Headlamp Mount Panel Replacement

| Headlamp Mount Panel Replacement |

| Removal Procedure |

Refer to Approved Equipment for Collision Repair Warning .

Refer to Glass and Sheet Metal Handling Warning .

| Note | ||

|

Section in specified areas only. Sectioning outside of these areas may compromise the structural integrity of the vehicle. The sectioning procedures have been developed as a more cost-effective alternative to complete replacement. |

| 1. |

Disable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Repair as much of the damaged area as possible. Refer to

Dimensions - Body

.

|

|

| 4. |

Remove all related panels and components.

|

|

| • |

Remove the battery tray. Refer to

Battery Tray Replacement (Diesel)

Battery Tray Replacement (LHU/A20NFT)

.

|

| • |

Remove the headlamp. Refer to

Headlamp Replacement

.

|

| • |

Remove the windshield washer solvent container. Refer to

Windshield Washer Solvent Container Replacement

.

|

| • |

Remove the front bumper impact bar. Refer to

Front Bumper Impact Bar Replacement

.

|

| • |

Remove the fuse box. Refer to

Underhood Electrical Center or Junction Block Replacement

.

|

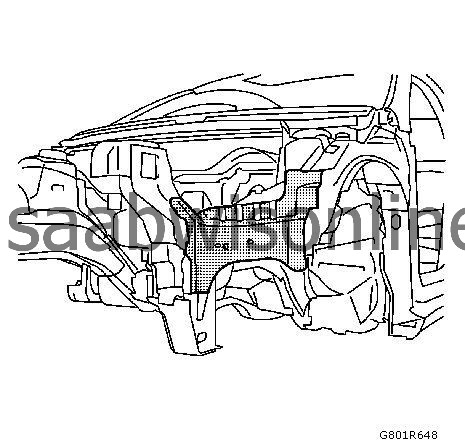

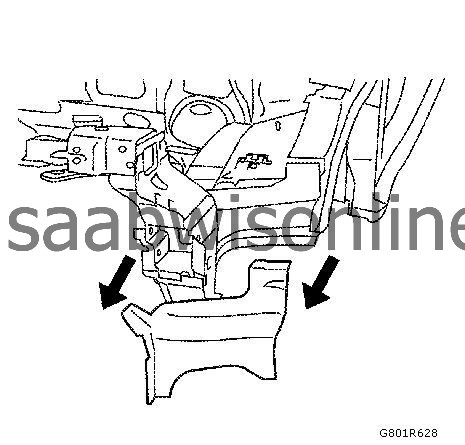

| 5. |

Cut out the headlamp mount panel.

|

||||||||||

| 6. |

Locate and drill out all of the necessary factory welds.

|

|

| 7. |

Remove the damaged headlamp mount panel.

|

|

| Installation Procedure |

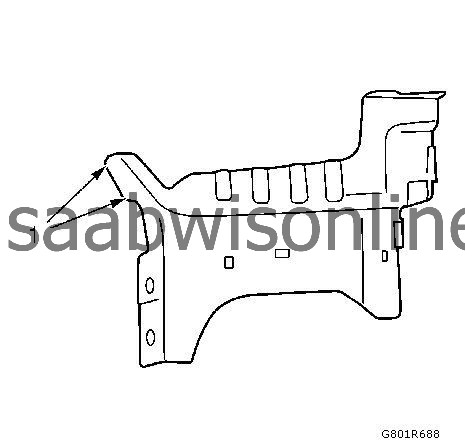

| 1. |

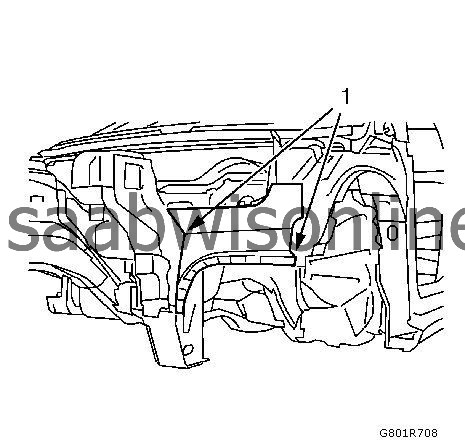

Prepare new headlamp mount panel outer in the area (1).

