DTC P2016 INTAKE MANIFOLD RUNNER POSITION SENSOR / SWITCH CIRCUIT LOW (BANK1)

|

|

DTC P2016 INTAKE MANIFOLD RUNNER POSITION

SENSOR / SWITCH CIRCUIT LOW (BANK1)

|

CHECK CURRENT DATA.

Start the engine.

Read the data of tumble generator valve position sensor

signal using Vehicle Diagnostic Interface

or OBD-II general scan tool.

|

Note

|

|

•

|

Vehicle Diagnostic Interface

For detailed operation procedure, refer to the “READ

CURRENT DATA FOR ENGINE”.

|

|

•

|

OBD-II general scan tool

For detailed operation procedures, refer to the OBD-II General

Scan Tool Instruction Manual.

|

Is the voltage less than 0.1 V?

|

•

|

Even if malfunction indicator

light lights up, the circuit has returned to a normal condition

at this time. A temporary poor contact of the connector may be the cause.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Poor contact

in tumble generator valve position sensor connector

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in coupling connector

|

|

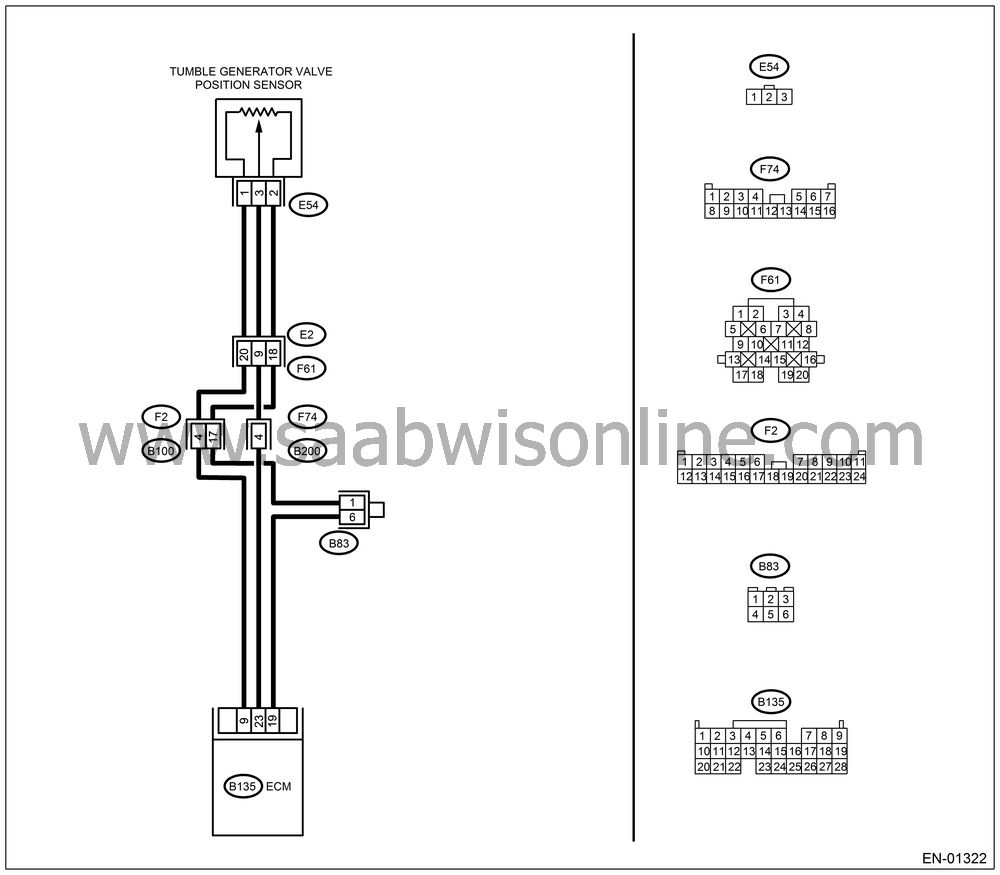

CHECK INPUT SIGNAL FOR ECM.

Measure the voltage between ECM connector and chassis ground

while throttle valve is fully closed.

Connector & terminal

(B135) No. 9 (+) — Chassis ground

(−):

Is the voltage more

than 4.5 V?

CHECK INPUT SIGNAL FOR ECM.

Measure the voltage between ECM connector and chassis ground.

Connector & terminal

(B135) No. 9 (+) — Chassis ground

(−):

Shake the ECM harness

and connector, while monitoring value of voltage meter. Does the

voltage change?

Repair the poor contact in ECM connector.

Contact Service Center.

CHECK INPUT SIGNAL FOR ECM.

Measure the voltage between ECM connector and chassis ground.

Connector & terminal

(B135) No. 23 (+) — Chassis ground

(−):

Is the voltage less

than 0.1 V?

CHECK INPUT SIGNAL FOR ECM. (USING Vehicle

Diagnostic Interface)

Measure the voltage between ECM connector and chassis ground.

Shake the ECM harness and connector, while monitoring value

of Vehicle Diagnostic Interface. Does

the voltage change?

Repair the poor contact in ECM connector.

CHECK HARNESS BETWEEN ECM AND TUMBLE GENERATOR VALVE POSITION SENSOR

CONNECTOR.

Turn the ignition switch to OFF.

Disconnect the connectors from throttle position sensor.

Turn the ignition switch to ON.

Measure the voltage between throttle position sensor

connector and engine ground.

Connector & terminal

(E54) No. 1 (+) — Engine ground (−):

Is the voltage more than 4.5 V?

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between tumble generator valve position sensor and ECM

connector

|

|

•

|

Poor contact in throttle position sensor connector

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in coupling connector

|

|

•

|

Poor contact in joint connector

|

|

CHECK HARNESS BETWEEN ECM AND TUMBLE GENERATOR VALVE POSITION SENSOR

CONNECTOR.

Turn the ignition switch to OFF.

Measure the resistance of harness between ECM connector

and throttle position sensor connector.

Connector & terminal

(B135) No. 23 — (E54) No. 3:

Is the resistance less than 1 Ω?

|

•

|

Repair the harness and connector.

|

|

•

|

|

Note

|

|

In this case, repair the following:

|

|

•

|

Open circuit

in harness between tumble generator valve position sensor and ECM

connector

|

|

•

|

Poor contact in ECM connector

|

|

•

|

Poor contact in tumble generator valve position sensor

connector

|

|

•

|

Poor contact in coupling connector

|

|

CHECK HARNESS BETWEEN ECM AND THROTTLE POSITION SENSOR CONNECTOR.

Measure the resistance of harness between tumble generator

valve position sensor connector and engine ground.

Connector & terminal

(E54) No. 3 — Engine ground:

Is the resistance more than 1 MΩ?

Repair the ground short circuit

in harness between tumble generator valve position sensor and ECM

connector.

CHECK POOR CONTACT.

Check poor contact in tumble generator valve position sensor

connector.

Is there poor contact in tumble generator

valve position sensor connector?

Repair the poor contact in tumble generator

valve position sensor connector.

Replace the tumble generator valve position

sensor.