Power train, to fit

| Power train, to fit |

| To fit |

| 1. |

Place the lifting trolley with power train under the raised car. Lower the car carefully and raise the lifting table. Raise the power train somewhat and fit the drive shaft in the hub. Make sure the lower steering swivel joints are fitted into their holes.

|

|

| 2. |

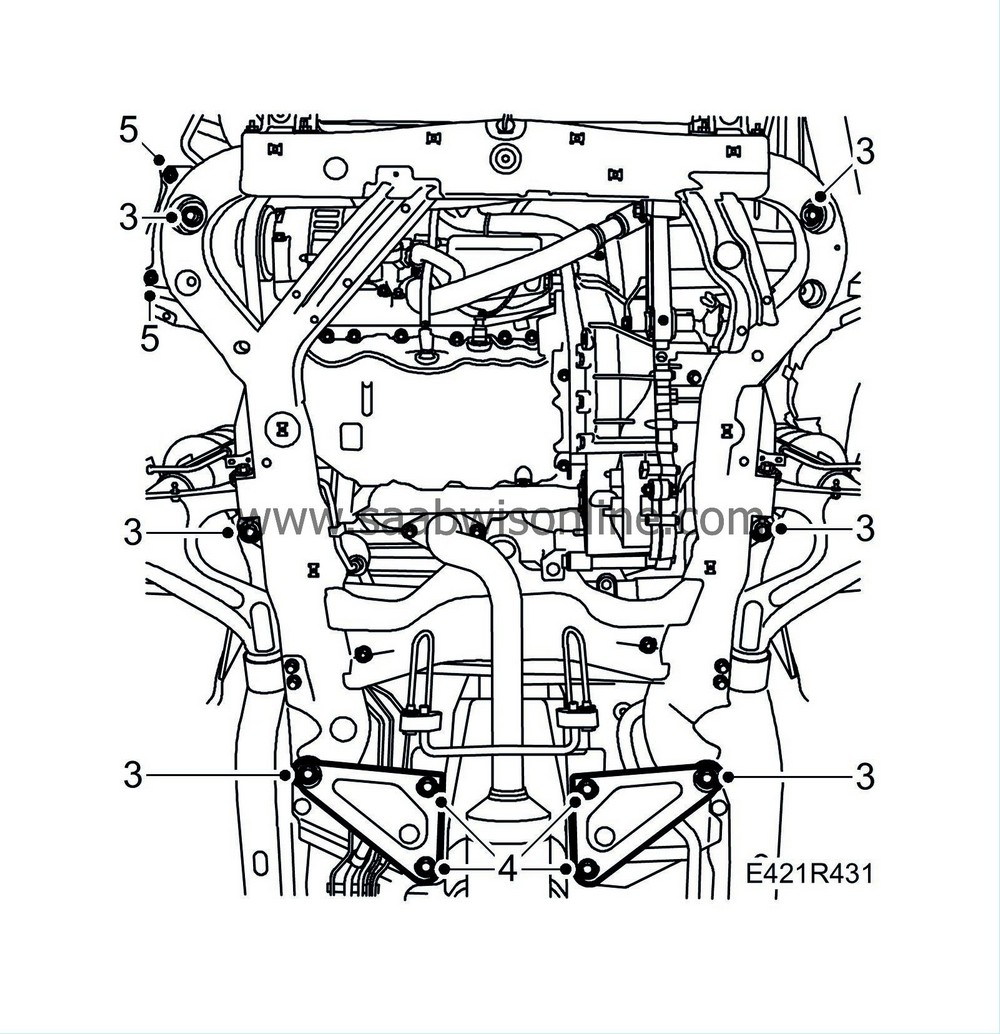

Tighten the subframe bolts. Check that the lifting trolley locating studs are correctly placed in the body reference holes.

|

|

| 3. |

Fit the subframe retaining bolts.

Tightening torque: 100 Nm + 45° (74 lbf ft + 45°)

|

|

| 4. |

Fit the triangular stiffeners.

Tightening torque: 63 Nm (46 lbf ft) |

|

| 5. |

Remove the lifting trolley and fit the two nuts by the air cleaner.

|

|

| 6. |

Fit the coolant pipe for the battery box.

|

|

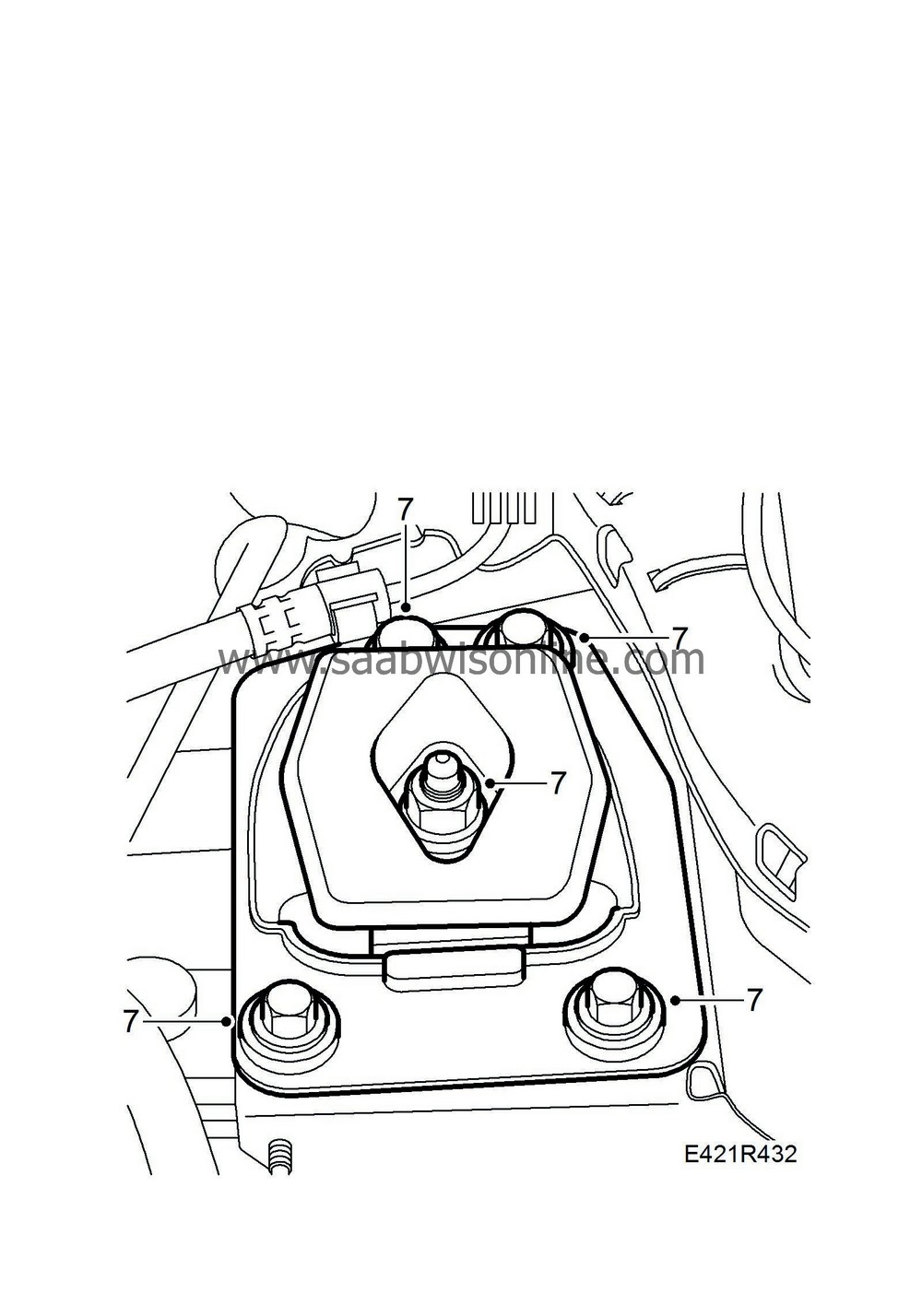

| 7. |

Lower the car and take the weight off the left-hand side of the engine. Fit the left-hand engine mounting. Lower the engine carefully.

Tightening torque: 64 Nm (47 lbf ft)

|

|

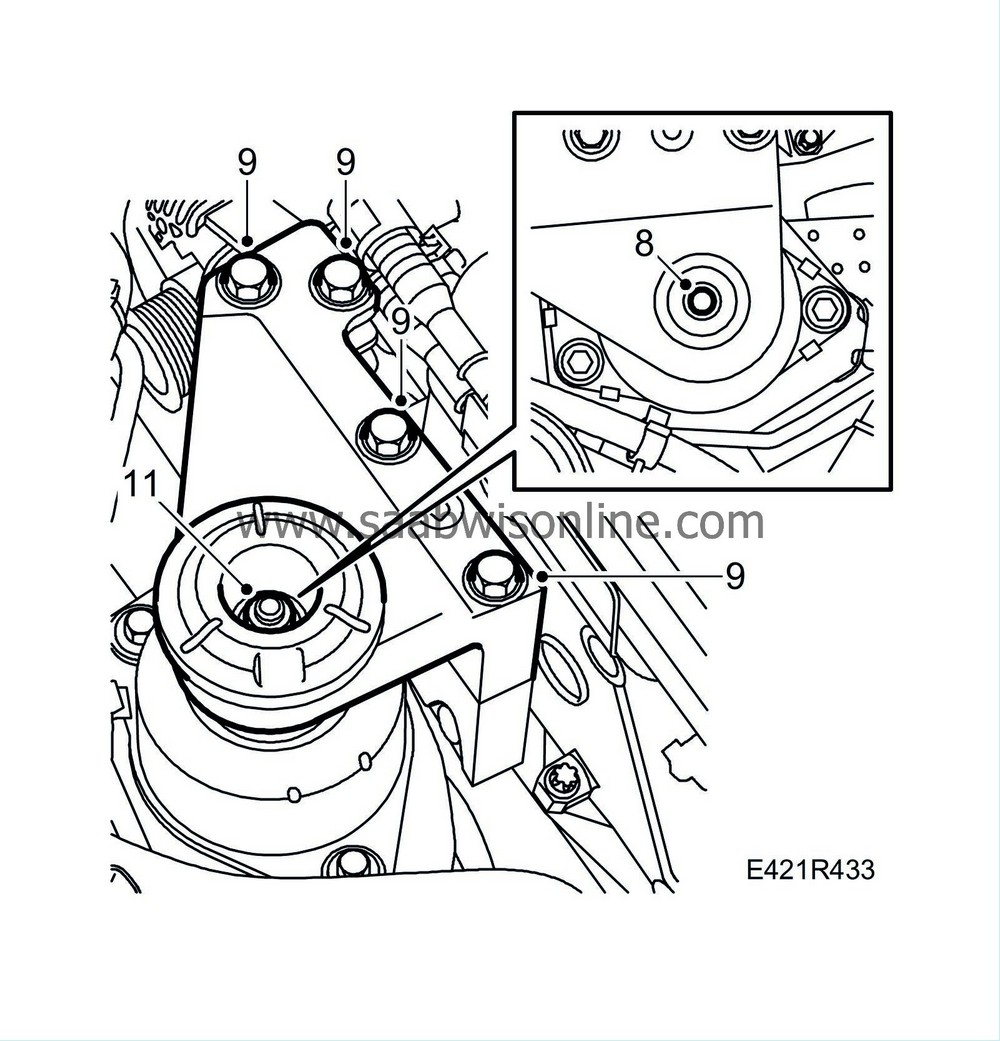

| 9. |

Fit the engine mounting vibration damper and nut and tighten the upper bracket retaining bolts.

Tightening torque 40 Nm + 60° (30 lbf ft + 60°) |

|

| 10. |

Raise the car and remove the wedges from the subframe.

|

|

| 11. |

Lower the car completely and remove the jack· Tighten the nut to the right of the engine mounting.

Tightening torque 105 Nm (77 lbf ft) |

|

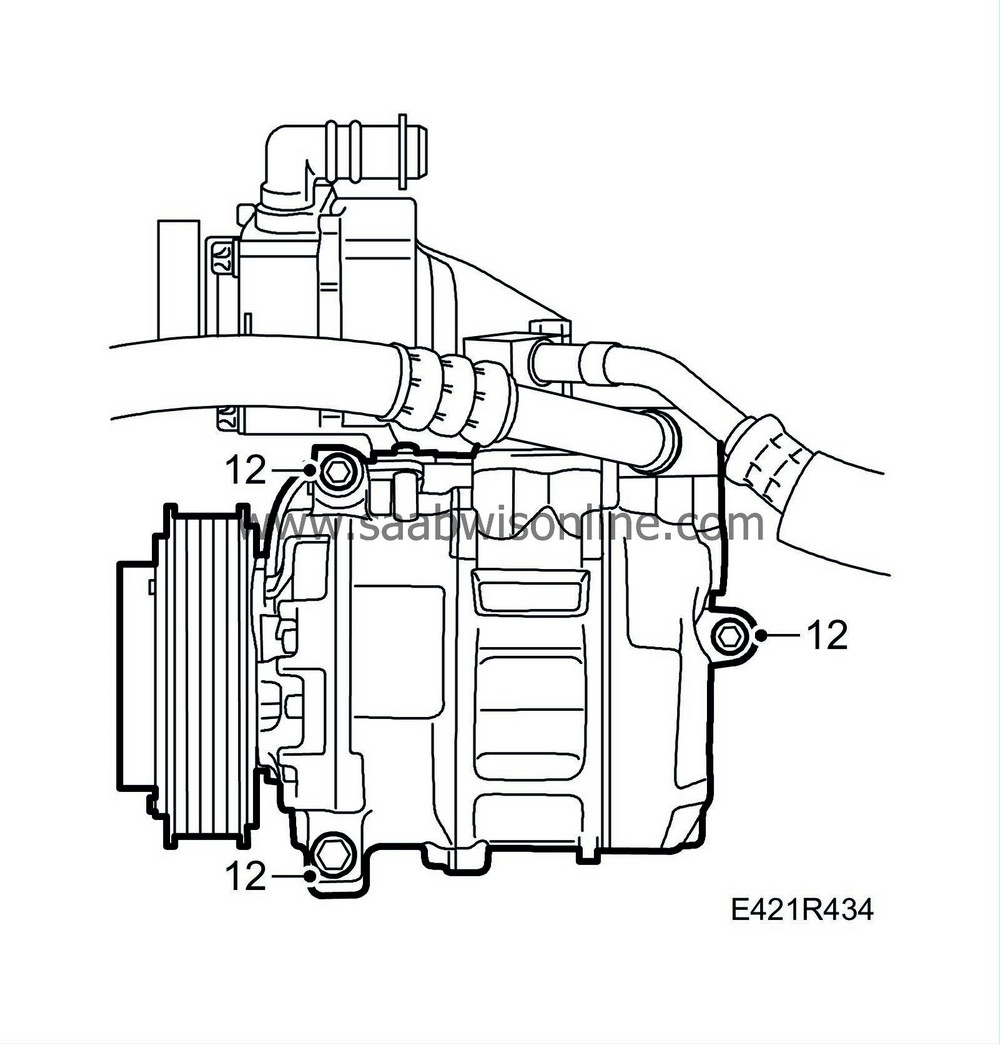

| 12. |

Clip the cable ties and fit the A/C compressor bolts while putting the power steering pipe in place. Refit the A/C pipes in their clips.

