Camshaft Timing Chain Adjustment

|

|

Camshaft Timing Chain Adjustment

|

Special Tools

EN-49212

Camshaft Fixer

For equivalent regional tools, refer to

Special Tools (LDK, LHU)

.

|

3.

|

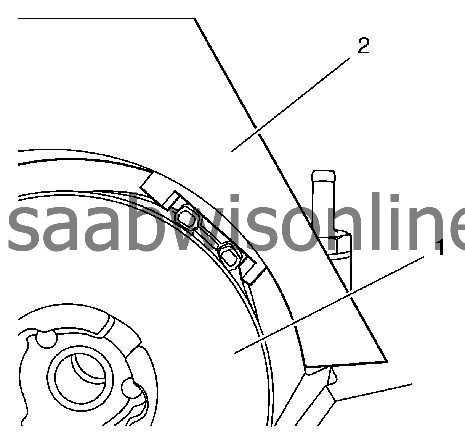

Rotate the crankshaft balancer mark (1) to the oil pump housing mark (2).

|

|

5.

|

If the adjustment is NOT correct, release the timing chain from camshaft position actuator - intake (1) and rotate anti clock wise the intake camshaft up to the fixing from the

EN-49212-2

camshaft fixer (2).

|

|

1.

|

Install the timing chain to the camshaft position actuator - intake.

|

|

|

•

|

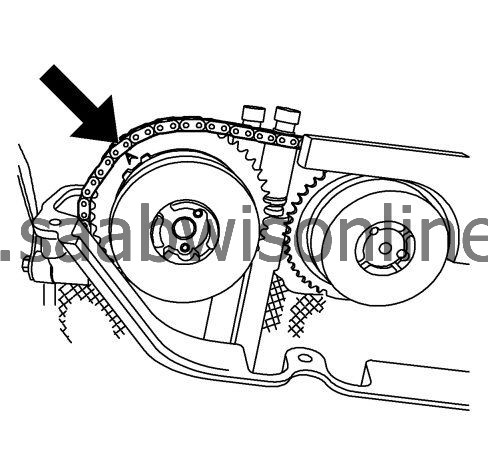

Count the number of the end to end connectors of the camshaft timing chain between the mark on the intake camshaft drive pulley and the mark on the exhaust camshaft drive pulley.

|

|

|

•

|

The timing chain must have 29 end to end connectors to guarantee a correct adjustment.

|

|

|

•

|

During assembly it is necessary to tension the timing chain.

|

|

|

•

|

Turn the camshaft in clockwise direction to install the exhaust camshaft drive pulley.

|

|

|

•

|

Install the exhaust camshaft drive pulley and fixes with that fastener in the camshaft.

|

|

3.

|

Fix the exhaust camshaft with the

EN-49212-1

camshaft fixer .

Check setup over again.

|

|

4.

|

Refer to

Fastener Caution

.

Tighten the camshaft position actuator - intake to

30 Nm (22 lb ft) 100 degrees

|

|

5.

|

Tighten the camshaft position actuator - exhaust to

30 Nm (22 lb ft) 100 degrees

.

|

|

6.

|

Remove

EN-49212

camshaft fixer .

|

|

9.

|

Turn the crankshaft two round and examine the track tension and the attitudes again.

|