DTC P0341 CAMSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PERFORMANCE (BANK 1 OR SINGLE SENSOR)

|

|

DTC P0341 CAMSHAFT POSITION SENSOR “A” CIRCUIT

RANGE/PERFORMANCE (BANK 1 OR SINGLE SENSOR)

|

CHECK ANY OTHER DTC ON DISPLAY.

Is any other

DTC displayed?

Inspect the relevant DTC using “List

of Diagnostic Trouble Code (DTC)”.

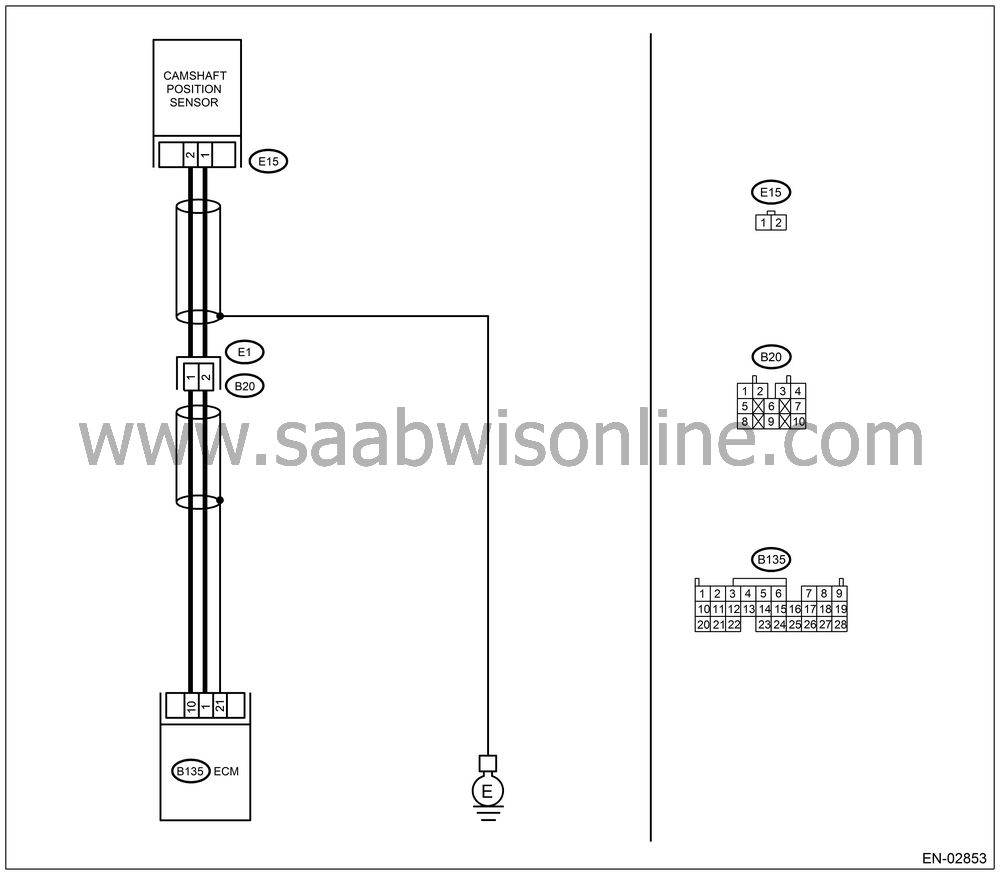

CHECK HARNESS BETWEEN CAMSHAFT POSITION SENSOR AND ECM CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connector from camshaft position sensor.

Measure the resistance of harness between camshaft

position sensor connector and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:

Is the resistance more than 100 kΩ?

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between camshaft position sensor and ECM connector

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in coupling connector

|

|

CHECK HARNESS BETWEEN CAMSHAFT POSITION SENSOR AND ECM CONNECTOR.

Measure the resistance of harness between camshaft position

sensor connector and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:

Is the resistance less than 10 Ω?

|

•

|

Repair the ground short circuit

in harness between camshaft position sensor and ECM connector.

|

|

•

|

|

Note

|

|

The harness between both connectors

are shielded. Repair ground short circuit in harness together with

shield.

|

|

CHECK HARNESS BETWEEN CAMSHAFT POSITION SENSOR AND ECM CONNECTOR.

Measure the resistance of harness between camshaft position

sensor connector and engine ground.

Connector & terminal

(E15) No. 2 — Engine ground:

Is the resistance less than 5 Ω?

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between camshaft position sensor and ECM connector

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in coupling connector

|

|

CHECK CONDITION OF CAMSHAFT POSITION SENSOR.

Is

the camshaft position sensor installation bolt tightened securely?

Tighten the camshaft position sensor

installation bolt securely.

CHECK CAMSHAFT POSITION SENSOR.

Remove the camshaft position sensor.

Measure the resistance between connector terminals

of camshaft position sensor.

Terminals

No. 1 — No. 2:

Is the resistance 1 — 4 kΩ?

Replace the camshaft position sensor.

CHECK CONDITION OF CAMSHAFT POSITION SENSOR.

Turn the ignition switch to OFF.

Is the camshaft

position sensor installation bolt tightened securely?

Tighten the camshaft position sensor

installation bolt securely.

CHECK CAM SPROCKET.

Remove the front belt cover.

Are the cam sprocket teeth cracked

or damaged?

Replace the cam sprocket.

CHECK INSTALLATION CONDITION OF TIMING BELT.

Turn the camshaft, and align alignment mark on cam sprocket

with alignment mark on timing belt cover LH.

Is

the timing belt dislocated from its proper position?

Repair the installation condition

of timing belt.

Replace the camshaft position sensor.