DTC P0304 CYLINDER 4 MISFIRE DETECTED

|

|

DTC P0304 CYLINDER 4 MISFIRE DETECTED

|

CHECK ANY OTHER DTC ON DISPLAY.

Is any other

DTC displayed?

Inspect the relevant DTC using “List of Diagnostic Trouble Code (DTC)”.

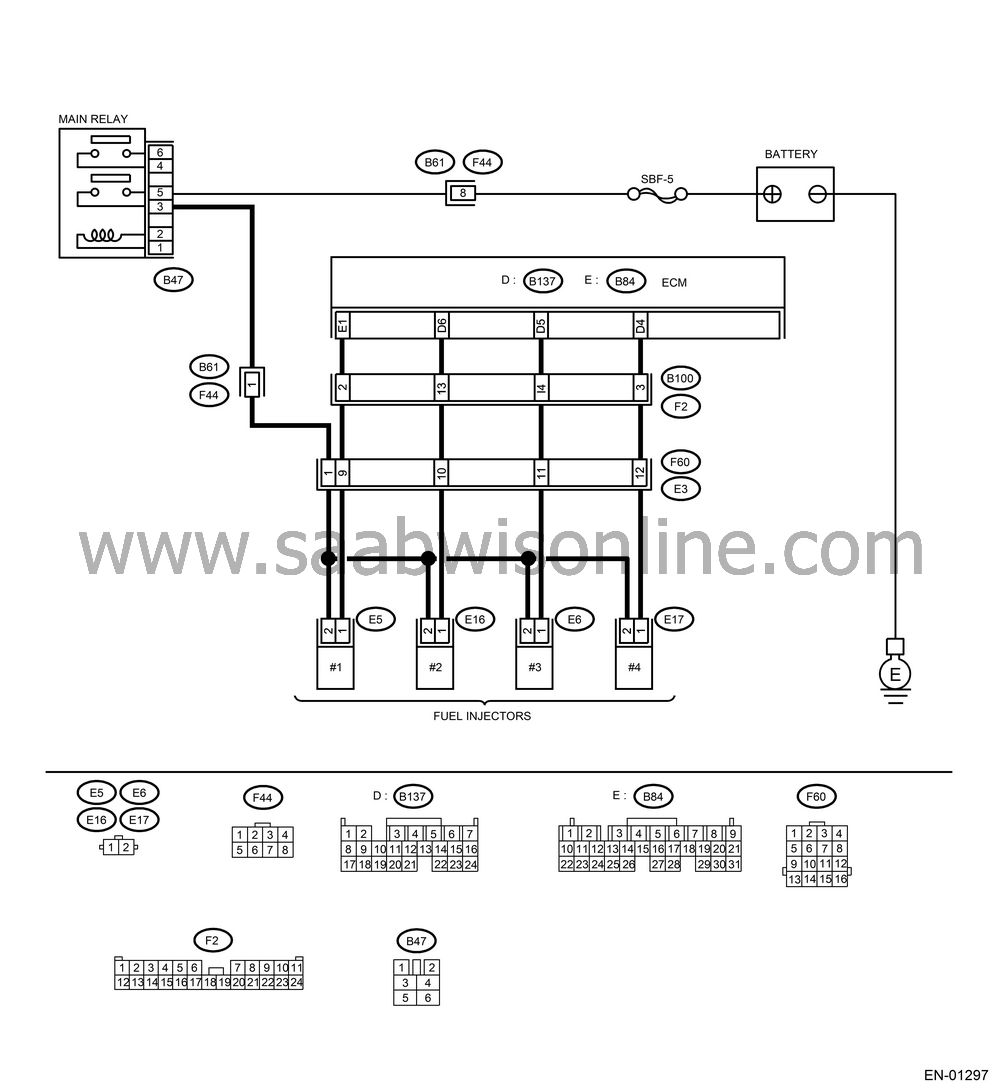

CHECK OUTPUT SIGNAL FROM ECM.

Turn the ignition switch to ON.

Measure the voltage between ECM connector and chassis

ground on faulty cylinders.

Connector & terminal

#1 (B84) No. 1 (+) — Chassis

ground (−):

#2 (B137) No. 6 (+) — Chassis

ground (−):

#3 (B137) No. 5 (+) — Chassis

ground (−):

#4 (B137) No. 4 (+) — Chassis

ground (−):

Is the

voltage more than 10 V?

CHECK HARNESS BETWEEN FUEL INJECTOR AND ECM CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connector from fuel injector on faulty

cylinders.

Disconnect the connector from ECM.

Measure the resistance between ECM connector and engine

ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 1 — Engine ground:

#2 (E16) No. 1 — Engine ground:

#3 (E6) No. 1 — Engine ground:

#4 (E17) No. 1 — Engine ground:

Is the resistance more than 1 MΩ?

