DTC P0453 EVAPORATIVE EMISSION CONTROL SYSTEM PRESSURE SENSOR HIGH INPUT

| DTC P0453 EVAPORATIVE EMISSION CONTROL SYSTEM PRESSURE SENSOR HIGH INPUT |

DTC DETECTING CONDITION:

| • |

Two consecutive driving cycles with fault

|

|

| • |

GENERAL DESCRIPTION

|

|

| Important | ||

|

After repair

or replacement of faulty parts, conduct Clear Memory Mode

|

||

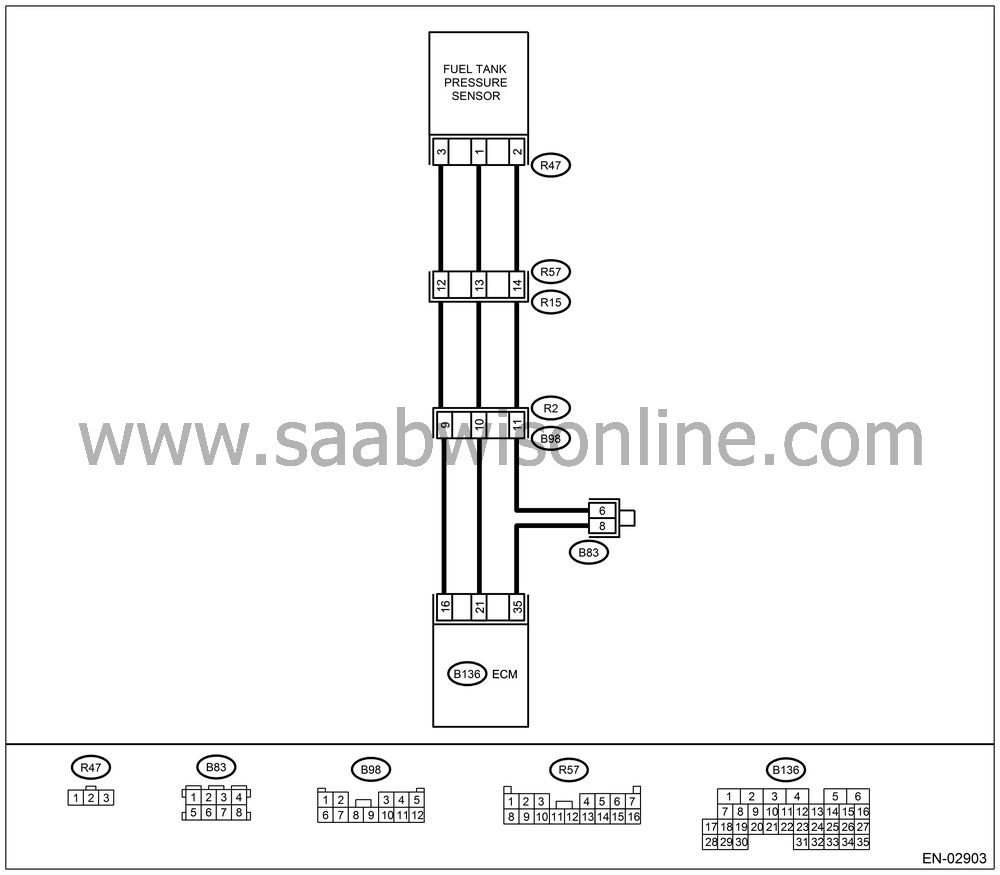

WIRING DIAGRAM:

CHECK CURRENT DATA.

Turn ignition switch to OFF.Remove the fuel filler cap.

Install the fuel filler cap.

Turn ignition switch to ON.

Read the data of fuel tank pressure sensor signal using Vehicle Diagnostic Interface or the OBD-II general scan tool.

Is the measured value more than 2.8 kPa (21.0 mmHg, 0.827 inHg)?

| Yes |

| No |

CHECK POWER SUPPLY TO FUEL TANK PRESSURE SENSOR.

Measure the voltage between ECM connector and chassis ground.Connector & terminal

(B136) No. 16 (+) — Chassis ground (−):

Is the voltage more than 4.5 V?

| Yes |

| No |

CHECK POWER SUPPLY TO FUEL TANK PRESSURE SENSOR.

Measure the voltage between ECM connector and chassis ground.Connector & terminal

(B136) No. 16 (+) — Chassis ground (−):

Does the voltage change by shaking the ECM harness and connector?

| Yes |

Repair poor contact in ECM connector.

| No |

CHECK INPUT SIGNAL FOR ECM.

Measure the voltage between ECM and chassis ground.Connector & terminal

(B136) No. 21 (+) — Chassis ground (−):

Is the voltage less than 0.2 V?

| Yes |

| No |

CHECK INPUT SIGNAL FOR ECM. (USING Vehicle Diagnostic Interface.)

Read the data of fuel tank pressure sensor signal using Vehicle Diagnostic Interface.| Note | ||

| • |

Vehicle Diagnostic Interface

For detailed operation procedures, refer to “READ

CURRENT DATA FOR ENGINE”.

|

|

Does the measured value change by shaking the ECM harness and connector?

| Yes |

Repair poor contact in ECM connector.

| No |

CHECK HARNESS BETWEEN ECM AND COUPLING CONNECTOR IN REAR WIRING HARNESS.

Turn ignition switch to OFF.Remove the rear seat cushion.

Separate rear wiring harness and fuel tank cord.

Turn ignition switch to ON.

Measure the voltage between rear wiring harness connector and chassis ground.

Connector & terminal

(R15) No. 12 (+) — Chassis ground (−):

Is the voltage more than 4.5 V?

| Yes |

| No |

| • |

Repair harness and connector.

|

|

| • |

|

|||||||||||||

CHECK HARNESS BETWEEN ECM AND COUPLING CONNECTOR IN REAR WIRING HARNESS.

Turn ignition switch to OFF.Disconnect the connector from ECM.

Measure the resistance of harness between ECM and rear wiring harness connector.

Connector & terminal

(B136) No. 21 — (R15) No. 13:

(B136) No. 35 — (R15) No. 14:

Is the resistance less than 1 Ω?

| Yes |

| No |

| • |

Repair harness and connector.

|

|

| • |

|

|||||||||||||

CHECK FUEL TANK CORD.

Disconnect the connector from fuel tank pressure sensor.Measure the resistance of fuel tank cord.

Connector & terminal

(R57) No. 13 — (R47) No. 1:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair open circuit in fuel tank cord.

CHECK FUEL TANK CORD.

Measure the resistance of fuel tank cord.Connector & terminal

(R57) No. 14 — (R47) No. 2:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair open circuit in fuel tank cord.

CHECK FOR POOR CONTACT.

Check for poor contact in fuel tank pressure sensor connector.Is there poor contact in fuel tank pressure sensor connector?

| Yes |

Repair poor contact in fuel tank pressure sensor connector.

| No |

Replace the fuel tank pressure

sensor.

CHECK HARNESS BETWEEN ECM AND FUEL TANK PRESSURE SENSOR CONNECTOR.

Turn ignition switch to OFF.Disconnect the connector from fuel tank pressure sensor.

Turn ignition switch to ON.

Read the data of fuel tank pressure sensor signal using Vehicle Diagnostic Interface or the OBD-II general scan tool.

Is the measured value more than 2.8 kPa (21.0 mmHg, 0.827 inHg)?

| Yes |

Repair short circuit to battery in harness between ECM and fuel tank pressure sensor connector.

| No |

Replace the fuel tank pressure

sensor.