Piston, Connecting Rod, and Bearing Cleaning and Inspection

|

|

Piston, Connecting Rod, and Bearing Cleaning and Inspection

|

Special Tools

EN-45059

Torque Angle Sensor Kit

For equivalent regional tools, refer to

Special Tools

.

|

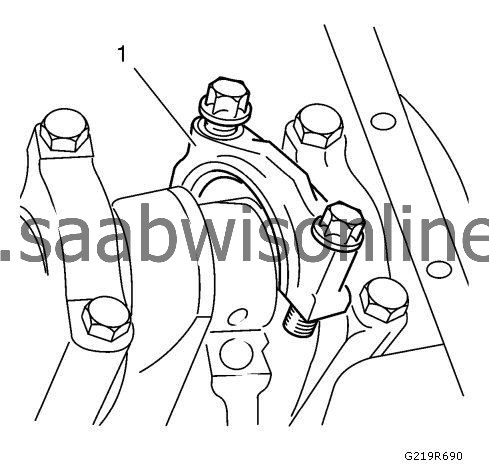

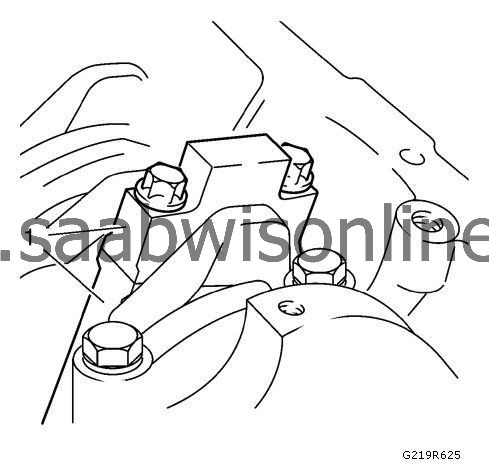

2.

|

Remove the connecting rod bearing cap (1).

|

|

|

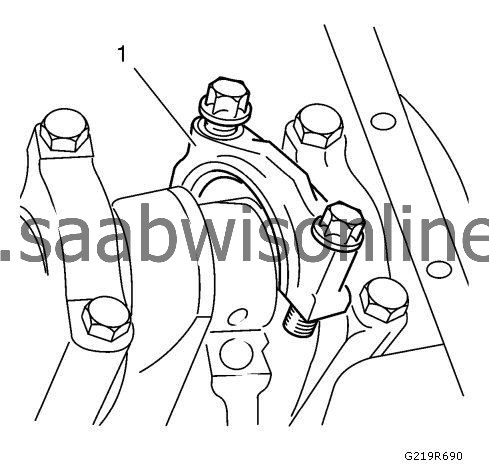

2.1.

|

Mark the installation position (1) of the connecting rod bearing cap.

|

|

|

2.3.

|

Degrease the connecting rod bearing cap and wet the connecting rod bearing clip with engine oil.

|

|

3.

|

|

Note

|

|

Do not rotate the crankshaft.

|

Lay on plastigage. Refer to

Adhesives, Fluids, Lubricants, and Sealers

Lay plastigage (flexible plastic thread) over the entire width of the connecting rod bearing journal.

|

|

4.

|

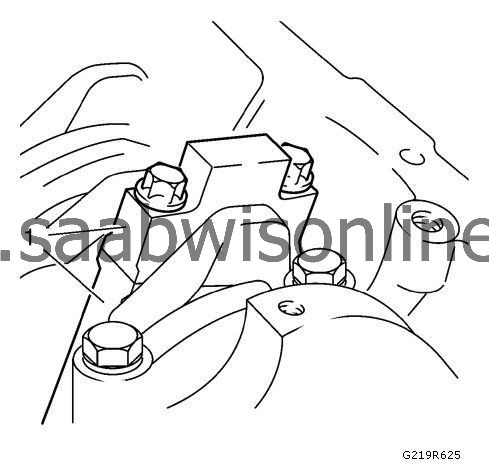

Install the connecting rod bearing cap.

|

|

5.

|

Refer to

Fastener Caution

.

Tighten the 2 bolts in three passes using the

EN-45059

sensor kit:

|

|

|

5.1.

|

First pass tighten to

35 Nm (26 lb ft)

.

|

|

|

5.2.

|

Second pass tighten to an additional

45 degrees

|

|

|

5.3.

|

Third pass tighten to an additional

15 degrees

|

|

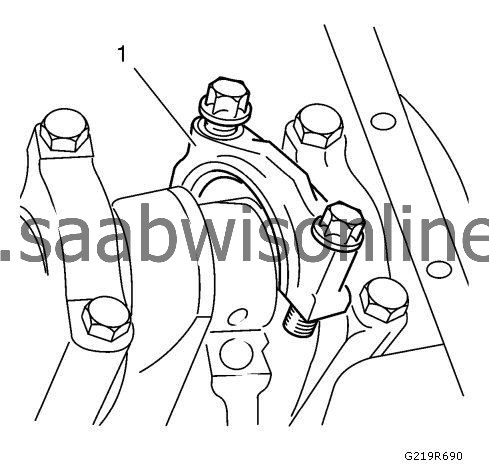

6.

|

Remove the connecting rod bearing cap (1).

Remove the 2 bolts.

|

|

7.

|

|

Note

|

|

When reading the value, do not confuse millimeters and inches on the measuring scale (1).

|

Measure the connecting rod bearing play.

|

|

|

•

|

Compare the width of the flattened plastic thread with the measuring scale.

|

|

|

•

|

Permissible connecting rod bearing play: 0.019-0.071 mm (0.0007-0.0028 in).

|

|

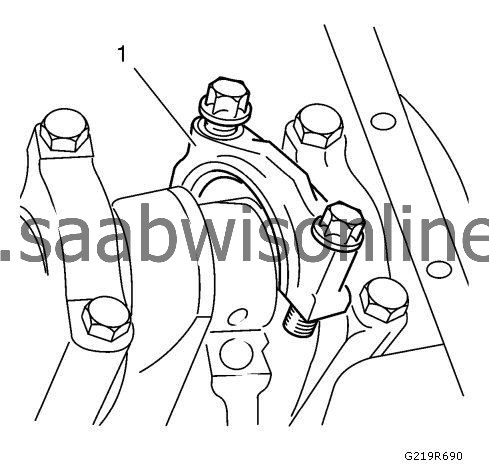

8.

|

|

Note

|

|

Check markings on parts.

|

Install the connecting rod bearing cap.

|

|

|

•

|

Wet the connecting rod bearing journal and con-rod bearing clips with engine oil.

|

|

9.

|

Tighten the 2 bolts in three passes using the

EN-45059

sensor kit:

|

|

|

9.1.

|

First pass tighten to

35 Nm (26 lb ft)

|

|

|

9.2.

|

Second pass tighten to an additional

45 degrees

|

|

|

9.3.

|

Third pass tighten to an additional

15 degrees

|