Tightening torque: 24 Nm (18 lbf ft)

|

|

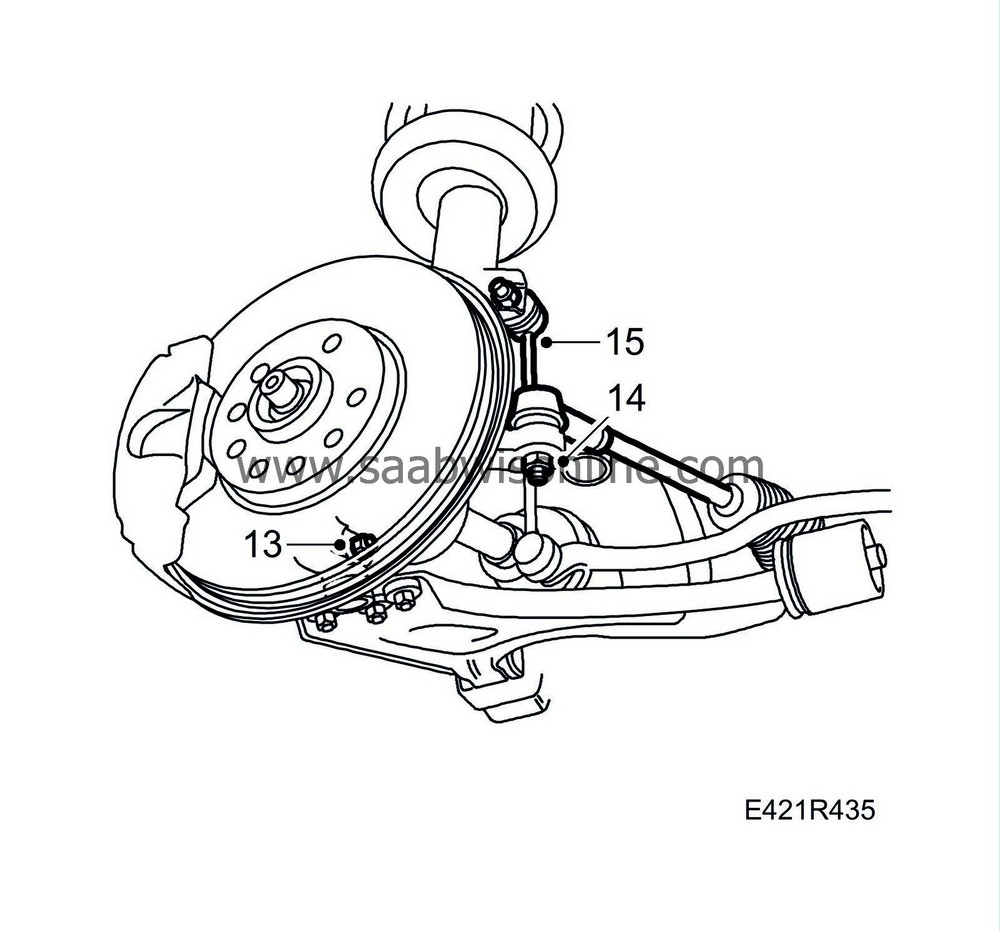

| 14. |

Fit the track rod ends to the steering swivel member.

Tightening torque: 50 Nm (37 lbf ft) |

|

| 15. |

Fit the upper nuts to the anti-roll bars. Hold with a wrench so that they do not rotate and become damage, or hold the hexagonal pin with a socket.

Tightening torque: 84 Nm (62 lbf ft) Tightening torque, nut with steel lock: 95 Nm (66 lbf ft) |

|

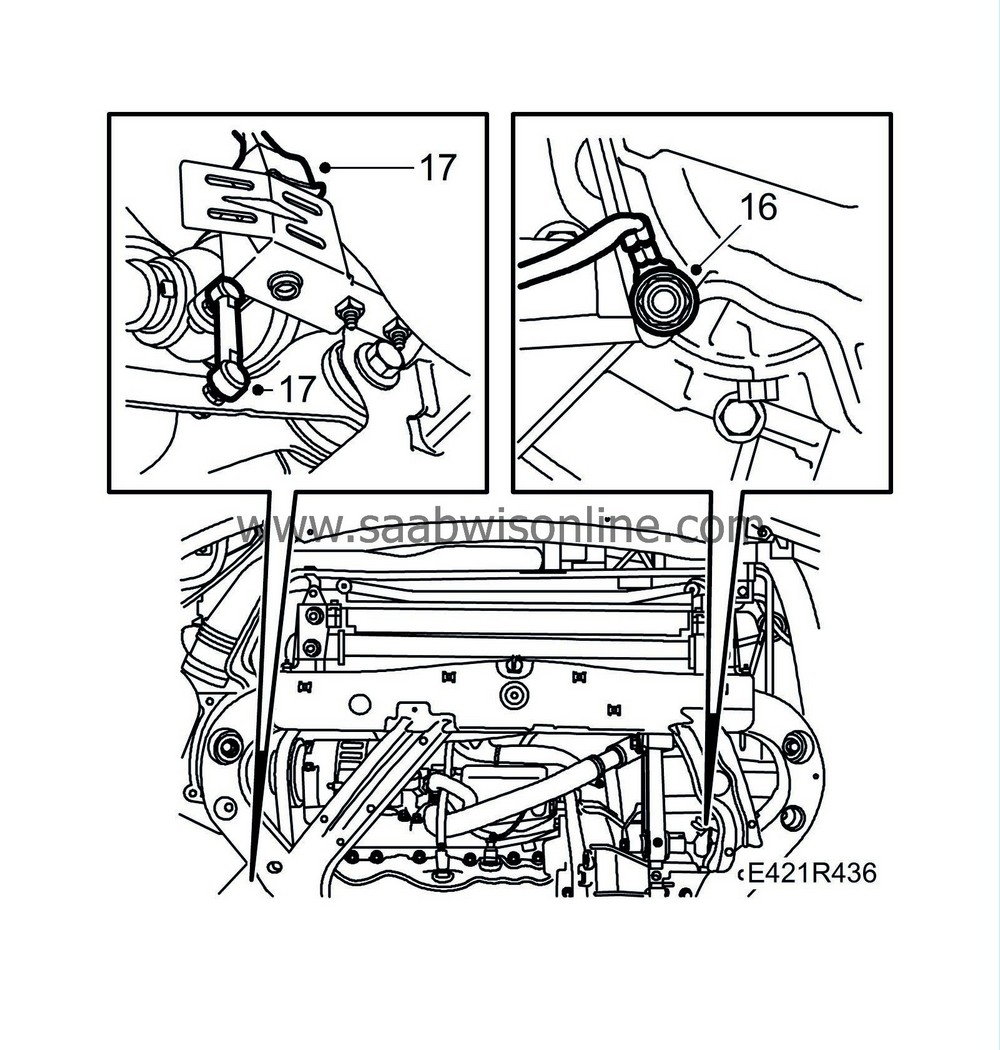

| 16. |

Aut:

Secure the battery cable in the clip on the gearbox.

All:

Fit the ground cable to the gearbox.

|

|

| 17. |

Plug in the connector to the headlamp control module on the link arm (xenon headlamps only).

|

|

| 18. |

Lower the car and remove the

83 95 212 Strap

from the condenser and charge air cooler.

|

|

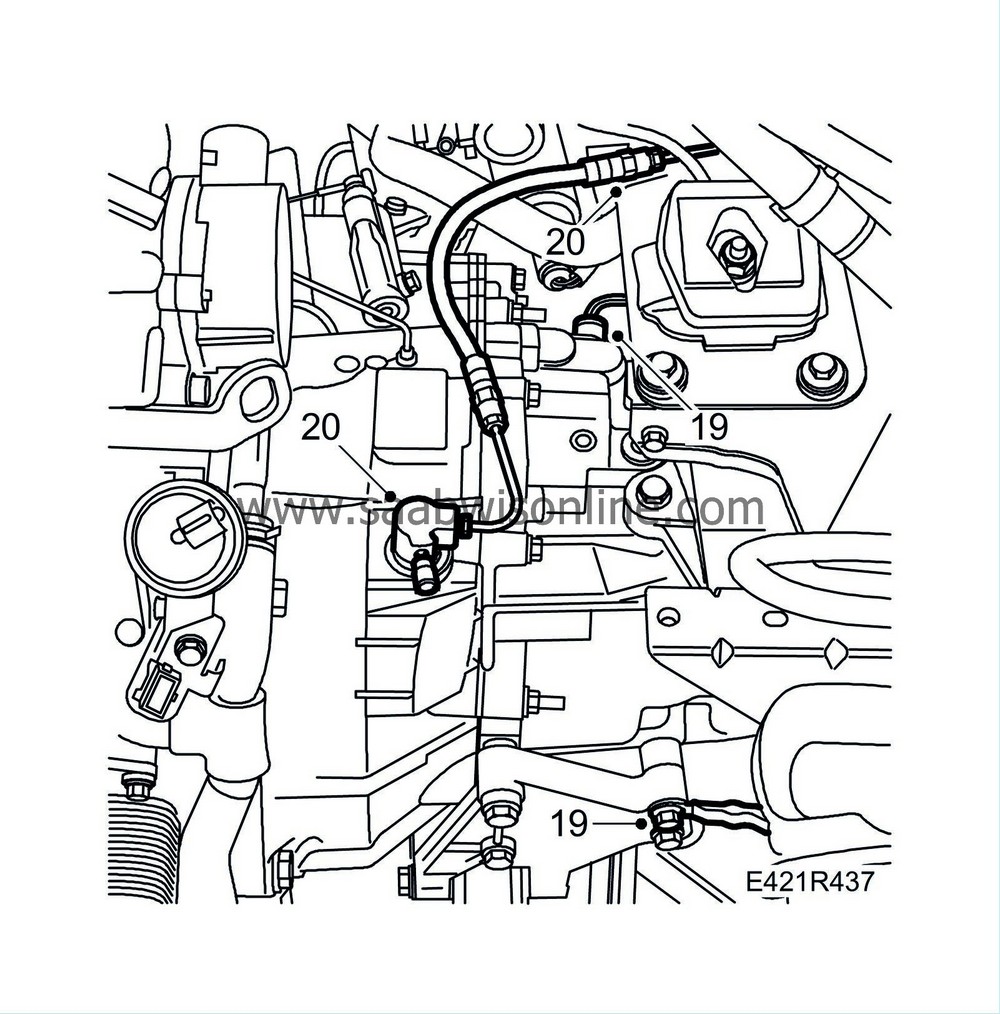

| 19. |

Man:

Plug in the connector for the reversing light switch and fit the ground cable to the gearbox.

Aut: Fit the gear selector to the gearbox.

|

|

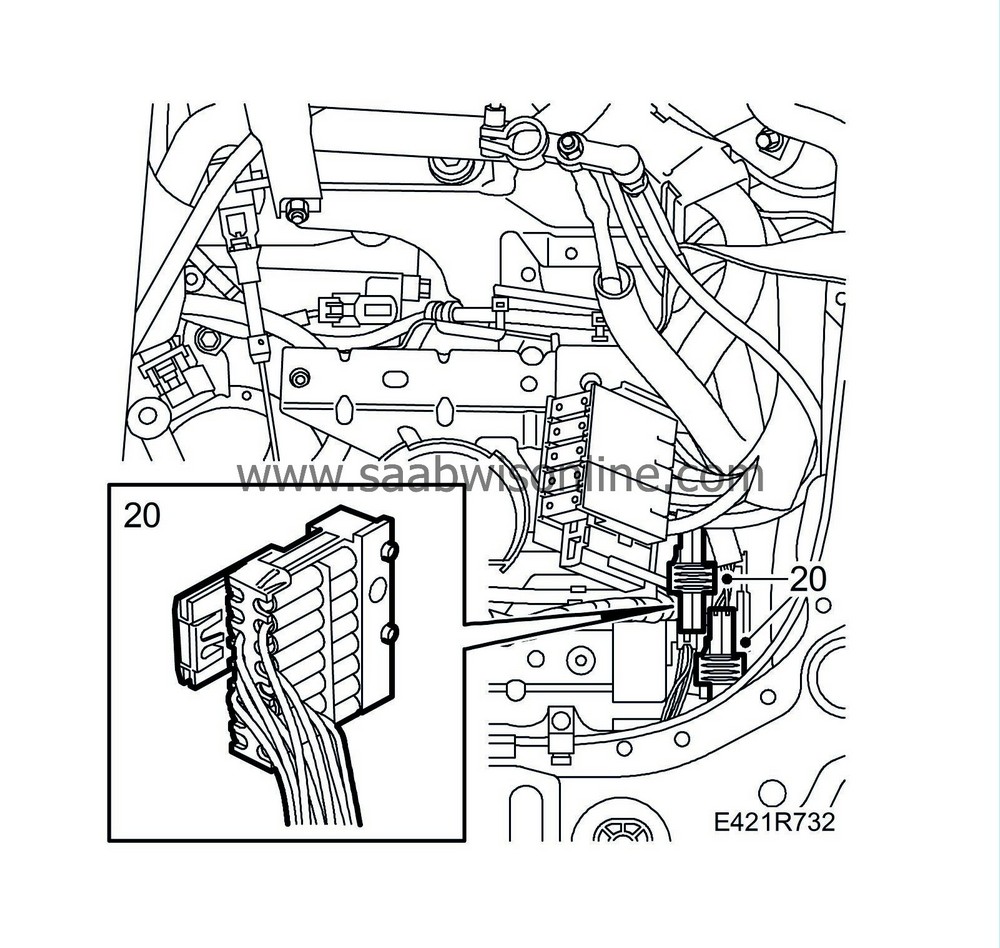

| 20. |

Man:

Remove the clip by the slave cylinder and fit the connection to the delivery pipe. Secure the clip.

Aut: Fit the forward-facing connector onto the bracket by the structural member. Connect the gearbox connector to the structural member.

|

|

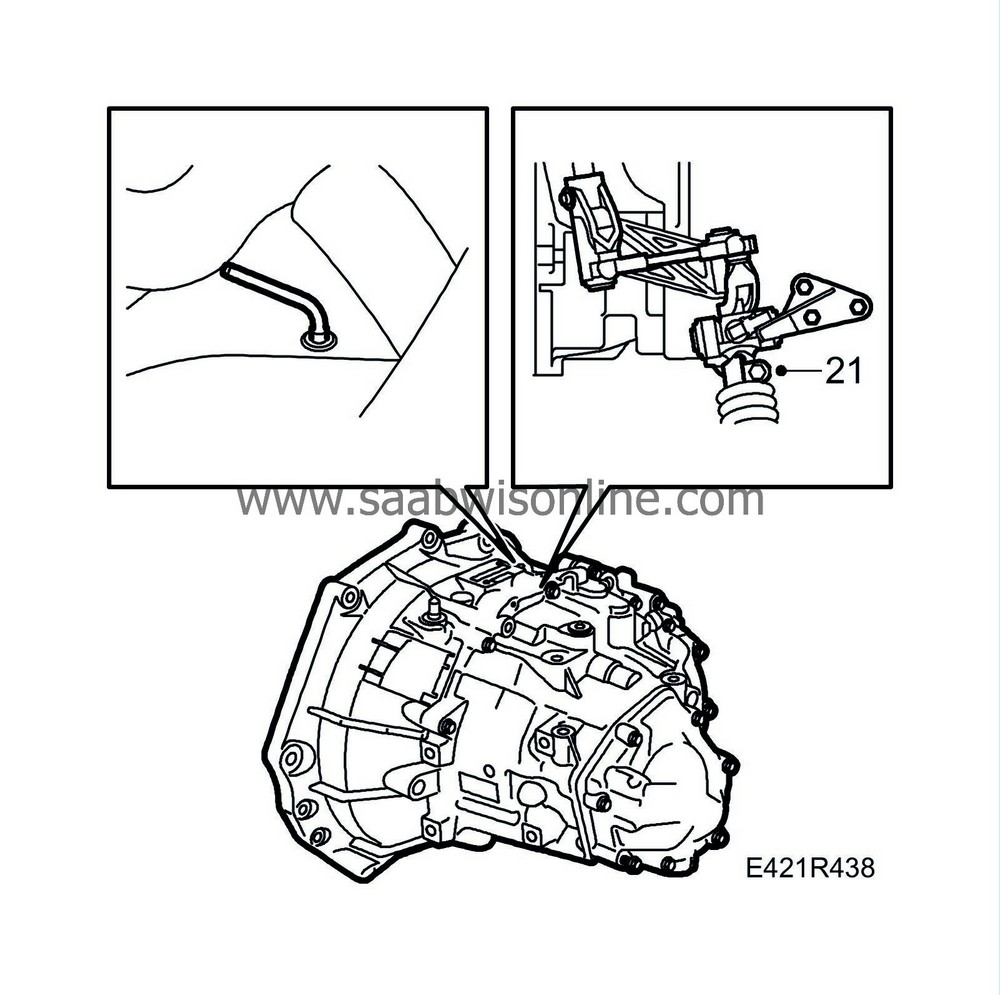

| 21. |

Man:

Remove

87 92 335 Lock pin

from the gear lever housing and connect the gear linkage to the gear lever. Engage 4th gear and insert

87 92 632 Lock pin

. Tighten the clamp on the gear linkage.