2x slots 6x20 mm (0.2x0.8 in) .

|

|

| 2. |

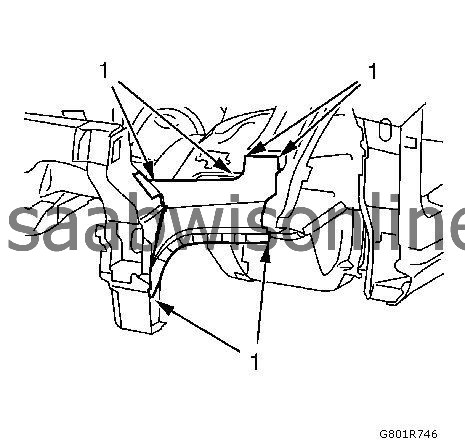

Apply bodywork repair through structural adhesive (1) to body. Refer to

Structural Adhesive Body Repairs

.

|

|

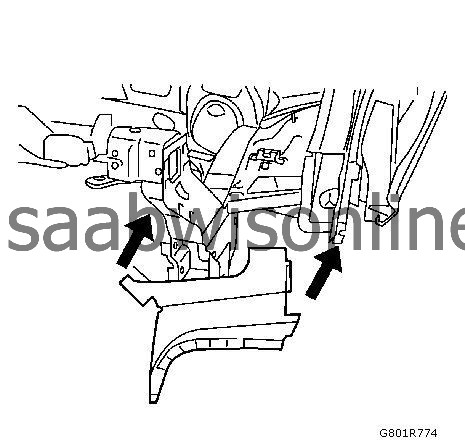

| 3. |

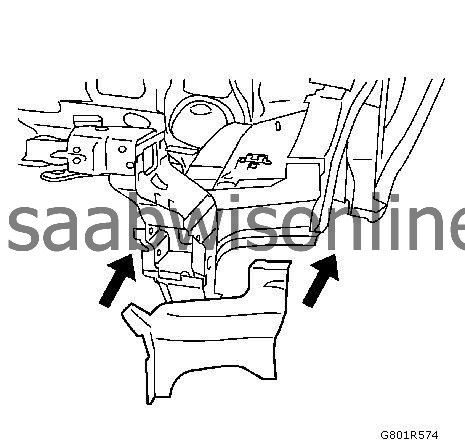

Position the headlamp mount panel.

|

|

| 4. |

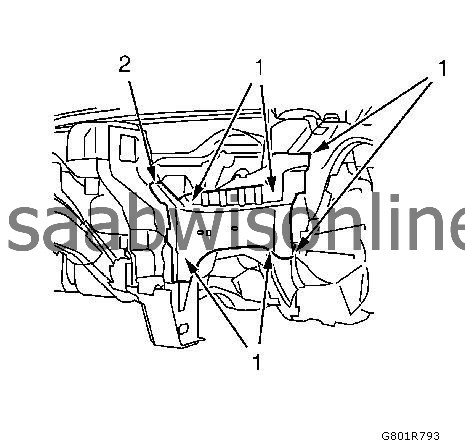

Spot weld (1) the headlamp mount panel inner accordingly.

|

|||||||

| 5. |

Apply bodywork repair through structural adhesive (1) to body. Refer to

Structural Adhesive Body Repairs

.

|

|

| 6. |

Position the headlamp mount panel outer.

|

|

| 7. |

Spot weld (1) the headlamp mount panel outer accordingly.

|

|||||||

| 8. |

MIG-braze (2) the headlamp mount panel outer.

|

|

| 9. |

Grind MIG-brazed seams.

|

|

| 10. |

Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to

Anti-Corrosion Treatment and Repair (Base)

Anti-Corrosion Treatment and Repair (Corrosion Protection)

.

|

|

| 11. |

Install all related panels and components.

|

|

| • |

Install the battery tray. Refer to

Battery Tray Replacement (Diesel)

Battery Tray Replacement (LHU/A20NFT)

.

|

| • |

Install the headlamp. Refer to

Headlamp Replacement

.

|

| • |

Install the windshield washer solvent container. Refer to

Windshield Washer Solvent Container Replacement

.

|

| • |

Install the front bumper impact bar. Refer to

Front Bumper Impact Bar Replacement

.

|

| • |

Install the fuse box. Refer to

Underhood Electrical Center or Junction Block Replacement

.

|

| 12. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 13. |

Enable the SIR system. Refer to

SIR Disabling and Enabling

.

|

|