| 2. |

If the work is carried out in the order front right, front left, rear left, rear right, then basic adjustment of the lathe will be facilitated.

|

|

| 3. |

Remove the brake caliper without remove the brake line. Suspend the caliper with a cable tie. Refer to

To remove

for the front wheels and

To remove

for the rear wheels.

|

|

| 4. |

Measure the disc. Refer to

Checking for lateral runout and variation in thickness, front wheels

and

Checking for lateral runout and variation in thickness, rear wheels

.

|

|

| 5. |

Clean the mating surface between the brake disc and the connecting plate.

|

|

| 6. |

Fit the tool for runout compensation (accessory 25) in the brake caliper bracket.

|

|

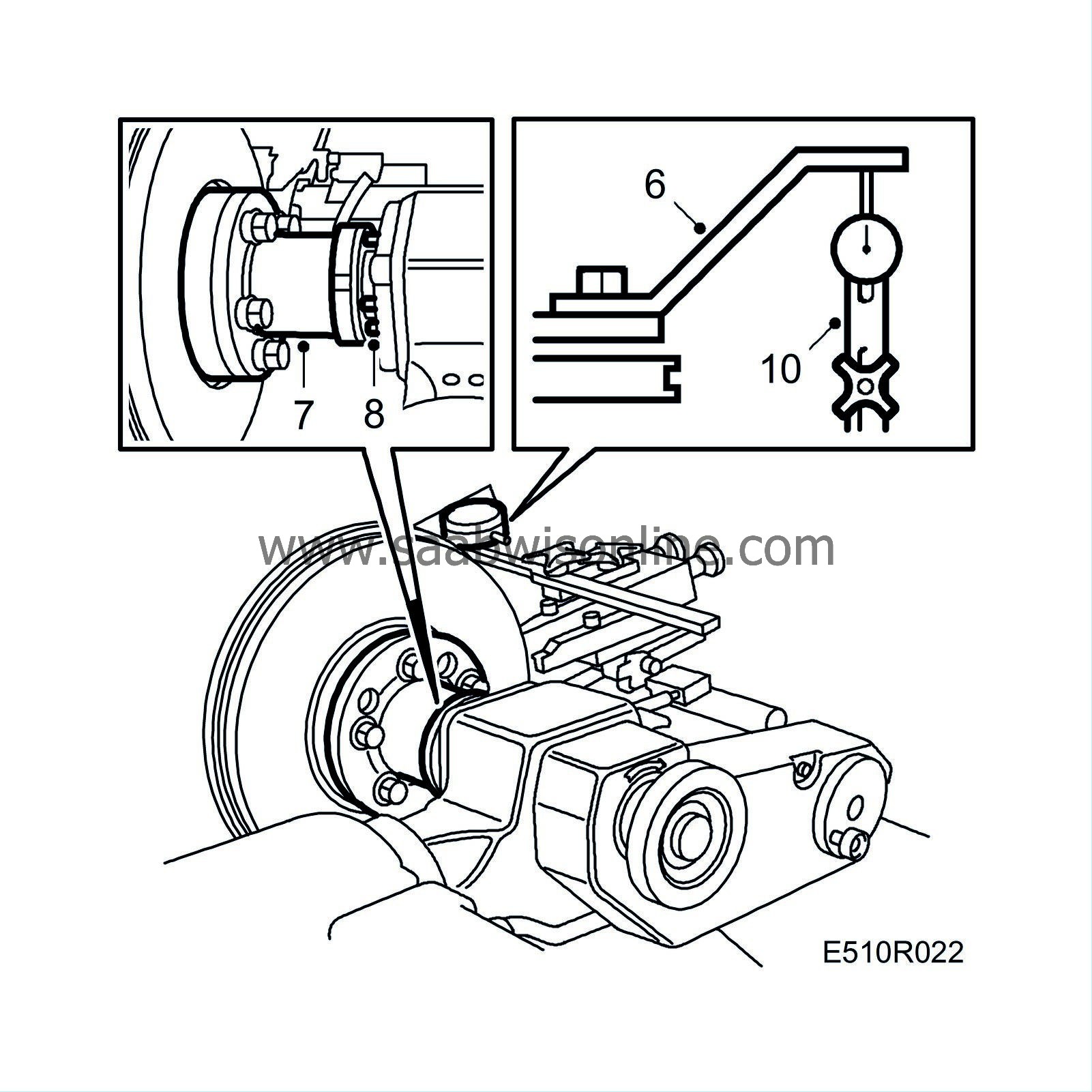

| 7. |

Fit the connecting plate with the wheel studs.

