Quarter Outer Panel Replacement

|

|

Quarter Outer Panel Replacement

|

Refer to

Approved Equipment for Collision Repair Warning

.

Refer to

Glass and Sheet Metal Handling Warning

.

|

1.

|

|

Note

|

|

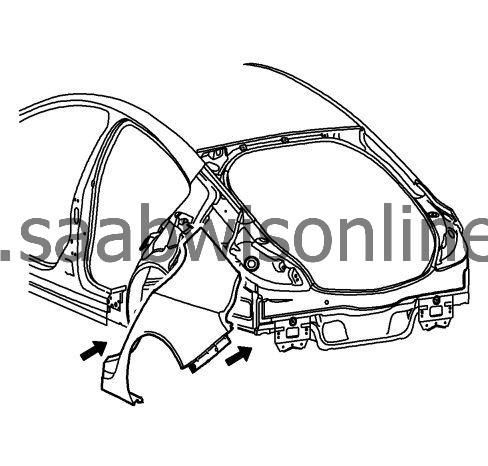

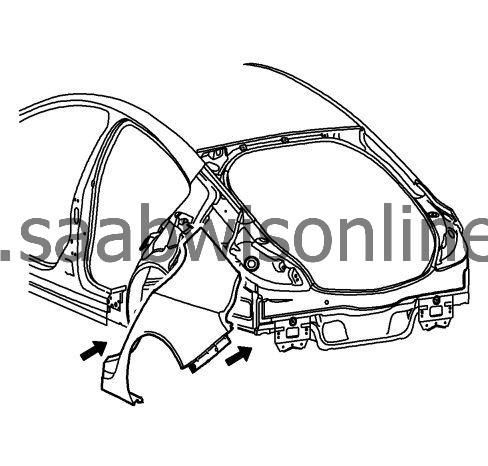

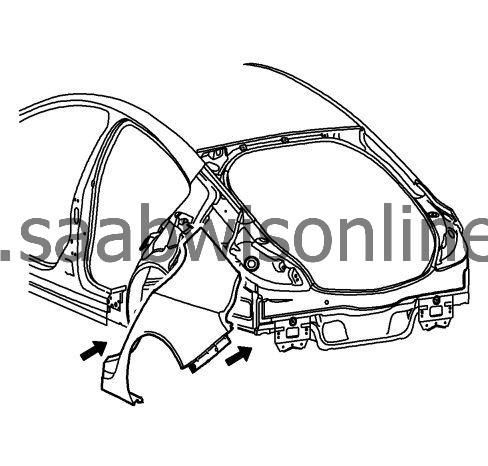

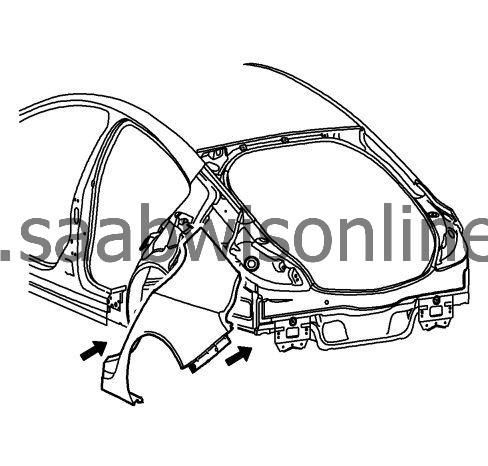

Section in specified areas only. Sectioning outside of these areas may compromise the structural integrity of the vehicle. The sectioning procedures have been developed as a more cost-effective alternative to complete replacement.

|

Disable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|

3.

|

Remove all related panels and components.

|

|

5.

|

|

Note

|

|

Do not damage any inner panels or reinforcements.

|

|

Note

|

|

Note the number and location of the welds for installations of the service part.

|

Cut out the quarter outer panel.

|

|

6.

|

Locate and drill out all of the necessary factory welds.

|

|

7.

|

|

Note

|

|

Do not damage any inner panels or reinforcements.

|

|

Note

|

|

Note the number and location of the welds for installations of the service part.

|

Cut out the quarter outer panel.

|

|

8.

|

Locate and drill out all of the necessary factory welds.

|

|

9.

|

|

Note

|

|

Note the number and location of the welds for installations of the service part.

|

Locate and drill out all of the necessary factory welds.

|

|

10.