Tightening torque: 22 Nm (16 lbf ft)

|

|

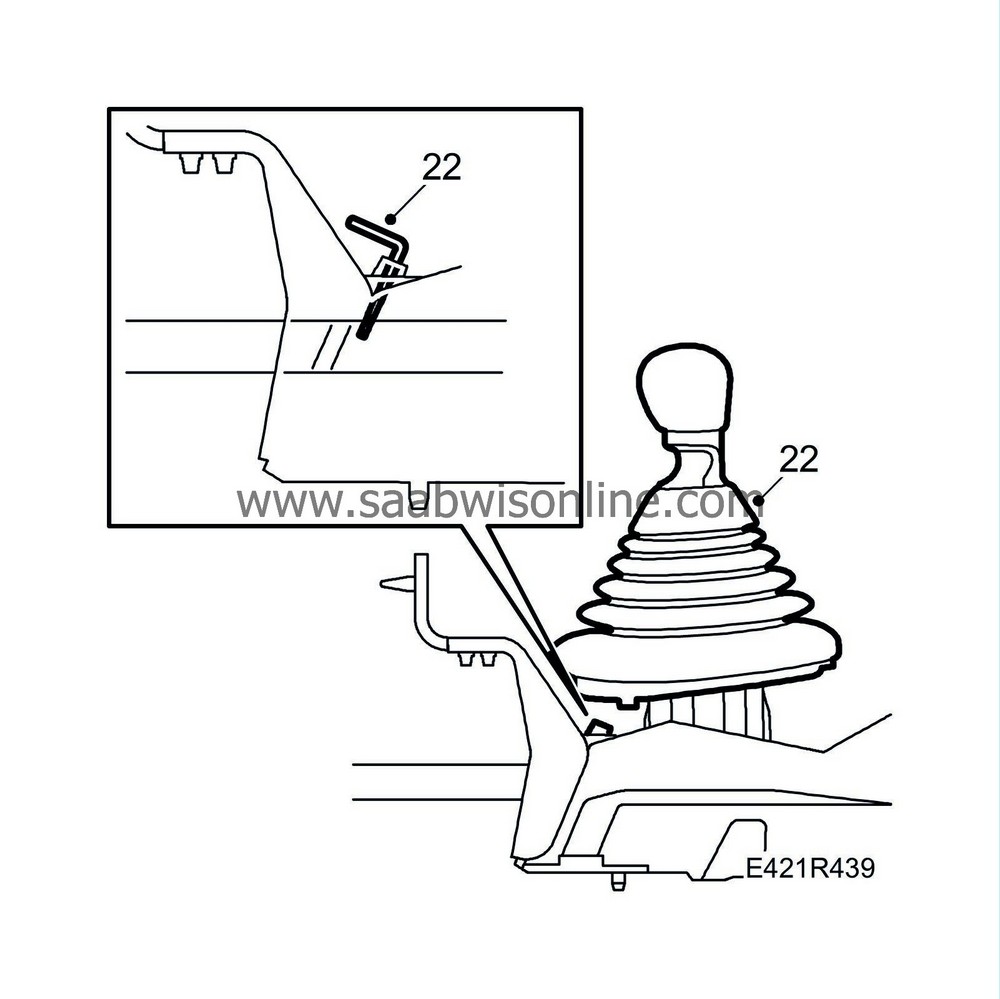

| 22. |

Man:

Remove the lock pins, check the gear positions and check that the ignition key can be inserted and removed. Insert the plastic plug into the gearbox. Fit the gear lever gaiter.

|

|

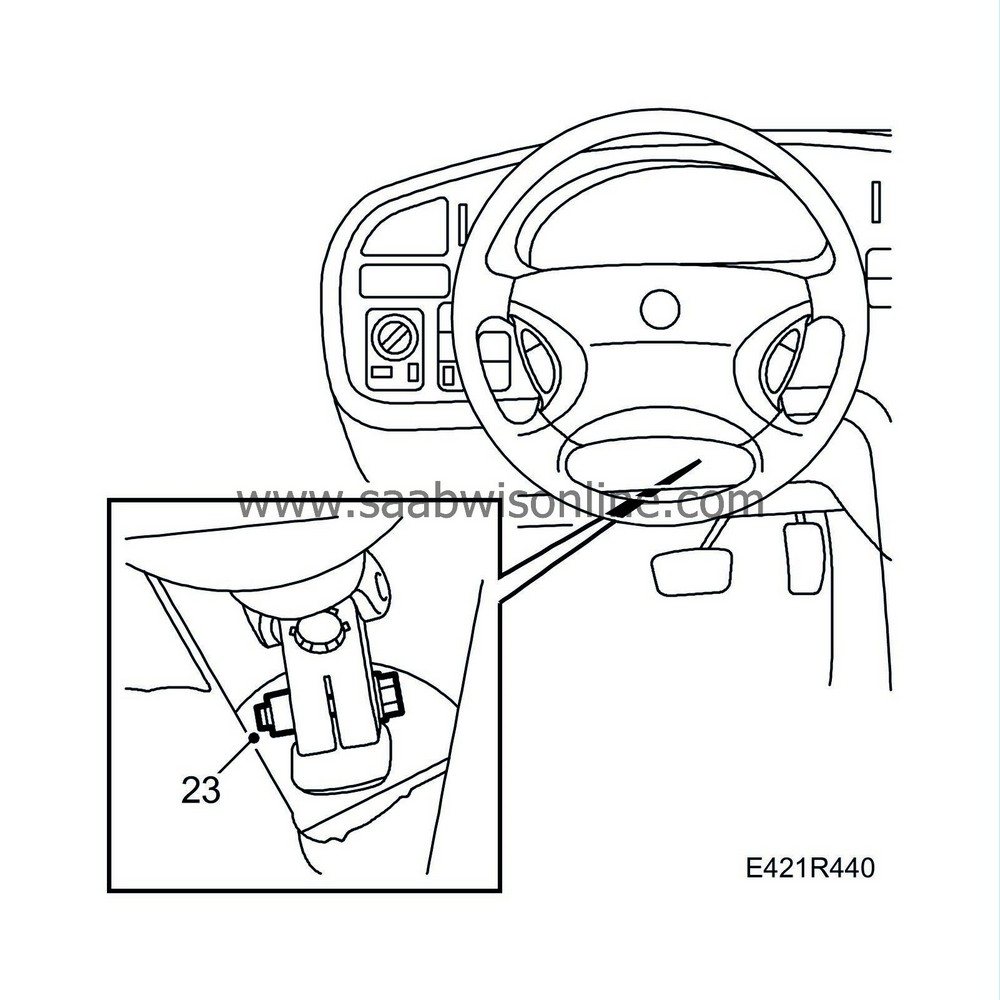

| 23. |

Connect the steering column from the steering gear inside the cabin.

|

|

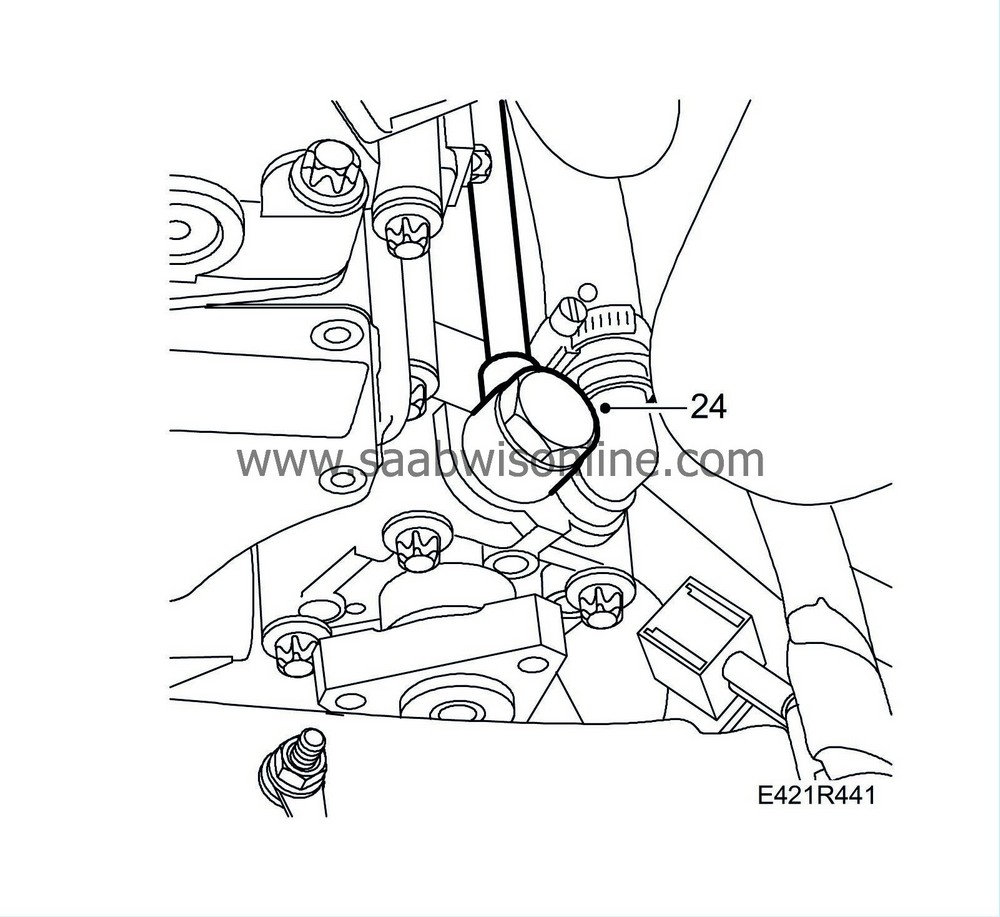

| 24. |

Fit the banjo screw on the power steering pump. Remove the hose pinch-off pliers.

|

|

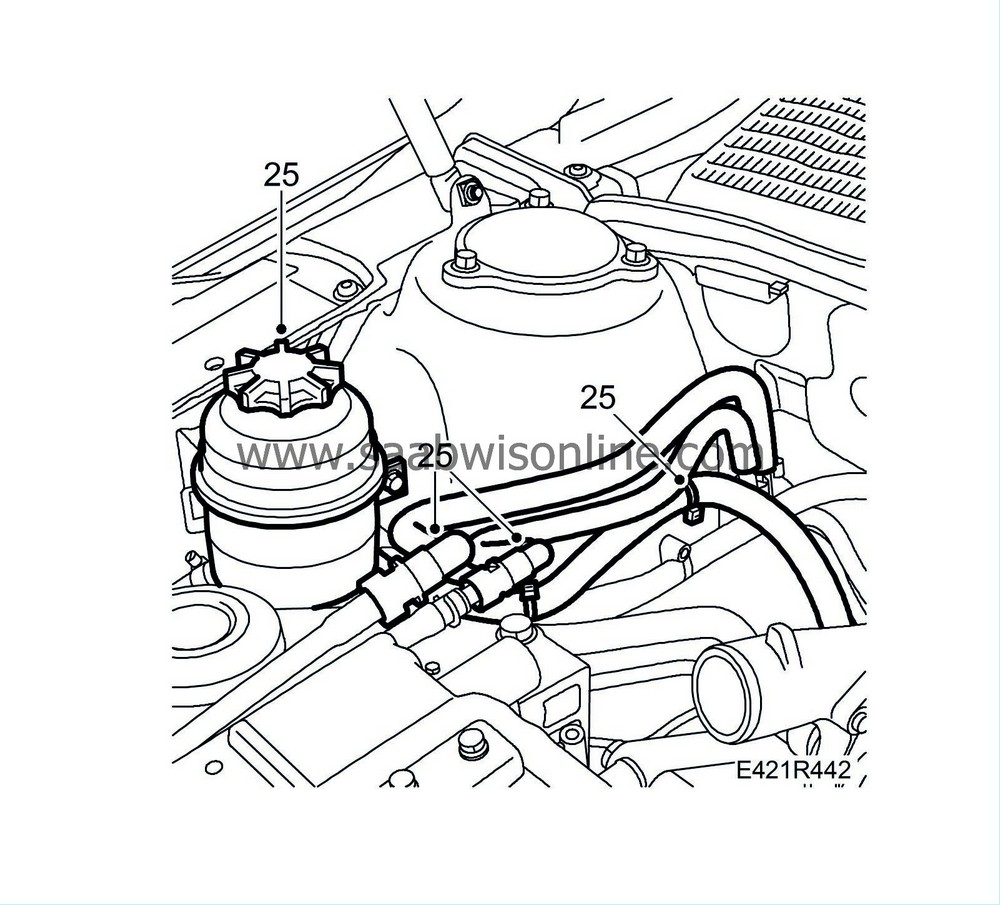

| 25. |

Fit the power steering fluid reservoir and the upper clips on the power steering return line. Connect the fuel lines.

|

|

| 26. |

Plug in the connector to the AC compressor.

