Cylinder Honing

| Cylinder Honing |

| Special Tools |

EN-8087 Cylinder Bore Gauge

For equivalent regional tools, refer to Special Tools (LDK, LHU) .

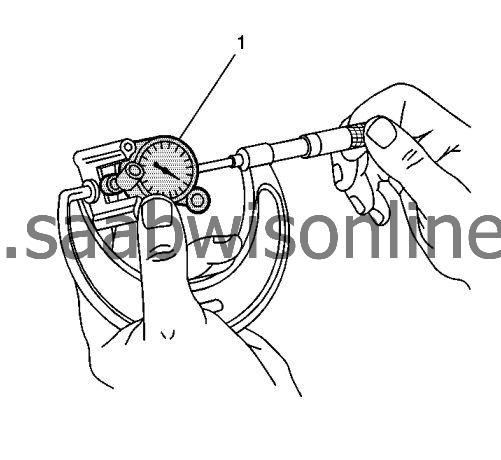

| 1. |

Measure the cylinder bore for out-of-round and taper.

|

|

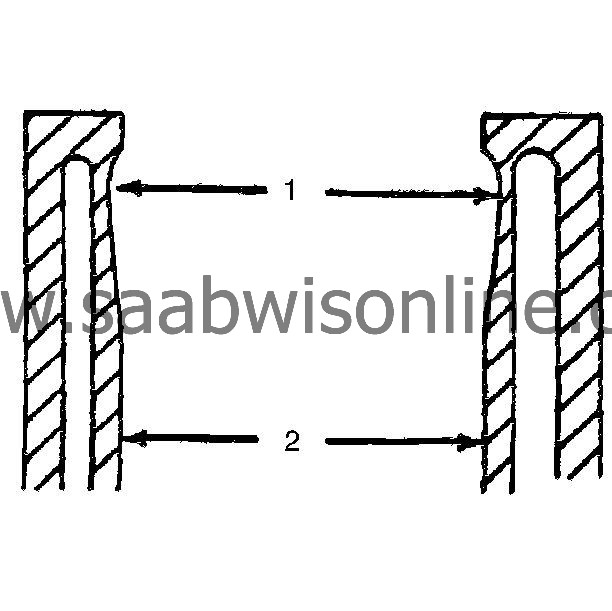

| 2. |

Measure dimension (1) at 13 mm (1/2 in) below the head gasket surface. Measure dimension (2) at 100 mm (4 in) below the head gasket surface.

|

|

| 4. |

Fine vertical scratches made by the ring ends do not, by themselves, cause excessive oil consumption. Do not hone the cylinder in order to remove these scratches.

|

|

| 5. |

If the bore is glazed but otherwise serviceable, lightly break the glaze with a hone. Replace the piston rings. Refer to

Piston, Connecting Rod, and Bearing Installation (LDK, LHU)

.

|

|

| 5.1. |

The honing stones must be clean, sharp, and straight.

|

| 5.2. |

Move the hone slowly up and down to produce a 45 degree cross-hatch pattern.

|

| 5.3. |

Clean the bore thoroughly with soap and water.

|

| 5.4. |

Dry the bore.

|

| 5.5. |

Rub clean engine oil in the bore.

|

| 5.6. |

Re-measure the bore.

|

| 6. |

If the cylinder bore is out of specification, install a new cylinder bore sleeve. Refer to

Cylinder Sleeve Removal

and

Cylinder Sleeve Installation

.

|

|

| 7. |

If honing is not required, clean the cylinder bores with hot water and detergent. Apply clean engine oil to the bore after washing and drying the bore.

|

|