|

Remove the damaged quarter outer panel.

|

|

1.

|

|

Note

|

|

Refer SPP, PSO welding parameters for resistance spot welding. See TIS Newsletter for equipment recommendations.

|

Cut the replacement quarter outer panel section in corresponding locations to fit the original panel. The sectioning joint should be trimmed to allow min. 1 times the metal thickness at the sectioning joint.

|

|

2.

|

|

Note

|

|

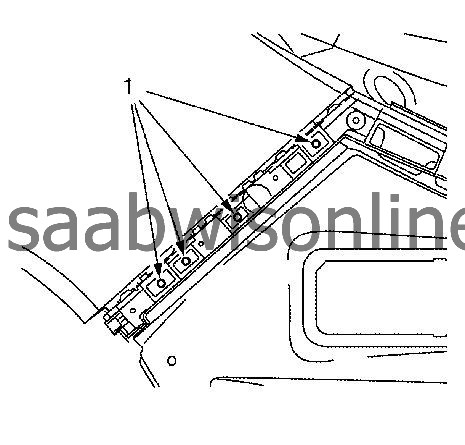

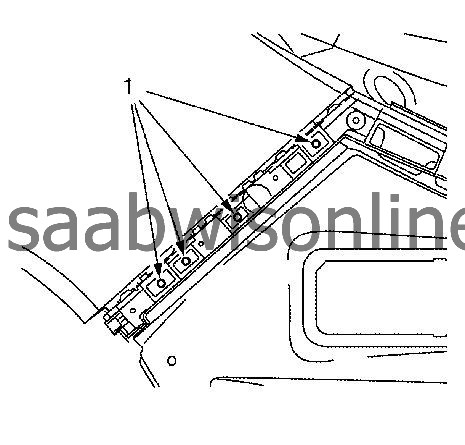

Pre-spot operation: The number of spots is specified in the documentation from the welding equipment manufacturer.

|

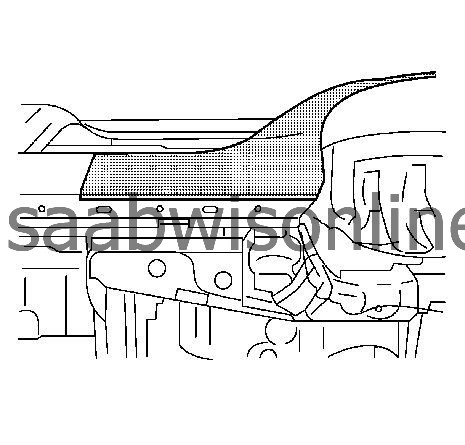

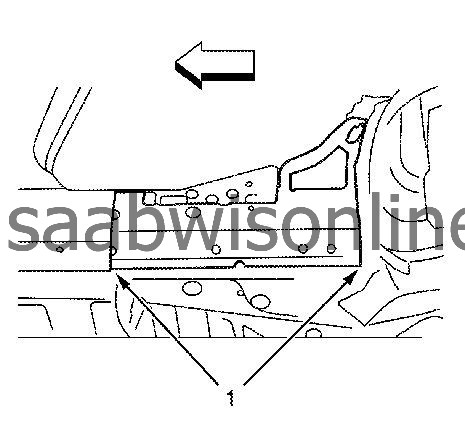

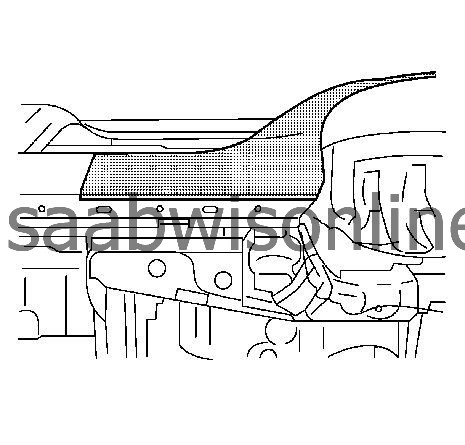

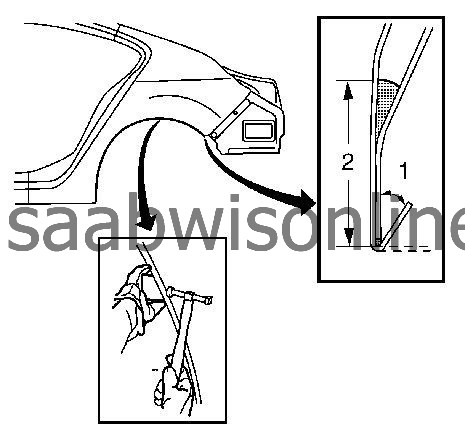

Prepare inner rocker panel (1) with reinforcement (PSO).

|

|

3.