Repair the ground short circuit

in harness between fuel injector and ECM connector.

CHECK HARNESS BETWEEN FUEL INJECTOR AND ECM CONNECTOR.

Measure the resistance of harness connector between ECM connector

and fuel injector on faulty cylinders.

Connector & terminal

#1 (B84) No. 1 — (E5) No. 1:

#2 (B137) No. 6 — (E16) No. 1:

#3 (B137) No. 5 — (E6) No. 1:

#4 (B137) No. 4 — (E17) No. 1:

Is the resistance less than 1 Ω?

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between ECM and fuel injector connector

|

|

•

|

Poor contact in coupling connector

|

|

CHECK FUEL INJECTOR.

Measure the resistance between fuel injector terminals on

faulty cylinder.

Terminals

No. 1 — No. 2:

Is

the resistance 5 — 20 Ω?

Replace the faulty fuel injector.

CHECK POWER SUPPLY LINE.

Turn the ignition switch to ON.

Measure the voltage between fuel injector and engine

ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 2 (+) — Engine

ground (−):

#2 (E16) No. 2 (+) — Engine

ground (−):

#3 (E6) No. 2 (+) — Engine

ground (−):

#4 (E17) No. 2 (+) — Engine

ground (−):

Is the

voltage more than 10 V?

Repair the poor contact in all

connectors in fuel injector circuit.

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between main relay and fuel injector connector on faulty

cylinders

|

|

•

|

Poor contact in coupling connector

|

|

•

|

Poor contact in main relay connector

|

|

•

|

Poor contact in fuel injector connector on faulty cylinders

|

|

CHECK HARNESS BETWEEN FUEL INJECTOR AND ECM CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connector from fuel injector on faulty

cylinder.

Turn the ignition switch to ON.

Measure the voltage between ECM connector and chassis

ground on faulty cylinders.

Connector & terminal

#1 (B84) No. 1 (+) — Chassis

ground (−):

#2 (B137) No. 6 (+) — Chassis

ground (−):

#3 (B137) No. 5 (+) — Chassis

ground (−):

#4 (B137) No. 4 (+) — Chassis

ground (−):

Is the

voltage more than 10 V?

Repair the battery short circuit

in harness between ECM and fuel injector. After repair, replace

the ECM.

CHECK FUEL INJECTOR.

Turn the ignition switch to OFF.

Measure the resistance between fuel injector terminals

on faulty cylinder.

Terminals

No. 1 — No. 2:

Is the resistance less than 1 Ω?

Replace the faulty fuel injector

and ECM

and ECM

CHECK INSTALLATION OF CAMSHAFT POSITION SENSOR/CRANKSHAFT

POSITION SENSOR.

Is the camshaft position sensor or

crankshaft position sensor loosely installed?

Tighten the camshaft position

sensor or crankshaft position sensor.

CHECK CRANK SPROCKET.

Remove the timing belt cover.

Is the crank

sprocket rusted or does it have broken teeth?

Replace the crank sprocket.

CHECK INSTALLATION CONDITION OF TIMING BELT.

Turn the crankshaft, and align alignment mark on crank sprocket

with alignment mark on cylinder block.

Is the timing

belt dislocated from its proper position?

Repair the installation condition

of timing belt.

CHECK FUEL LEVEL.

Is the fuel meter indication higher

than the “Lower” level?

Replenish the fuel so fuel meter

indication is higher than the “Lower” level. After

replenishing fuel;

CHECK STATUS OF MALFUNCTION INDICATOR LIGHT.

Clear the memory using Vehicle Diagnostic

Interface.

Start the engine, and drive the vehicle more than 10

minutes.

Is the malfunction indicator light

coming on or blinking?

CHECK CAUSE OF MISFIRE DIAGNOSED.

Was the

cause of misfire diagnosed when the engine is running?

Finish the diagnostics operation, if

the engine has no abnormality.

|

•

|

Repair the poor contact.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Poor contact

in ignition coil connector

|

|

•

|

Poor contact in fuel injector connector on faulty cylinders

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in coupling connector

|

|

CHECK AIR INTAKE SYSTEM.

Is there a fault

in air intake system?

|

•

|

Repair the air intake system.

|

|

•

|

|

Note

|

|

Check the following items:

|

|

•

|

Are there

air leaks or air suction caused by loose or dislocated nuts and

bolts?

|

|

•

|

Are there cracks or any disconnection of hoses?

|

|

CHECK CYLINDER.

Is there a fault in that

cylinder?

|

•

|

Repair or replace the faulty

parts.

|

|

•

|

|

Note

|

|

Check the following items.

|

|

•

|

Spark

plug

|

|

•

|

Fuel injector

|

|

•

|

Compression pressure

|

|

Go to DTC P0171 and P0172.

and ECM

and ECM