|

|

| 27. |

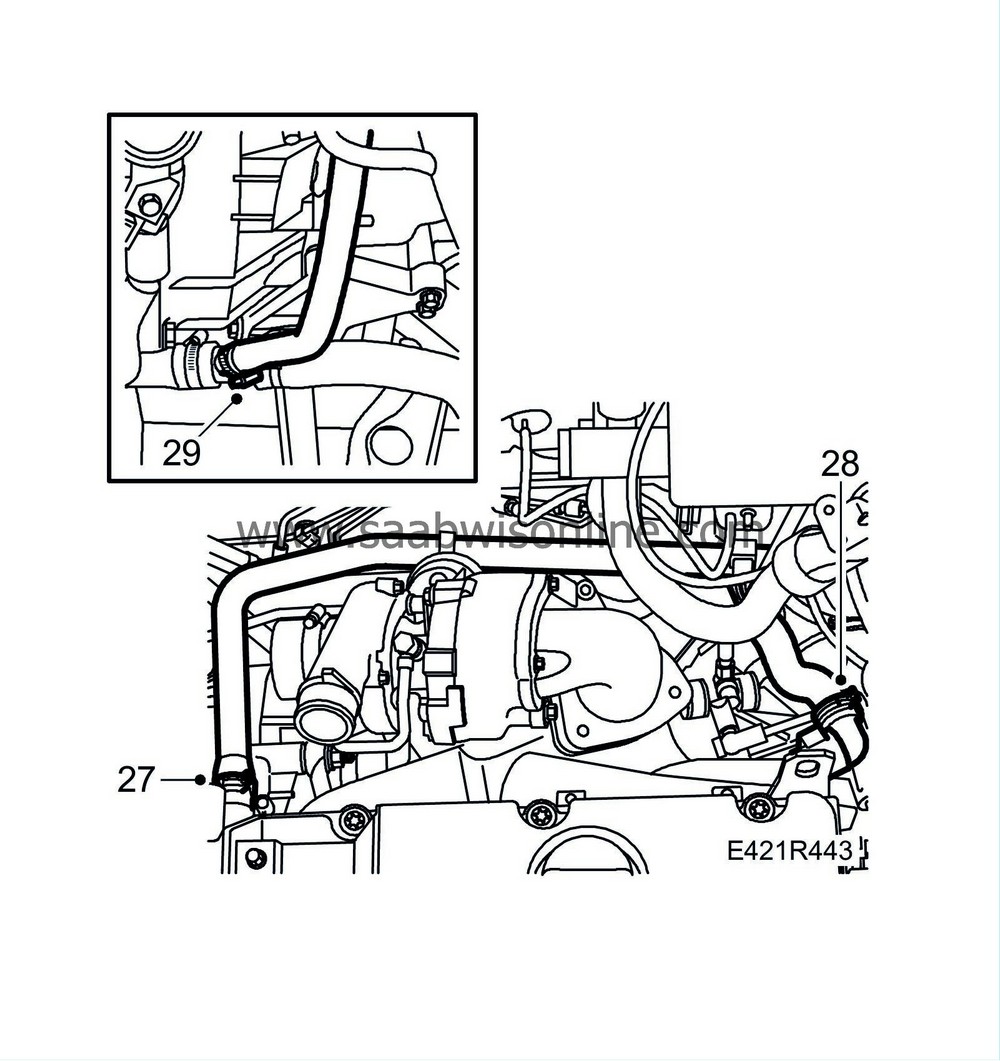

Connect the coolant hose to the generator bracket.

|

|

| 28. |

Connect the coolant hose to the rear coolant pipe quick release coupling.

|

|

| 29. |

Fit the coolant hose to the T-piece on the gearbox.

|

|

| 30. |

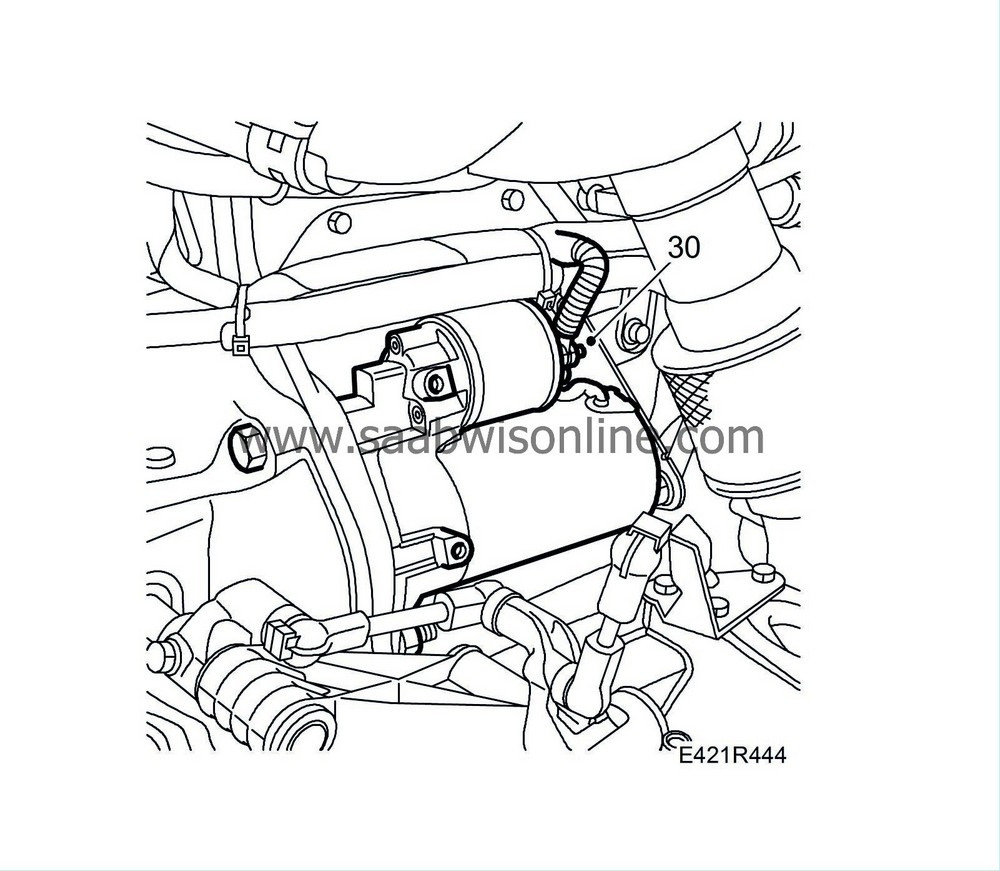

Attach the wiring harness to the starter motor.

|

|

| 31. |

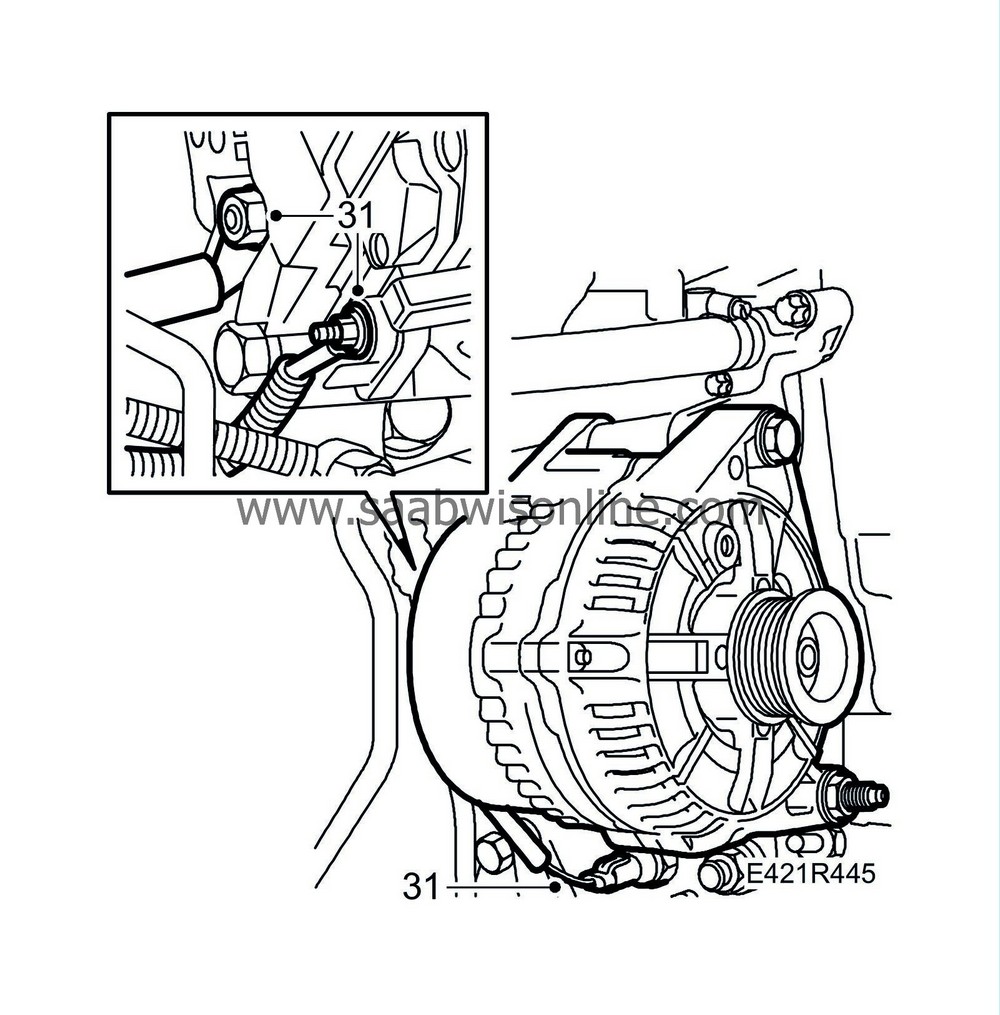

Raise the car and plug in the electric connectors to the generator and the oil pressure sensor.

|

|

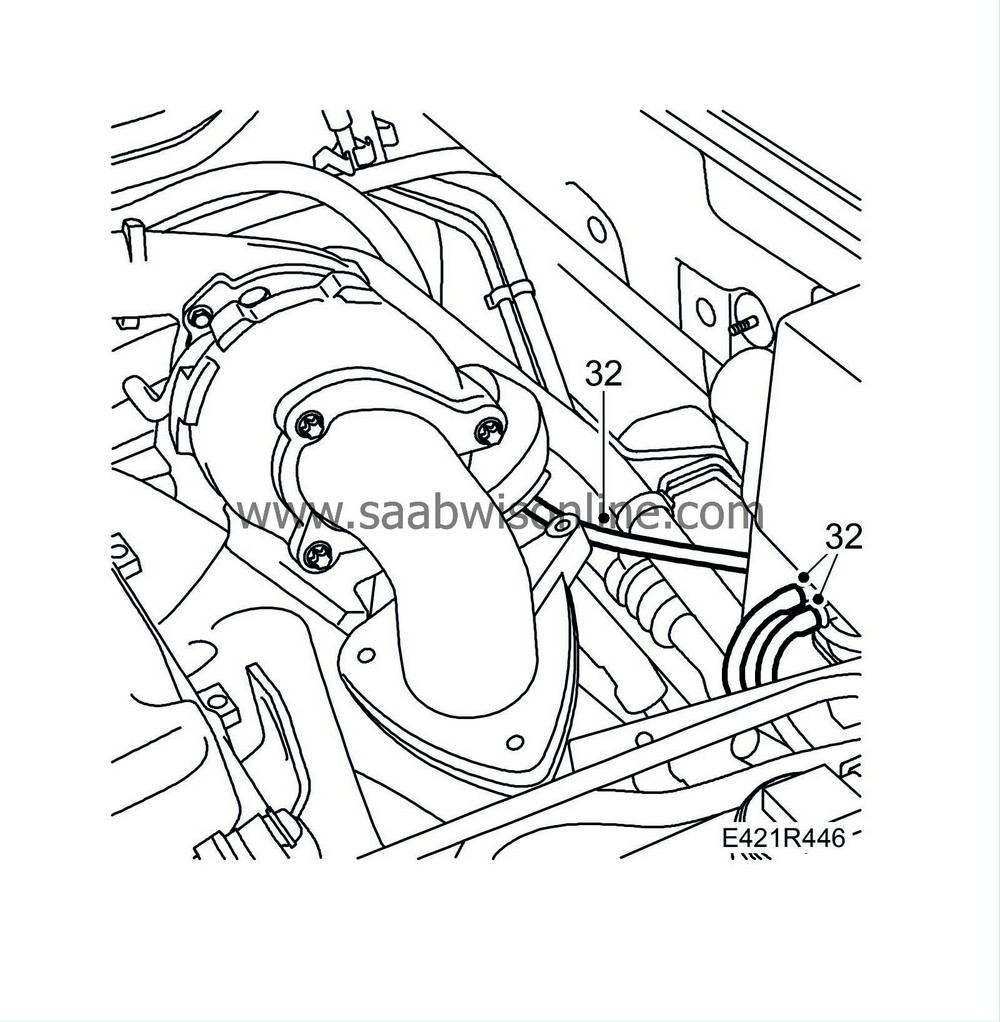

| 32. |

Lower the car and connect the vacuum hose to the turbocharger wastegate.

|

|

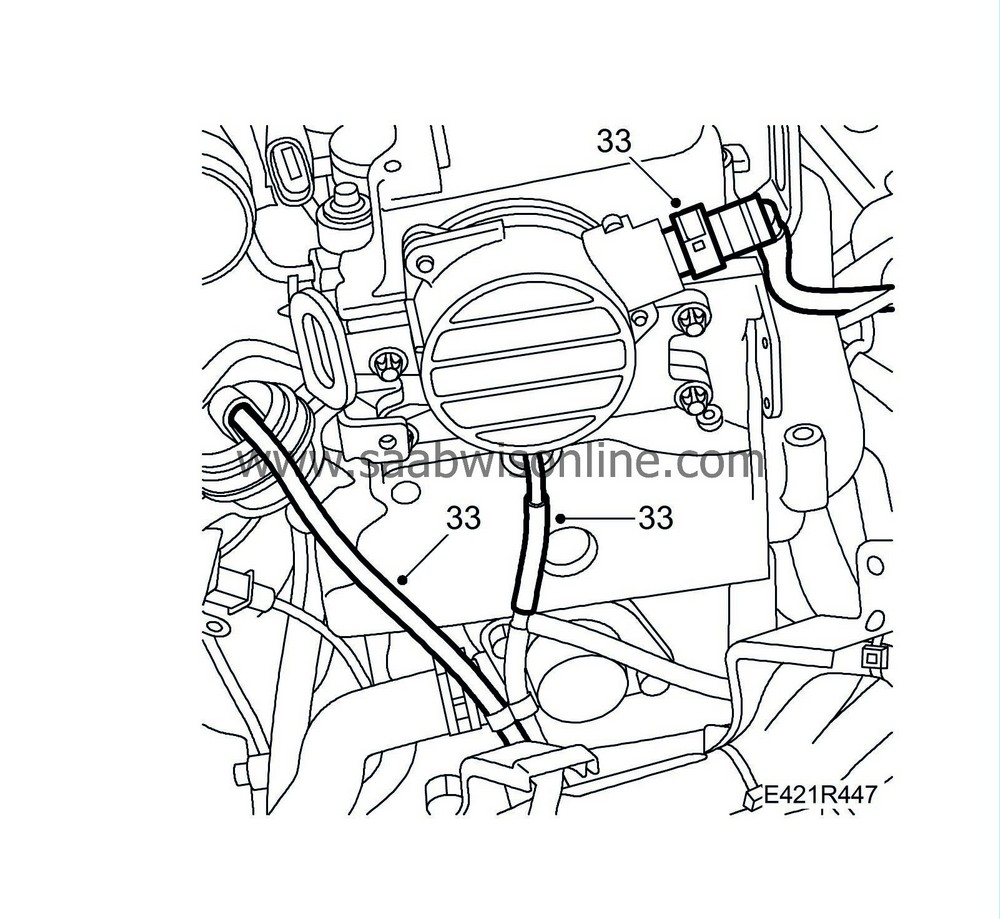

| 33. |

Connect the vacuum hose to the swirl throttle and the hoses to the vacuum pump.