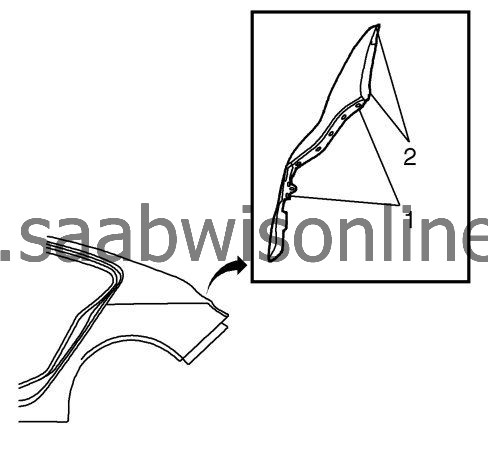

|

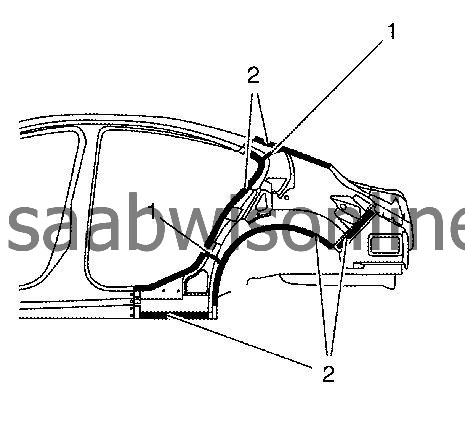

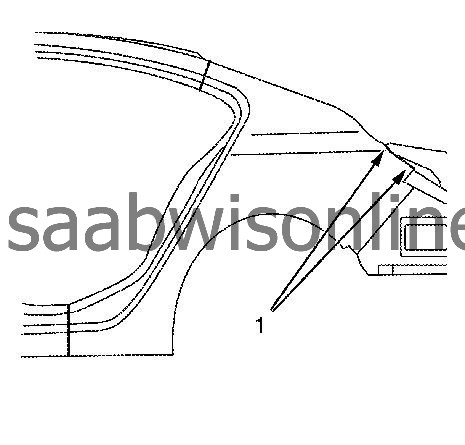

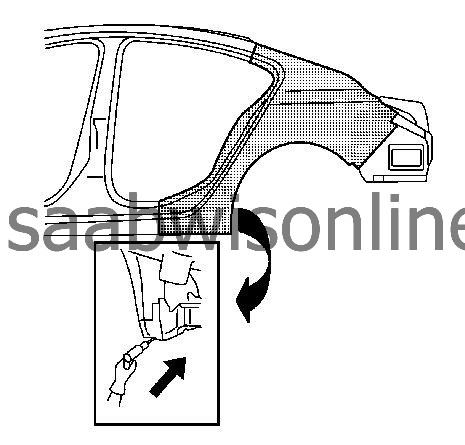

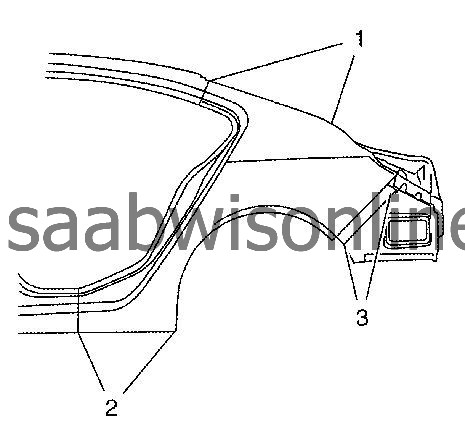

Prepare new quarter outer panel in the area (1).

