Slave cylinder

| Slave cylinder |

| 1. |

Remove the gearbox as described in the "Removing, fitting" section of "Manual gearbox"

.

.

|

|

| 2. |

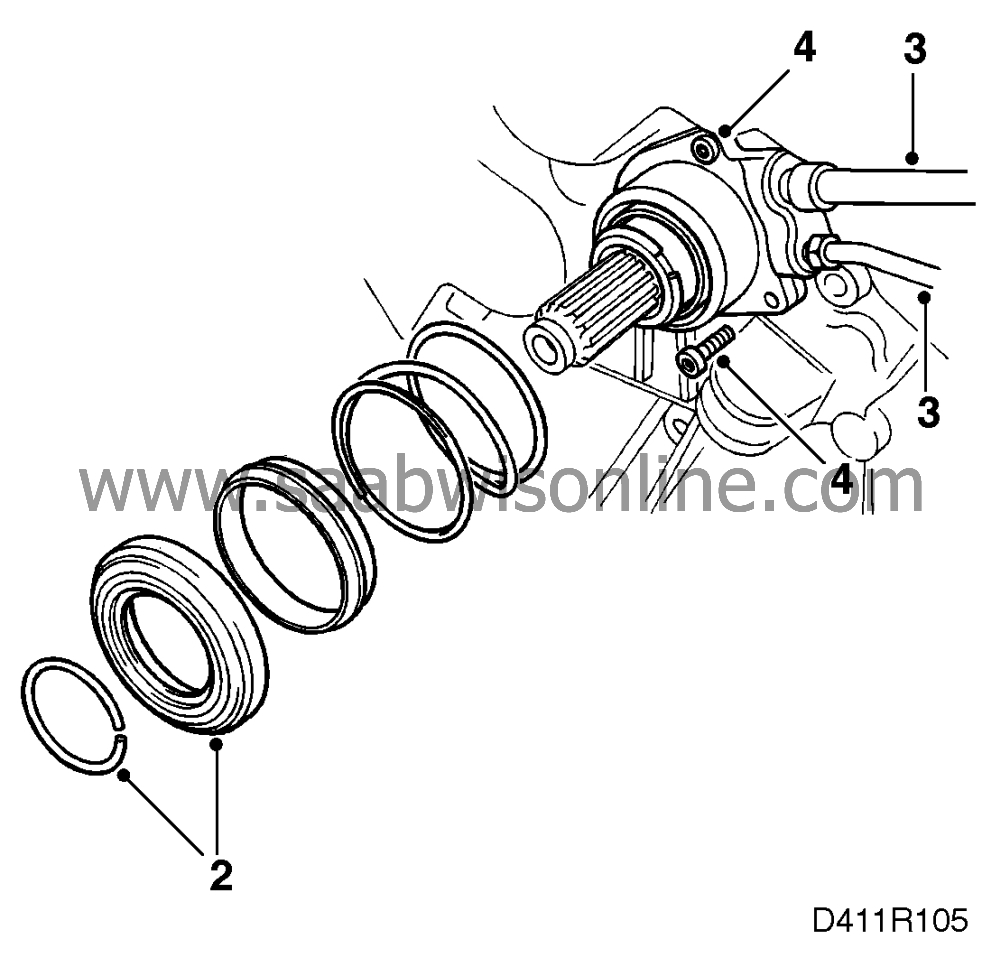

Remove the de-clutching bearing.

|

|

| 3. |

Remove the hydraulic pipe and bleed nipple from the slave cylinder.

|

|

| 4. |

Remove the slave cylinder's three retaining screws and withdraw the slave cylinder.

|

|

| To refit |

| 1. |

Apply thread sealant to the retaining screws.