|

|

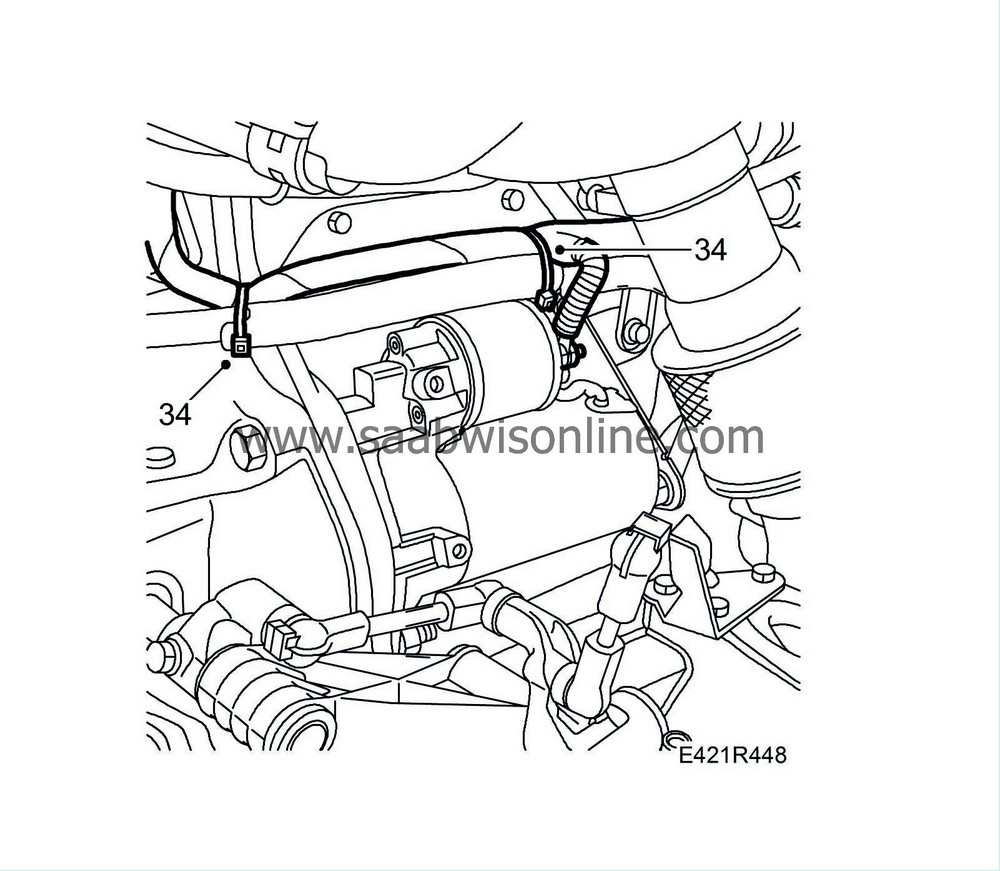

| 34. |

Use the other cable tie for the starter motor cable.

|

|

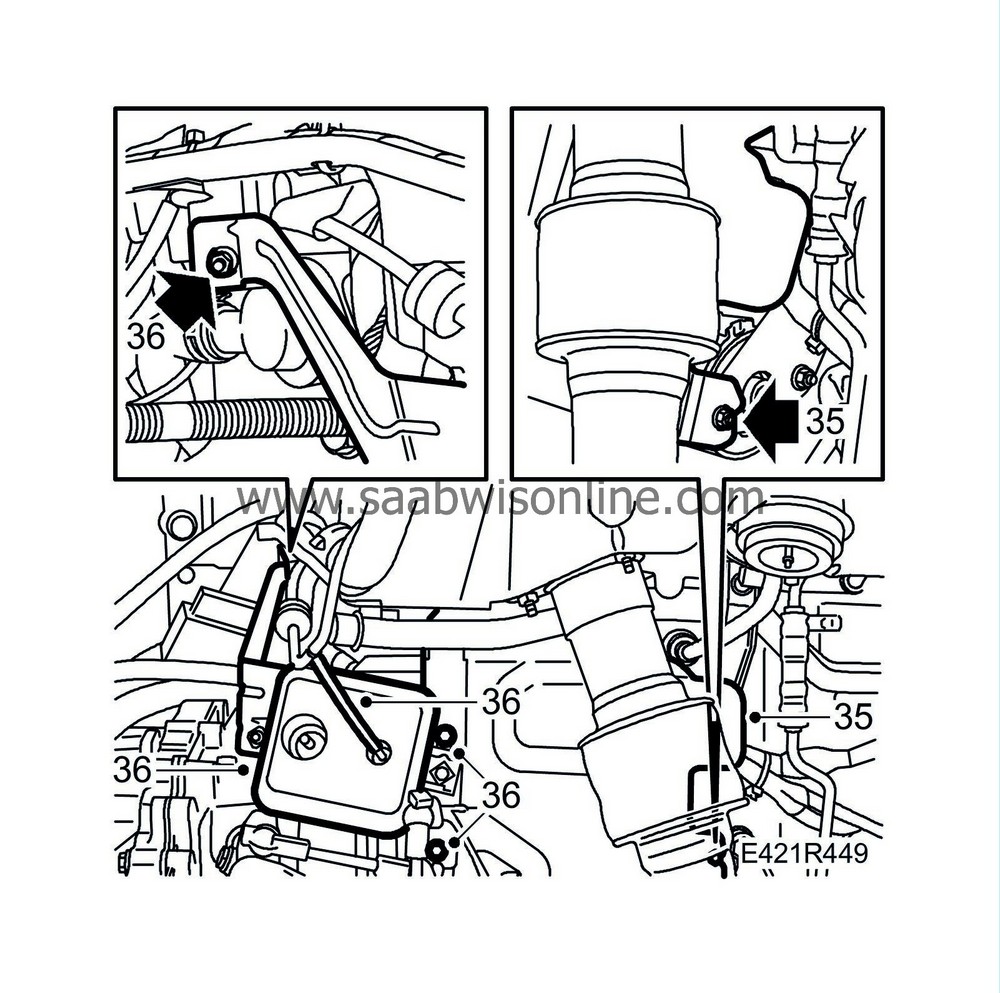

| 35. |

Fit the heat shield over the starter motor.

|

|

| 36. |

Fit the vacuum tank and attach the hose. Fit the vacuum tank stay to the cable rail.

|

|

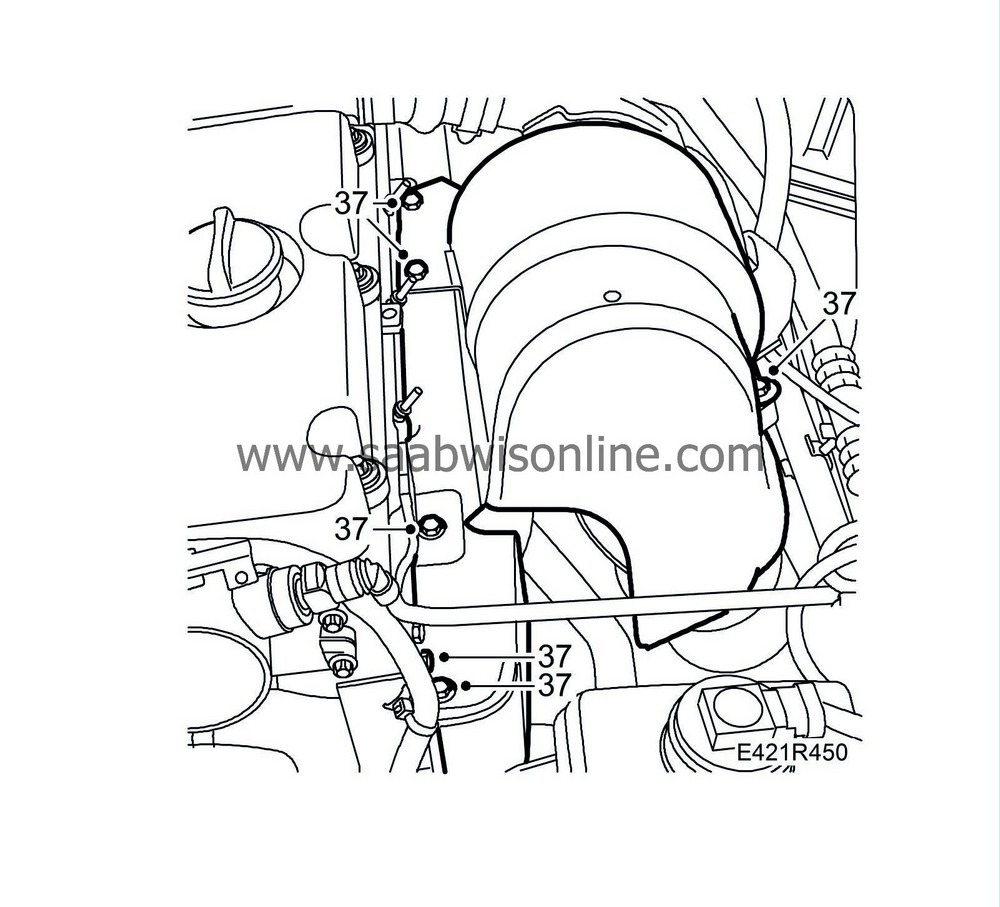

| 37. |

Fit the heat shields over the exhaust manifold and turbocharger.

|

|

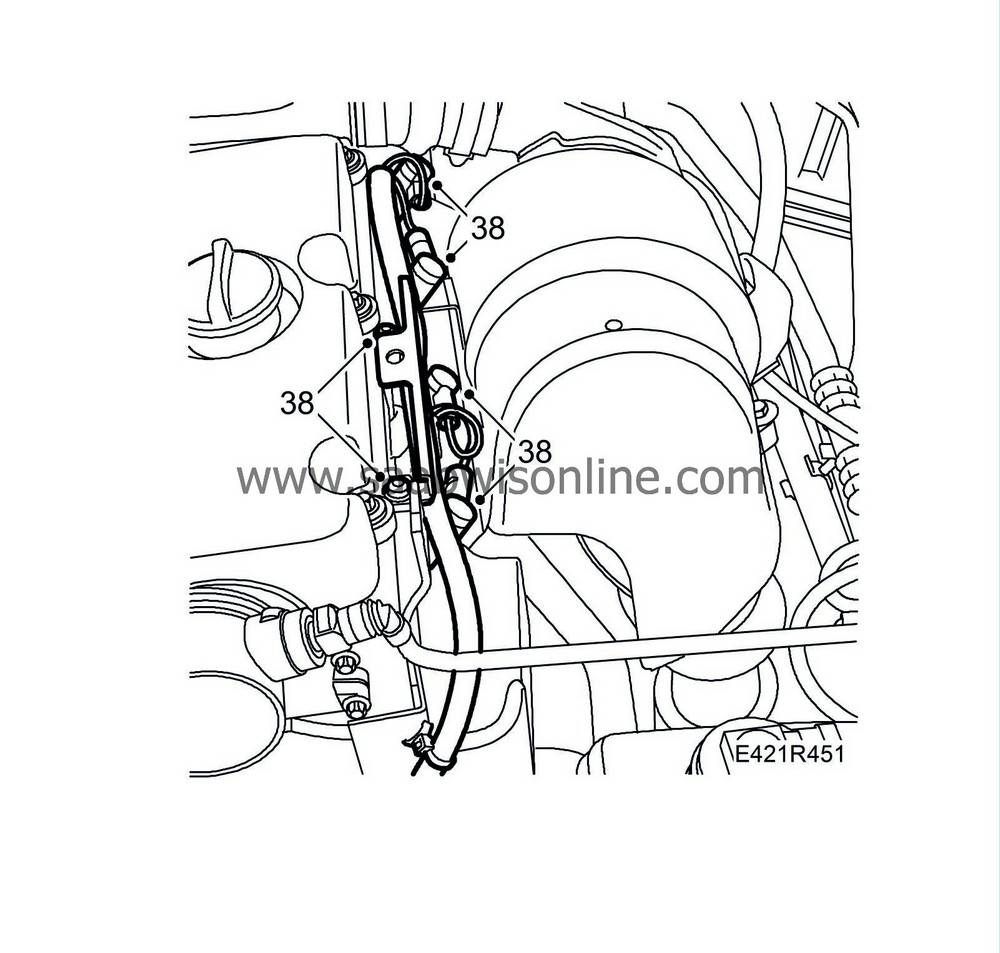

| 38. |

Connect the glow plug electric connections and fit the rear wiring harness mounting to the camshaft cover.

|

|

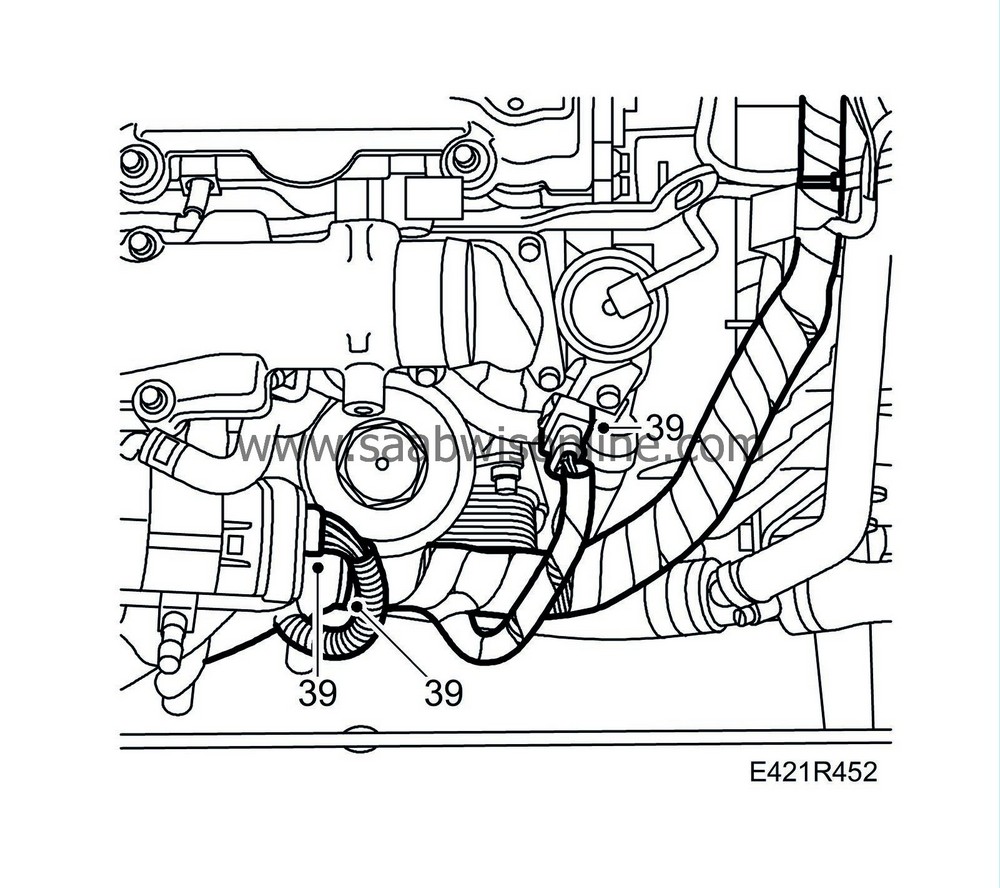

| 39. |

Attach the EGR valve connector and crankshaft position sensor connector.

