Engine Block Disassemble

| Engine Block Disassemble |

Special Tools

EN-8087 Cylinder GaugeFor equivalent regional tools, refer to Special Tools .

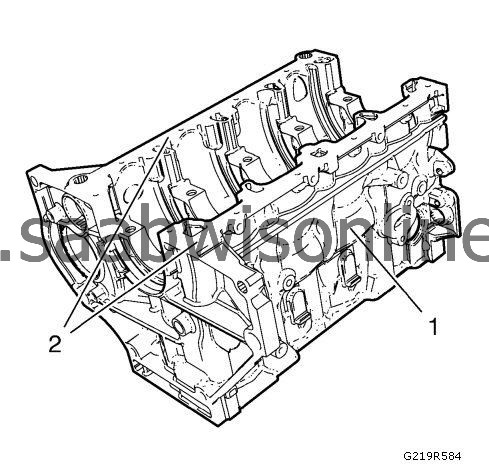

| 1. |

Clean the sealing material from the gasket mating surfaces (2).

|

|

| 2. |

Clean the engine block (1) and lower crankcase in a cleaning tank with solvent appropriate for aluminum. Refer to

Adhesives, Fluids, Lubricants, and Sealers

for the recommended solvent.

|

|

| 3. |

Flush the engine block with clean water or steam.

|

|

| 4. |

Clean the oil passages.

|

|

| 5. |

Clean the blind holes.

|

|

| 6. |

Spray the cylinder bores and the machined surfaces with engine oil.

|

|

| 7. |

Inspect the threaded holes. Clean the threaded holes with a rifle brush. If necessary, drill out the holes and install thread inserts. Refer to

Thread Inserts

.

|

|

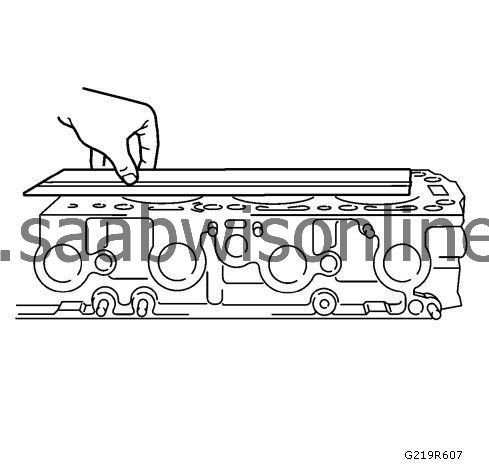

| 8. |

Inspect the engine block for sag in length and width on the sealing surfaces.

|

|||||||

| 9. |

Inspect the engine block for distortion along the diagonals.

If the deck surface is out of specification, replace the block. Do not machine the block.

|

|

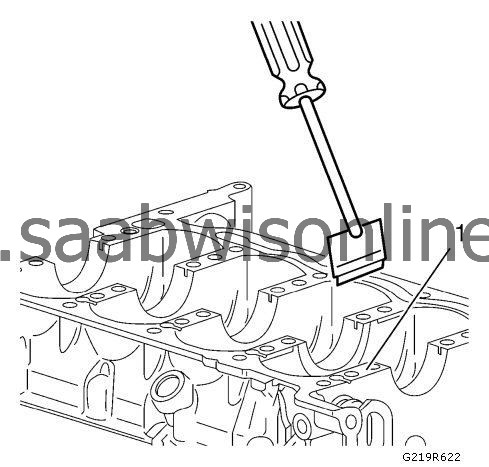

| 10. |

Clean the sealing material from the gasket mating surfaces (1) on the lower crankcase oil pan side.

|

|

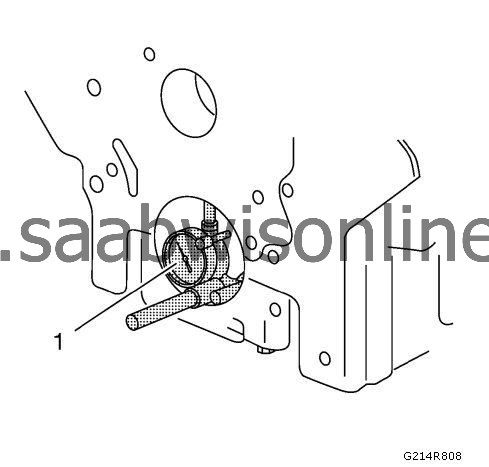

| 11. |

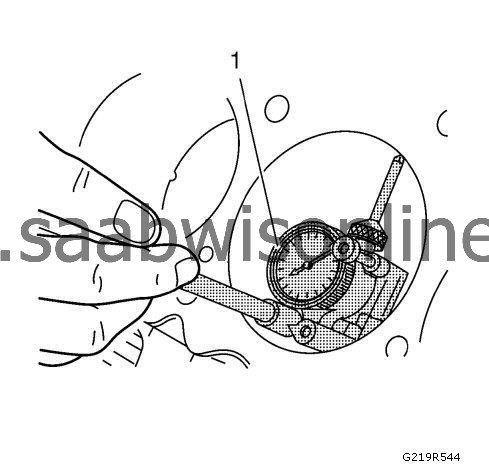

Inspect the crankshaft main bearing bores. Use the

EN-8087

gauge (1) to measure the bearing bore concentricity and alignment.

|

|

| 12. |

Replace the engine block and bed plate if the crankshaft bearing bores are out of specification.

|

|

| 13. |

Inspect the cylinder bores using the

EN-8087

gauge (1). Inspect for the following items:

|

|

| • |

Wear

|

| • |

Taper

|

| • |

Runout

|

| • |

Ridging

|

| 14. |

Refer to

Engine Mechanical Specifications (1.6L LLU)

.

|

|

| 15. |

If the cylinder bores are out of specification, replace the engine block.

|

|