7 slots (5x18 mm / 0.2x0.7 in)

|

|

4.

|

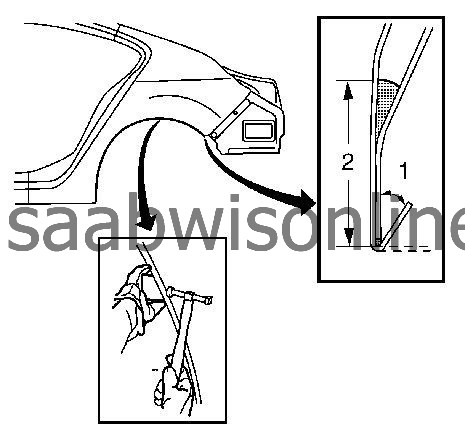

Prepare new quarter outer panel in the area (2).

6 slots (5x18 mm / 0.2x0.7 in)

|

|

5.

|

Position the new body side outer panel on the vehicle.

|

|

6.

|

Verify the fit of the new body side outer panel.

|

|

7.

|

Clamp the new body side outer panel into position.

|

|

8.

|

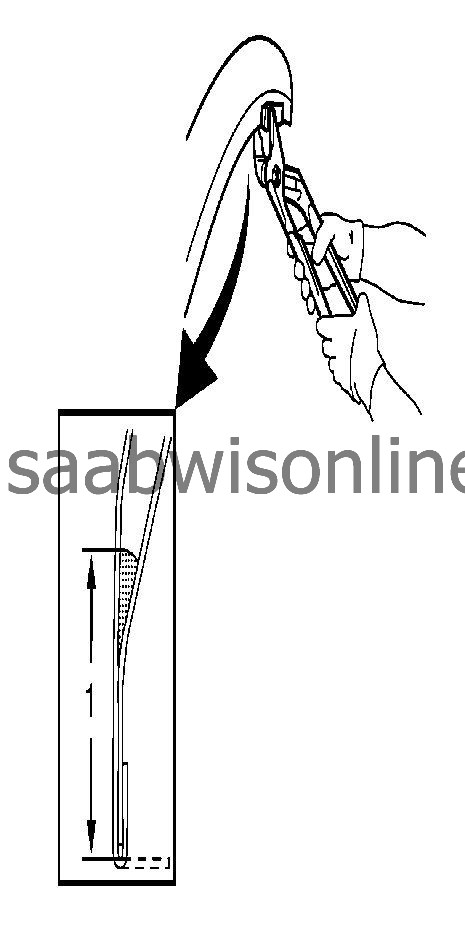

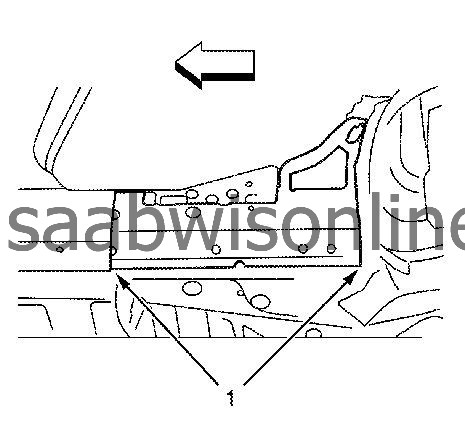

Drill fastening holes (1) for waterproof rivets.

4 holes

(4 mm / 0.16 in)

|

|

9.

|

Remove new quarter outer panel.

|

|

11.

|

Position the quarter outer panel on the vehicle.

|

|

12.

|

Verify the fit of the roof outer panel.

|

|

13.

|

Clamp the quarter outer panel into position.

|

|

14.

|

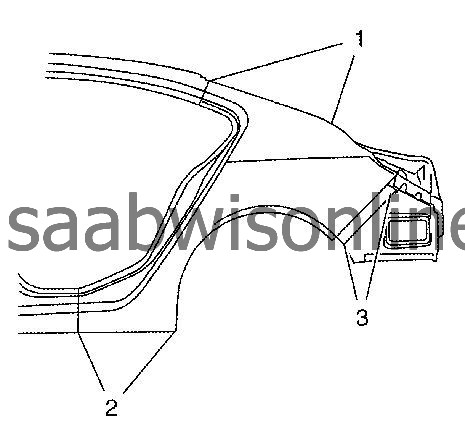

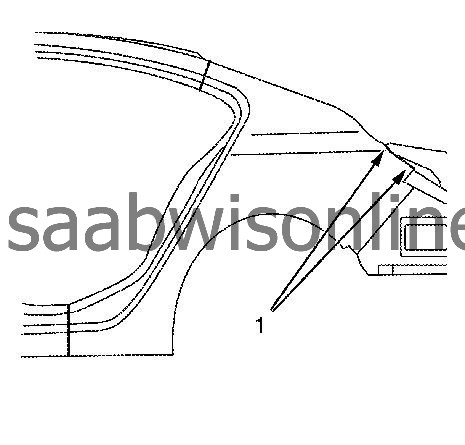

Spot weld (1) the quarter outer panel accordingly.