|

|

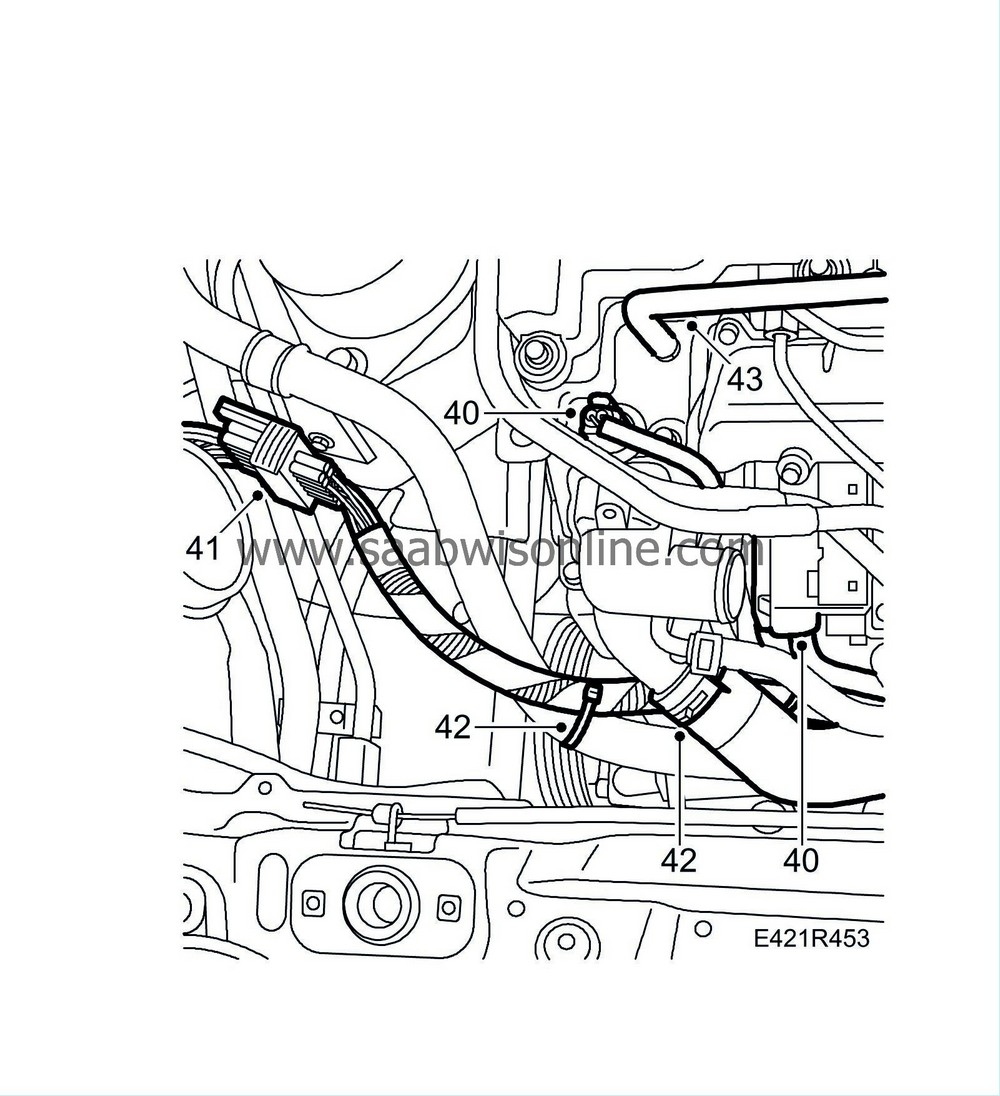

| 40. |

Attach the coolant temperature sensor and the engine control module connectors. See

Before changing a control module.

|

|

| 41. |

Attach the right-hand engine mounting connector and the coolant temperature sensor connectors.

|

|

| 42. |

Fit cable ties to the oil filter housing and the thermostat housing. Connect the lower hose to the thermostat housing.

|

|

| 43. |

Fit the coolant hose between the expansion tank and the engine.

|

|

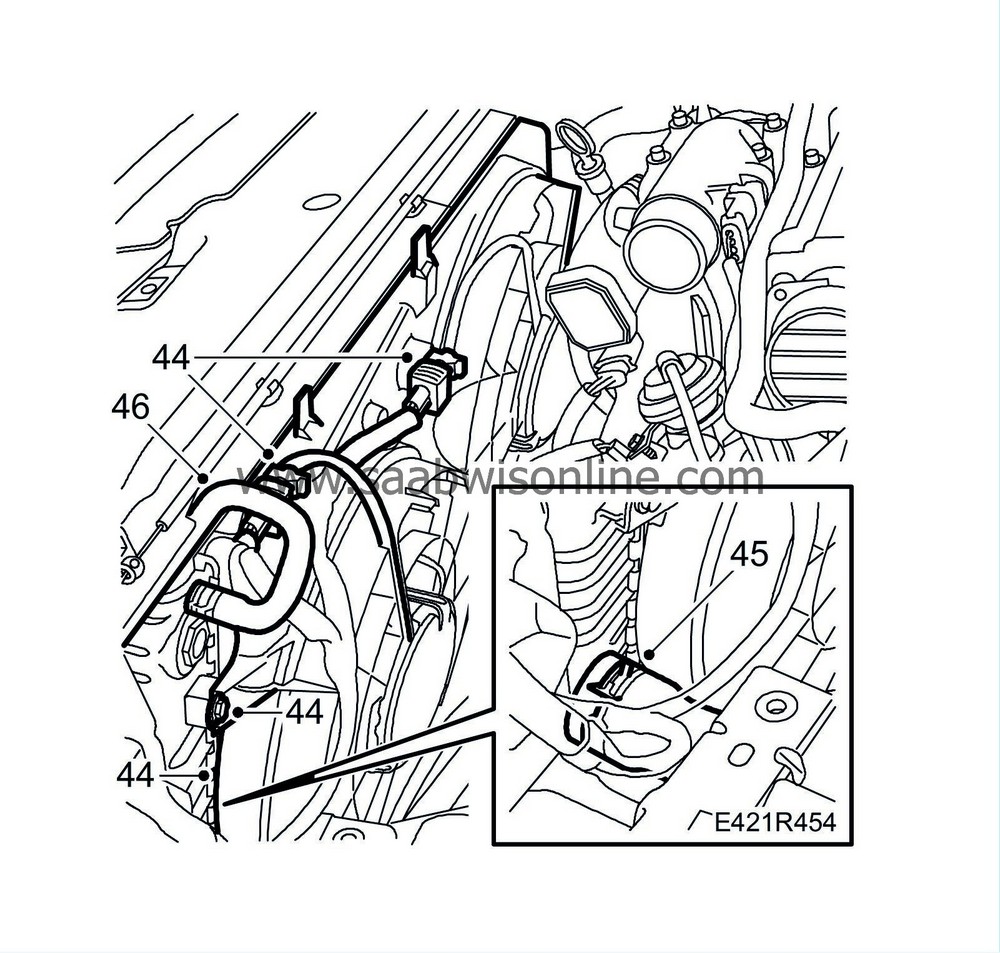

| 44. |

Fit the radiator and housing. Attach the radiator fan connectors.

|

|

| 45. |

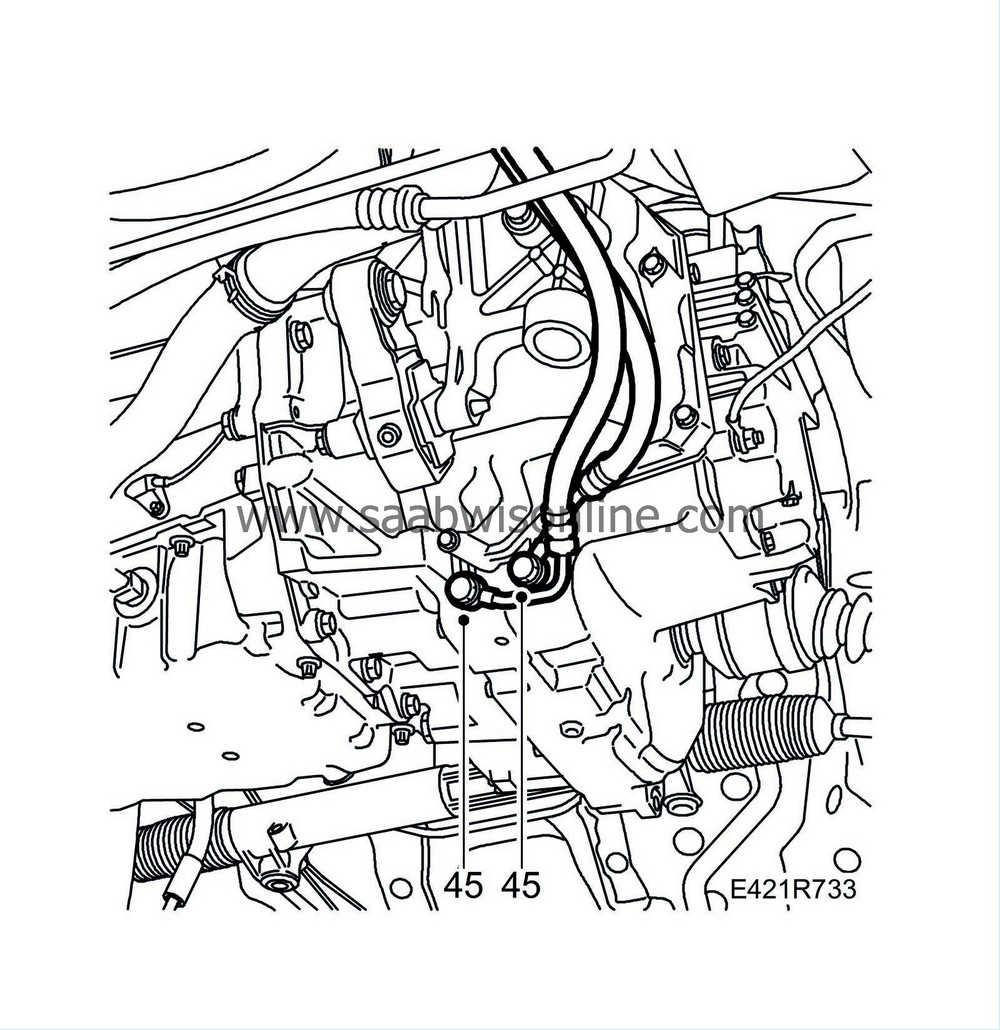

Aut:

Fit the oil cooler pipe to the gearbox.

All:

Fit the lower coolant hose.

|

|

| 46. |

Fit the ventilation hose between the radiator and the expansion tank.

|

|

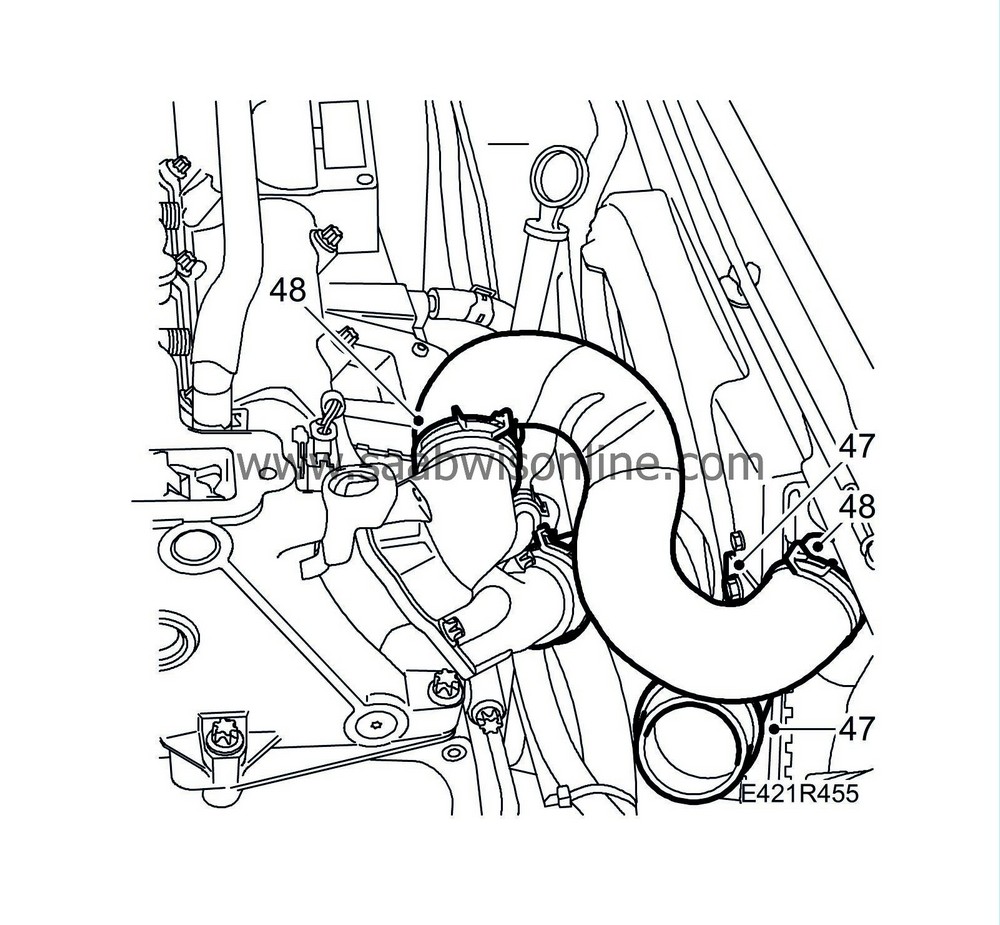

| 47. |

Fit the charge air pipe to the fan cowling.

|

|

| 48. |

Fit the radiator hose from the thermostat housing to the radiator.

|

||||||||||

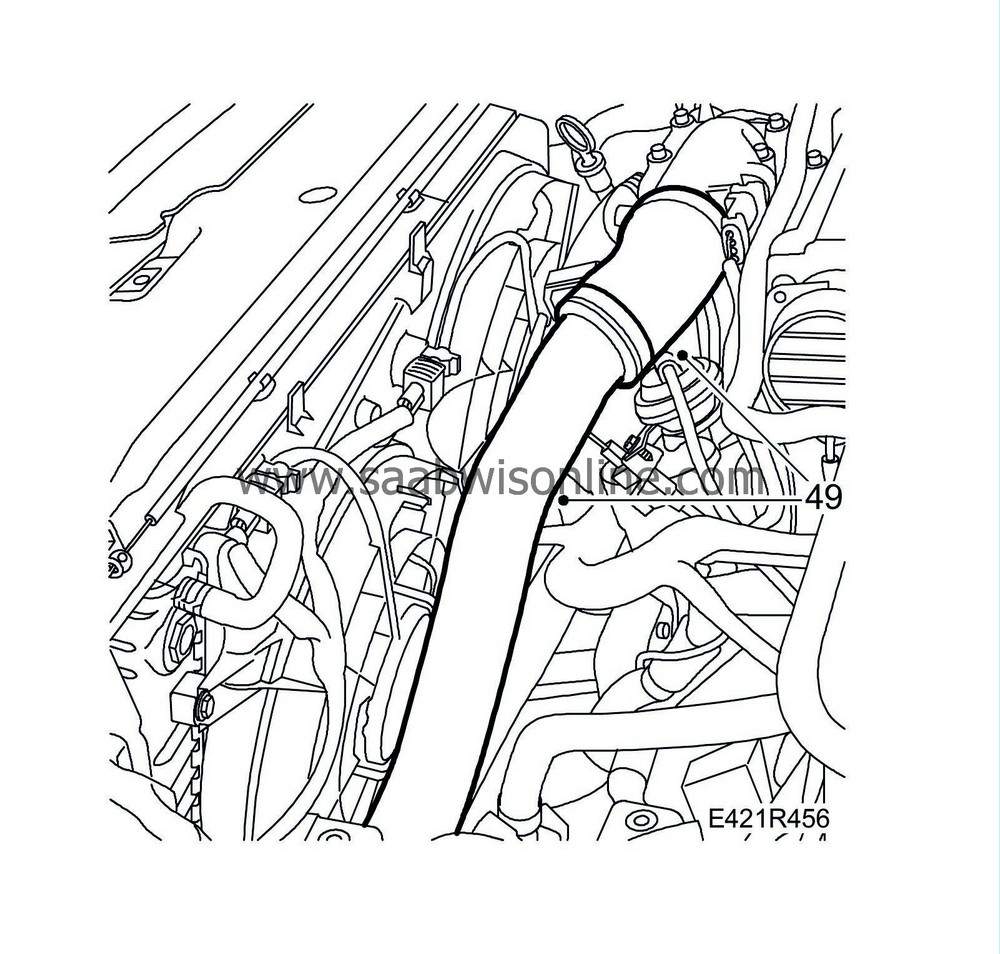

| 49. |

Attach the turbo delivery hose with pipes to the throttle body.