|

|

| 2. |

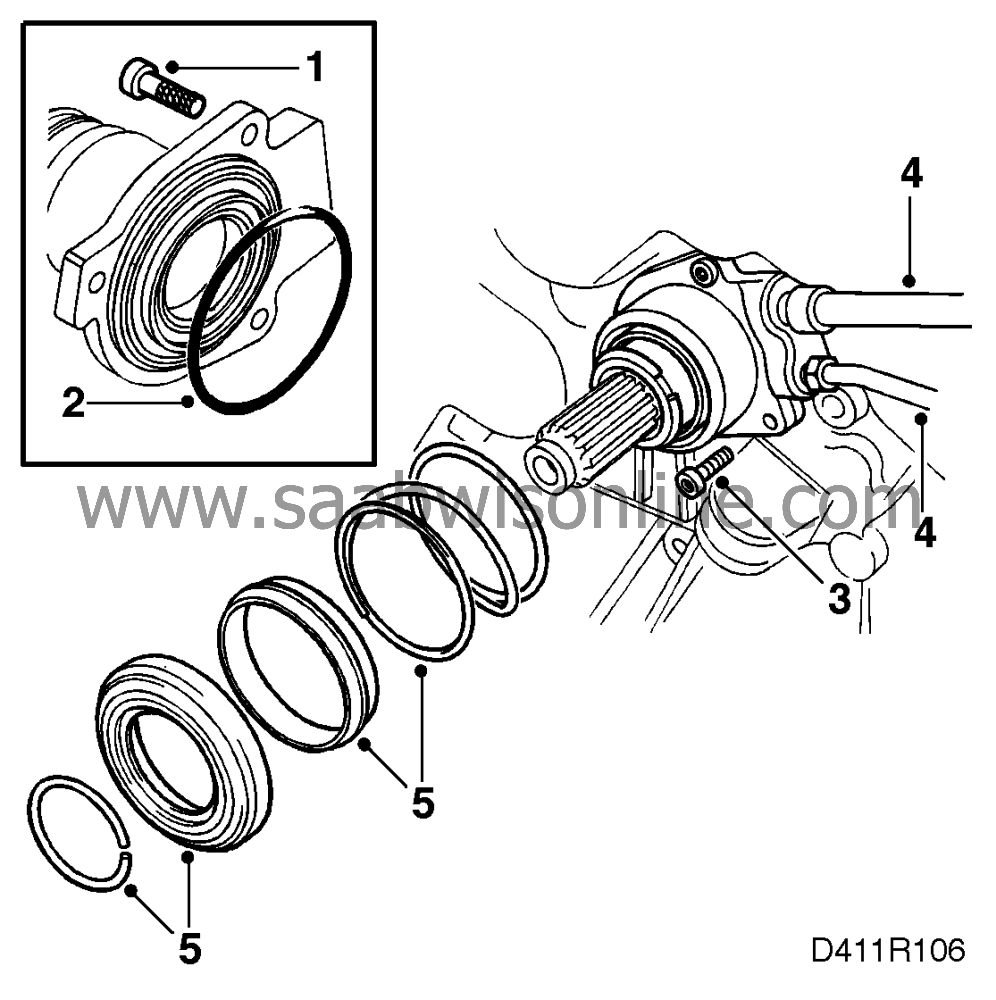

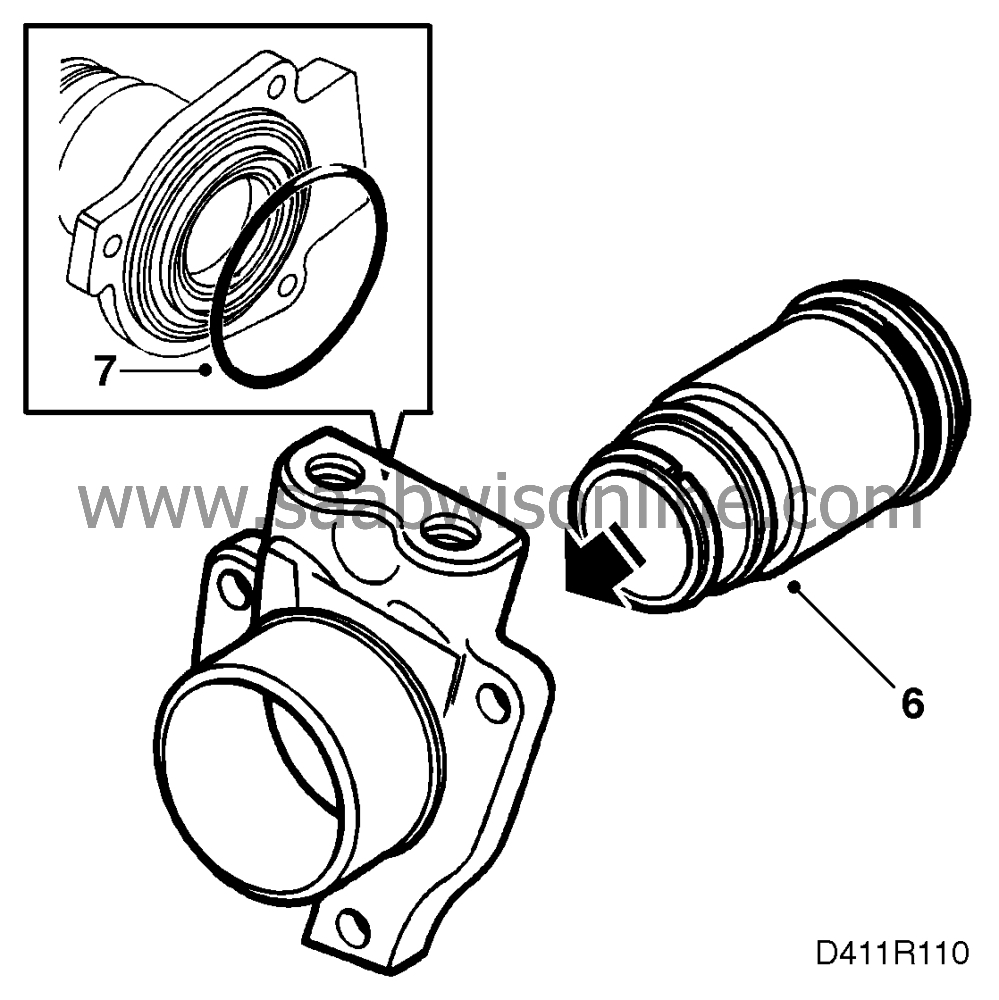

Fit a new O-ring on the slave cylinder. (Use non-acid vaseline to keep the O-ring in place during assembly.)

|

|

| 3. |

Screw the slave cylinder in place.

Tightening torque: 10 Nm (7.4 lbf ft). |

|

| 4. |

Fit the hydraulic pipe and bleed nipple on the slave cylinder.

|

|

| 5. |

Fit the release bearing with spring and locking ring. Check that the locking ring is properly located in its seat.

|

|

| 6. |

Fit the gearbox as described in the "Removing, fitting" section of "Manual gearbox"

.

.

|

|

| 7. |

Bleed the system, see

.

.

|

|

| Dismantling |

| 1. |

Remove the slave cylinder, see

.

.