|

|

15.

|

Spot weld (SPP) the quarter outer panel (2) accordingly.

|

|

16.

|

MIG-braze (1) the quarter outer panel.

|

|

17.

|

Rivet (3) on the quarter outer panel.

|

|

18.

|

MIG-braze (1) the quarter outer panel.

|

|

19.

|

MIG-braze (1) the quarter outer panel.

|

|

20.

|

Grind MIG brazed seams.

|

|

21.

|

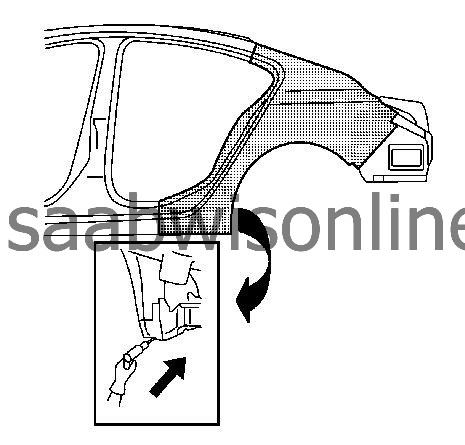

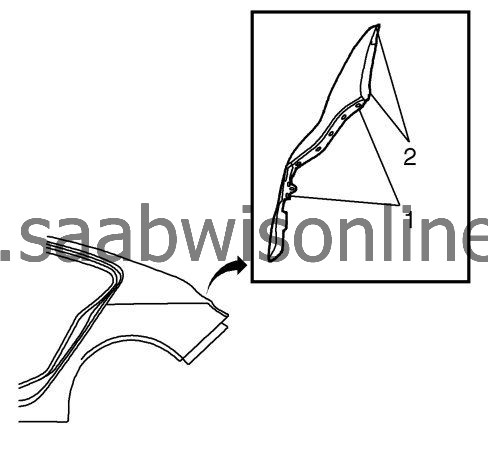

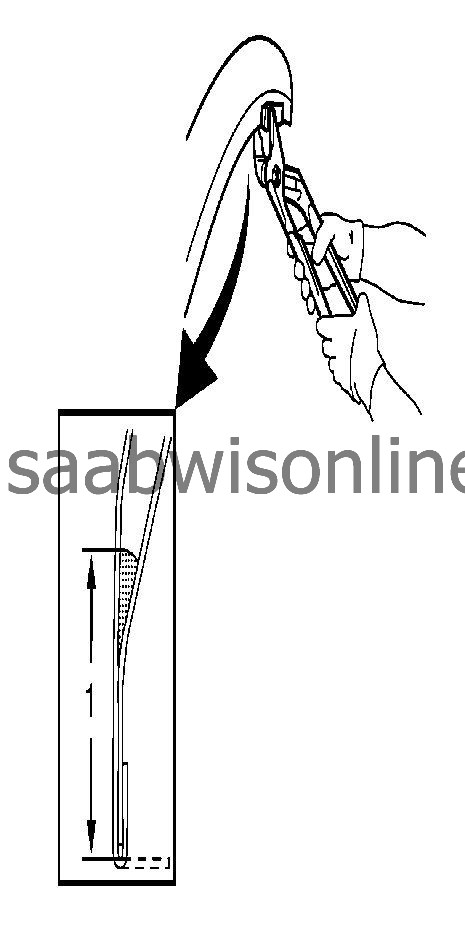

Pre-flange wheel housing.

Using a suitable hammer, bend over the flanged edge 45° (1), at the same time holding a small mallet or block against it. Use structural adhesive in the area (2).

|

|

22.

|

Bend the wheel arch.

|

|

|

22.1.

|

Apply excess adhesive as a seam seal and corrosion protection using a spatula or flat paintbrush. Use structural adhesive in area (1).

|

|

23.

|

Install all related panels and components.

|