|

|

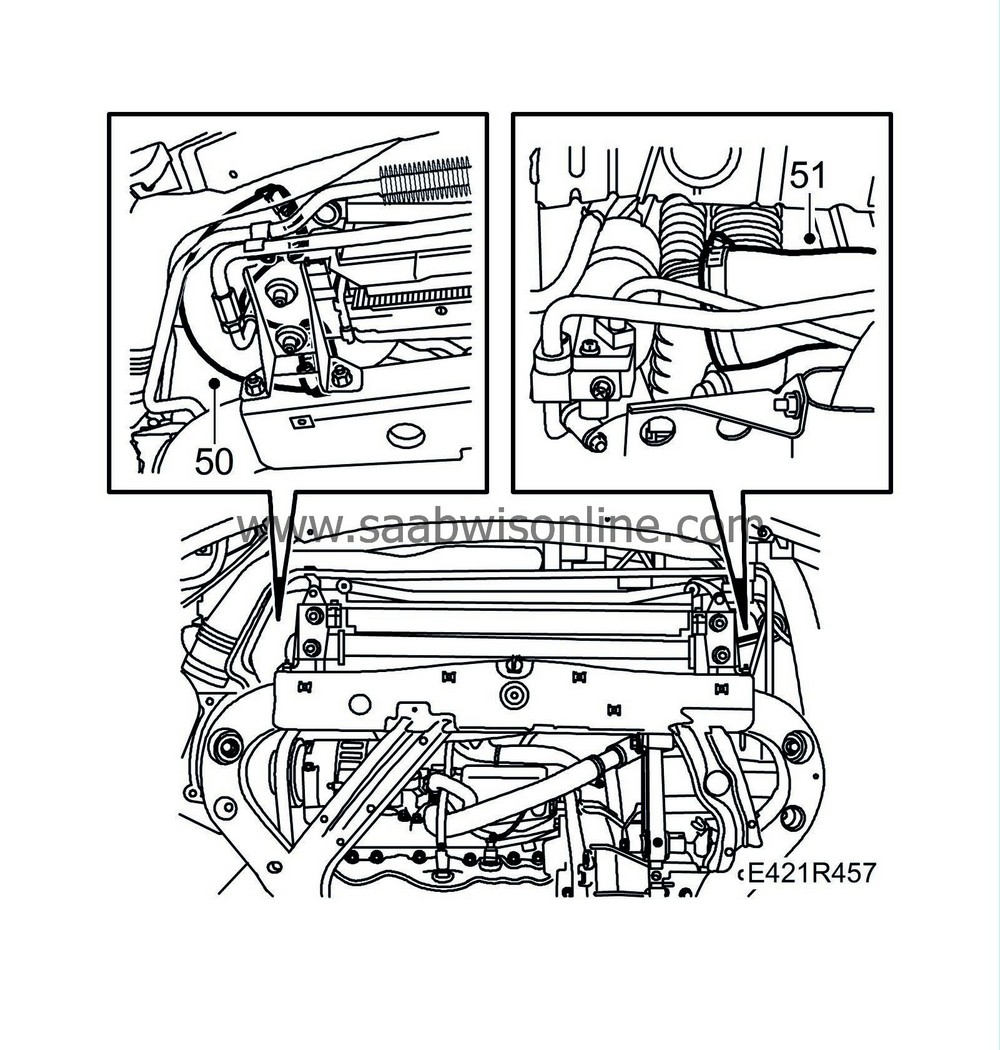

| 50. |

Raise the car and fit the turbo delivery hose to the charge air pipe on the right-hand side and to the charge air cooler.

|

|

| 51. |

Attach turbo delivery hose from the charge air pipe on the left-hand side.

|

|

| 52. |

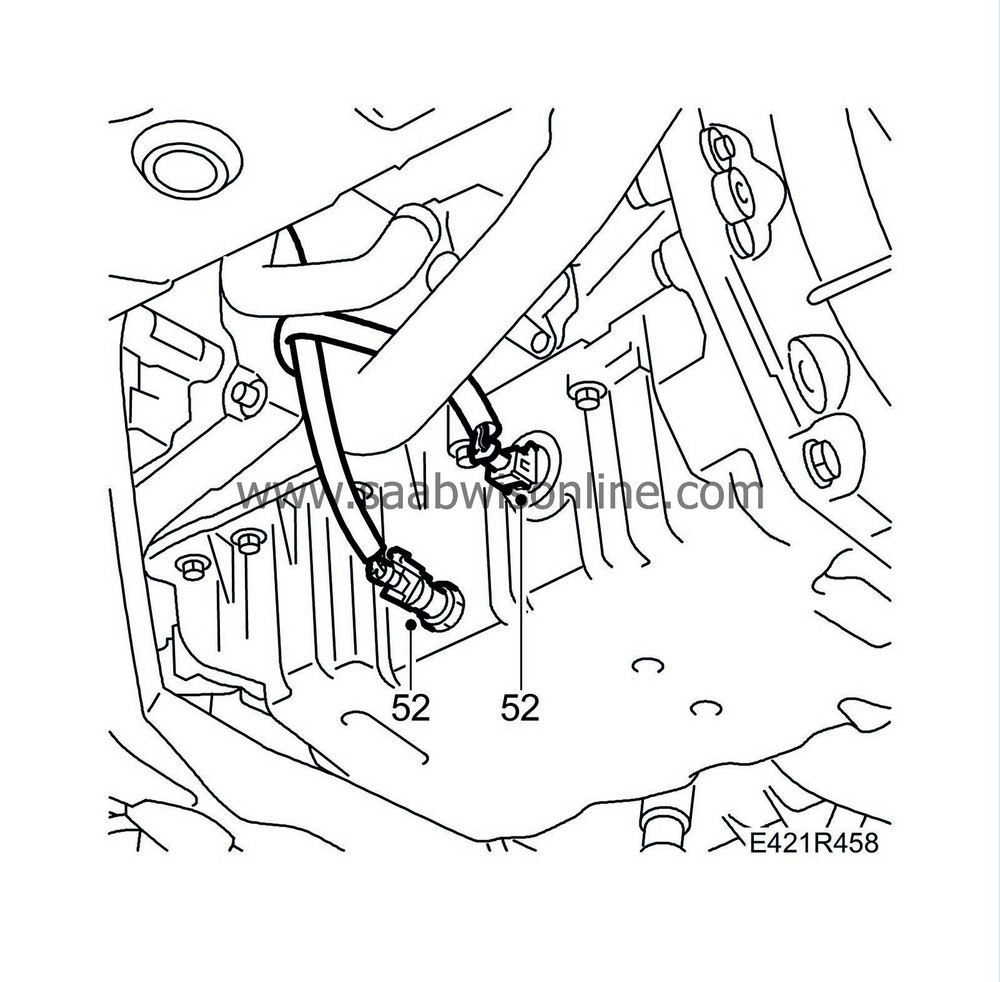

Plug in the oil temperature sensor and oil level sensor connectors.

|

|

| 53. |

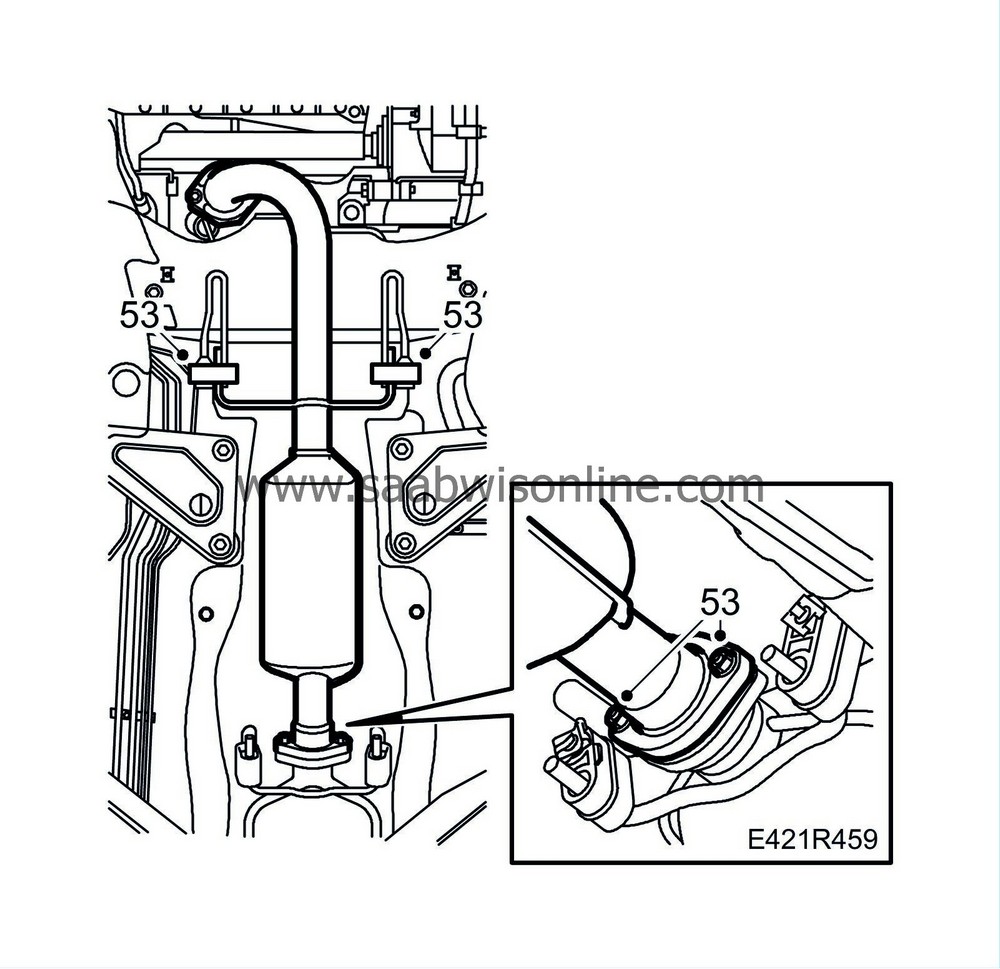

Aut:

Tighten the screws by the catalytic converter.

Man: Fit the catalytic converter with the rubber mountings. Tightening torque: 25 Nm (18 lbf ft)

|

|

| 54. |

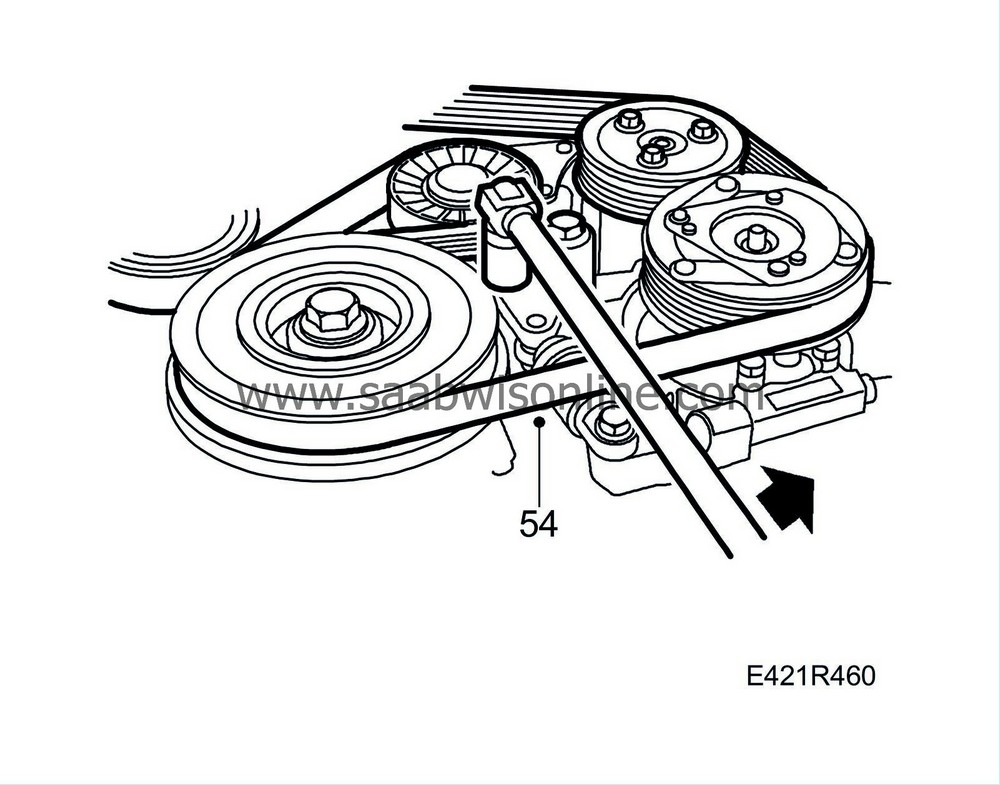

Relieve the tension of the belt tensioner and fit the multigroove V-belt. Check that the belt is correctly seated on all the pulleys and the rotation direction is correct according to the previous markings.

|

|

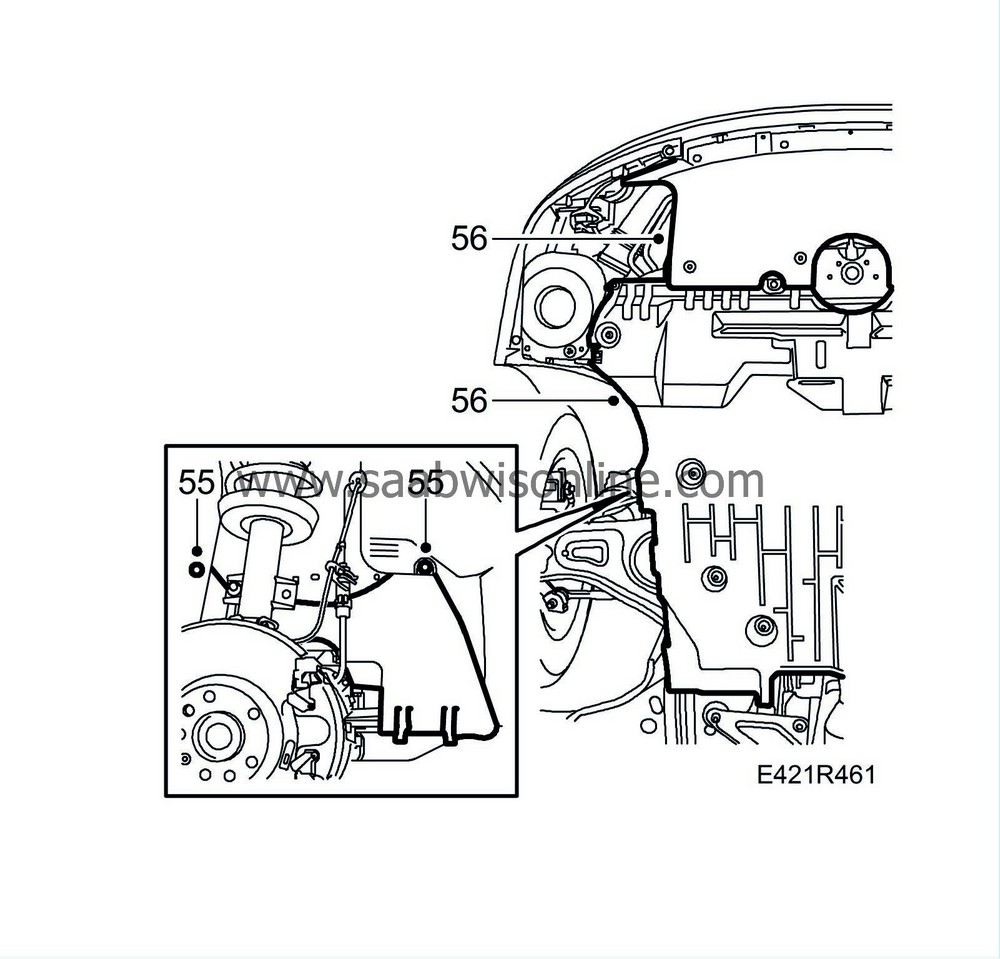

| 55. |

Fit the belt circuit's cover.

|

|

| 56. |

Fit the left-hand wheel housing cover, spoiler sections and lower engine cover.

|

|

| 57. |

Lower the car and fit the hub centre-nuts with the protective covers.