Tightening torque: 30 Nm (22 lbf ft). |

|

| 8. |

Back off the adjusting screws.

|

|

| 9. |

Clean the connecting surface and fit the lathe to the connecting plate, connect the lathe.

|

|

| 10. |

Connect the arm with the dial gauge resting against the runout compensation tool.

|

|

| 11. |

Start the lathe and note the highest and lowest readings. Switch off the lathe.

|

|

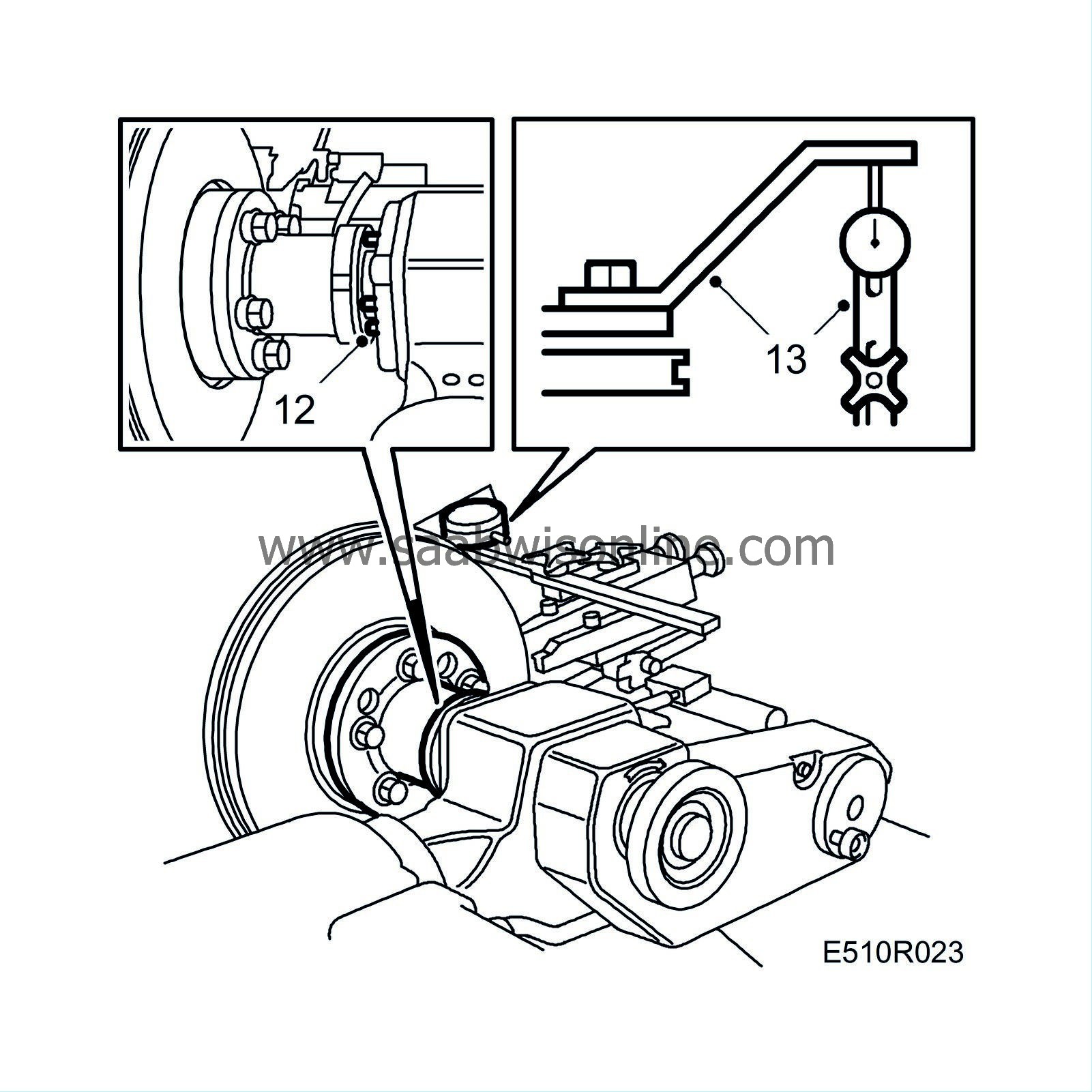

| 12. |

Adjust one of the four adjusting screws and repeat points 9 and 10 until the variation is less than 0.08 mm (0.003 in).

|

|

| 13. |

Remove the arm with dial gauge and the runout compensation tool.

|

|

| 14. |

Adjust the turning tools against the disc with the tool holder. Remove the locking screw and move the holder.

|

|

| 15. |

Set the automatic stop.

|

|

| 16. |

Feed out the tool holder and manually grind off the outer and inner rusty edges.

|

|

| 17. |

Set the turning depth and switch on automatic operation.

|

|

| 18. |

Check the brake disc.

|

|

| 19. |

Remove the lathe. Remove the connecting plate.

|

|

| 20. |

Fit the brake caliper. Refer to

To fit

for the front wheels and

To fit

for the rear wheels.

|

|

| 21. |

To grind (turn) the other side, the lathe will have to be turned upside down.

|

|

| 22. |

Grinding (turning) is then carried out as described above.

|

|