|

|

| 2. |

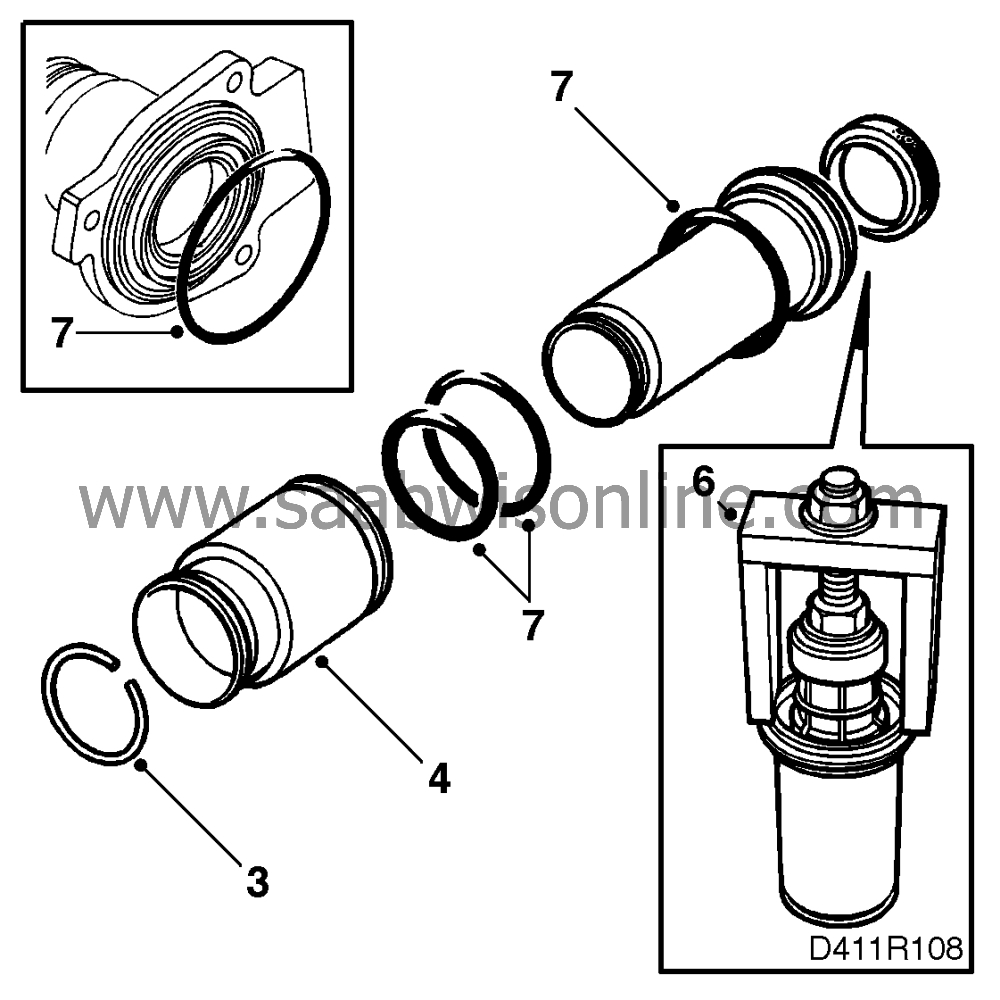

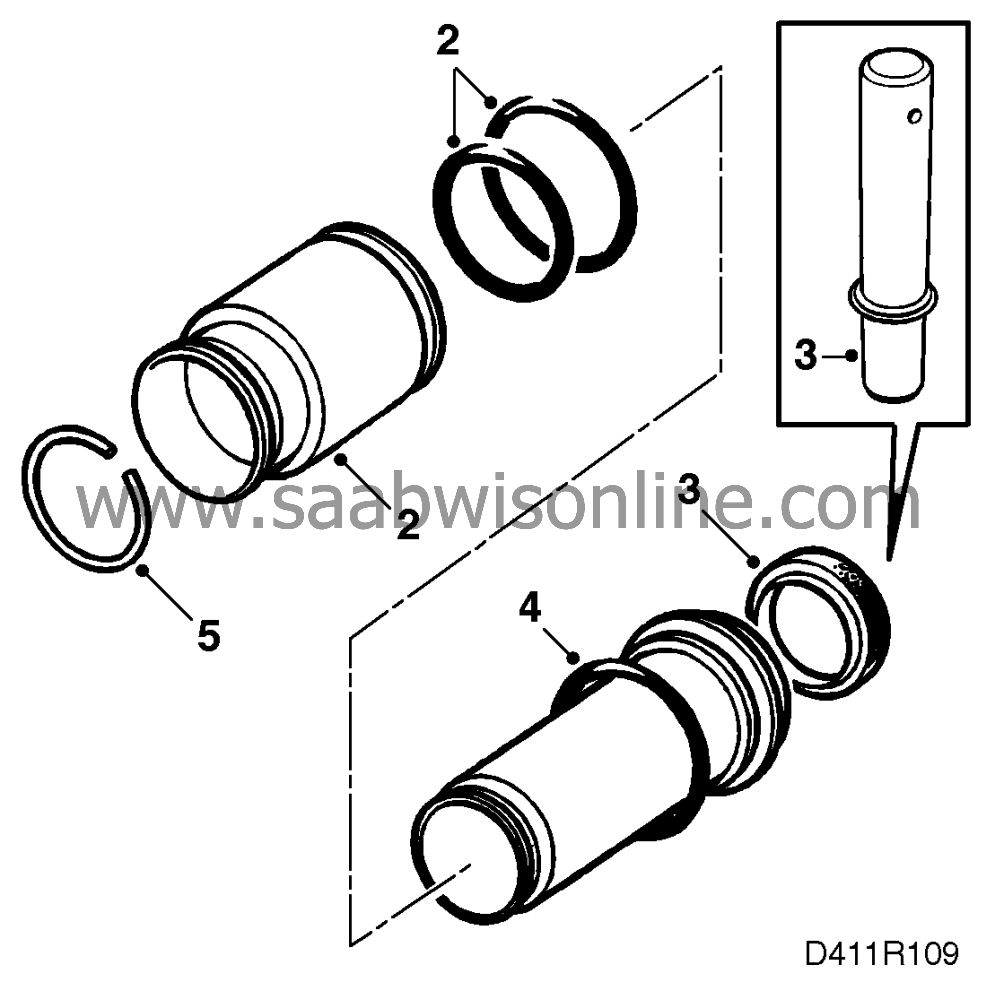

Press out the guide sleeve with plunger from the slave cylinder housing.

|

|

| 3. |

Remove the circlip which prevents the plunger from moving too far off the guide sleeve.

|

|

| 4. |

Pull the plunger off the guide sleeve.

|

|

| 5. |

Carefully cut off the rubber on the sealing ring inside the guide sleeve.

|

|

| 6. |

Fit tool 260 147 020 and pull out the sealing ring.

|

|

| 7. |

Remove the remaining seals.

|

|

| Assembly |

| 1. |

Make sure that the slave cylinder is thoroughly clean. Wash the parts in brake fluid or special cleaning fluid for hydraulic components, such as a mixture of washing spirits and acetone.

|

|

| 2. |

Fit two new seals on the plunger. Lubricates the seals with brake fluid or grease for brakes.

|

|

| 3. |

Press a new seal into the guide sleeve using tool 78 41 067 and lubricate it with Shell Grease 1344 LIEP II.

|

||||||||||

| 4. |

Fit on the guide sleeve the O-ring which seals between the guide sleeve and the slave cylinder body.

|

|

| 5. |

Slide the plunger in place and fit the circlip on the guide sleeve.

|

|

| 6. |

Insert the guide sleeve with plunger into the slave cylinder housing.

|

|

| 7. |

Fit the O-ring on the rear of the slave cylinder. Use non-acid vaseline to keep it in place during assembly.

|

|

| 8. |

Fit the slave cylinder, see

.

.

|

|