Tightening torque: 230 Nm (170 lbf ft) |

|

| 58. |

Fit the front wheels, see

Wheels

Tightening torque: 110 Nm (81 lbf ft) |

|

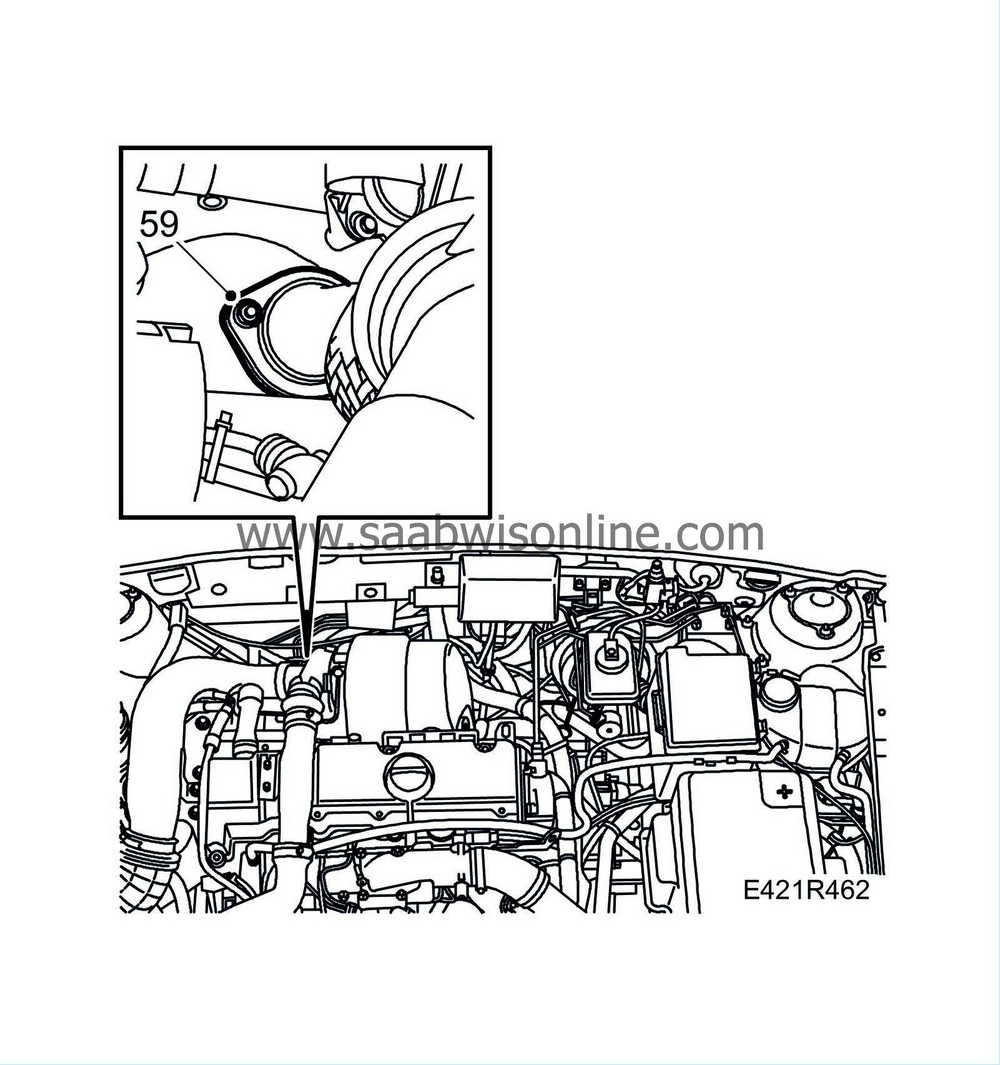

| 59. |

Man:

Fit the exhaust pipe's two lowermost nuts.

Tightening torque: 25 Nm (18 lbf ft)

|

|

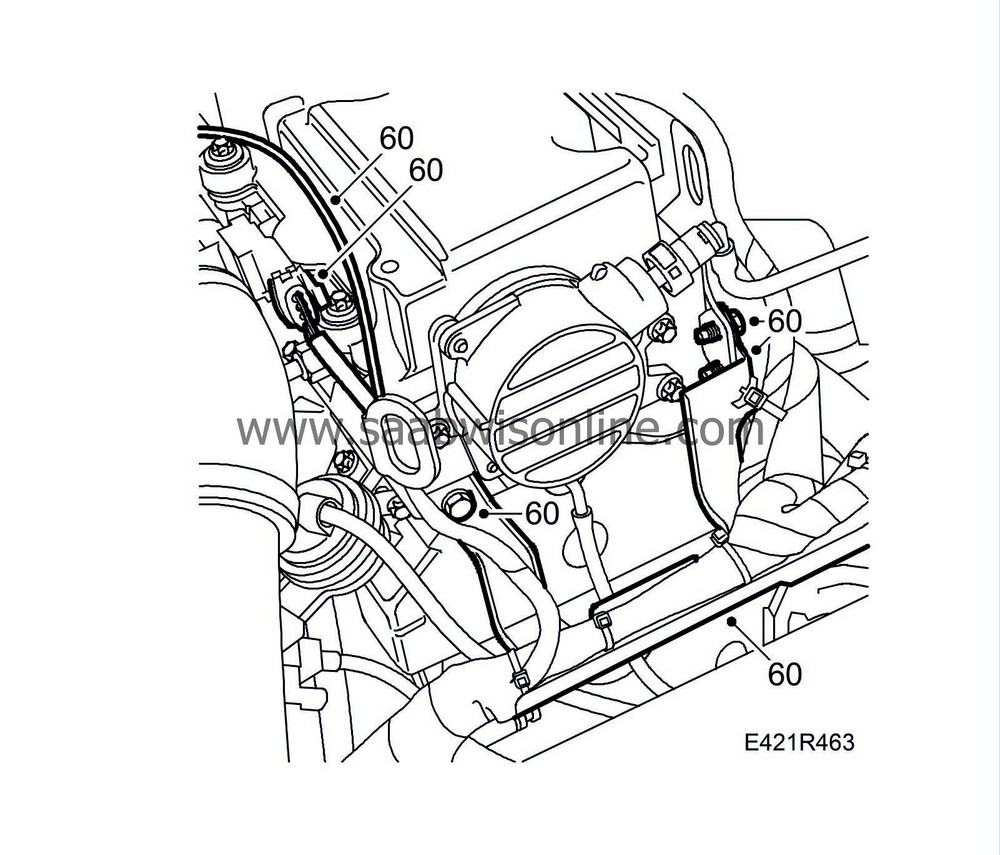

| 60. |

Plug in the pressure/temperature sensor connector and ground cable. Fit the cable rail.

|

|

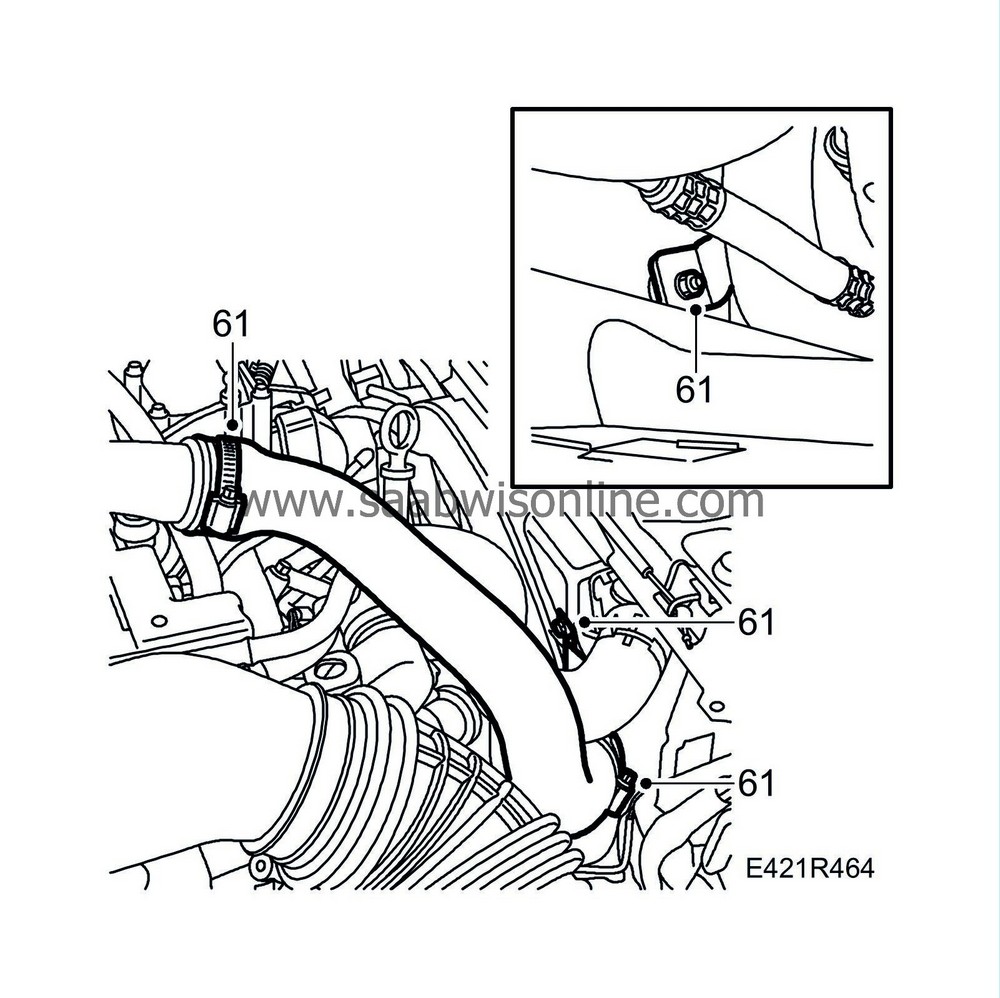

| 61. |

Man:

Fit the charge air hose and pipe to the turbo, and the charge air pipe to the fan cowling.

|

|

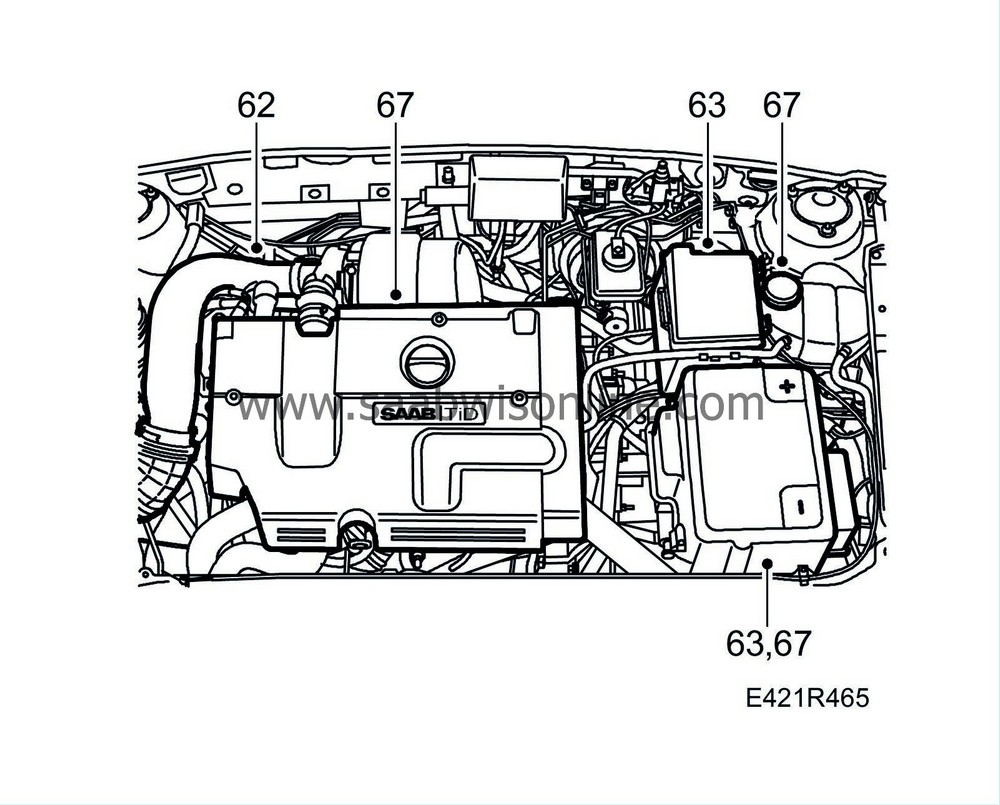

| 62. |

Fit the intake manifold from the mass air flow sensor to the turbocharger and camshaft cover.

Tightening torque, mass air flow sensor: 3.5 Nm (2.5 lbf ft)

|

|

| 63. |

Fit the main fuse box. Fit the battery tray and the maxi fuse holder.

|

|

| 64. |

Bleed the fuel system, see

Bleeding of fuel lines, 4 cyl

|

|

| 65. |

Fit the battery and connect the battery cables.

|

|

| 66. |

Bleed the clutch, see

Bleeding the hydraulic clutch system in the car

.

|

|

| 67. |

Fit the battery cover and upper engine cover. Add coolant to around 20 mm above the mark on the expansion tank. See

Coolant

|

|

| 68. |

Top up the power steering fluid.

|

|

| 69. |

Calibrate the ACC, adjust the SID and set the radio stations.

|

|

| 70. |

Carry out a road test to check all functions. Make sure the steering wheel is correctly positioned on a straight road. Make any necessary adjustments. Check the oil levels in the engine and gearbox.

|

|