Engine Block Cleaning and Inspection

|

|

Engine Block Cleaning and Inspection

|

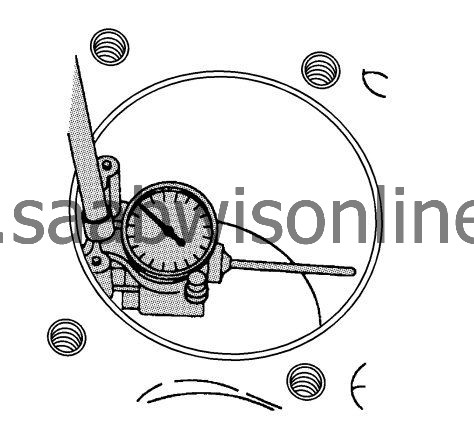

Measure the cylinder bore diameter 37 mm (1.457 in) from the deck face using the

EN 8087

gauge.

Compare your results with the

Engine Mechanical Specifications

. If the cylinder diameter exceeds the specifications, the cylinder block may be oversized to 0.25 mm (0.010 in). There is only one size of oversized pistons and rings available for service.

|

Measuring Cylinder Bore Taper

|

|

1.

|

Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centerline, at 10 mm (0.397 in) below the deck surface and record your measurement.

|

|

2.

|

Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centerline, at 100 mm (3.976 in) below the deck surface and record your measurement.

|

|

3.

|

Calculate the difference between the 2 measurements. The result will be the cylinder taper.

|

|

4.

|

Compare your results with the

Engine Mechanical Specifications

. If the cylinders exceed the specifications, the cylinder block may be oversized to 0.25 mm (0.010 in). There is only one size of oversized pistons and rings available for service.

|

|

Measuring Cylinder Bore Out-of-Round

|

|

1.

|

Measure both the thrust and non-thrust cylinder diameter at 10 mm (0.397 in) below the deck. Record your measurements.

|

|

2.

|

Calculate the difference between the 2 measurements. The result will indicate out-of-round at the upper end of the cylinder.

|

|

3.

|

Measure both the thrust and non-thrust cylinder diameter at 100 mm (3.976 in) below the deck surface. Record your measurements.

|

|

4.

|

Calculate the difference between the 2 measurements. The result will indicate out-of-round at the lower end of the cylinder.

|

|

5.

|

Compare your results with the

Engine Mechanical Specifications

. If the cylinders exceed these specifications, the cylinder block may be oversized to 0.25 mm (0.010 in). There is only one size of oversized pistons and rings available for service.

|

|

1.

|

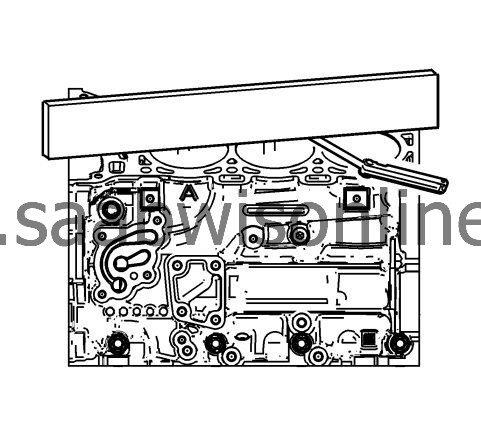

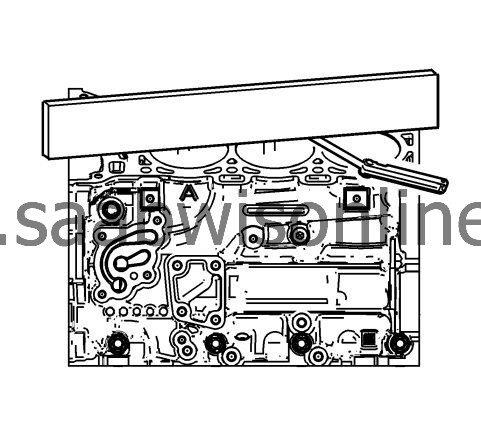

Ensure the engine block decks are clean and free of gasket material.

|

|

2.

|

Inspect the surface for any imperfections or scratches that could inhibit proper cylinder head gasket sealing.

|

|

3.

|

Place a straight-edge diagonally across the cylinder block deck face surface.

|

|

4.

|

Measure the clearance between the straight-edge and the cylinder block deck face using a feeler gauge at 4 points along the straight-edge.

|

|

5.

|

If the warpage is less than 0.05 mm (0.002 in), the cylinder block deck surface does not require resurfacing.

|

|

6.

|

If the warpage is between 0.05-0.20 mm (0.002-0.008 in) or any imperfections or scratches that could inhibit proper cylinder head gasket sealing are present, the cylinder block deck surface requires resurfacing.

|

|

7.

|

If resurfacing is required the maximum amount that can be removed is 0.25 mm (0.010 in).

|

|

8.

|

If the cylinder block deck surface requires more than 0.25 mm (0.010 in) material removal the block must be replaced.

|

Warning

Warning